D-I INDUSTRIAL DMT 220DL User manual

MARINE TRANSMISSION

INSTRUCTION MANUAL

The users should read this manual thoroughly before operation and

observe the operating method and pre autions for more effe tive operation.

MODEL

DMT 220DL

Introduction

This manual contains descriptions of construction, operation principle, correct

operation, handling method, caution for installation, simple maintenance and

overhaul, etc. regarding D-I Marine transmission (DMT220DL).

APPLICATION HYDRAULIC MARINE TRANSMISSION

MODEL DMT220DL

To use this product safely and correctly the users must read this manual

thoroughly and understand it enough before operation.

Keep this manual at a designated place for next time.

Please read the contents marked with in this manual and use this product

correctly.

Users must follow the instruction now that the contents marked with are very

important information on safety.

In this manual, DANGER degrees for wrong handling are divided into 4 degrees as

following table.

If the contents with this mark are ignored and it is

mishandled, urgent situations such as death, serious

injury could occur.

If the contents with this mark are ignored and it is

mishandled, it is possible to suffer a loss of life and

property or serious injury.

If the contents with this mark are ignored and it is

mishandled, a loss of property could occur.

The contents with this mark should be read carefully.

C O N TE N TS

CHAPTER 1 - - - - - - - - - - OVERVIEW

CHAPTER 2 - - - - - - - - - - STRUCTURE

CHAPTER 3 - - - - - - - - - - PRINCIPLES OF OPERATION

CHAPTER 4 - - - - - - - - - - HYDRAULIC SYSTEM

CHAPTER 5 - - - - - - - - - - INSTALLATION

CHAPTER 6 - - - - - - - - - - OPERATION

CHAPTER 7 - - - - - - - - - - MAINTENANCE AND OVERHAUL

CHAPTER 8 - - - - - - - - - - TROUBLESHOOTING

CHAPTER 9 - - - - - - - - - - DISASSEMBLY AND ASSEMBLY

OPTION Live P.T.O.

HOW TO DISASSEMBLE THE OUTPUT COUPLING

ANNEX Ⅰ TABLE OF PERIODIC OVERHAUL

ANNEX Ⅱ PARTS ORDER SHEET

ANNEX Ⅲ WARRANTY LETTER

THE MANUAL OF MARINE TRANSMISSION

━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━

- 1 -

CHAPTER 1 – OVERVIEW

1-1. FUNCTION

The D-I marine transmission described in this manual is the power-transmitting

device which transmits the power generated from Engine to Propeller.

The main functions are the ahead, neutral, astern and reduction of speed at fixed

rate. The marine transmission has the structure which can safely endure the power

generated by propeller’s propulsion.

The power for the ahead and astern is transmitted by clutches with hydraulic

multiple plates. The necessary hydraulic system is integral inside.

1-2. SPECIFICATIONS

※ The weight does not include the fly wheel housing Ass’y, coupling Ass’y,

propeller coupling and mounting brackets.

Model Reduction

ratio

Max.

Input

speed

Max.

Input

torque

Operating

pressure

Lubricating

pressure

Dry

Weight

Flow of

cooling water

(rpm) (kgf-m) (kg/㎠) (kg/㎠) (kg) (ℓ/min)

DMT220DL

3.50

4.04

2500

209

20~26 2~4 440 90~120

4.47 198

4.72 177

THE MANUAL OF MARINE TRANSMISSION

━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━

- 2 -

D-I marine transmission must be applied to marine engine with regulated

capacity, otherwise the slip, overheat or breakage could happen to power transmission

system.

The capacity for use must be observed and if there are any inquiries, please

contact D-I Industrial Co., Ltd.

D-I marine transmission must not be used for the marine engine which is

rotated clock wise seen from the rear of the engine.

If D-I marine transmission needs to be used for the engine with clock wise rotation,

please contact D-I Industrial Co., Ltd. for consultation.

[ C.C.W ENGINE ] [ C.W ENGINE ]

THE MANUAL OF MARINE TRANSMISSION

━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━

- 3 -

CHAPTER 2 - STRUCTURE

2-1. OVERVIEW

D-I marine transmission is the reduction device which generates ship’s propulsion

and consists of five(5) major components such as input shaft sub Ass’y, astern

shaft sub Ass’y and output shaft Ass’y, etc. in driveline system.

Now that the hydraulic clutches controlled by oil pressure are applied for ahead

and astern operation, there are pump Ass’y to generate oil pressure, oil cooler,

selector valve Ass’y, valve holder Ass’y and pump holder Ass’y in hydraulic system.

The marine transmission is directly mounted to engine flywheel housing by bolts.

The power is transmitted from the outer part which is assembled onto engine

flywheel to input shaft through the inner part with rubber blocks.

