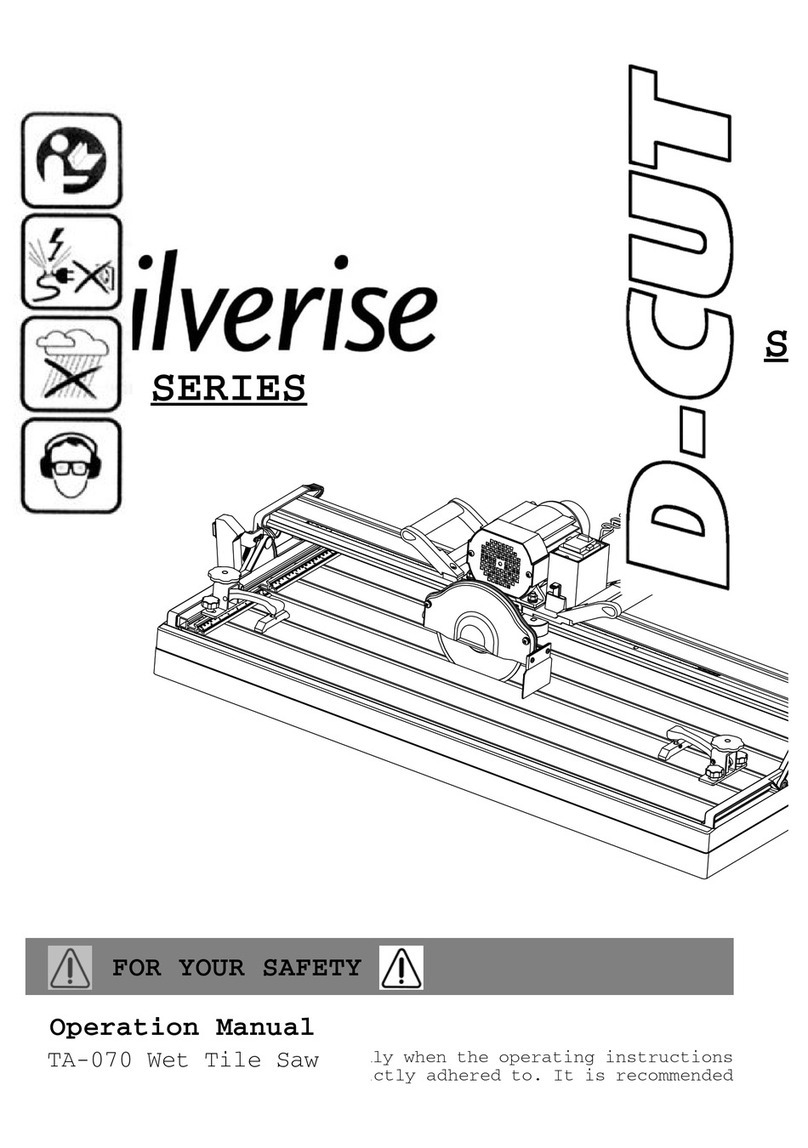

D-CUT Silverise Series User manual

SERIES

O

peration Manual

D-Cut TD-080 Wet Tile Saw

FOR YOUR SAFETY

This saw can be operated safely only when the operating instructions

have been completely read and strictly adhered to. It is

recommended to receive practical instruction before using the saw

for the first time.

Always inspect cable and plug before using the saw. The outlet

must be grounded. Have damage repaired only by a qualified

professional.

Do not use the saw in standing water or expose rain.

