D.A.S. AERO-12 User manual

User's Manual

Antes de utilizar el equipo, lea la sección

“Precauciones de seguridad” de este manual.

Conserve este manual para futuras consultas.

Before operating the device, please read the

“Safety precautions” section of this manual.

Retain this manual for future reference.

AERO-12

CONTENTS

SYSTEM DESCRIPTION

SAFETY PRECAUTIONS

WARRANTY

DECLARATION OF CONFORMITY

CONNECTION

LINE DRAWINGS

RIGGING SYSTEM

TROUBLESHOOTING

CONFIGURATION

5

3

4

6

6

8

9

14

7

10 to 13

Manual del Usuario / aero 12 / User’s Manual

SPECIFICATIONS

Precauciones de Seguridad

Safety Precautions

Caja acústica pasiva / Passive loudspeaker enclosure

æro 12

3

Manual del Usuario / aero 12 / User’s Manual

Conserve y lea todas estas instrucciones.

Siga todas las advertencias.

El signo de exclamación dentro de un triángulo indica la

existencia de componentes internos cuyo reemplazo puede

afectar a la seguridad.

Keep these instructions.

Heed all warnings. Follow all instructions.

The exclamation point inside an equilateral triangle indicates the

existence of internal components whose substitution may affect

safety.

El doble cuadrado indica equipo de Clase II. The double square indicates Class II device.

Limpie con un paño seco. No use limpiadores con disolventes.

Las especificaciones se encuentran en la etiqueta de la parte

posterior del producto.

The specifications can be found on the rear label of the product.

Clean only with a dry cloth. Do not use any solvent based

cleaners.

No existen partes ajustables por el usuario en el interior de este

equipo. Cualquier operación de mantenimiento o reparación

debe ser realizada por personal cualificado. Es necesario el

servicio técnico cuando el aparato se haya dañado de alguna

forma, tal como que haya caído líquido o algún objeto en el

interior del aparato, haya sido expuesto a lluvia o humedad, no

funcione correctamente o haya recibido un golpe.

No user serviceable parts inside. Refer all servicing to qualified

service personnel. Servicing is required when the apparatus has

been damaged in any way, such as power-supply cord or plug is

damaged, liquid has been spilled or objects have fallen into the

apparatus, the apparatus has been exposed to rain or moisture,

does not operate normally or has been dropped.

No emplace altavoces en proximidad a equipos sensibles a

campos magnéticos, tales como monitores de televisión o

material magnético de almacenamiento de datos.

Do not place loudspeakers in proximity to devices sensitive to

magnetic fields such as television monitors or data storage

magnetic material.

Este símbolo indica que el presente producto no puede ser

tratado como residuo doméstico normal, sino que debe

entregarse en el correspondiente punto de recogida de equipos

eléctricos y electrónicos.

This symbol on the product indicates that this product should

not be treated as household waste. Instead it shall be handed

over to the applicable collection point for the recycling of

electrical and electronic equipment.

El cableado exterior conectado al equipo requiere de su

instalación por una persona instruida o el uso de cables flexibles

ya preparados.

The outer wiring connected to the device requires installation by

an instructed person or the use of a flexible cable already

prepared.

El equipo cuenta con dos conectores de entrada en paralelo

para facilitar la conexión de varias cajas en paralelo.

Note that the two input connectors are wired in parallel to

provide easy parallel connection of several enclosures.

El colgado del equipo sólo debe realizarse utilizando los herrajes

de colgado recomendados y por personal cualificado. No

cuelgue el equipo de las asas.

The appliance should be flown only from the rigging points and

by qualified personnel. Do not suspend the box from the

handles.

Equipo diseñado para funcionar entre -25ºC y 70ºC. La

humedad relativa máxima del 95% con 40ºC de temperatura

ambiente.

Working temperature ranges from -25ºC to 70ºC. The maximum

relative humidity of 95% with ambient temperature 40ºC.

Equipo IP-33 según la norma IEC 60529: 1989 + M1 @ 1999.

Certificado EN54: 2426-CPR-141

IP-33 equipment (IEC 60529: 1989 + M1 @ 1999).

EN54 certificate: 2426-CPR-141

Todos nuestros productos están garantizados por un periodo de 24

meses desde la fecha de compra.

Las garantías sólo serán válidas si son por un defecto de

fabricación y en ningún caso por un uso incorrecto del producto.

Las reparaciones en garantía pueden ser realizadas,

exclusivamente, por el fabricante o el servicio de asistencia técnica

autorizado.

Otros cargos como portes y seguros, son a cargo del comprador

en todos los casos.

Para solicitar reparación en garantía es imprescindible que el

producto no haya sido previamente manipulado e incluir una

fotocopia de la factura de compra.

