5 6

50 0 30 60 90 120

60

70

80

90

Rotational speed (rps)

AC motor

Conventional

DC motor

Reluctance DC motor

Motor eciency (%)

Small load Large load

Low capacity High capacity

More than 20%

Power

source

Raise frequency

Lower frequency Low-speed rotation

High-speed rotation

Compressor

Compressor

Inverter Power Control

Non-inverter type air conditioner

High

capacity

Low

capacity

Power

source Constant speed

rotation Fixed capacity

Inverter Advantages Compared to Non-Inverter

PAM Control

What Is DC Inverter?

Daikin calls an inverter model that is equipped with a DC motor DC Inverter. A DC motor oers higher eciency

than an AC motor. A DC motor uses the powerof magnets to attract and repel to generate rotation. A DC motor

that isequipped with high-power neodymium magnets, which enable even greatereciency, is called a Reluctance

DC motor.

Energy-Saving Technological Features

Swing Compressor

Reluctance DC Motor for Compressor

Daikin DC Inverter models are equipped with

the Reluctance DC motor for compressor. The

Reluctance DC motoruses 2 dierenttypes of

torque, neodymium magnet*1and reluctance

torque*2. This motorsaves energy by generating

more power with a smaller electric current than

AC or conventional DC motors. It is more

ecient at the low frequencies most commonly

used by air conditioners,*3improving eciency

by approximately20%.

DC Motor for Fan

The DC motor allowsne rotation

control, whichreduces energy

consumption. The motoralso

providesimprovements in

operational eciency of up to 40%,

compared to an AC motor. These

improvements are particularly

noticeable in the low-speed range.

*1. A neodymium magnet is approximately 10 times stronger than a standard ferrite

magnet.

*2. The torque created by the change in power between the iron and magnet parts.

*3. The frequency range used by air conditioners during periods of stable operation.

This is the range in which air conditioners operate for the longest periods.

The swing compressor can

reduce operational vibration and

sound because its piston moves

smoothly inside the compressor.

Swing bush

Integral piston of

blade and roller

Refrigerant gas

Neodymium magnets are used

in the pink-coloured area.

Reluctance DC motor

Swing compressor

Thanks to its smooth rotation, the

swing compressor decreases

friction and vibration. It also

preventsthe leakageof

refrigerant gasduring

compression. These advantages

provide quiet and ecient

compression.

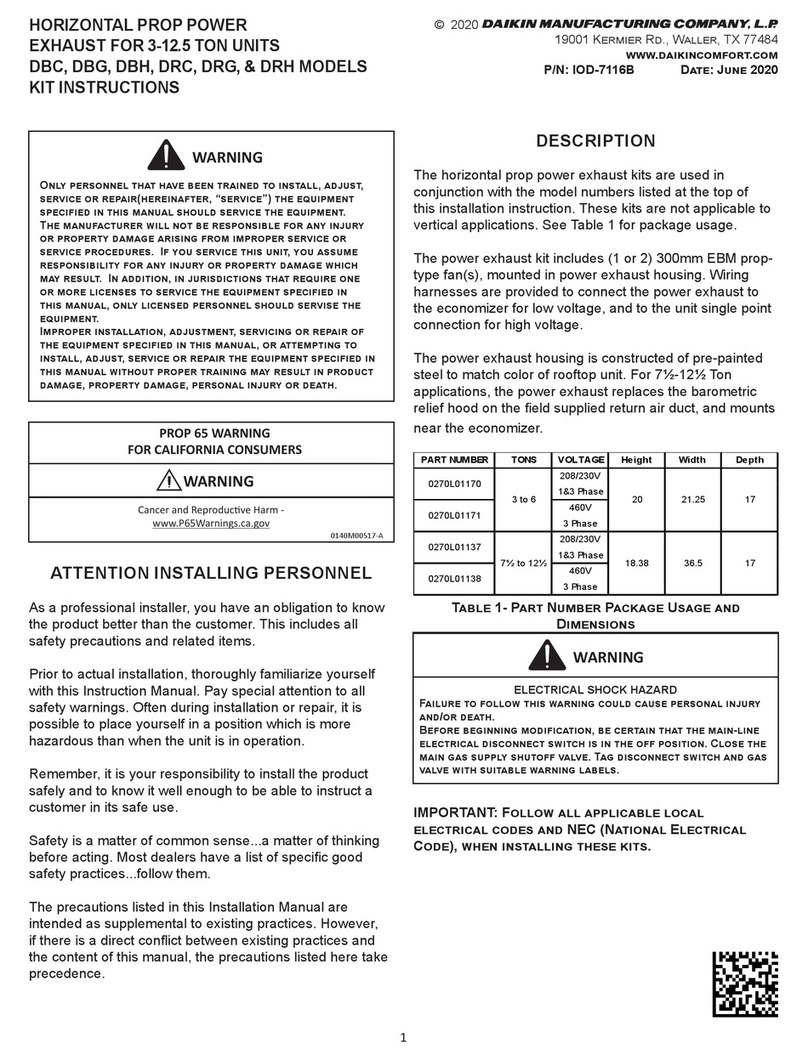

PAM (Pulse Amplitude Modulation)

control reduces energy loss by

controlling how often the converter

switches on and o.

Inverters are devices that are able to vary their operating capacity by adjusting frequency. Inverter air

conditioners can vary their cooling capacity by adjusting the power supply frequency of their compressors.

In contrast, non-inverter air conditioners have a xed cooling capacity and can only control the indoor

temperature by starting or stopping their compressors.

Eciency of Reluctance DC motor *4

Inverter air conditioners are able to vary their operating capacity. Non-inverter air conditioners can

only operate at a xed capacity.

This diagram is a representation for illustrative purpose only.

Variable Capacity Operation

ComfortableTemperature Control

Too cool

Not cool

During cooling operation

Compressor o

Non-inverter type

Inverter type

Cools a room

in less time

Small temp.

dierence

Compressor o

Temp.

Starts

Time

Set

temp.

EnergySaving

After the indoor temperature

approaches the set temperature,

Inverter Control adjusts to low

capacity operation to maintain this

temperature. This makes inverter

models more energy-saving than

non-inverter models, which must

repeatedly start or stop their

compressors to maintain the room

temperature.

Comfortable

Inverter air conditioners nely adjust

capacity according to changes in the

air-conditioning load andthe dierence

between the indoor temperature and

set temperature is small. These give

higher comfort levels than with non-

inverter air conditioners.

Powerful

Inverter air conditioners operate at

maximum capacity as soon as they

start up. As a result, the set

temperature can be reached more

quickly.

Energy Savings

200 300 400 500 600 700 800 900 1000

0

20

40

80

60

100

Eciency (%)

Motor speed (rpm)

AC motor

Approx.

40%

increase

Approx.

20%

increase

DC motor

*5. Data are based on studies conducted

under controlled conditions at a Daikin

laboratory using Daikin products.

*4. Data are based on studies conducted

under controlled conditions at a Daikin

laboratory using Daikin products.

Eciency of DC motor for fan *5

(

comparison with a conventional AC motor

)