In other words, the power is transmitted by the flexible coupling between engine

and marine transmission.

Responsibility for Torsional vibration

Torsional vibration analysis is carried out by the engine maker or independent consultants.

D-I Industrial Co., Ltd. can provide relevant data for the analysis of marine transmission

supplied by D-I Industrial Co.,Ltd.

The equipment installer is responsible for ensuring the torsional compatibility of the

propulsion system.

D-I Industrial Co.,Ltd. has no liability for noises/damages of marine transmission and

damages of flexible coupling and other drive units caused by that kind of vibration.

For safe operation, users should refer to instruction manual prior to operation.

[Fig-1] Construction of Marine transmission

ASTERN SHAFT ASS’Y

Flexible Coupling

(CENTA coupling)

INPUT SHAFT ASS’Y

OUTPUT SHAFT GROUP

THE MANUAL OF MARINE TRANSMISSION

━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━

- 4 -

2-2. INPUT SHAFT SUB ASS’Y

1) Outer Part

The outer part has the grooves in regular shape for the rubber blocks to be

assembled to transmit the power. It is assembled to engine flywheel by

screws.

2) Inner Part

The Inner part is assembled to input coupling by reamer bolts and has the

structure for the rubber blocks to be assembled.

3) Rubber blocks

They are rubber products and relieve the rotational vibration by engine which

means they let the power transmitted smoothly.

4) Input shaft

The input shaft is assembled to the input coupling by spline and shrink-fitted

to input clutch housing. Key on the input shaft is assembled to pinion

coupling to transmit the power of LIVE PTO.

5) INPUT SHAFT ASS’Y

The input shaft sub Ass’y consists of input clutch housing, clutch piston, steel

plates, sintered plates, back plate and return spring.

The steel plates have inner teeth which engage with the input pinion and

sintered plates have outer teeth which engage with the input clutch housing.

The steel plates and sintered plates are alternately assembled one by one and

when the selector valve lever is shifted in ahead position, the oil pushes the

clutch piston to actuate the input clutch. At this moment, the steel plates and

sintered plates are engaged and the power is transmitted from the input clutch

housing to input pinion.

When the lever is shifted in neutral position, the clutch piston returns to its

original position by the return spring. At this moment, the oil is drained from

the clutch piston section and the clutch is automatically disengaged.

