D-CUT TA-070 User manual

S

SERIES

This saw can be operated safely only when the operating instructions

have been completely read and strictly adhered to. It is recommended

Operation Manual

TA-070 Wet Tile Saw

FOR YOUR SAFETY

to receive practical instruction before using the saw for the first time.

Always inspect cable and plug before using the saw. The outlet must

be grounded. Ground Fault Circuit Interrupter (GFCI) protection should

be provided on the circuit(s) or outlet(s) to be used for this saw.

Have damage repaired only by a qualified professional.

Do not use the saw in standing water or expose rain.

Wear hearing protection and safety goggles.

zAlways remove the plug from the power supply socket before removing

saw from work area, when interrupting work and when not using the

saw.

zInsert the plug into the power socket only when the saw is

switched off.

zAlways place the cable away from the saw towards the outside

of the saw table.

zDo not carry the saw by the cable.

zWear sturdy footwear.

zDo not use the saw when the blade is not installed properly.

zAlways switch off the saw before lifting the table for cleaning.

zOnly use original D-Cut accessories.

zNever leave the saw running unattended.

zKeep guards in place. Adhere to safety guidelines: (ANSI)

American Safety Standards Institute.

zNever stand or lean on equipment. Serious injury could occur

if the machine is tipped or is unintentionally contacted.

zDo not over reach. Keep footing and balance at all times.

zDisconnect tools. Before servicing, and when changing

accessories such as blades or profile tools. Turn off equipment!

zUse the correct tools. Do not force the equipment or accessory

to do a job for which it was not designed

zUse proper extension cord. Improper cord length and/or gauge

are the leading cause of premature electric motor failure! When

in doubt use heavier gauge cord.

FOR YOUR SAFETY

zCluttered areas and benches invite injuries

2

zKeep work area well lit.

zAvoid body contact with earthed or grounded surfaces (e.g. pipes,

radiators, ranges, refrigerators).

zDo not let persons, especially children, not involved in the work

touch the tool or the extension cord and keep them away from the

work area.

zWhen not in use, tools should be stored in a dry locked-up place,

out of reach of children.

zDo not force small tools to do the job of a heavy-duty tool.

zDo not use tools for purposes not intended; for example do not

use circular saws to cut tree limbs or logs.

zDo not wear loose clothing or jewelry; they can be caught in moving

parts.

zNon-skid footwear is recommended when work out doors

zWear protective hair covering to contain long hair.

zWhere possible use clamps or a vice to hold the work. It is safer

than using your hand.

zKeep cutting tools sharp and clean for better and safer

performance.

zFollow instruction for lubricating and changing accessories.

zInspect tool cords periodically and if damaged have them repaired

by an authorized service facility.

zKeep handles dry, clean and free from oil and grease.

zWhen not in use, before servicing and when changing accessories

such as blades, bits and cutters, disconnect tools from the power

supply.

zForm the habit of checking to see that keys and adjusting wrenches

are removed from the tool before turning it on.

zWatch what you are doing, use common sense and do not operate the

tool when you are tired.

zBefore further use of tool, it should be carefully checked to

determine that it would operate properly and perform its intended

function.

zCheck for alignment of moving parts, binding of moving parts,

breakage of parts, mounting and any other conditions that may

affect its operation.

zA guard or other part that is damaged should be properly repaired

or replaced by an authorized service centre unless otherwise

indicated in the instruction manual.

zHave defective switches replaced by an authorized service centre.

zDo not use the tool if the switch does not turn it on and off.

zThis electric tool complies with the relevant safety rules.

Qualified persons using original spare parts should only carry

out repairs, otherwise this may result in considerable danger to

the user.

3

FOR YOUR SAFETY

zTo avoid the possibility of the appliance plug or receptacle getting

wet, position tile saw to one side of a wall-mounted receptacle to

prevent water from dripping onto the receptacle or plug. The user

should arrange a trip loop in the cord connecting the saw to a

receptacle. The drip loop is that part of the cord below the level

of the receptacle, or the connector if an extension cord is used,

to prevent water traveling along the cord and coming in contact with

the receptacle.

zIf the plug or receptacle does get wet, DON’T unplug the cord.