Wear hearing protection and safety goggles.

zAlways remove the plug from the power supply socket before removing saw

from work area, when interrupting work and when not using the saw.

zInsert the plug into the power socket only when the saw is switched off.

zAlways place the cable away from the saw towards the outside of the saw

table.

zDo not carry the saw by the cable.

zWear sturdy footwear.

zDo not use the saw when the blade is not installed properly.

zAlways switch off the saw before lifting the table for cleaning.

zOnly use original D-Cut accessories.

zNever leave the saw running unattended.

zKeep guards in place. Adhere to safety guidelines: (ANSI) American Safety

Standards Institute.

zNever stand or lean on equipment. Serious injury could occur if the machine

is tipped or is unintentionally contacted.

zDo not over reach. Keep footing and balance at all times.

zDisconnect tools. Before servicing, and when changing accessories such as

blades or profile tools. Turn off equipment!

zUse the correct tools. Do not force the equipment or accessory to do a job

for which it was not designed

zUse proper extension cord. Improper cord length and/or gauge is the

leading cause of premature electric motor failure! When in doubt use

heavier gauge cord.

zAn extra space needs to be remained around the machine as the working

table moves over the machine edge.

2

INNOVATION PUT TO WORK

Here at D Cut Products, Inc. We are always looking

to come out with new innovative products.

Check out Our Website for Updates at

www.dcutproducts.com

or contact us at

The serial number of your saw is

located on the left side above

the switch.

FOR YOUR (90 DAY) WARRANTY TO BE EFFECTIVE ON ALL

ELECTRICAL MOTOR AND PARTS SUCH AS THE SWITCH AND THE

CONTROL DEVICE, GAS ENGINE, AND PARTS, ALSO FOR YOUR

(1) ONE YEAR WARRANTY ON ALL OTHER PARTS, EXCLUDING

ABOVE COMPLETE THE WARRANTY CARD (PLEASE INCLUDE THE

SERIAL NUMBER) AND MAIL IT IN AS SOON AS POSSIBLE.