1

3

2

5

4

THE MANUAL OF MARINE TRANSMISSION

━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━

- 5 -

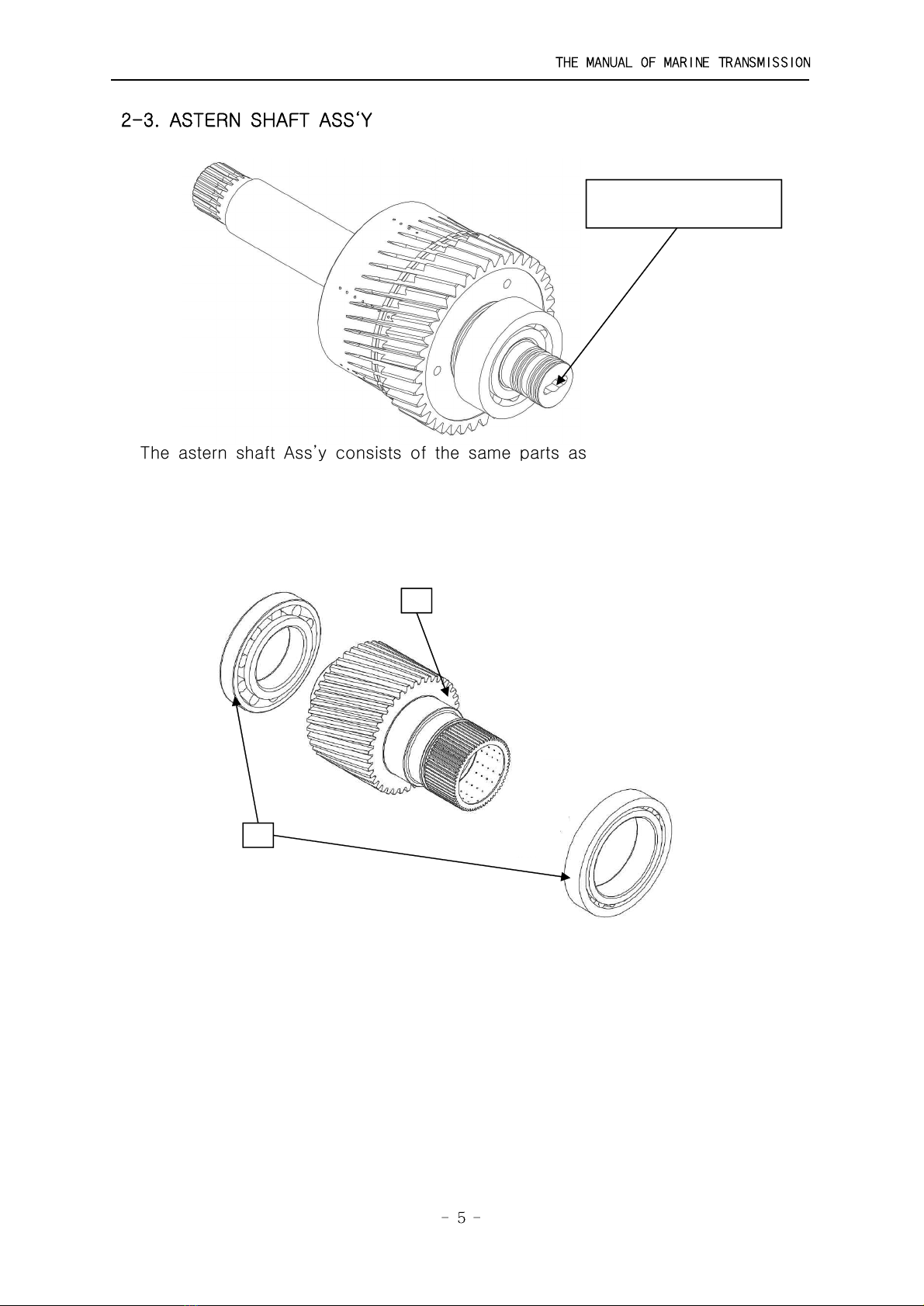

2-3. ASTERN SHAFT ASS‘Y

The astern shaft Ass’y consists of the same parts as the input shaft Ass’y

except for the astern shaft sub Ass’y and pump driving block at the rear of

shaft.

2-4. PINION

1) Taper roller bearing

Taper roller bearings which are shrink-fitted to pinions are assembled to sides

of case and case cover. They support the load generated by pinions’ rotation.

2) Pinion

The input and astern pinion are identical and are engaged with the output

shaft gear. When the ahead or astern operation is on, the power is transmitted

from the input shaft sub Ass’y to output shaft gear.

Unlike other models, the shim adjustment for DL model is carried out after

assembled to case Ass’y.

1

2

A

A

Key slot for driving gear

of hyd’ pump

THE MANUAL OF MARINE TRANSMISSION

━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━

- 6 -

2-5. OUTPUT SHAFT ASS‘Y

1) Output shaft

Output Shaft has the support by 2 taper roller bearings and shrink-fitted with

output gear. ON the input side’s taper, the output coupling is assembled.

2) Output gear

The output gear is shrink-fitted to output shaft and engaged with the input and

astern pinion at all times.

3) Taper roller bearings

The taper roller bearings fixed on both sides of the output shaft support the

thrust force generated from the propeller during the ahead or astern actuation.

4) Output coupling

The output coupling is assembled to output shaft in taper and is firmly fixed

by a plate and screws.

2-6. CASE, CASE COVER, BEARING CARRIER

The case, case cover and bearing carrier is made of cast iron.