Disconnect the fuse or circuit breaker that supplies power to the

tool. Then unplug and examine for the presence of a circuit faults.

zUse only extension cords that are intended for outdoor use. These

extension cords are identified by marking2Acceptable for use with

outdoor appliances; store indoors while not in use. Use only

extension cords having an electrical rating not less than the rating

of the product. Do not use damaged cords. Examine extension cords

before using and replace if damaged. Do not abuse extension cords

and do not yank on any cord to disconnect. Keep cords away from heat

and sharp edges. Always disconnect the extension cord from the

receptacle before disconnecting the product from the extension

cord.

zWARNING – To reduce the risk of electrocution, keep all connections

dry and off the ground. Do not touch plug with wet hands.

zGround Fault Circuit Interrupter (GFCI) protection should be

provided on the circuit(s) or outlet(s) to be used for the tile saw.

Receptacles are available having built-in GFCI protection and may

be used for this measure of safety.

4

INNOVATION PUT TO WORK

Here at D Cut Products, Inc. We are always looking

to come out with new innovative products.

Check out Our Website for Updates at

www.dcutproducts.com

Or contact us at

FOR YOUR (90 DAY)

WARRANTY TO BE EFFECTIVE ON ALL ELECTRICAL MOTOR

AND PARTS SUCH AS THE SWITCH AND THE CONTROL DEVICE,

GAS ENGINE, AND PARTS, ALSO FOR YOUR (1) ONE YEAR

WARRANTY ON ALL OTHER PARTS, EXCLUDING ABOVE

COMPLETE THE WARRANTY CARD (PLEASE INCLUDE THE

SERIAL NUMBER) AND MAIL IT IN AS SOON AS POSSIBLE.

The serial number of your saw

is located on the front side

the gearbox of the motor.