GARANTÍA

Manual del Usuario / aero 12 / User’s Manual

4

WARRANTY

All our products are warrantied against any manufacturing defect

for a period of 2 years from date of purchase.

The warranty excludes damage from incorrect use of the product.

All warranty repairs must be exclusively undertaken by the factory

or any of its authorised service centers.

To claim a warranty repair, do not open or intend to repair the

product.

Return the damaged unit, at shippers risk and freight prepaid, to

the nearest service center with a copy of the purchase invoice.

Manual del Usuario / aero 12 / User’s Manual 5

DECLARACIÓN DE CONFORMIDAD

DECLARATION OF CONFORMITY

DAS Audio Group, S.L.

C/ Islas Baleares, 24 - 46988 - Pol. Fuente del Jarro - Valencia. España

(Spain).

Declara que aero 12:

Declares that aero 12:

Cumple con los objetivos esenciales de las Directivas:

Abide by essential objectives relating Directives:

l Low Voltage Directive 2006/95/EC

l Regulation (EU) No 305/2011 - Constrution Products

(Certificate of Constancy of Performance: 0359-CPR-00429)

Y es conforme a las siguientes Normas Armonizadas Europeas:

In accordance with Harmonized European Norms:

l EN 60065:2014

Audio, video and similar electronic apparatus. Safety requirements.

l EN 54-24:2008

Fire detection and fire alarm systems. Part 24: Components of voice

alarm systems. Loudspeakers.

SYSTEM DESCRIPTION LINE DRAWINGS

ALL DIMENSIONS IN MILLIMETERS

688

316

385

6Manual del Usuario / aero 12 / User’s Manual

The æro 12 compact line array system joins the

family of professional sound touring products

The system incorporates an impressive battery

of high tech features that take compact line array

systems to an unprecedented level of

performance. The latest optimized DAS Audio

components have been combined with enclosures

designed for rapid deployment, precise coverage

and high acoustic output.

The æro 12 incorporates a DAS 12LN4C, 12”

low frequency transducer. The transducer employs

a 75 mm (3”) voice coil and neodymium magnet

motor assembly. Effective heat evacuation is

achieved by way of the Total Air Flux (TAF) cooling

scheme which permits high power handling and

low power compression.

High frequency reproduction relies on the

exceptional characteristics of the new DAS M-75N

neodymium comprssion driver designed for use in

applications where high SPL and low distortion are

required. A pure titanium diaphragm featuring a 75

mm (3”) copper-clad, aluminium flat-wire voice coil

yields high sensitivity, low distortion and extended

frequency response. Each motor system has a

copper shorting ring surrounding the pole piece

which effectively reduces eddy current induced

distortion with the added benefit of increasing the

very high frequency output by reducing the

inductive rise of the voice coil. The driver is

attached to a new BPS-9010 aluminium waveguide-

horn assembly.

The PL-12S (steel transporting dolly) and AX-

aero12S2 (rigging bumper) accessory allow for any

type of flown of the æro 12 system.

The easily portable and rugged enclosure is

manufactured using Birch plywood and finished

with a durable black paint. The trapezoidal æro12’s

shape and rear located splay angle adjusters keep

the front spacing between adjacent elements the

same, providing the array with a “seamless” front

baffle, for improved array performance. The

captive rigging system splay angles range from 0º

to 10º and can be adjusted in 0.5º increments

from 0º to 3º, and 1º increments from 3º to 10º

allowing a wide range of column curvatures to be

accomplished.

The complies with the european æro 12

standard EN54-24 for using as voice alarm

device for fire detection and fire alarm systems.

The æro 12 also guaranties the best

performance under harsh weather conditions.

After installation, do not remove any safety panels while the system is in use. Service and/or technical

operations should be performed only by authorized personnel.

Follow the amplifier's user manual for the amplifier connection.