3

4

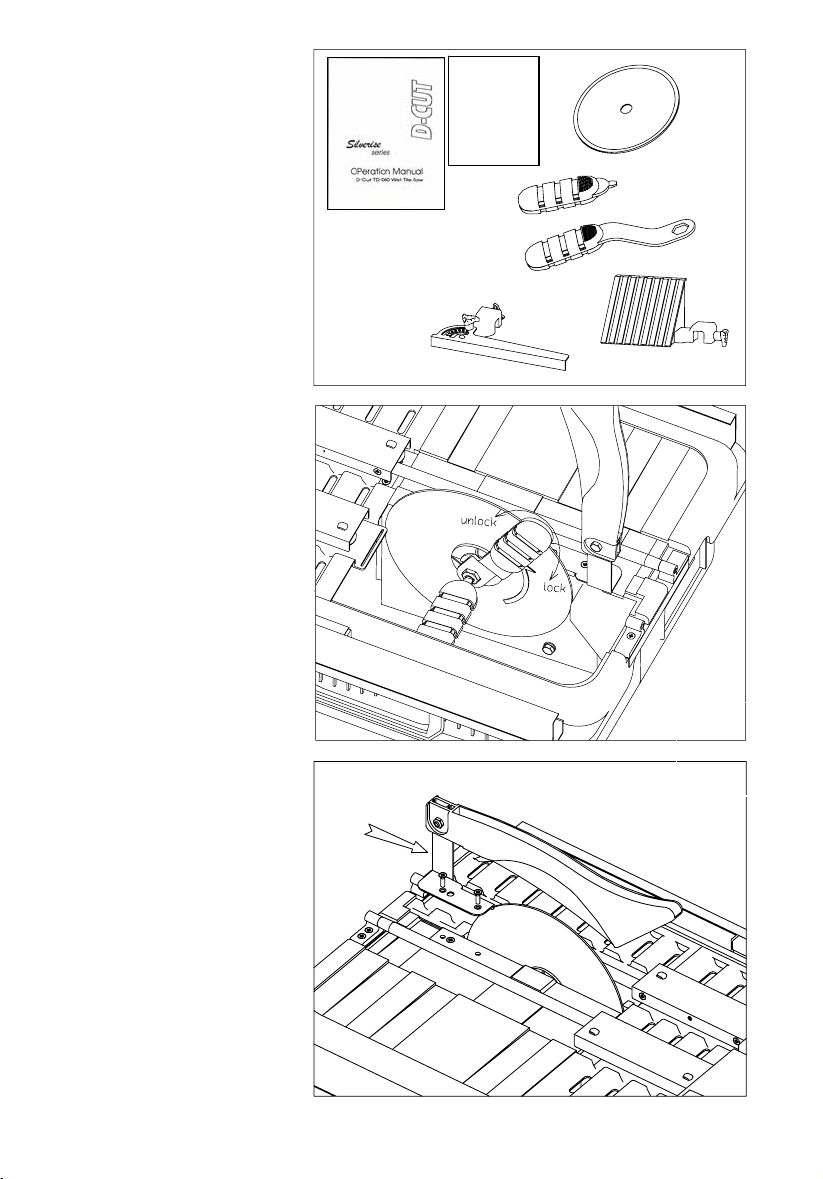

Fig.1

Warranty

card

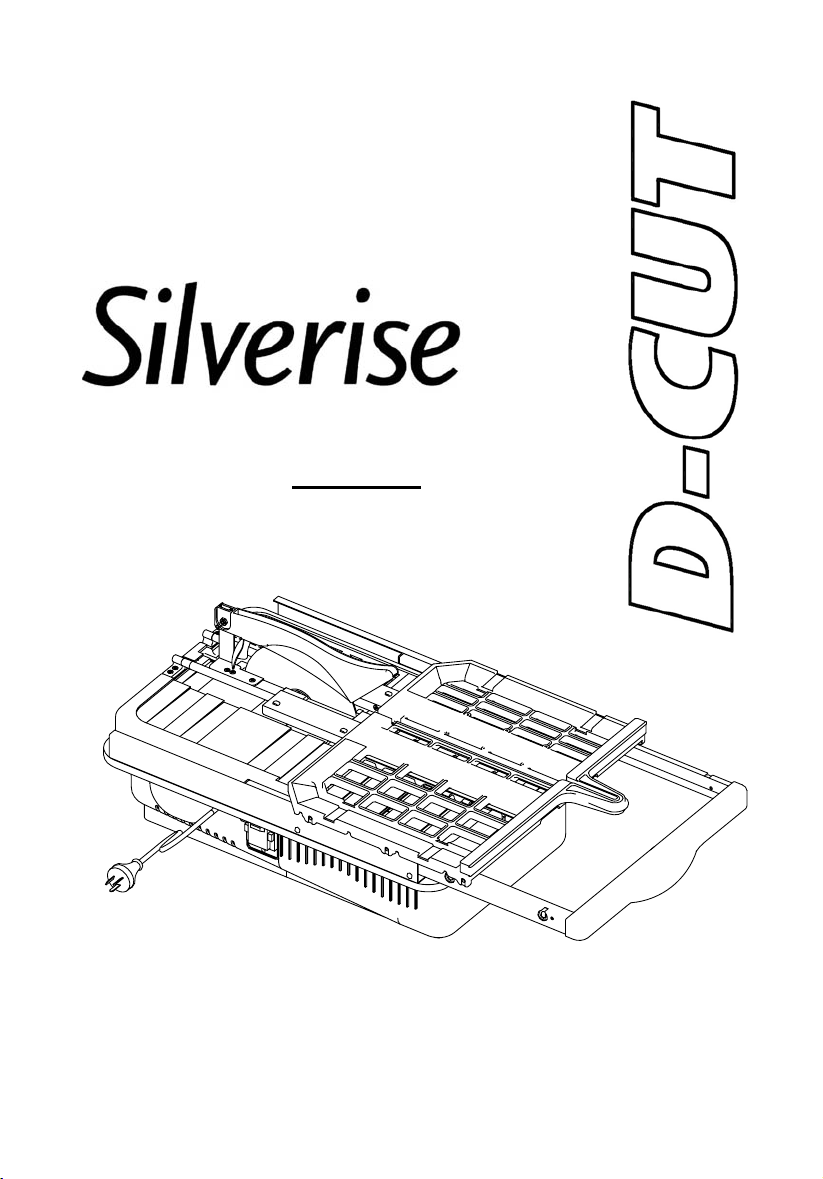

Contents in the Box:

(1) Continuous rim

diamondblade,

(2) 45 degree

attachments, (1) wrench

set, (1) operation manual

and Warranty card.

