7

OPERATION

Connect the mains lead to an electrical socket-outlet.

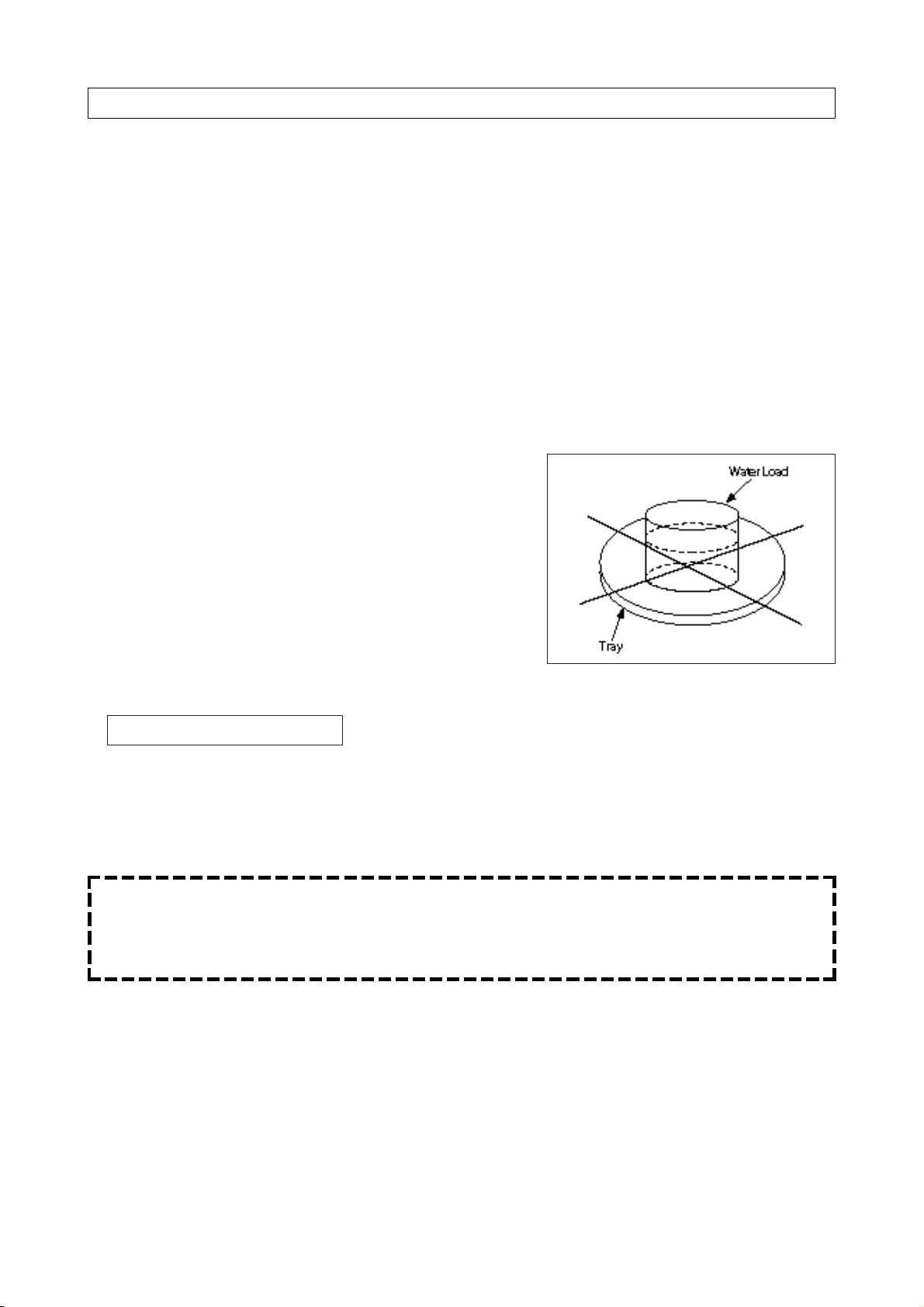

After placing the food in a suitable utensil, open the door and put it on the glass turtable, Glass turntable must always be in

place during cooking.