3

1

2

4

THE MANUAL OF MARINE TRANSMISSION

━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━

- 7 -

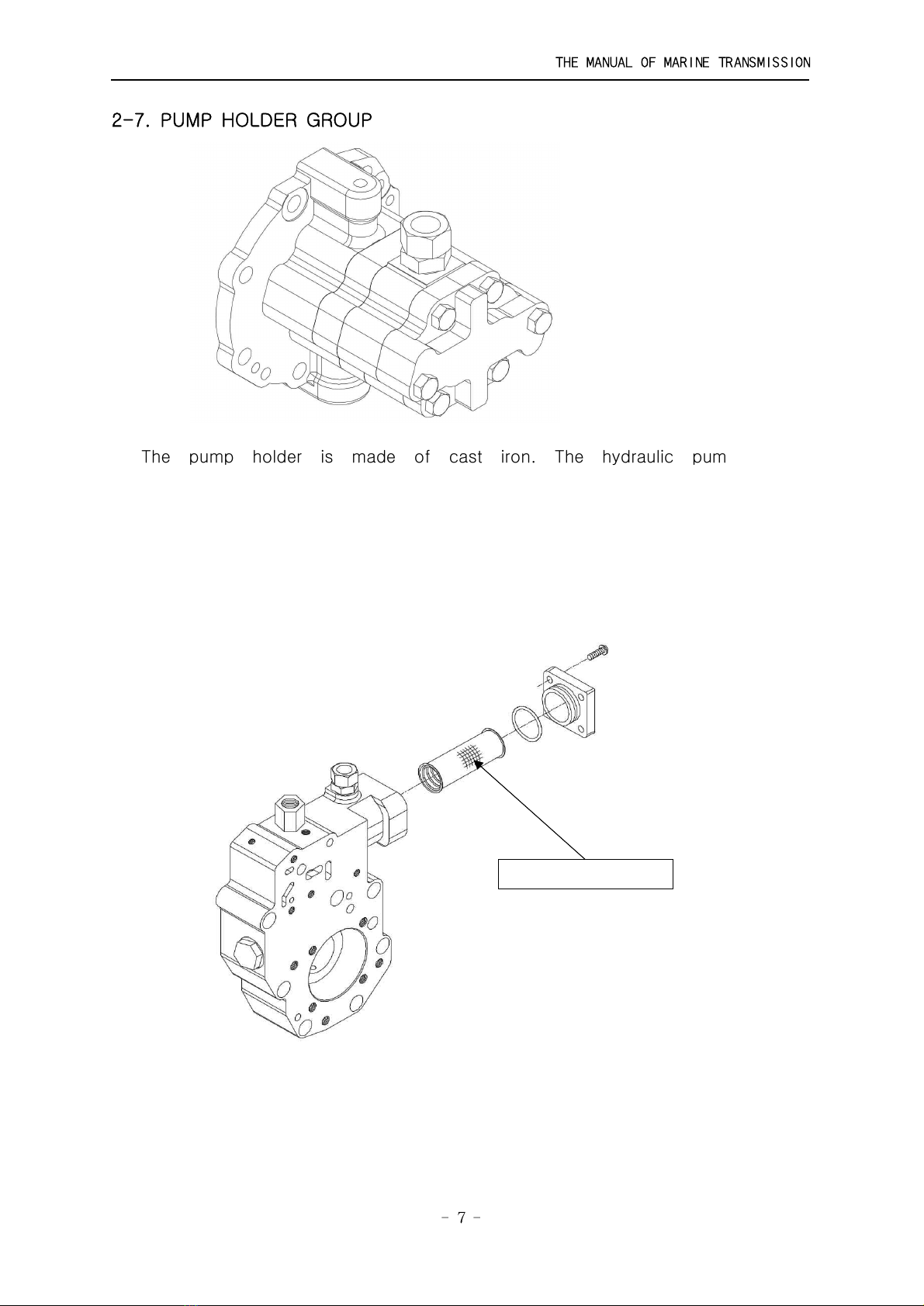

2-7. PUMP HOLDER GROUP

The pump holder is made of cast iron. The hydraulic pump is the

circumscribed gear type, and bolted on the pump holder. The pump driving

gear is driving block and spline fitted at the end of the astern shaft, and

rotated at the same speed as that of engine, but in the opposite to engine

direction.

2-8. SECONDARY OIL FILTER

This is attached to the inlet of the valve holer to re-filtrate oil which is

filtered through a strainer on the inlet side of the pump before leading it to

the bearing carrier.

it has the structure to easily be cleansed by disassembling only filter’s cover.

Periodic Inspection : Refer to ANNEX Ⅰ

OIL FILTER ASS’Y

THE MANUAL OF MARINE TRANSMISSION

━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━

- 8 -

2-9. SELECTOR VALVE ASS’Y

1) Selector valve body

The selector valve body is made of cast iron, and bolted on the valve holder.

The main components are the pressure-regulating valve and piston to control

the operating pressure and orifice plate to adjust the impact and time when

operating.

2) Valve stem

The valve stem is rotated in the valve body, and has three ports leading oil to

the passages for ahead, neutral, and astern position. The pressured oil for

actuation of the clutch is led to each clutch through these passages.

3) Lever / Stem valve

The lever is fixed on the valve stem with a spring pin, and clutch operation for

ahead, neutral, or astern position can be performed by operation of this lever.

And it is provided with a proper control head to make remote control.

※4) Trolling Valve Ass'y (Option part)

Trolling valve is a device that controls imperceptibly the rotation of output shaft

at the low rpm of engine. It is constructed to control remotely by the cable.