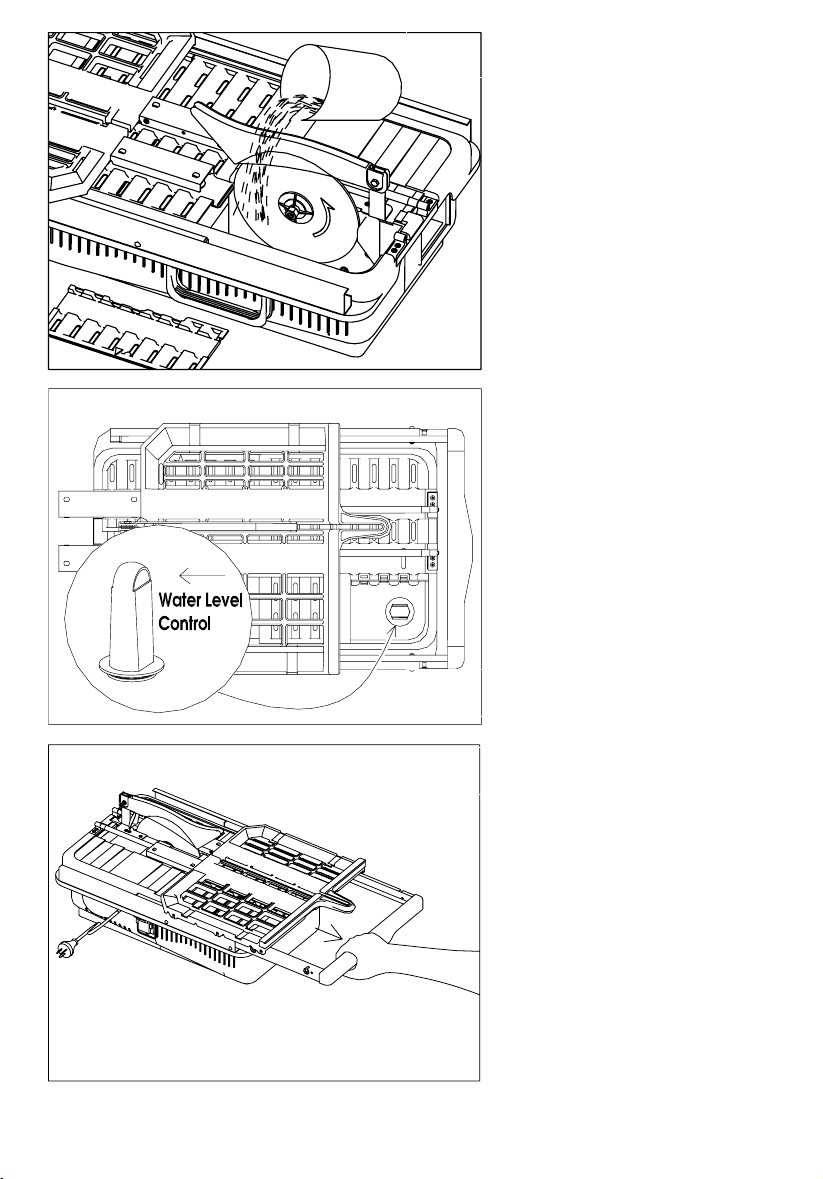

Installation of the Blade

Open the “Open/Close

cover” and use provided

the wrench to install the

provided blade. Make

sure the cutting direction

shown on the blade is the

same direction of the

running motor.

