www.daewoopower.bg

7

GENERAL SAFETY INSTRUCTIONS

IMPORTANT INFORMATION

• The machine is only designed for trimming grass and brush cutting.

• The only accessories to be used with the engine unit as a drive source are the cutting units we recommend in the

chapter "Technical data".

• Never use the machine if you are tired, if you have consumed alcohol, or if you are taking medicines that can affect

your sight, your judgement or the control of your body.

• Use personal protective equipment. See the section "Personal protective equipment".

• Never use a machine that has been modified so that it no longer corresponds with the original design.

• Never use a machine that is faulty. Follow the maintenance, control and service instructions in this Operator's

Manual. Some maintenance and service actions should be carried out by trained and qualified specialists. See the

chapter "Maintenance".

• All covers and guards must be fitted before starting the machine. Check that the spark plug cap and HT ead are

not damaged, otherwise you could get an electric shock.

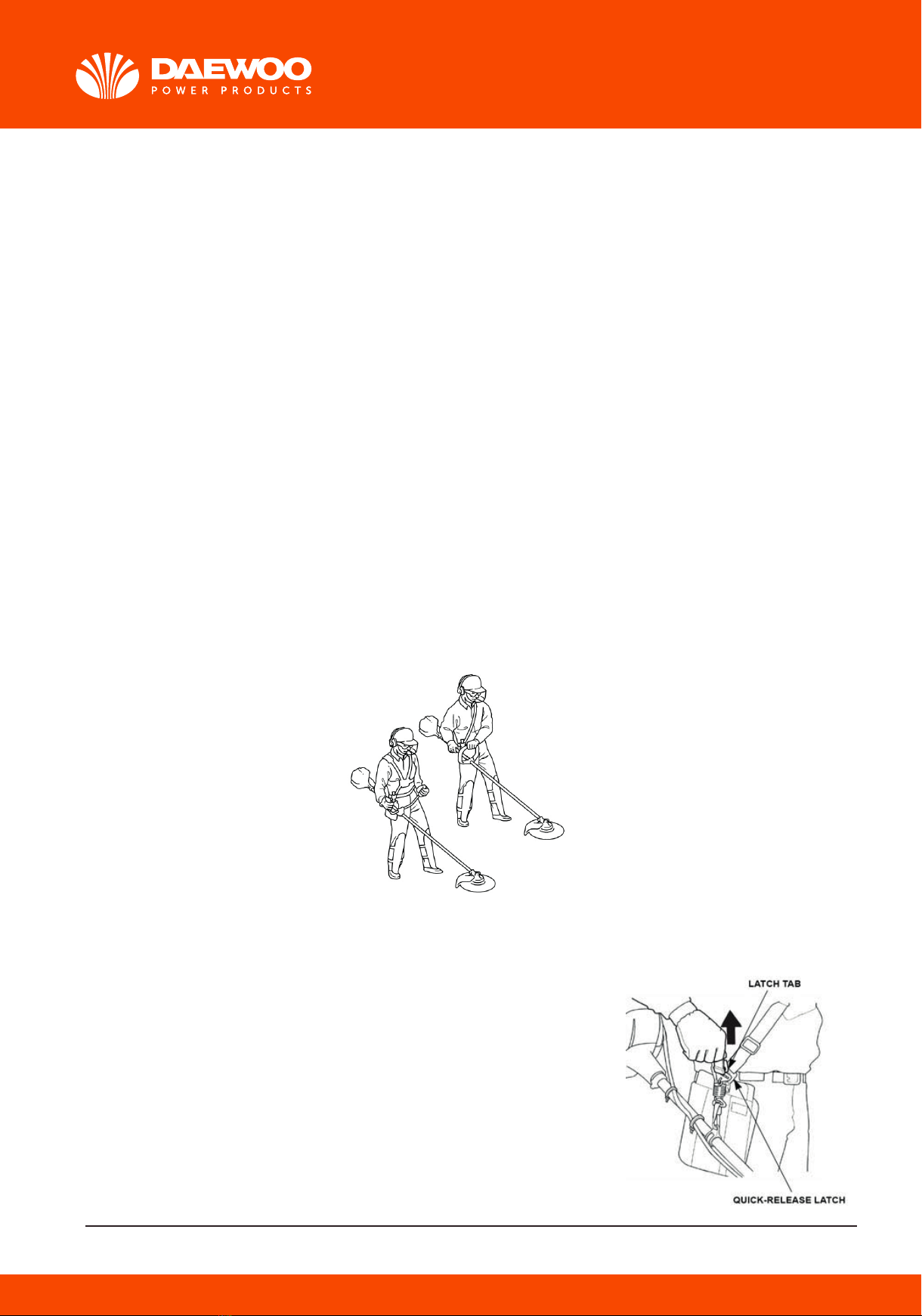

• The machine operator shall ensure, while working, that no persons or animals come closer than 15 metres. When