[Option]

Trolling valve position

Selector valve Selector valve group Trolling valve ass’y

THE MANUAL OF MARINE TRANSMISSION

━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━

- 9 -

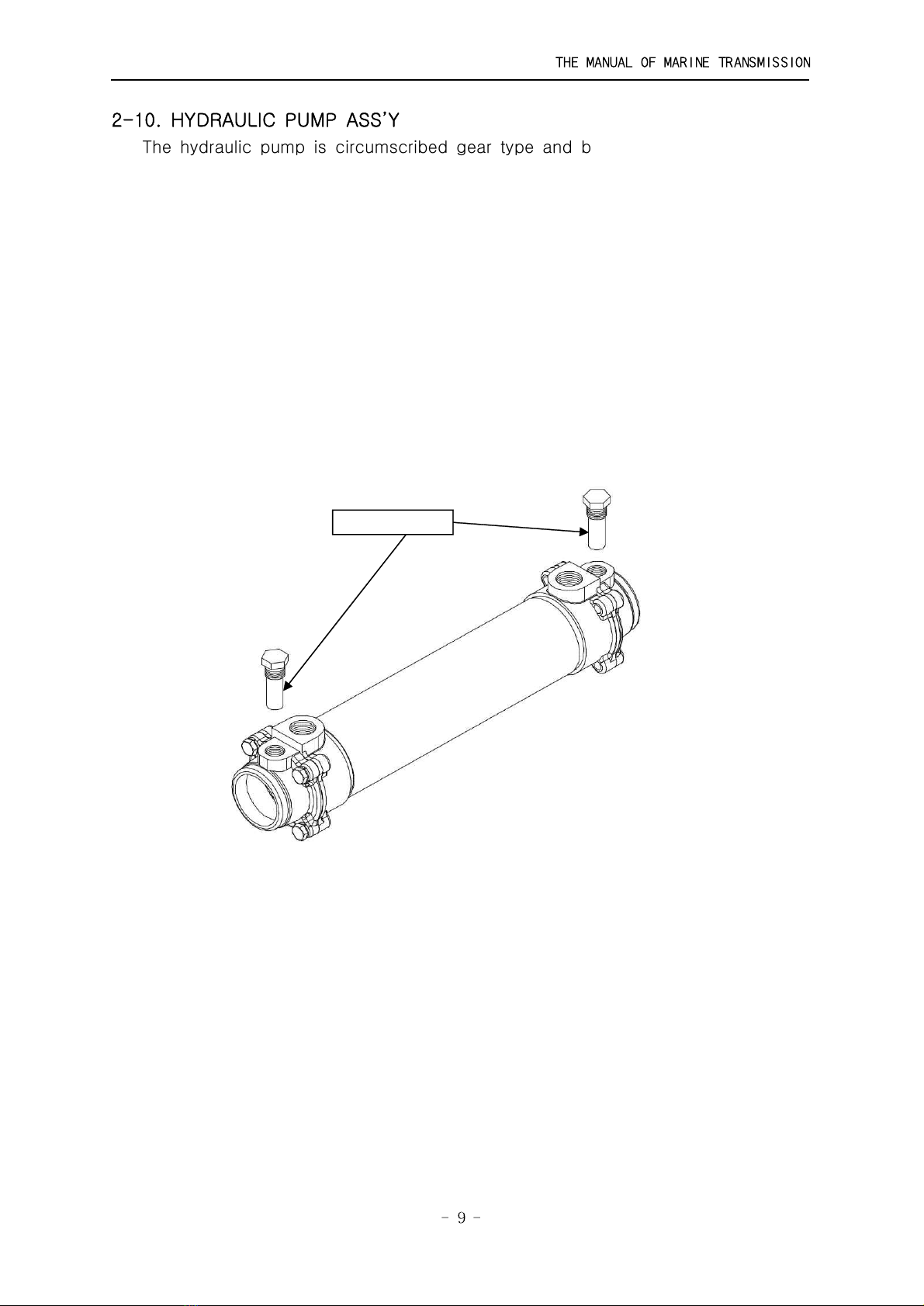

2-10. HYDRAULIC PUMP ASS’Y

The hydraulic pump is circumscribed gear type and bolted on the pump holder.

The pump driving gear is driving block and spline fitted at the end of the

astern shaft, and rotated at the same speed as that of engine, but in the

opposite to engine direction.

2-11. SCREEN FILTER ASS’Y

The screen filter assembly is connected with a suction pipe of the pump inlet

side of filtrating oil and fixed on the bottom side of the case cover with screws.

It is easy to clean by removing the screen filter cover.

Periodic Inspection : Refer to ANNEX I

2-12. OIL COOLER

Oil Cooler is the device that cools the operating oil inside of marine gearbox

and uses the seawater as cooling water. It is bolted on the cooler fixing block

fitted in the case and cools the oil supplied from hydraulic pump and sends to

the secondary oil filter. It uses Aluminum brass pipe which is strong against

corrosion, and applies the Zinc anode.