5

6

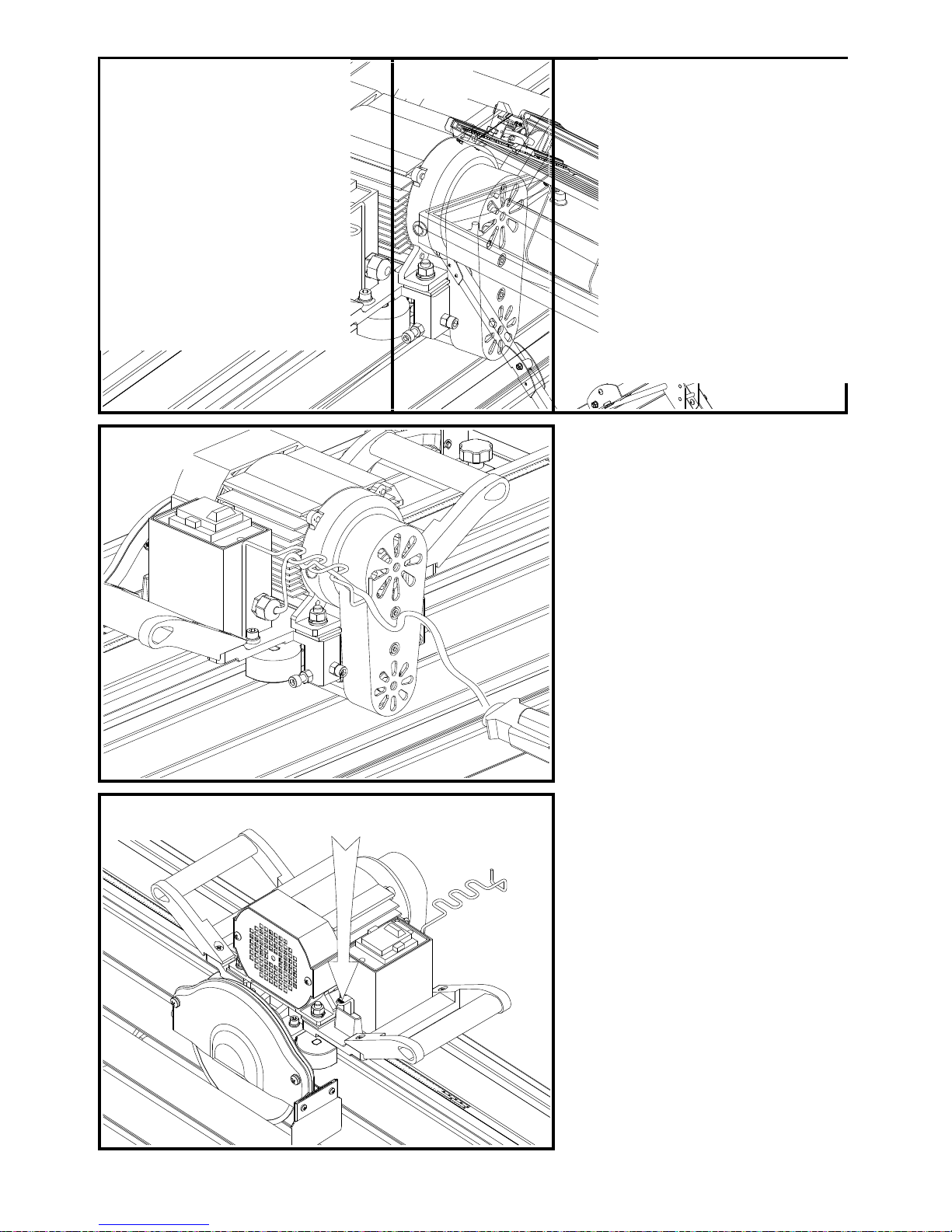

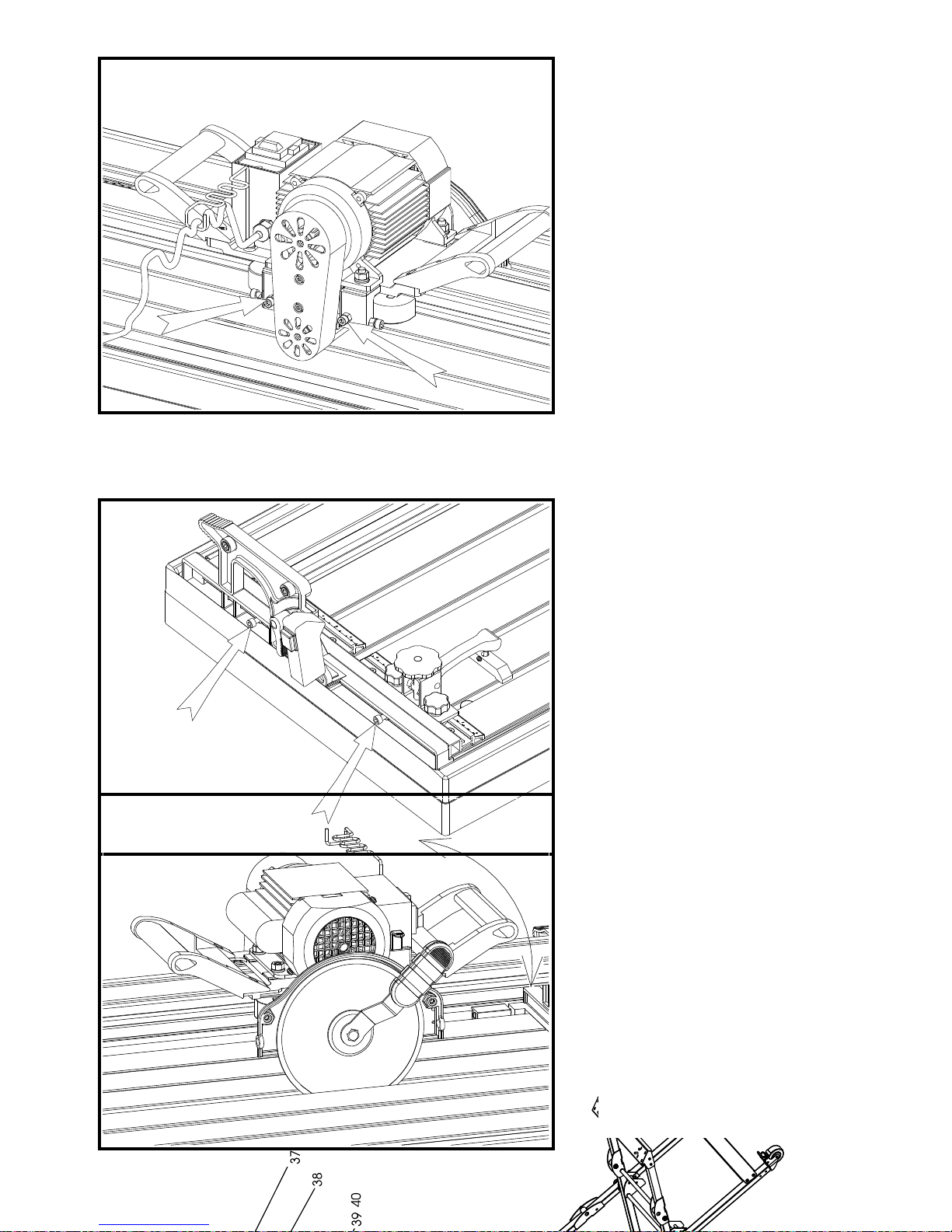

Fig.1

Fig.

2

Fig.

3

0-90°Attachment----1P

Press

mechanism------2P

Operation manual--- 1P

Warranty card-------

--1P

Steel Stand

Open folded stand in

a flat area.

Contents In the Box:

Wench-------------- - -

----1P

Installation

Press down wheel

brakes as shown. Set

the saw onto the

4pins of the stand

and use provided

screw to lock the saw

to the stand.

Fig.4

Open the table

Remove all tools,

debris etc. from the

saw table. Lock the

side plate in

position and lift the

table allowing the

rod from the concave

recesses molded into

the tray. This

enables the saw table

to remain in the open

When storing the saw

always turn the stand

90 degree to keep it

inside of the working

table area.

Core Stand

The cord stand is for

the support of the

electrical cord in a

safe manner.

