-2-

TABLE OF CONTESNTS

1. SAFETY INFORMATION................................................................................................3

1.1 OPERATING PRECAUTIONS ........................................................................................3

1.2 PRECAUTIONS FOR POWER SUPPLY AND ELECTRIC SHOCK................................4

1.3 PRECAUTIONS FOR ROTATING PARTS......................................................................4

1.4 PRECAUTIONS FOR DISASSEMBLING AND MODIFYING...........................................4

1.5 PRECAUTIONS FOR HANDLING OF PLASTIC PARTS ................................................5

1.6 PRECAUTION FOR COOLANTS....................................................................................5

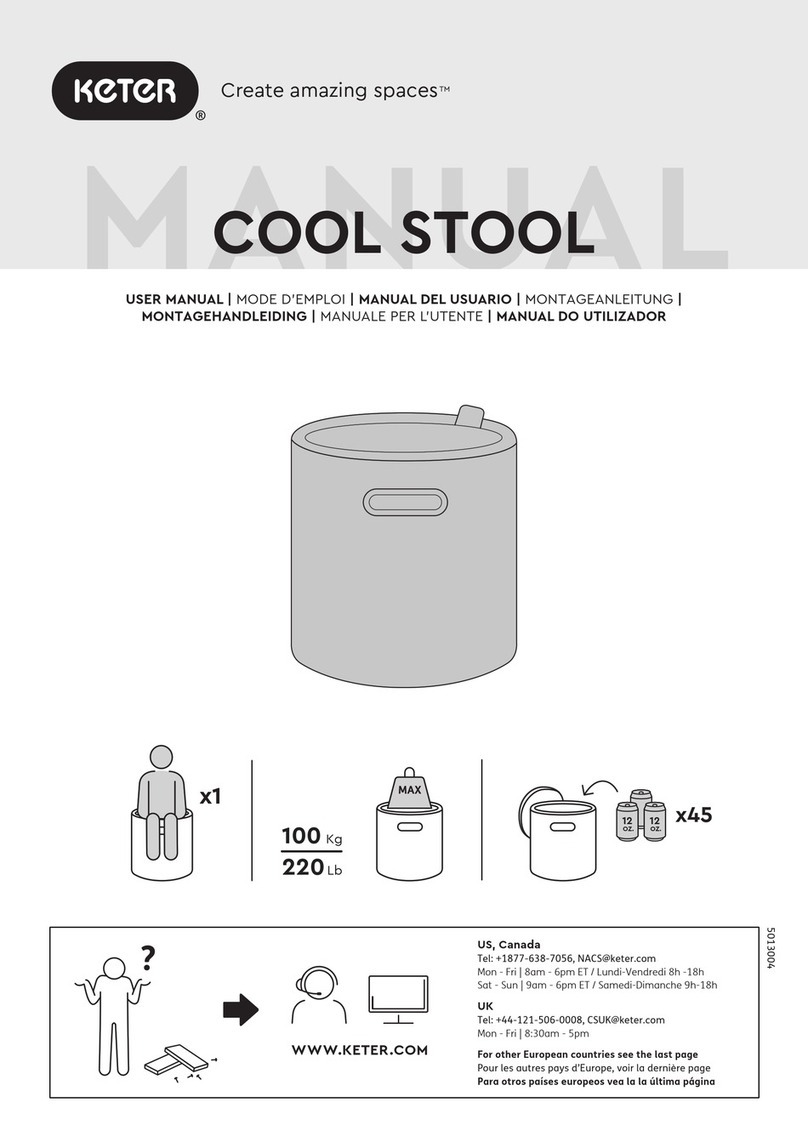

PRODUCT SPECIFICATION..........................................................................................6

2.1 TECHNICAL SPECIFICATIONS .....................................................................................6

2.2 EXTERNAL DIMENSIONS..............................................................................................6

2.3 RATED DUTY CYCLE ....................................................................................................7