Periodic Inspection : Refer to ANNEX Ⅰ

ZINC ANODE

THE MANUAL OF MARINE TRANSMISSION

━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━

- 10 -

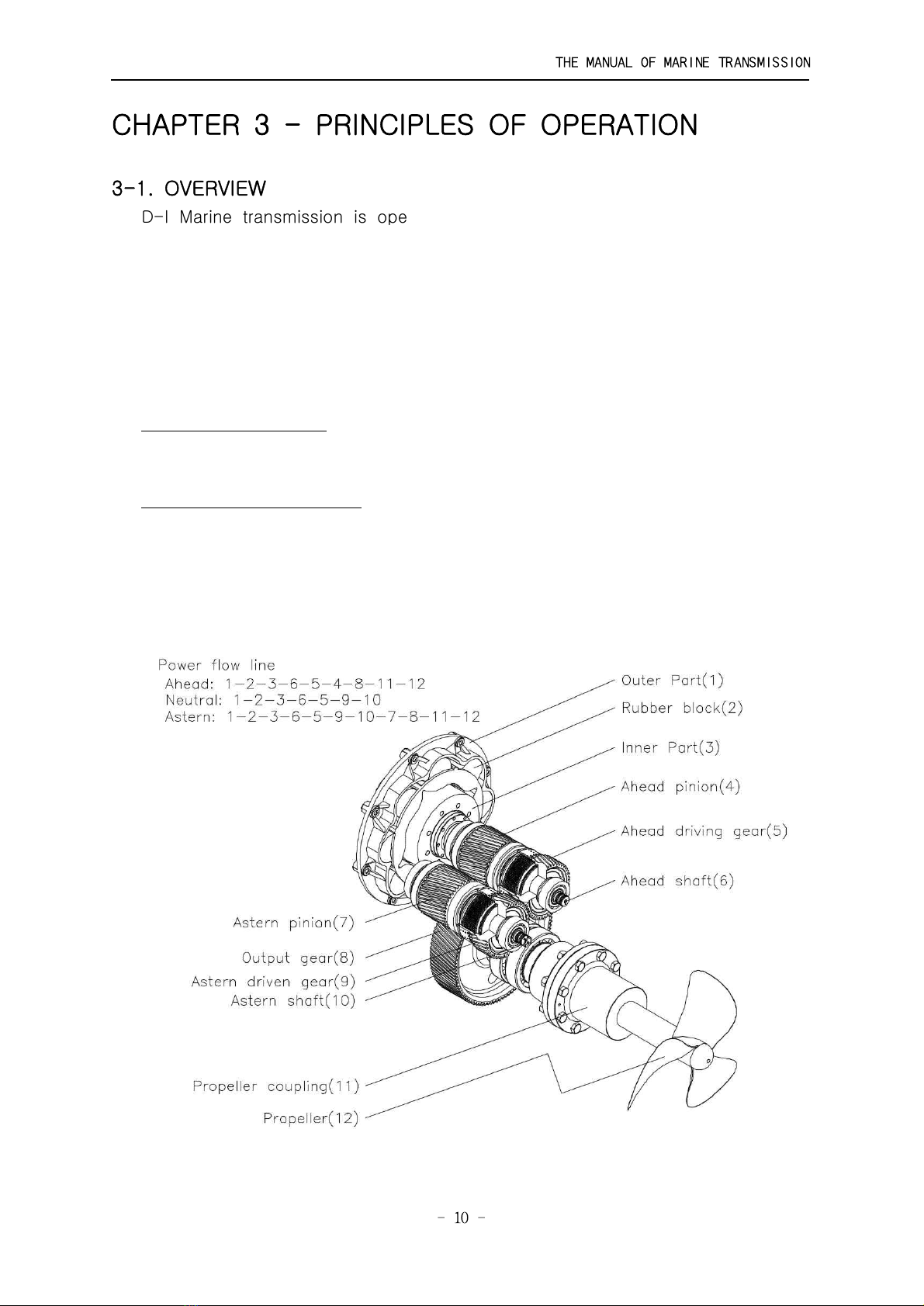

CHAPTER 3 - PRINCIPLES OF OPERATION

3-1. OVERVIEW

D-I Marine transmission is operating with the hydraulic pressure and must be

operated within the limits of rated load capacity, and has the same capacity

and reduction ratio for the ahead and astern actuation. Therefore it can be

appropriately used in the application of twin engine system.

The clutches are hydraulic multi -plates types and performed by the hydraulic

pressure. The lubrication for the each part is divided into 2 ways, one is

lubricated by force and another by scattering.

* Lubrication by force: the input shaft spline, input coupling oil seal, bearings,

gears, pinion gears, internal steel plates and external sintered plates, clutch

housing gears and etc.

* Lubrication by scattering: bearings, pinion gears, output gear.

3-2. DIRECTION OF ROTATION

The input shaft is rotated in the same direction as that of engine, and the

output shaft in the opposite direction during ahead actuation but in the same

direction during astern actuation.