Warning: The rotating

direction of the blade is

very important for cutting

correctly. Fig.2

Fig.3

Installation of the Guard

Use provided wrench to

install the blade guard

and the supporting bar

shown in Fig.3.

Warning: Do not remove

the middle screw as this is

to hold the motor housing.

5

6

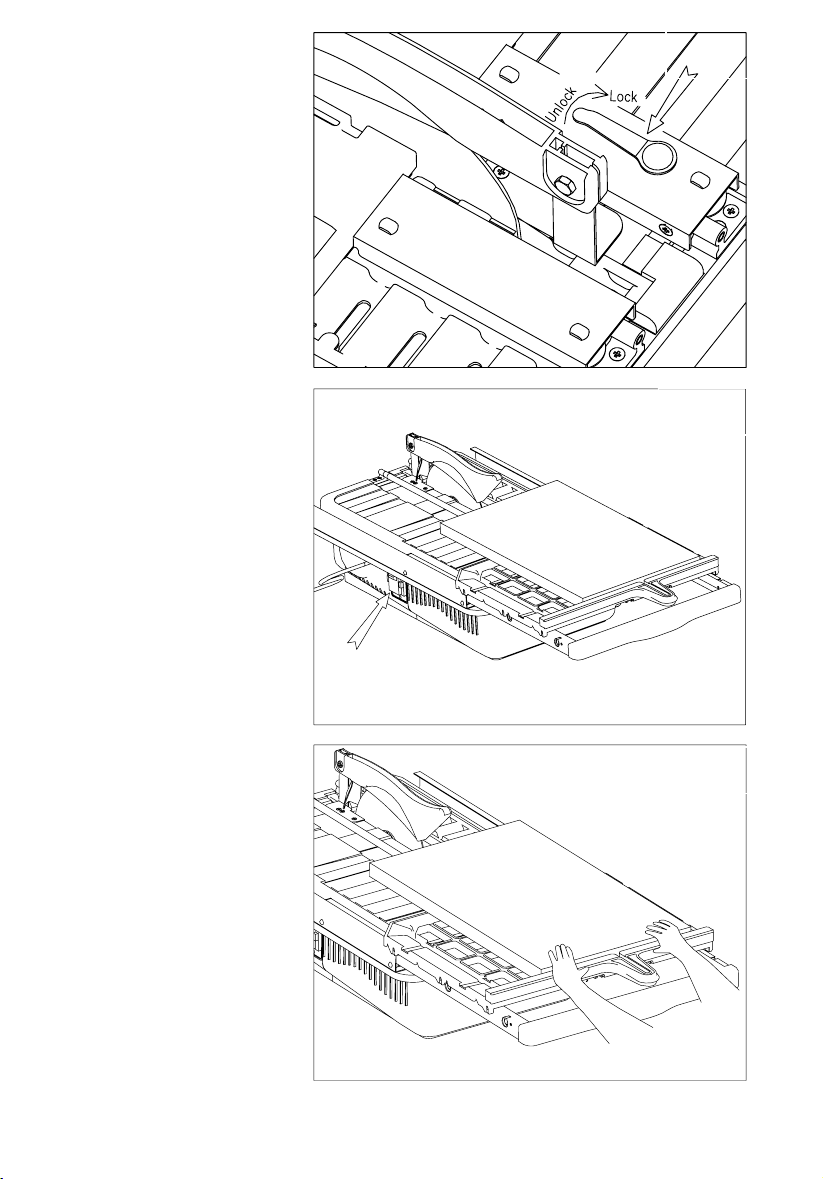

Fill Water

Open the “Open/

cover” then pour water into

the tray. Water can be

added or refilled as

needed during saw

operation.

Close

Supporting Bar

Extend out fully the

supporting bar before

moving the table. As

shown in Fig.6

Fig.4

Water Level Limit

The plug for the water tray

shown in Fig.5 is also a

water level control device.