In case the oven is operated in the grill mode, use the Metal Rack and place food on the metal Rack.

Shut the door.

Make sure that it is firmly closed.

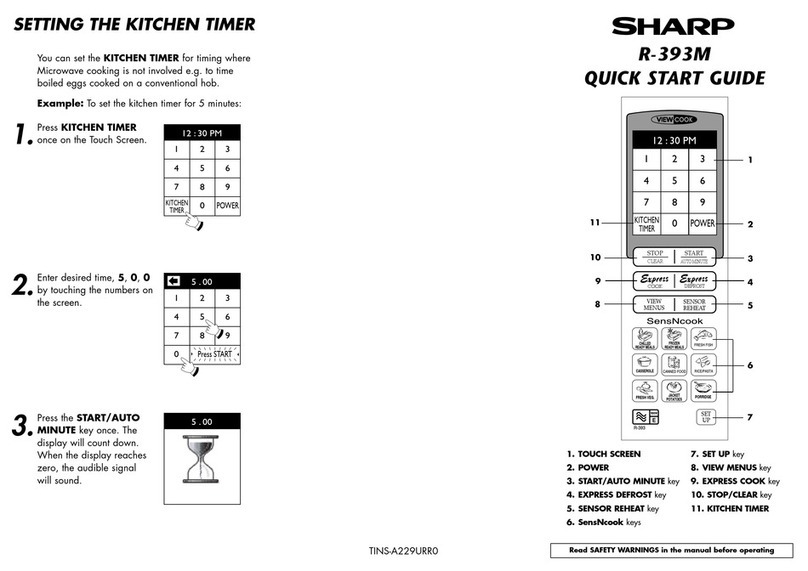

How to set each function

To set MICROWAVE Cooking

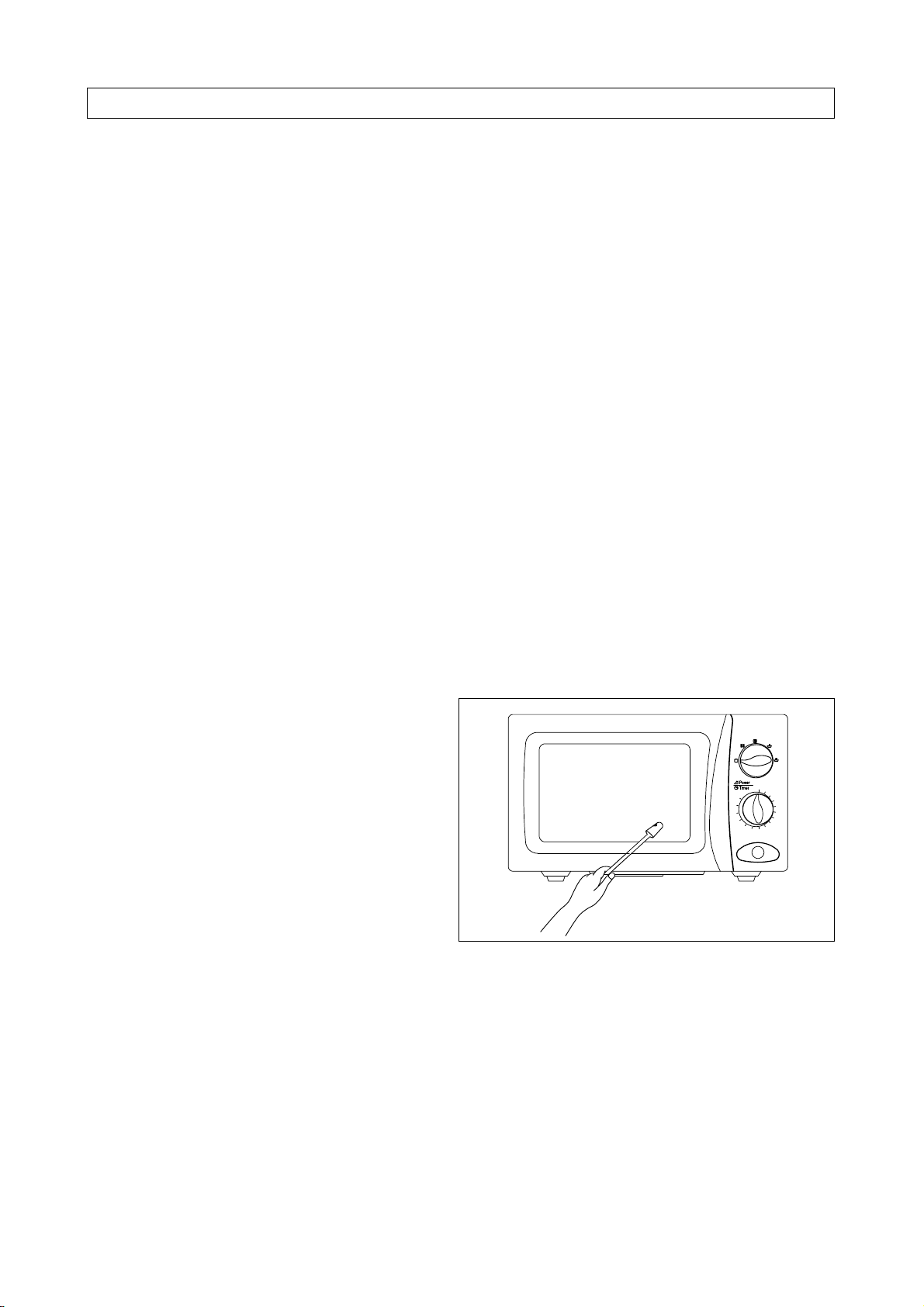

• Set the variable POWER SELECTOR to desired power level.

To set GRILL Cooking

• Set the POWER SELECTOR to the (grill) opsition.

To set COMBI Cooking

• Set the POWER SELECTOR to the (combi) opsition.

Set the time control by turning the timer knob and then the oven operate in selected cooking mode.

If turning the timer knob for less than 2 minutes, turn it past 2 minutes and then back to the desired time.

The oven will be turned off automatically when the timer point to “OFF”.

Then take out foods.