Manual del Usuario / aero 12 / User’s Manual 7

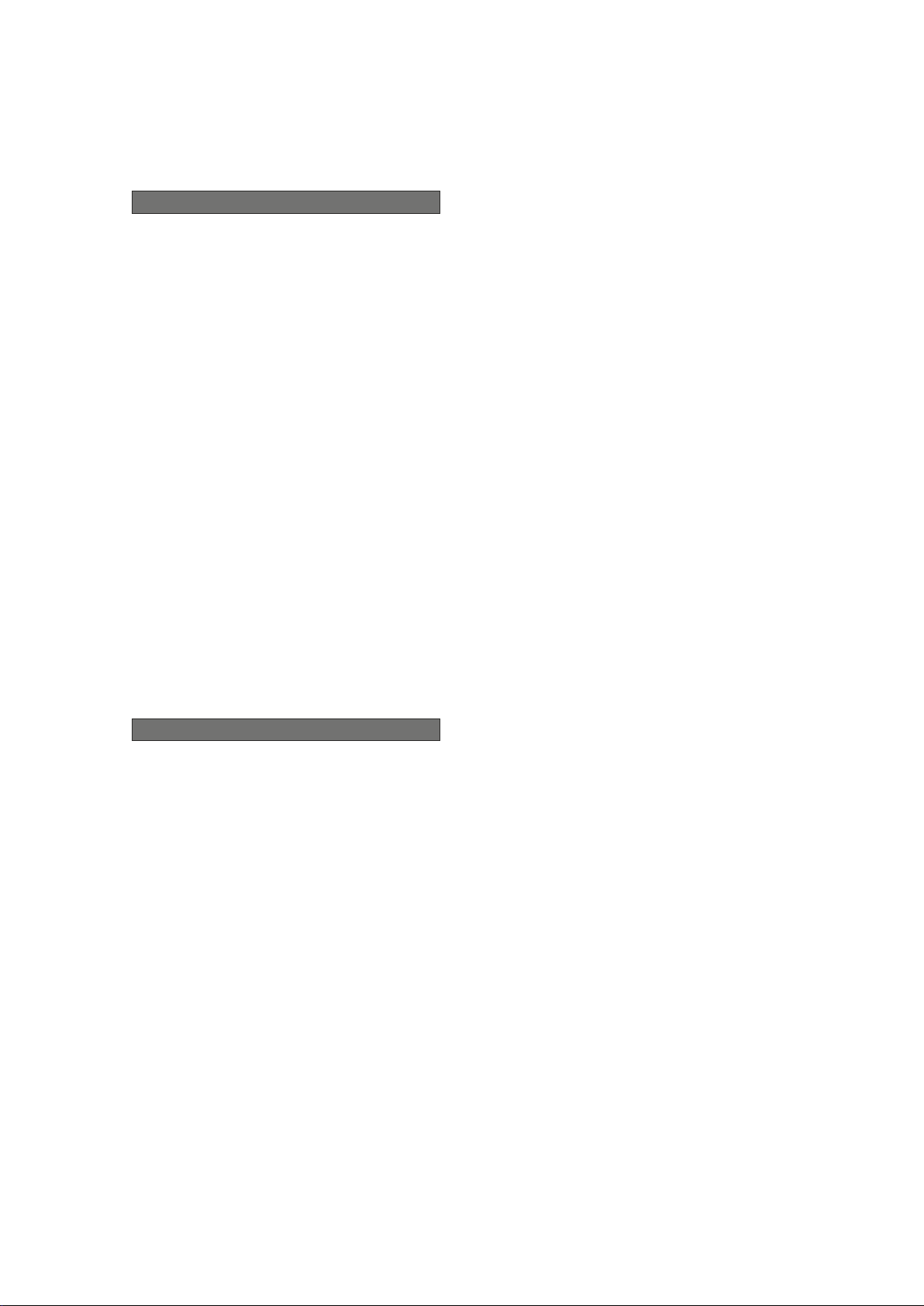

CONNECTION

The aero 12 can be used as a full range cabinet in voice applications or any application requiring high

SPL.

The amplifier unit is not in the cabinet so the connection has to be made. The user needs to

connect the amplifier's output to the input connector of the aero 12 cabinet. The connection has to

be made with the amplifier unplugged.

The DSP-2060 Digital Signal Processor is recommended for setup. This processor includes a

specific factory preset for the aero 12 optimizing the system´s performance.

The connection is made on the rear panel of the cabinet by way of a barrier strip connector.

+INPUT

-INPUT

+OUTPUT

-OUTPUT

The system includes 5m of connection wire

ready to use.

The color code is:

.- Blue --> +

.- Brown --> -

8

Model

R

RMS Power Handling

P

Program Power Handling

K

Peak Power Handling

On-axis frequency Range

Nominal Impedance

Minimum Impedance

On-axis Sensitivity 1W/1m

Peak SPL at Full Power

Nominal -6dB Beamwidths

Enclosure Material

Color/Finish

Transducers/Spare Parts

Connector

Dimensions (H x W x D)

Net Weight

Accesories

DSP2060A EQ

aero 12

400 W

800 W

1600 W

62 Hz - 22 Hz

8 Ohms

7,4 Ohms @ 140 Hz

100 dB SPL

132 dB SPL

90º Horizontal x 10º Vertical

Birch Plywood

Black / Polyurea

LF: 1 x 12LNC/GM 12P

HF: 1 x M75N/GM M-75N

Barrier strip

31,6 x 140 x 60 cm

12,4 x 55 x 23,6 in

27 kg (59,4 lbs)

AX-aero12 Rigging Grid

AX-Combo12 Rigging Adapter

KITGS-AX-aero12

PL-12S Steel Stacking Dolly

Frequency Q Gain

6k11 0,5 -5

2k52 4,3 -2,9

6k47 4 -3

14k3 6,7 -5

SPECIFICATIONS

250 W

62 Hz - 22 kHz

8 Ohms

7,4 Ohms @ 140 Hz

81,4 dB

107 dB

500Hz, 132º. 1kHz, 91º.