Over filling the water will be

drained from the opening

at the top of the plug to

protect the motor.

Fig.5

Fig.6

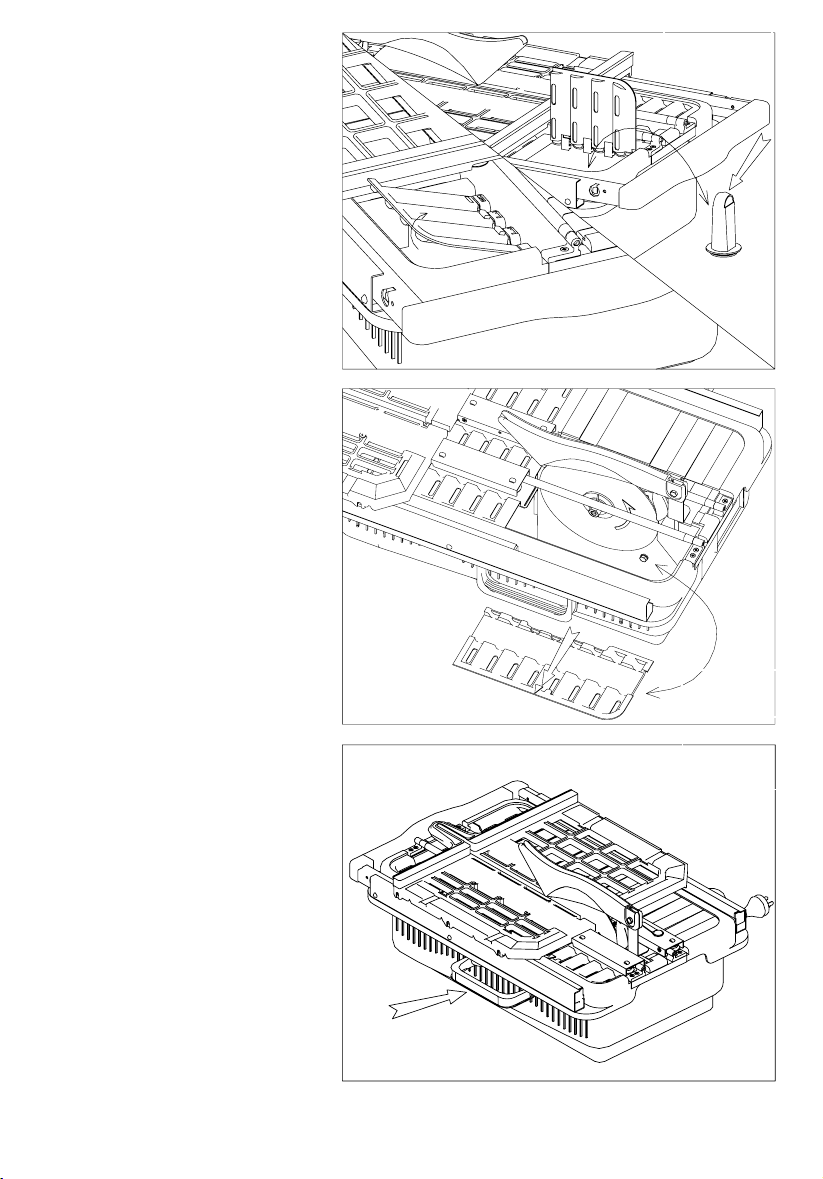

Placing a Tile on the Table

Place a tile on the moving

table, flush against the

table back shown in Fig.8.

And then turn on the

motor.

Table Lock/Unlock Lever

Unlock the table as shown

in Fig.7 before moving the

table.

Fig.7

Fig.8

Cutting

After placing the tile on

the moving table, use

two hands to hold both

table back and the tile,

slowing push towards to

the running blade as

shown in Fig.9

Warning:

Never put hand(s) on the

notch port of the moving

table.