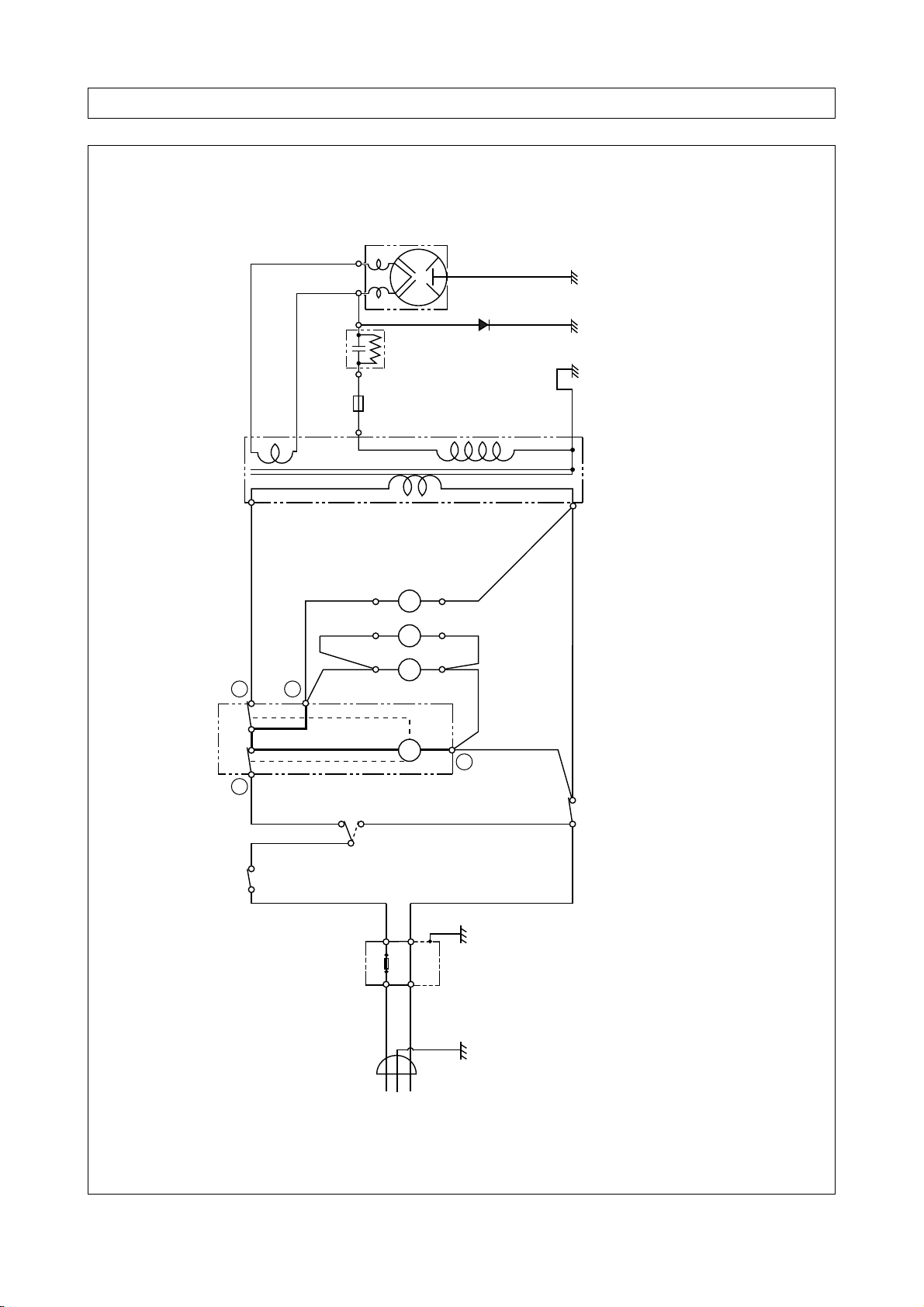

• To prevent the oven operating with the door open, your is fitted with safety door interlock switches.

If you wish to inspect the inspect the food during the cooking time, simply open the door.

The oven will sutomatically stop the cooking. To continue cooking, you simply close the door.

• If you wish to stop the cooking during the cooking simply turn the timer knob the point “OFF”.

Cooking can be reset at any time during the cooking cycle by only turing the timer knob.

• Do not let the timer continue to operate after removing food.

NOTE: When using the GRILL or COMBI mode;

• Do not open the door so often, the temperature inside the oven decrease and the cooking may not complete in setting

time.

• Never touch the oven window and metal interior of the oven when taking food in and out, because of the temperature

inside the oven and door is ver high.

• When using thess modes, be careful as the tray will be hot to touch, use oven gloves or pot holders while handing tray.

COOKING UTENSILS

Before use, the user should check the tensils are suitable for use in microwave ovens.

SYMBOL POWER LEVEL OUTPUT POWER

DEFORST 33%

MED-HIGH 77%

HIGH 100%

1

2

3

4

5

6

7

Material Grill cooking Microwave cooking Combined cooking

Glass (general) No Yes (1) No

Glass (heat resistant Yes Yes Yes

Glass-ceramic and ceramic (heat resistant) Yes Yes (1) Yes (1)

Earthenware Yes Yes Yes

China (heat resistant) Yes Yes Yes

Plastic (general) No Yes (2) No

Plastic (heat resistant) Yes (2) Yes (2) Yes (2)

Aluminium foil containers/aluminium foil Yes Yes (3) Yes

Metal baking tins Yes (4) No Yes (4)

Metal (pots. pans, etc) Yes No No

Paper No Yes No

1. Without metal parts or metal trims.

2. Some plastics are heat-proof only to certain temperatres. Check carefully!

3. It is possible to use aluminium foil to shield delicate areas of food (this prevents over-cooking).

4. Metal tins can be used in the comination methods, however if these are very deep, they will greatly reduce the efficiency,

as metal shields the microwave energy from the food.