2kHz, 95º. 4kHz, 91º.

500Hz, 144º. 1kHz, 84º.

2kHz, 40º. 4kHz, 20º.

Birch Plywood

Black / Polyurea

LF: 1x 12LNC/GM 12P

HF: 1x M75N/GM M-75N

Type B

Barrier strip

31,6 x 68,8 x 38,5 cm

12,4 x 27 x 15,2 in

27 kg (59,5 lb)

AX-aero12 Rigging Grid,

AX-Combo12 Rigging Adapter,

PL-12S Steel Transporting Dolly

Frequency Q Gain

6k11 0,5 -5

2k52 4,3 -2,9

6k47 4 -3

14k3 6,7 -5

T

Nominal Power :

On-axis Freq Range (-10dB):

Nominal Impedance:

Minimum Impedance:

F,S

On-axis Sensitivity 1w/4m :

M

Measured Max SPL at 4m :

C

Horizontal Coverage (-6dB) :

C

Vertical Coverage (-6dB) :

Enclosure Material:

Colour/Finish:

Transducers/Spare Parts:

Environmental Type:

Connector:

Dimensions (H x W x D):

Net weight:

Optional Accessories:

DSP2060A EQ:

[Included processing for

1box flat response]

TNominal Power based on a 100h test using a 6dB crest factor pink

noise signal filtered according to the IEC 60268-1:1985 norm and

band-pass filtered with Butterworth 24dB/Oct filters from 89Hz to

11,2kHz.

SSensitivity and Max SPL measured using a 6dB crest factor pink

noise, averaged from 100Hz to 10kHz in 1/3 Octave bands.

CCoverage measured from 500Hz to 4kHz in Octave bands.

MObtained by integration over a period of at least 30s.

F Correction Flat.

RBased on a 2 hour test using a 6dB crest factor pink noise signal.

PConventionally, 3dB higher than RMS measure, although this already,

utilizes a program signal.

K R

Corresponds to the signal crests for the test described in .