several operators are working in the same area the safety distance should be at least double tree length, however,

at least 15 metres.

WARNING!

Faulty cutting equipment or an incorrectly sharpened blade increases the risk of accidents. When the engine is

started with the choke in either the choke or start throttle positions the cutting equipment starts to rotate immediate-

ly.

Never start the machine indoors. Bear in mind the dangers of inhaling the engine's exhaust fumes.

Observe your surroundings and make sure that there is no risk of people or animals coming into contact with the

cutting equipment.

Place the machine on the ground, ensure the cutting equipment runs free of twigs and stones. Push the machine

body towards the ground using your left hand. (NOTE! Not with your foot). Grip the starter handle with your right

hand and pull the starter cord.

Fuel safety

• Always use a fuel container with an anti-spill valve.

• Never fill the machine while the engine is running.

Always stop the engine and let it cool for a few minutes before refuelling.

Provide good ventilation when filling or mixing fuel (petrol and 2-stroke oil).

Move the machine at least 3 m from the filling position before starting.

• Never start the machine:

a)If you have spilt fuel on it. Wipe up all spillage.

b)If you have spilt fuel on yourself or your clothes. Change your clothes.

c)If there is a fuel leak. Make regular checks f leakage from the

fuel cap and the fuel supply pipes.

Transport and storage

Store and transport the machine and fuel so that any leakage

or fumes do not risk coming into contact with sparks or naked flames.

For example, electric machines, electric motors, electrical switches/power

switches, heaters or the like When storing and transporting fuel approved

containers intended for this purpose must be used When storing the machine

for long periods the fuel tank must be emptied. Contact your local petrol

station to find out how to dispose of excess fuel.