Fig.9

7

Attachment

Use the attachment shown

in Fig.10 as a limitation

stopper when repeatedly

cutting same size of the tile.

Warning:

Remove this attachment

from the table when not

needed.

Fig.10

0-90 Degree Attachment

Unlock the screw o

attachment shown in Fig.11

and set it to the proper

angle between 0-90

degrees, then lock the

degree setting screw.

Warning:

Remove this attachment

from the table when not

needed.

n the

Fig.11

4

5 Degree Attachment (2)

Set this attachment in right

position where 45 Degree is

assured, then lock the

attachment to the table

back shown in Fig.12.

Warning:

Remove this attachment

from the table when not

needed.

Fig.12

8

Drain the Water

Open the top cover right

above the water plug

shown in Fig.13 and pull the

plug.

Fig.13

Cleaning the Saw

Pour a bucket of clean

water from the “Open/

Close cover” throughout

the water tray and use the

provided scraper to clean

and remove the cutting

debris and slurry

Fig.14

Carrying

A conve

Handle

nient carrying

handle is located on the

side of the saw, opposite to

the switch, for

transportation purpose.

Fig.15

9

10

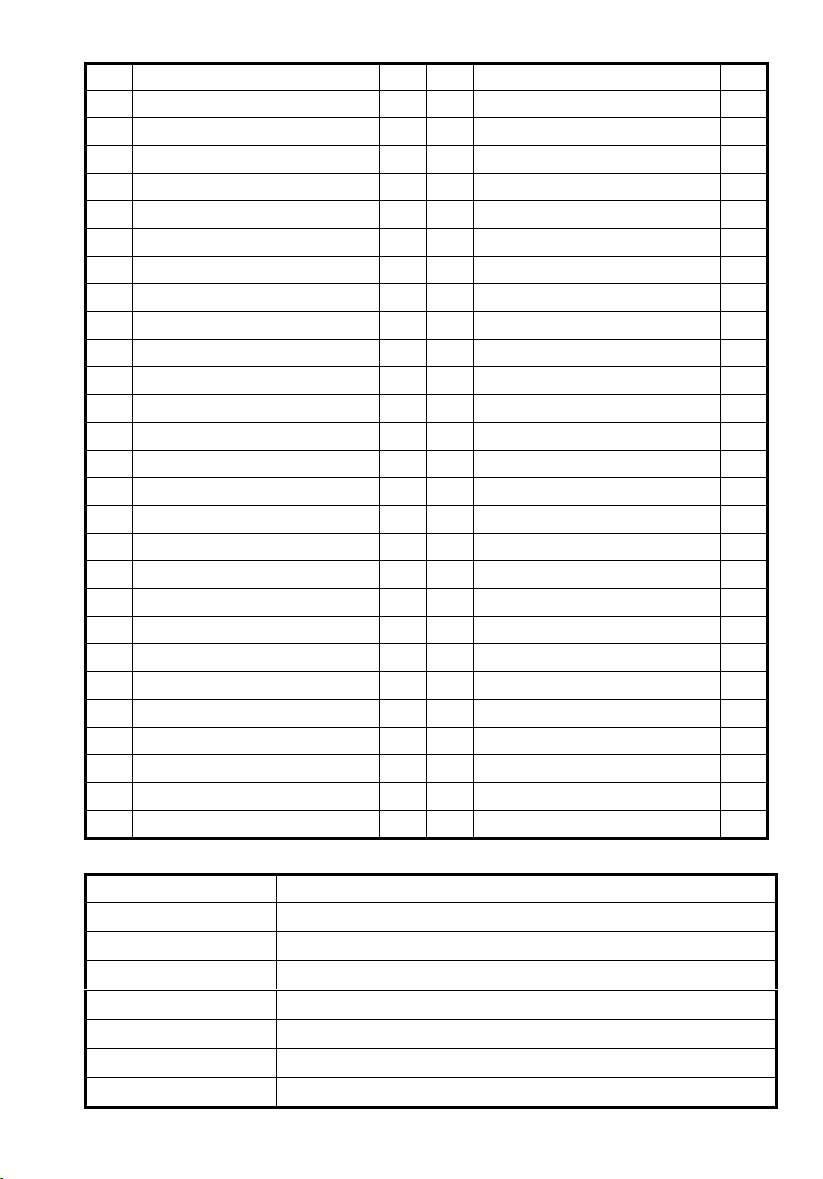

Specifications:

11

TD-080 Parts List

Parts Descri

p

tion Q't

y

Parts Descri

p

tion Q't

y

1 Table assembly 1 28 Small pulley 1

2 Screw M4 4 29 Large pulley 1

3 Hex nut M4 4 30 Shaft ring 12mm 2

4 Open Ring 4mm 6 31 Water Tank 1

5 Roller on supporting frame 6 32 Seal spacer 6mm 4

6 Pin for roller 6 33 Flat spacer 6mm 4

7 Support frame 2 34 Inner water stopper 1

8 Water tank cover 1 35 Hex nut M6 1

9 Wire connector 1 36 Inner flange 1

10 Electrical wire 1 37 Blade 1

11 Shaft for blade 1 38 Locking nut M10 1

12 Bearing cover 1 39 Outer flange 1

13 Screw M6 2 40 Hex screw M6 1

14 Switch assembly 1 41 Open/close cover 1

15 Screw M4 2 42 Hex nut M6 1

16 Hex nut M4 2 43 Blade guard bracket 1

17 Motor cover 1 44 Screw M4 3

18 ST-screw 4.2×13 6 45 Nut for guard bracket 1

19 Guide duct 1 46 Blade guard 1

20 Bearing 628 1 47 Guide positioning plate 2

21 Motor fan 1 48 Flat-head screw M4 5

22 Motor assembly 1 49 Guide base 4

23 Capacity 1 50 Support bar assembly 1

24 Hex nut M8 1 51 Guide assembly 2

25 Motor locking bar 1 52 0-45 degree attachment 1

26 Bearing 6002 1 53 45 degree attachment 1

27 Timing belt 1 54 Table Lock/Unlock Lever 1

Motor: 110V-120V/ 60Hz, 1.0H

p

/ 220V-240v, 50-60Hz, 735w

Rip Cut 25.5inch / 650mm

Diagonal Cut 18inch / 450mm

Cutting Depth 1-1/2inch / 40mm

Blade Size 8inch / 200mm

Blade Bore Size 5/8inch / 22.2mm, 25.4mm

Size(L×W×H) 610mm×420mm×225mm

Weight 31Lb/14KGS

12

Trouble shooting:

1No

ade to make sure s o ght

borking piece is 8)

2Mo

ann tio

br cords for da g

3. Tab ng cutting p e

a allation.

b earing status.

4 osi

arking table rn m nds

.

b. Change blade.

Pro ts contact you t zed

NVIRONMENT P TEC

.t cutting straight

.Check bla it’ n ti

.Make sure w flush against table back (Fig.

.tor doesn’t work

.Check power source co ec n.

.Check powe ma e.

le vibration duri roc ss

. Check blade inst

. Check blade-w

. L ng cutting speed

.Back-up the wo

and the re-start the motor

, tu the otor off for 30 seco

* blem still exis r au hori D Cut Service Center

E AL RO TION

Waste electrical products sh not be disp hold

. Please recycle where faciliti it. C

y or retailer for recycl ad .

D CUT P

1041N. Lo

ombard

l: 630-9 916-9101

www.dcutproducts.com

ould osed of with house

waste es ex heck with your local

Authorit ing vice

RODUCTS, INC.

mbard Road

L , IL 60148 USA

Te

Email: sales

16-9100 Fax: 630-

@dcutproducts.com

This manual suits for next models

1

Table of contents

Other D-CUT Saw manuals