Manual del Usuario / aero 12 / User’s Manual

EN54-24 based Technical specifications

Technical specifications

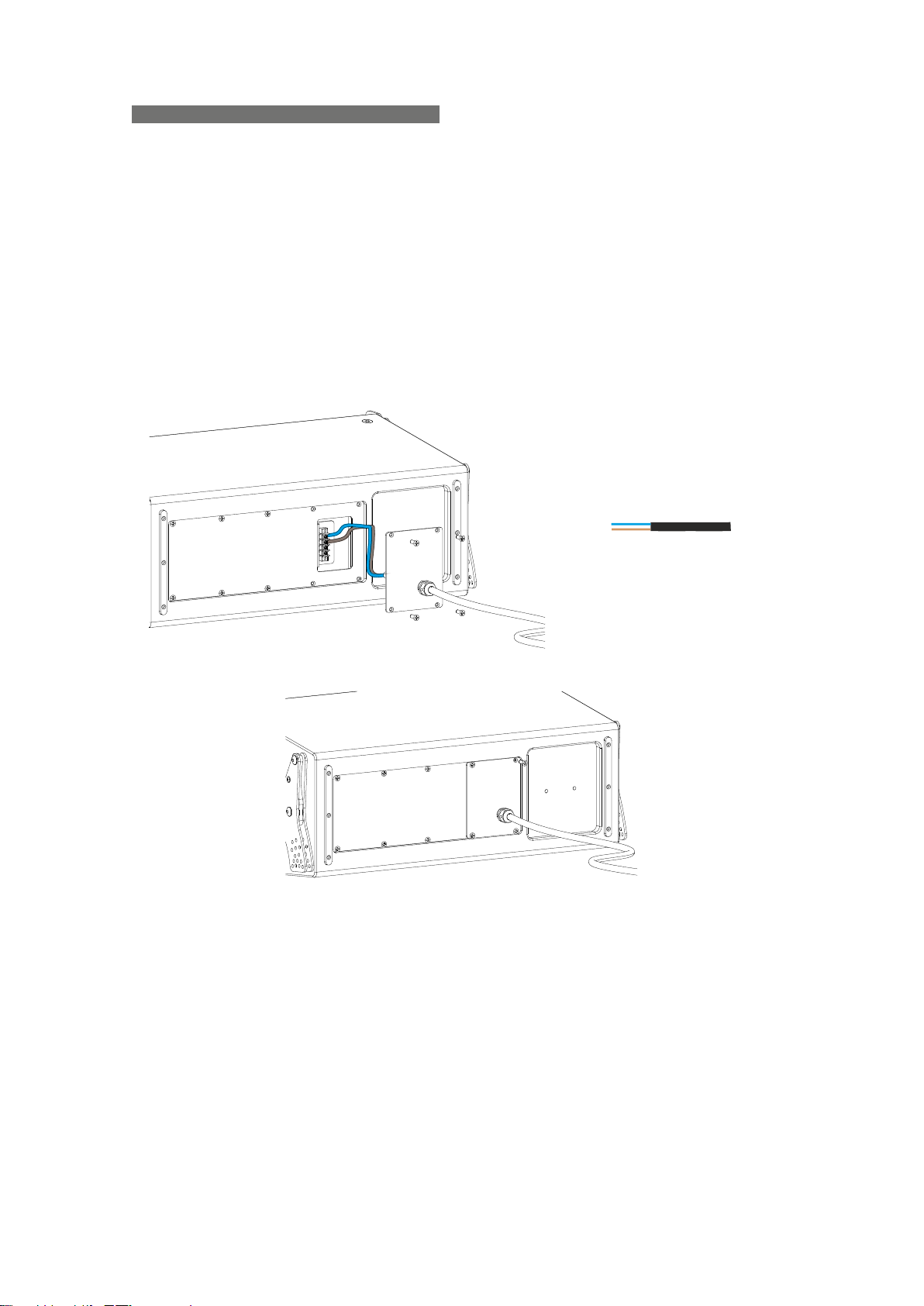

CONFIGURATION

12 x aero 12

Manual del Usuario / aero 12 / User’s Manual

This is an example of one of the possible configurations:

9

LINK

LINK

LINK

LINK

LINK

LINK

LINK

LINK

-24 -24 -24 -24-12 -12 -12 -12-6 -6 -6 -6-3 -3 -3 -3

Limit Limit Limit Limit

Power

A/P

Bridge A-B Bridge C-D

PRC A PRC B PRC C PRC D

Link Link Link

OCM OCM OCM OCM

-6

-12

-4

-2

0

Atten. dB

-6

-12

-4

-2

0

Atten. dB

-6

-12

-4

-2

0

Atten. dB

-6

-12

-4

-2

0

Atten. dB

Ch. A Ch. B Ch. C Ch. D

PROFESSIONAL

POWER

AMPLIFIER

power distro L1 L2 L3

I

o

FI4030mA 4pol.

FI-Schalter

Aero 12 Accessories

Dollies (optional)

Rigging frames

AX-Aero12S2 x 2

2 x PL-12S

Amplifier Racks

-24 -24 -24 -24-12 -12 -12 -12-6 -6 -6 -6-3 -3 -3 -3

Limit Limit Limit Limit

Power

A/P

Bridge A-B Bridge C-D

PRC A PRC B PRC C PRC D

Link Link Link

OCM OCM OCM OCM

-6

-12

-4

-2

0

Atten. dB

-6

-12

-4

-2

0

Atten. dB

-6

-12

-4

-2

0

Atten. dB

-6

-12

-4

-2

0

Atten. dB

Ch. A Ch. B Ch. C Ch. D

PROFESSIONAL

POWER

AMPLIFIER

power distro

L1 L2 L3

I

o

FI4030mA 4pol.

FI-Schalter

A12_Rack: 10U rack with 1x DSP-2060A + 3xD100

RIGGING SYSTEM

10 Manual del Usuario / aero 12 / User’s Manual

Warning

This manual contains needed information for

flying DAS Audio line array systems, description of

the elements and safety precautions. To perform

any operations related to flying the system, read

the present document first, and act on the

warnings and advice given. The goal is to the allow

the user to become familiar with the mechanical

elements required to fly the acoustic system, as

well as the safety measures to be taken during

set-up and teardown.

Only experienced installers with adequate

knowledge of the equipment and local safety

regulations should fly speaker boxes. It is the

user's responsibility to ensure that the systems to

be flown (including flying accessories) comply with

state and local regulations.

The working load limits in this manual are the

results of tests by independent laboratories. It is

the user's responsibility to stay within safe limits. It

is the user's responsibility to follow and comply

with safety factors, resistance values, periodical

supervisions and warnings given in this manual.

Product improvement by means of research and

development is on going at DAS Audio.

Specifications are subject to change without

notice.

To this date, there is no international standard

regarding the flying of acoustic systems. However,

it is common practice to apply 5:1 safety factors

for enclosures and static elements. For slings and

elements exposed to material fatigue due to

friction and load variation the following ratios must

be met; 5:1 for steel cable slings, 4:1 for steel

chain slings and 7:1 polyester slings. Thus, an

element with a breaking load limit of 1000 kg may

be statically loaded with 200 kg (5:1 safety factor)

and dynamically loaded with 142 Kg (7:1 safety

factor).