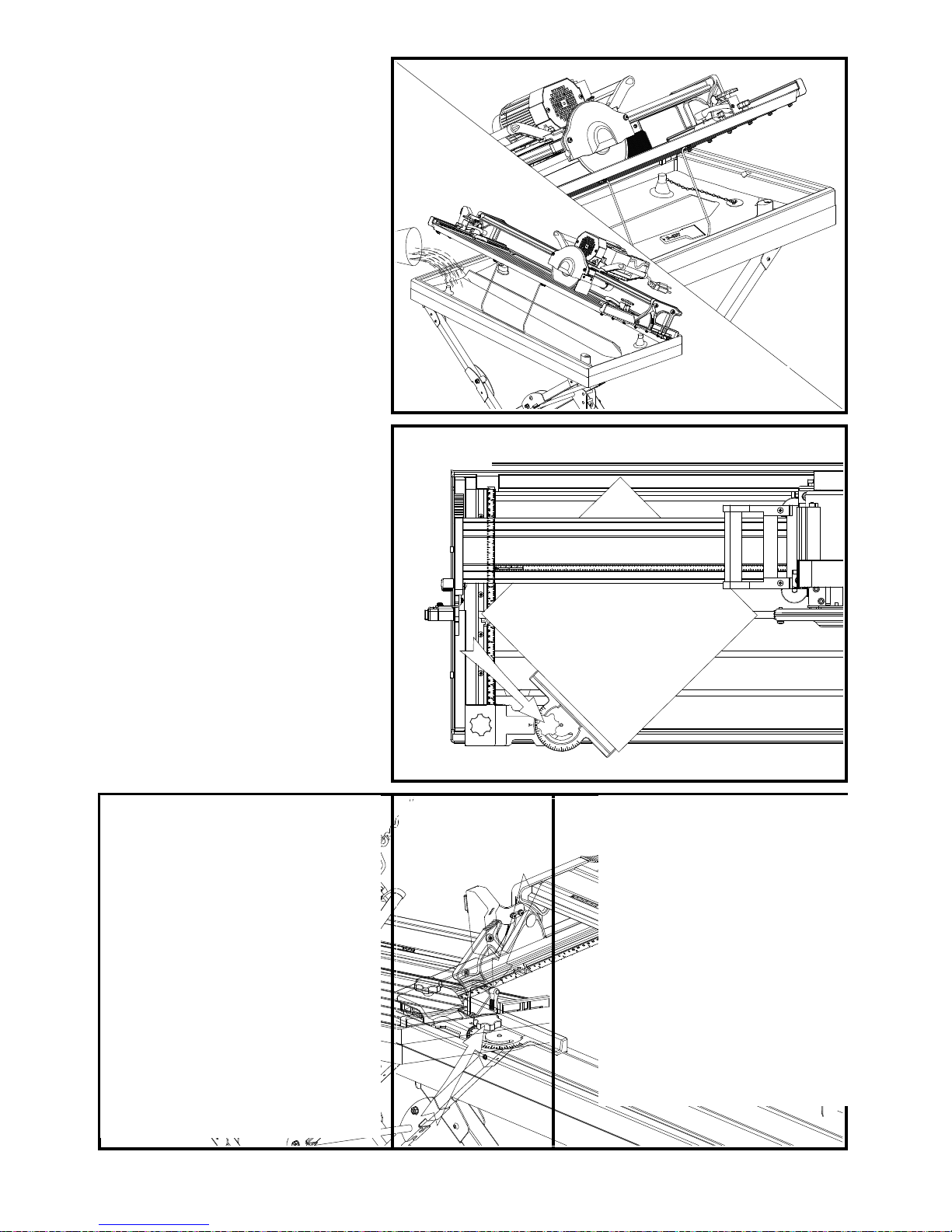

Fig.

7

Please enlace the

electrical cord on

the cord stand.

Electrical Cord

Fig.5

Fig.

6

Pull up the slide

plate Lock as shown

in Fig.6 before

operation. For safe

transportation or

when storing the saw,

always lock the slide

plate.

Slide Plate Locking

7

Fig.1

0

图

8

Fig.

9

Cutting:

Insert a piece of tile

under the guide rails

and keep a flat and

straight side against

the gauge. Use the

clap to hold the tile.

Stand along the

saw/table comfortably

and start the saw and

push the saw towards

the tile.

Fill the water tray

with approx.5 gallons

(23liters) of clean

water to the indicated

water level. Water can

be added or refilled

as needed during the

operation of the saw.

Fill Water Pull-Push Operation

Two handles are built

within the slide plate

/ motor mechanism. The

saw can be saw can be

either pushed to cut,

or pulled to cut, based

on the operator’s

comfort level or

preference.

Fig.

8

Fig.1

1

Pul

l

Push

Laser Scriber

Pull down the switch

as shown in Fig.9.

The laser will be

opened.

8

Clean

Drain the water by

pulling the chain

attached to the plug

on the bottom of the

water tray. Use the

provided scraper to

clean and remove the

cutting debris and

slurry and pour a

bucket of clean water

throughout the water

reservoir tray.

Fig.1

3

Fig.1

2

0-90°Attachment (1)

Unlock the screw on the

attachment shown in

Fig.14 and set it to the

proper angle between

0-90°, and then lock the

degree setting screw.

Warning:

Remove this attachment

from the table when not

needed.

Fig.1

4

0-90°Attachment (2)

Use the attachment

shown in Fig.15 as a

limitation stopper when

repeatedly cutting same

size of the tile.

Warning:

Remove this attachment

from the table when not

needed.

Fig.1

5

Shown and lift the

motor-end to 45°for 45

°beveling cutting.

