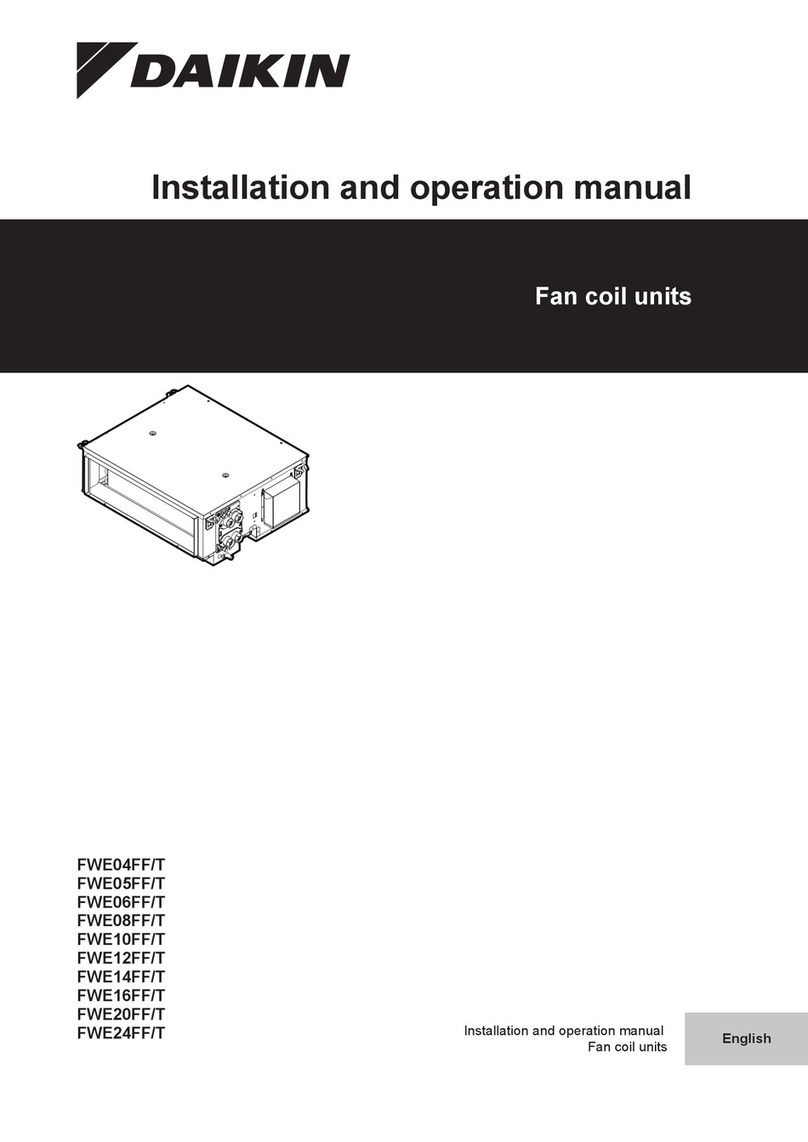

www.DaikinApplied.com 5 IM 1272 • OPTILINE VERTICAL FAN COILS

Installation of Units with Risers Attached

WARNING

Use solder to connect the risers. Do not use Silfos (brazing) as this will

cause the pipe to overheat and the insulation to be damaged.

NOTICE

Daikin does not advise on the location or method of anchoring as this is

the responsibility of the engineering company retained to design the riser

system.

CAUTION

Sharp edges and coil surfaces are a potential injury hazard. Avoid contact

with them.

A rectangular opening is made in the oor slab, usually

sleeved before pouring the oor. Refer to the catalog or

submittals for sizes.

Rotate the unit from the horizontal position to vertical so that

the bottom end of the risers insert into the expanded end of the

risers on the unit below. 2" is allowed in the riser length for the

depth of the insertion. Shim the unit plumb.

Before making the solder joint, ensure that the run outs

from the supply and return risers are centered in the slots in

the cabinet. If this is not done there is considerable risk of

distorting the run out when the hot water riser expands causing

the run out to contact the edge of the slot in the sheet metal

potentially causing failures or leaks. Also ensure that the

condensate riser stub out is at 90° to the cabinet so that the

drain hose is not kinked.

Connect the risers by soldering (not brazing) using 95/5

solder. An additional cap of 50/50 solder can be added for

extra strength.

Ensure that the horizontal run-out from each riser is centered

in the slot in the cabinet and that the run-out from the riser

is at 90º as it enters the cabinet, prior to soldering the risers.

Anchoring the risers to the oor slabs is the responsibility

of the contractor. Shim the unit plumb. It is not necessary to

use a pad under the unit. Fire stopping the oor opening and

making good the riser insulation at the oor opening is the

responsibility of the contractor. Check that the drain hose is

not kinked before soldering the condensate riser. If the risers

incorporate expansion compensation loops, remove the

support brackets after anchoring the risers.

The fan coil unit has unions at the shut o valves. These

ttings must be checked prior to pressure testing the system by

the contractor as part of the installation procedure. Mechanical

ttings can loosen during transportation and handling. If

contractor /installer deem it necessary to tighten mechanical

ttings Daikin does not assume any responsibility for this

procedure. It is stressed that the component manufacturer’s

recommended procedures be strictly followed.

The coil is pressure tested hydrostatically at the factory using

a propylene glycol solution. Trace amounts of this solution are

allowed to remain in the coil to ensure that the coil does not

freeze during transportation. After testing on site with water the

fan coil unit must not be exposed to freezing temperatures.

Riser anchoring is required for two purposes. The risers are

anchored to the oor slab at one or more points in the height

of the building so that they do not slip down under gravity.

The second reason is to spread the expansion in opposite

directions from the anchor point. Typically risers will be

anchored at the midpoint of the height of the building. If there

are riser expansion loops included in the risers inside the unit,

the anchor point will be at the midpoint between two sets of

loops. For example in a 16 story building there will be a loop

on the hot water riser on oor 8 and anchors at oors 4 and 12.

After anchoring, the risers are in eect attached to the building

structure so it does not matter if the plastic straps holding the

risers to the unit break o after installation.

• Complete the riser insulation at the solder joint is the

responsibility of the contractor

• Fire stop the oor opening in accordance with code

Flushing and Testing

The fan coil is normally equipped with ball type shut o valves.

The unit is shipped with the ball valves open to the coil.

After checking mechanical ttings inside the unit for tightness,

it is recommended that the units on each riser stack are

pressure tested using compressed air or nitrogen.

• Close the ball valves and ush the riser system

• Open the supply side ball valve and bleed air from the

coils. The coil has a manual air vent for this purpose.

The top of each riser should also have an air vent (not

provided by the factory)

• Test the units and risers hydrostatically. Open the return

side ball valve after testing

• Check that the strainer mesh is not choked, if there are

strainers included with the unit