When flying a system, the working load must

be lower than the resistance of each individual

flying point in the enclosure, as well as each box.

Hanging hardware should be regularly inspected

and suspect units replaced if in doubt. This is

important to avoid injury and absolutely no risks

should be taken in this respect. It is highly

recommended that you implement an inspection

and maintenance program on flying elements,

including reports to be filled out by the personnel

that will carry out the inspections. Local

regulations may exist that, in case of accident,

may require you to present evidence of inspection

reports and corrective actions after defects were

found.

Absolutely no risks should be taken with

regards to public safety. When flying enclosures

from ceiling support structures, extreme care

should be taken to assure the load bearing

capabilities of the structures so that the installation

is absolutely safe. Do not fly enclosures from

unsafe structures. Consult a certified professional if

needed. All flying accessories that are not supplied

by DAS Audio are the user's responsibility. Use at

your own risk.

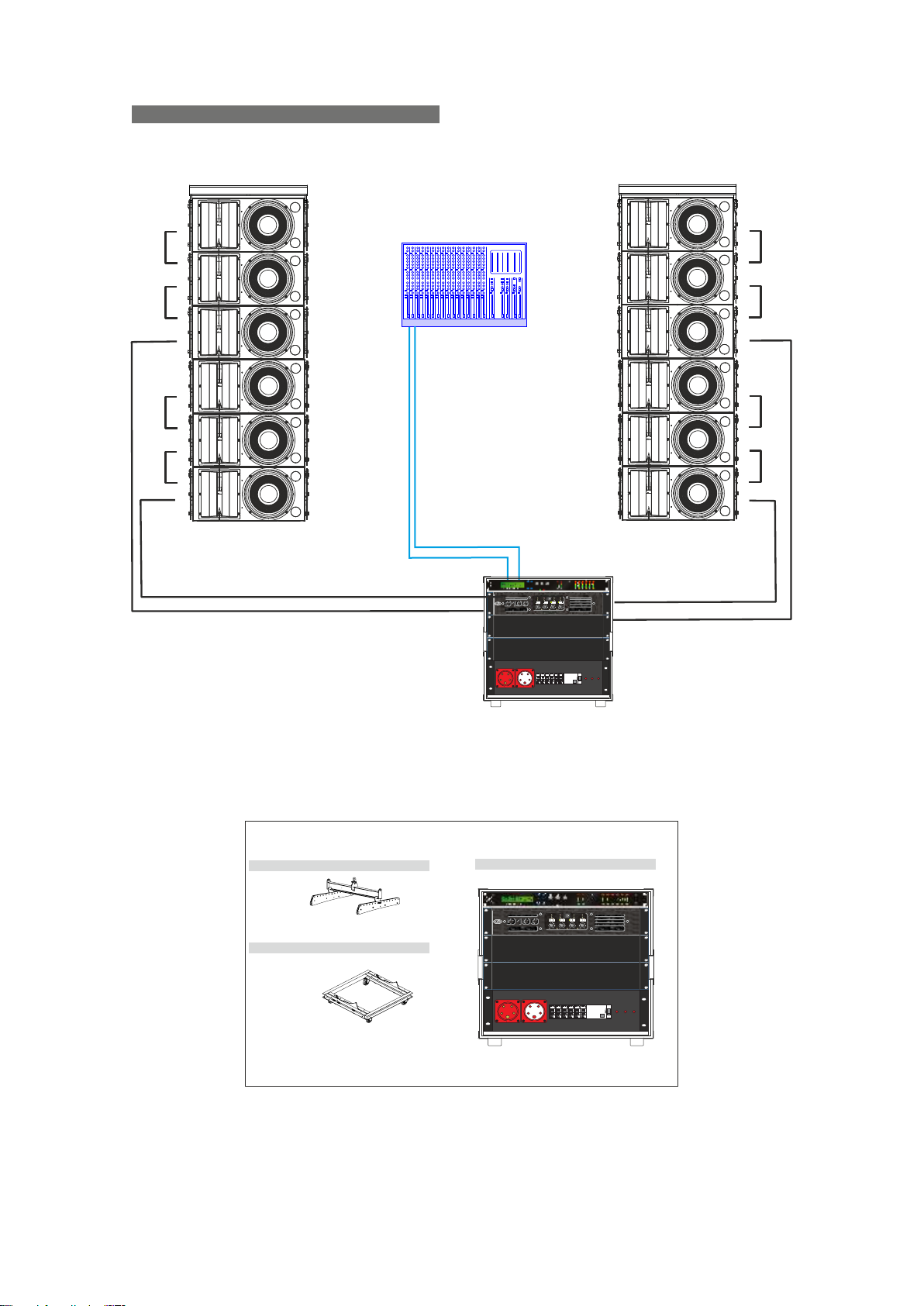

Description

DAS Audio æro 12 line array systems, include

2 rigging structures on each side of the box.