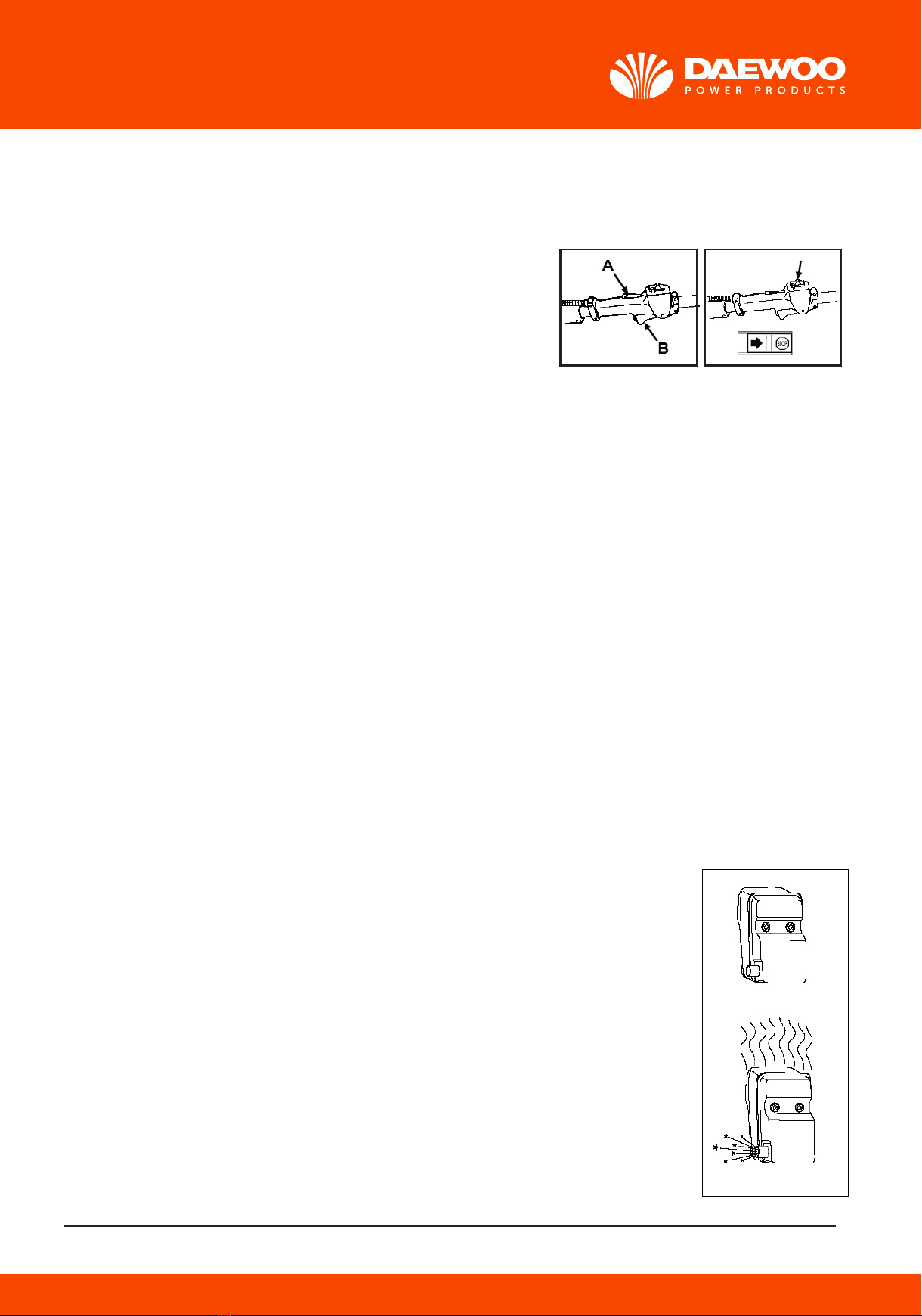

1. Throttle trigger lock

The throttle trigger lock is designed to prevent the throttle from accidentally being engaged. When the trigger lock (

is pressed into the handle (= when you hold the handle) the throttle (B) is released. When the grip on the handle is

released the throttle and the throttle trigger lock return to their original positions. This takes place via two indepen-

dent return spring systems. This means that the throttle is automatically locked in its "idling" position.

2. Stop switch

The stop switch should be used to stop the engine.

3.Debris shield

This debris shield is intended to prevent objects from being thrown

towards the operator and to protect the operator from unintentionel contact with the cutting attachment.

WARNING!

Under no circumstances may the cutting equipment be used without an approved debris shield fitted.

CONTROL AND SERVICE OF THE MACHINE’S SAFETY EQUIPMENT

1. Throttle trigger lock

• Check that the throttle is locked in the "idling position" when the throttle trigger lock is in its original position.

• Press in the throttle trigger lock and make sure it returns to its original position when released.

• Ensure that the throttle and throttle trigger lock move easily and that their return spring systems function.

• See section "Start". Start the machine and apply full throttle. Release the throttle and check that the cutting equip-

ment stops and remains at a standstill. If the cutting equipment rotates with the throttle in the idling position then the

carburetor's idling setting must be checked.

• 2. Stop switch

• Start the engine and make sure that the engine stops when the stop switch is moved to the stop

3. Debris shield

• Check that the shield is undamaged and not cracked.

• Replace the shield if it has been exposed to impact or is cracked.

• Always use the prescribed blade and shield combination.

• 4. Blade and Trimmer head

• 1) Grass blades are intended for brush cutting.

• 2) The trimmer head is intended for trimming grass.

• 5. Locking nut

• A locking nut is used to secure some types of cutting equipment on the output shaft

6. Muffler

The muffler is designed to give the lowest possible noise level and to direct

the engine's exhaust fumes away from the operator. .

In countries that have a warm and dry climate the risk of fire is obvious.

We have therefore fitted certain mufflers with a spark arrestor screen. Make

sure that your muffler is fitted with this kind of screen.

It is extremely important that the instructions for checking, maintaining

and servicing the muffler are followed.

Exercise great care when handling fuel. Bear in mind the risk of fire, explosions and inhaling fumes.

WARNING!

Min 3 m