[Fig-2] Drive line system of marine Transmission

THE MANUAL OF MARINE TRANSMISSION

━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━

- 11 -

3-3. POWER TRANSMISSION (Refer to Fig.2)

1) Neutral position

① The power is transmitted from the outer part bolted to engine flywheel to

inner part with rubber blocks in order.

② The inner part transmits the power to input coupling and then the power is

transmitted to input shaft through the input coupling’s spline. At this moment,

the input clutch housing which is shrink-fitted to input shaft also rotates

because the inner teeth of input clutch housing are engaged with outer teeth

of sintered plates.

③ At the same time, the outer teeth of input clutch housing are engaged with

outer teeth of astern clutch housing and inner teeth of astern clutch housing

are engaged with outer teeth of sintered plates, so the astern clutch housing

and sintered plates rotate in the opposite direction of engine.

④ Any rotating parts of marine transmission do not transmit the power in

the neutral condition.

2) Ahead position

① The high-pressure oil from the selector valve pushes the clutch piston in

the input clutch and then steel plates adhere to sintered plates.

② Friction plates rotate in the same direction of input clutch housing.

③ The pinion engaged with steel plates rotates.

④ The power is transmitted to output gear and propulsion force(opposite direction of

engine) occurs.

3) Astern position

① The high-pressure oil from the selector valve pushes the clutch piston in

the astern clutch and then steel plates adhere to sintered plates.

② Friction plates rotate in the same direction of astern clutch housing.

③ The pinion engaged with steel plates rotates.

④ The power is transmitted to output gear and propulsion force(same direction of

engine) occurs.

[Fig-3] Sequence of power transmission

Ahead position Astern position Neutral position

THE MANUAL OF MARINE TRANSMISSION

━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━

- 12 -

CHAPTER 4 - HYDRAULIC SYSTEM

4-1. OVERVIEW

The hydraulic system is shown in Fig.4. The oil contained in the marine

transmission flows into the pump through the oil strainer, and high pressure oil

that is discharged from the gear pump is led to the selector valve body

through the oil cooler, the secondary oil filter and the valve holder. And then,

the oil is regulated to the determined pressure by means of the oil pressure

regulating valve before being led to the valve stem for clutch actuation.

By changing the oil direction of the valve stem, the oil is led to either the

ahead or astern actuation clutch.

[Fig-4] Hydraulic circuit diagram

THE MANUAL OF MARINE TRANSMISSION

━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━

- 13 -

4-2. SELECTOR VALVE GROUP

1) Flow of the pressured oil by operation of the selector valve is shown in

[Fig.5]. The pressured oil discharged from the gear pump is led to the

direction of the arrow "P" in [Fig.6], and then into the hole of the valve

stem.

2) When the selector valve is operated for ahead or astern position, part of the

oil is led to the rear surface of the clutch piston to actuate the clutch, and

another part of it is led to the oil pressure regulating piston through the

orifice of a check valve to raise the oil pressure to the determined pressure

gradually. And the rest of the oil by continuous discharge from the hydraulic

pump, pushes the oil pressure regulating valve and flows through the

passage "L" into the lubricating oil passage to forced-lubricate respective

parts with pressure regulated by means of the lubricating oil pressure

regulating valve.

3) When the selector valve is shifted toward the neutral position, the return

spring of the clutch returns the clutch piston to disconnect the clutch, and

the piston is also returned to lower the pressure down.

[Fig-5] Oil flow path of valve stem - [SEC. A-A of Fig-6]

[Fig-6] SELECTOR VALVE GROUP

THE MANUAL OF MARINE TRANSMISSION

━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━

- 14 -

CHAPTER 5 - INSTALLATION

Installation of marine transmission have an important effect on the function and

performance of the marine transmission.

GAUGE / TOOL SPEC. REMARK

DIAL GAUGE 0.01

MAGNET BASE -

THICKNESS GAUGE 0.01 ~ 1

WRENCHES M16 ~ M32

The Key, which is used for starting a marine engine, should be pulled off

before installing Marine transmission to the Marine engine.

5-1. CHECK POINT BEFORE INSTALLATION

D-I marine transmission is supplied to customers without oil. Thus, before

operation, make sure that the marine transmission is fed with oil SAE #30 and

check the oil amount with oil gauge. (Oil Quantity : check with the name plate)

- MARINE TRANSMISSION Recommended Oil -

5-2. INSTALLATION

The alignment of the engine and the marine transmission is the most important

factor for normal performance and life extension.

1) Engine bed

Use the engine bed made of well-dried rigid wood or steel.

If the engine bed is not rigid, the alignment will be deviated due to the vibration

of the engine or other influence.

2) Supporting

The support brackets for the marine transmission have to be fixed on the engine bed

firmly like the engine mounting. Especially, the bolts of flywheel housing and brackets

(where the arrows point at in the below figure) should be tightened firmly.