Unlock two screws as

45°Cutting

9

Warning: If it is not

needed please don’t

adjustment the twos

screws.

Setting Accuracy(1)

Adjustment the two

screws as shown in

Fig.16 the verticality

of the gauge and the

blade can be regulated

if it is needed.

Fig.1

6

Fig.1

7

Warning: If it is not

needed, please don’t

adjustment the twos

screws.

Setting Accuracy (2)

Adjustment the two

screws as shown in

Fig.16 the gap of the

wheel and the guide rail

can be regulated if it is

needed.

Chang Blade

Remove the front

blade guard and use

the provided wench

loosens the flange to

change the blade.

Fig.1

8

10

11

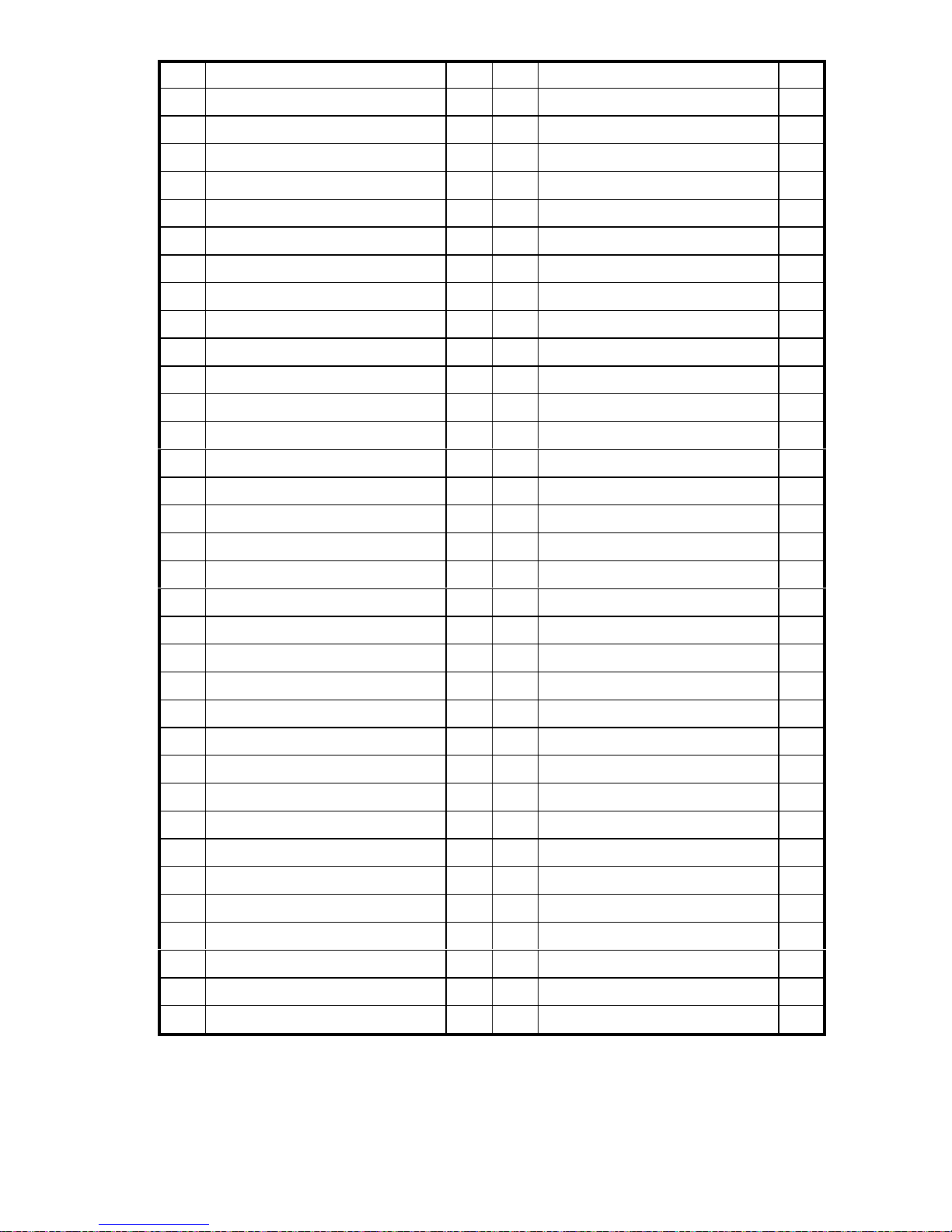

Parts Description Q’t Parts Description Q’t

1 Water Tray

1

35 Inner Hex screw M5×25

1

2 Inner Hex screwM6×20

2

36 Flat washer 5mm

2

3 Hex Nut M6

2

37 Inner Hex screw M5×40

1

4 Laser head assembly

1

38 Belt cover

1

5 Cross screw M4×10

2

39 Inner Hex screw M6×20

2

6 Flat washer 4mm

2

40 Big Flat washer

2

7 Left revolving bracket

1

41 Small pulley

1

8 Left bracket

1

42 Cord stand

1

9 Cross screwM5×35

6

43 Handle

2

10 Gauge base

1

44 Capacitance

1

11 Rail

1

45 ST-Screw 4.2×20

2

12 Cross screw M6×20

2

46 Hex screw M8×20

4

13 Front blade guard

1

47 Shaft cover

1

14 Hex bolt M8×20

1

48 Shaft for blade

1

15 7"blade

1

49 Wheel ping

4

16 Inner flange

1

50 Wheel base

2

17 Cross screw M6×20

2

51 Sleeve

4

18 Rear blade guard

1

52 Bearing 619/6-2Z

8

19 Hex nut M6

2

53 Wheel

4

20 Bearing base

2

54 Hex screw nut M6

4

21 Bearing 6202-2RZ

2

55 Water stop assembly

1

22 Cross screw M4×5

4

56 Outer flange

1

23 Spring washer 4mm