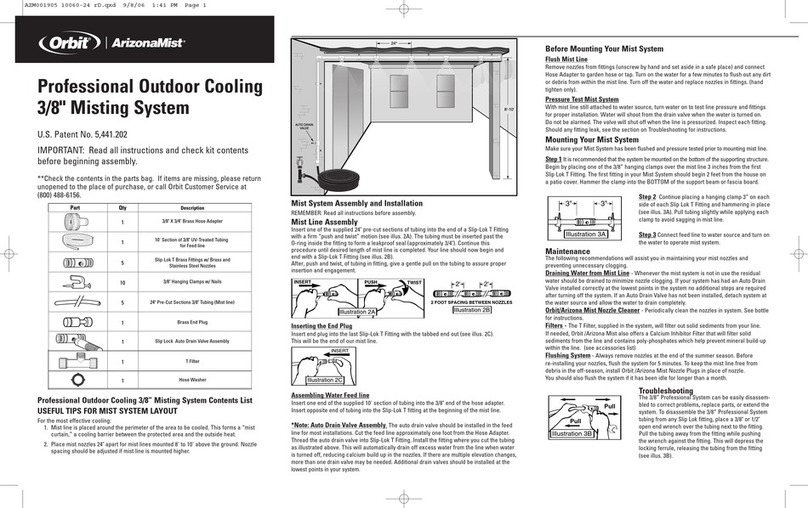

INSTALLATION ..............................................................................................................7

3.1 PRECAUTIONS BEFORE AND THE ENVIRONMENT OF THE INSTALLATION ...........7

3.2 INSTALTION AND CONNECTION..................................................................................8

REMOVING THE COOLING UNIT..................................................................................9

START-UP / DRAINAGE ................................................................................................9

MAINTENANCE............................................................................................................10

MEANING OF GRAPHIC SYMBOLS............................................................................11

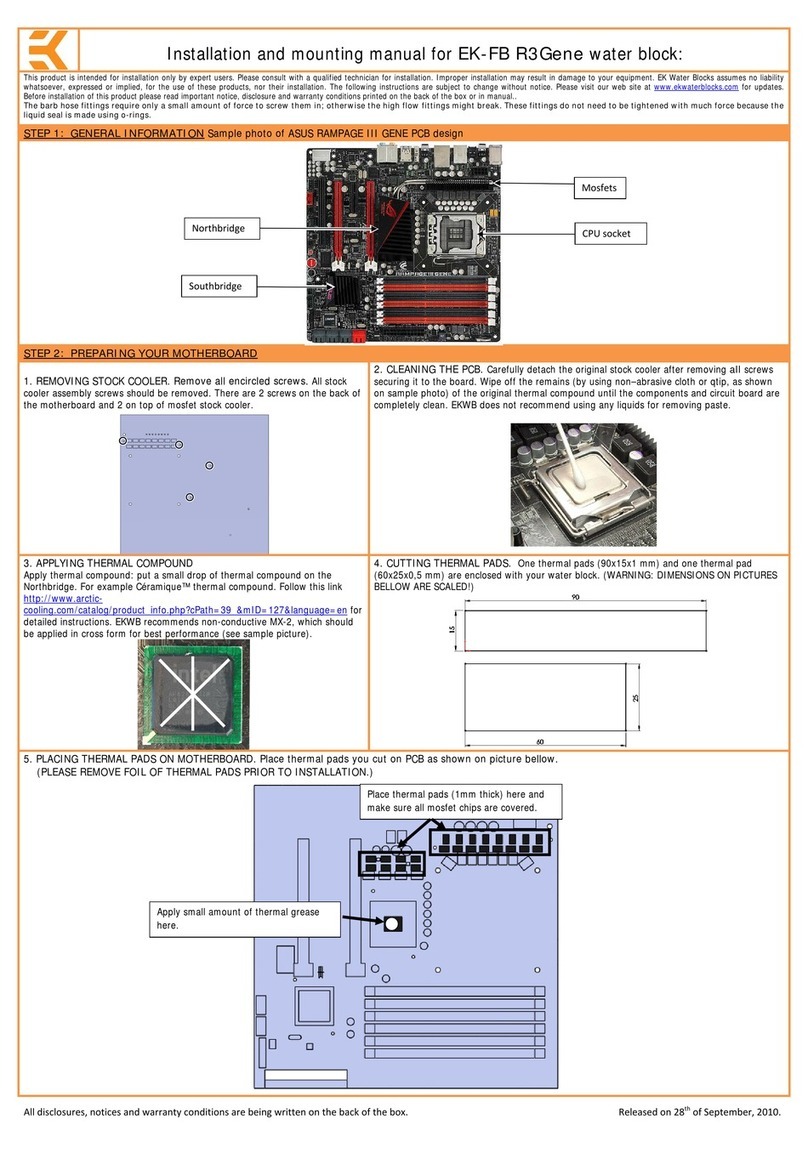

7.1 COMPONENTS ............................................................................................................11

WIRING DIAGRAM.......................................................................................................13

COOLANT CIRCUIT DIAGRAM....................................................................................13