Manufactured from zinc plated steel they are

painted black and are affixed to an internal plate

with special crop resistant screws. Two special

stainless steel guides are assembled to each of

the structures, allow for stacking or flying of boxes.

Splay angles can be changed from 0º to 3º in 0.5º

increments and from 3º to 10º in 1º increments.

Shown in the next picture, detail of the mechanical

parts (rear and front guides) for fly the aero12 as

well an explanation of the different holes and the

performance of them.

In a grey colour the used holes for fly the system.

Rear guide

Front guide

Next illustration shows a detail of the silk

screen on the aero 12 rigging hardware each

indicating what angle is obtained. To set the

guides, 6mm quick release safety pins should be

used.

WARNING: WEIGHT

LIMIT 16 UNITS

0.5º 0º

1º

2º

2.5º

3º

5º

4º

1.5º

8º

7º

9º

10º

6º

The aero 12 includes 6 6mm safety pins which

allow coupling the upper aero 12 with the lower as

well with the fly accesory AX-aero12S2.

The final angle and the fly point are provide by

the simulation of the system done with the Ease

Focus software.

The EASEFocus is a free download software.

Using it, it is possible to make the simulations

of DAS Audio line array systems and applications.

As a result the software will provide the right

angles bettwen the cabinets and the fly point of

the accessory to obtain the best uniformity in the

vertical coverage of the system in the audience

area.

1234567891011121314

Refer to the user manual for more

information of this accessory, on our website.

WARNI NG: W EIGHT

LIMIT 16 UNITS

0.5º 0º

1º

2º

2.5º

3º

5º

4º

1.5º

8º

7º

9º

10º

6º

Manual del Usuario / aero 12 / User’s Manual

Next illustration show the accessory AX-

aero12S2 and detail of the silk screen of the

accessory indicating numbered flying points

depending on the desidered angle of the system

and indicating the max number of the cabinets that

can be fly to the accessory on each position.

Refer to the next link for more information

about the software:

http://focus.afmg.eu/

11

Selected angle

Point A

Point B

Manual del Usuario / aero 12 / User’s Manual

n 1

n 2

12

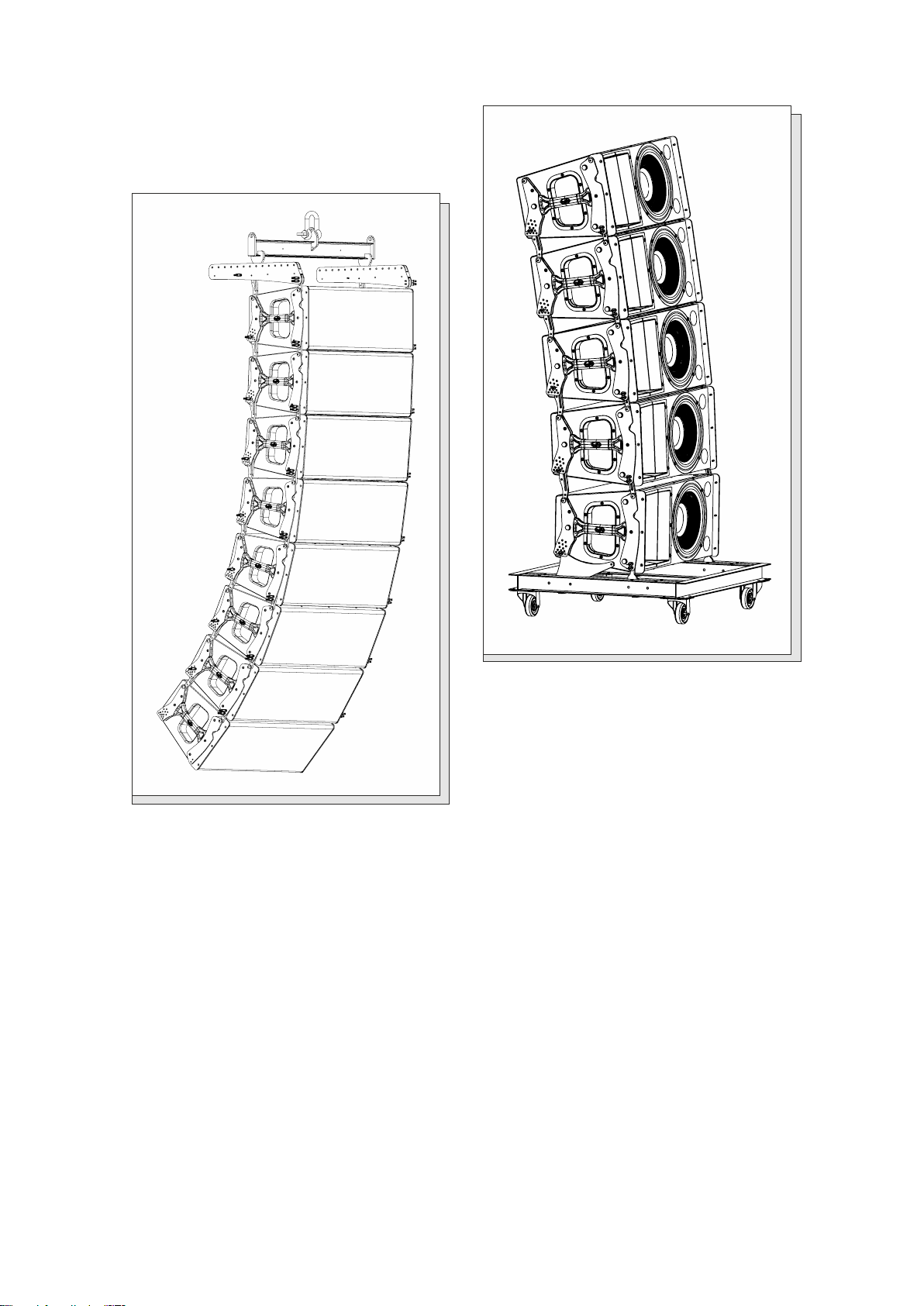

Follow the next steps to setup the aero 12

line array system:

1.- Take out the rear guide of both sides of

the cabinet.

2.- Take out the front guide of both sides of

the cabinet.

3.- Put, over the guides, the left and right

pannels of the AX Aero12 S2 accessory.

4.- Put the pin through the slotted hole of the

front guide of the cabinet and the FRONT

possition n1 of the AX-Aero12S2.

5.- Put the pin through the hole of the rear

guide of the cabinet and the REAR possition of

the AX-Aero12S2.

6.- Put the pin through the hole of the front

guide of the cabinet and the FRONT possition

n2 of the AX-Aero12S2.

7.- Put the central bar of the AX-Aero12S2 in

the fly point provides for the application by the

EaseFocus software.

8.- Take out the rear and front guides of the

next aero12 cabinet.

9.- Put together the upper side of the 2º

aero 12 and the lower side of the 1º cabinet.

10.- Put the pin through the slotted hole of the

front guide of the cabinet (Point A).

11.- Put the pin through the hole of the rear

guide in the designed angle provides by the

EaseFocus prediction software.

12.- Put the pin through the hole of the front

guide of the cabinet (Point B).

In case of require transport the aero12 in stacked possition, DAS Audio offers the PL-12S accessory which

allows, using the rear and front guides of the aero12, place one cabinet over the other. The angle bettwen the

cabinets for transporting should be 0º.

For more information about PL-12S, see your user’s manual, on our website.

Repeat the previous steps as many times as

cabinets make up the system.

The result should be similar to the next one:

Manual del Usuario / aero 12 / User’s Manual 13

Manual del Usuario / aero 12 / User’s Manual

PROBLEM

1 - No sound from any units.

2 – No sound from one unit.

3 – Poor stereo image or weak bass

output.

CAUSE

1.1 – No signal present in the

amplifier

1.2 – Defective cable.

1.3 – High number of speakers

connected in the same amplifier’s

channel.

2.1 – No signal present in the UNIT.

3.1 – Wrong connection

SOLUTION

1.1.1 – Check that the amplifier is

on.

1.1.2 – Check that the gain is set

above its minimum setting.

1.1.3 – Check that there is a signal

to your amplifier from your mixer.

1.2.1 – Check that the cable from

the sound source to the UNIT is

connected correctly. Replace the

cable if defective.

1.2.2 – Check that none of the

connected cables are cut or frayed.

1.3.1 – Check the minimum

impedance requirements of your

amplifier.

2.1.1 – Check that the cable

between the UNITS is connected

correctly. Replace the cable if

defective.

3.1.1 – Check the polarities (+/-) and

be sure that all the speakers are well

connected.

3.1.2 – Check the balance control

on the mixer.

TROUBLESHOOTING

14

UM_AE12_06_EN

www.dasaudio.com

DAS Audio Group, S.L. C/. Islas Baleares, 24. 46988 Fuente del Jarro - Valencia - SPAIN Tel. +34 96 134 0860

Table of contents

Other D.A.S. Enclosure manuals

Popular Enclosure manuals by other brands

Rosewill

Rosewill FBM-05 user manual

CRU Dataport

CRU Dataport RTX220-QR quick start guide

American Products

American Products FREEDOM owner's manual

FRIEDHELM LOH

FRIEDHELM LOH Rittal AX 1485.744 Assembly instructions

StarTech.com

StarTech.com DRW115SAT user guide

StarTech.com

StarTech.com RK920WALM installation guide