Name Manufacturer

Daphne Marine Oil SX30 S-Oil

Delo 1000 Marine 30 GS Caltex

diamond Marine T103(TBN13 SAE#30) MICHANG OIL IND,CO.,LTD.

Exxmar 12TP30 Esso Oil Co., Ltd

Mobilgard 312(SAE#30) Mobil KOREA

Shell Gadinia Oil 30 Showa Shell Oil Co., Ltd

Jomo marines D13 Japan Energy Corporation

THE MANUAL OF MARINE TRANSMISSION

━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━

- 15 -

Bolts for Housing and Brackets of marine transmission should be tightened

firmly. If not, a noise, vibration or breakage of housing can be occurred.

3) Alignment

The alignment of marine transmission's output shaft coupling and the propeller

shaft coupling should be precise and the allowable deviation is as indicated in

the following figures :

The alignment must be made only when the ship is afloat, not in a

dock. In addition, in case of a wooden ship, periodic check should be

made every one or two months since the engine bed may be bent up to

about six months after initial installation, and also a FRP or steel ship

must be checked periodically.

Engine

Shim

Engine

Shim

Bracket

Engine bed

Marine

gearbox

THE MANUAL OF MARINE TRANSMISSION

━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━

- 16 -

CHAPTER 6 - OPERATION

6-1. PREPARATIONS FOR OPERATION

1) Check the whole parts of marine transmission and if the bolts, nuts, etc.

are loosened.

2) Check the oil level with oil level gauge and neutral pressure.

2-1) Check if the neutral pressure(1~5 kgf/㎠) is formed within 30 seconds at

idle RPM after the engine starts up. (If not, just stop the engine and then

check relevant parts)

2-2) After running the engine at idle RPM for 2~3 minutes, stop the engine

and check the oil level in 2~3 minutes.

3) Place the selector valve lever on the neutral position before starting the

engine.

Check the oil amount in marine transmission before operation.

If the oil is not enough, fill it up with oil.

If the neutral pressure is not formed, just stop the engine.

6-2. OPERATION AND STOP

1) Run the engine at idle RPM for about 10 minutes for warming-up.

2) During 10 minutes warming-up, check on oil leakage, abnormal noise,

over-heat, cooling water condition, etc.

3) Check the neutral oil pressure as increasing the engine RPM gradually.

(The clutch oil pressure is 1~5 kgf/㎠ at engine idle RPM in neutral position)

4) Check if the operating oil pressure is normal when operating the marine

transmission in ahead and astern position. (Refer to 1-2 "Specifications")

When decreasing the engine RPM, the operating oil pressure could be

decreased a little bit, however, it is normal.

5) The shifting of selector valve lever to ahead or astern position must be taken

at 50% of rated engine RPM or under.

6) The oil temperature during continuous operation is 50-90℃, but it could be

increased a little bit by frequent ahead and astern shifting.

7) Observe abnormal noises, over-heat, etc. all the time during operation.

If abnormal conditions are found, stop the engine and find out the causes

of them and then take measures to solve them.

8) Be sure to place the selector valve lever on the neutral position before

stopping the engine.

9) To use emergency screws in an emergency

In case that the ahead clutch is slipped or not operated, it can be engaged

mechanically by emergency measures. The ahead clutch has three screws

called emergency screws assembled and it can be engaged by tightening the

screws. If the failure is repairable on the spot, repair it correctly as referring

THE MANUAL OF MARINE TRANSMISSION

━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━━

- 17 -

to "Trouble shooting". If it is not repairable on the spot, enter the nearest port

by using the emergency screws and then repair it.

Shifting of selector valve lever to ahead and astern position

must be taken at 50% of rated engine RPM or under.

* How to use the emergency screws

1) First, stop the engine.

2) Remove the valve holder cover shown in [Fig.7].

3) After disassembling the hexagon screw remarked in the [Fig 8], seek the

emergency screws of [Fig 9] by turning the flywheel of engine and tighten

the 3 emergency screws with the 5mm hexagon wrench (Torque: 130kg.cm)

4) Re-assemble the removed hexagon socket screw.

* To make the ahead clutch return to original condition, loosen the emergency

screw again.

To use the emergency screws means that the ahead clutch

is engaged all the time. Therefore, be careful when the

engine starts up because the vessel moves forward once

the engine is on. During a sail, the selector valve must be

placed on the ahead position and the engine should be

operated at 70% of rated engine RPM or under.

When using the emergency screws, fill the marine

transmission with oil till the oil level comes up to center of

astern shaft.

The vessel should slow down before entering the port and

be taken in tow because the astern function does not work

while using the emergency screws.

Table of contents