4

57 Square neck bolt M8×25

2

24 Rubber

4

58 Right revolving

bracket

1

25 Inner Hex screw M6×20

4

59 Inner Hex scre

w

M6×20

4

26 Stop water board

1

60 Spring washer 6mm

4

27 Inner Hex screw M6×16

4

61 Lock screw

2

28 Slide panel

1

62 Flat washer 6mm

2

29 Motor

1

63 Pin

2

30 Hex screw M8

4

64 Open ring 6mm

2

31 Spring washer 8mm

4

65 Right gauge base

1

32 Switch

1

66 Working table

1

33 Big pulley

1

67 Steel stand

1

34 Timing belt 150L050

1

Trouble shooting:

1. Not cutting straight

a. Check blade to make sure it’s on tight

12

b. Make sure working piece is flush against the gauge.

2. Motor doesn’t work

a. Check power source connection.

b. Check power cords for damage.

3. Table vibration during cutting process

a. Check blade installation.

b. Check blade-wearing status.

4. Losing cutting speed

a. Stop work and allow the motor to cool off for at least 20

minutes.

b. Change a new blade and try again.

*Problem still exists contact your authorized D Cut Service Center

Specifications:

110-120v, 60Hz, 1.3HP/220-240v, 50-60Hz,

1000W

Motor

Rip Cut 34 ” /860mm

Diagonal Cut

18 ” /450mm

Cutting Depth 1-1/4 ” / 32mm

Arbor

7/8 ” , 1 ” / 22.2mm, 25.4mm

Size (L×W×H) 44 ” ×20 ”×18 ” /1125mm×504mm×450mm

Weight

33Lb /15kg

13

ENVIRONMENTAL PROTECTION

Waste electrical products should not be disposed of with household

waste. Please recycle where facilities exit. Check with your local

Authority or retailer for recycling advice.

D CUT PRODUCTS, INC.

1041N. Lombard Road

Lombard, IL 60148 USA

Tel: 630-916-9100 Fax:

630-916-9101

www.dcutproducts.com

14

Table of contents

Other D-CUT Saw manuals