Basic Machinery

ONE Quartz fabrication shops should be fitted with machinery designed to work with natural

quartz surfaces while providing the highest quality possible. Consideration of heavy equipment

should be carefully researched and implemented before working with ONE Quartz.

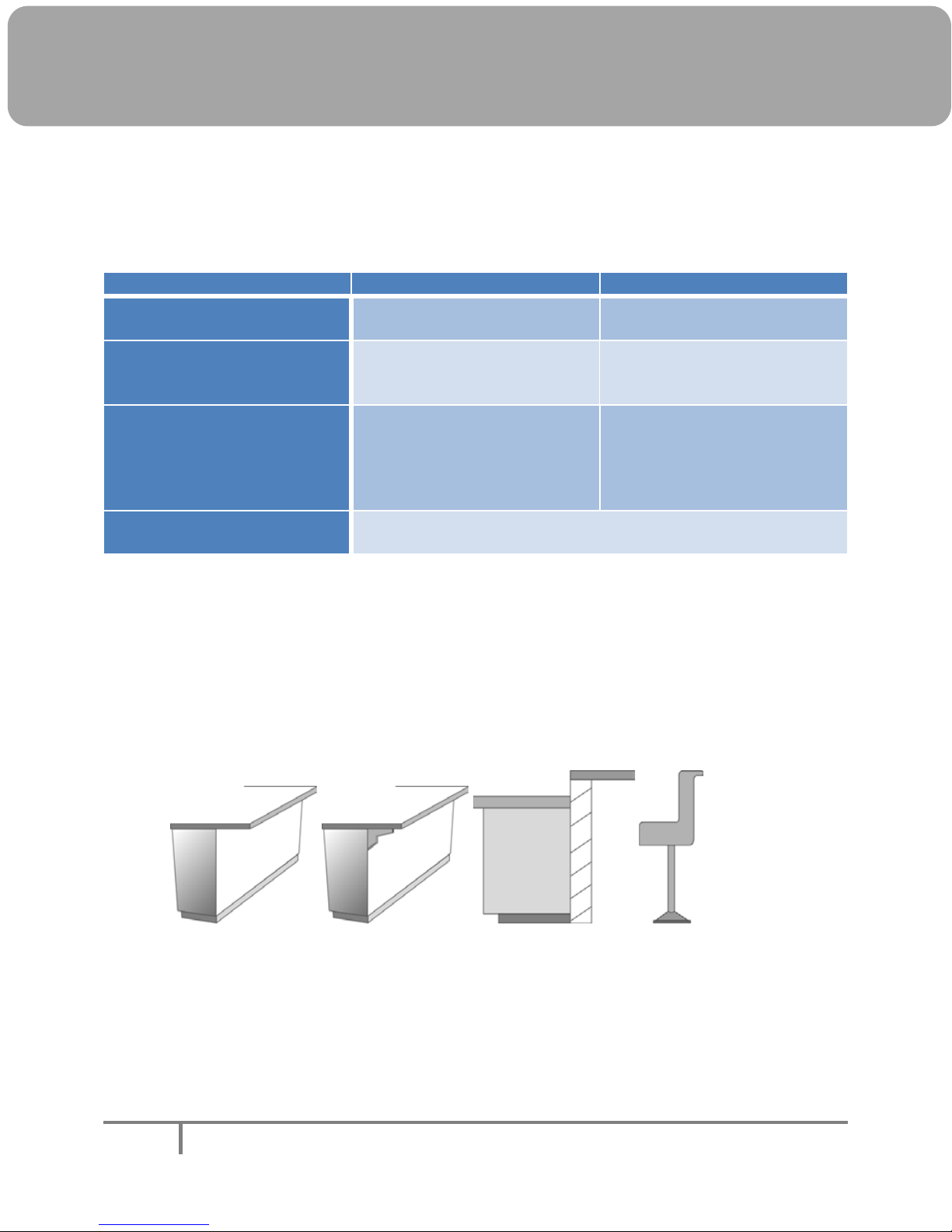

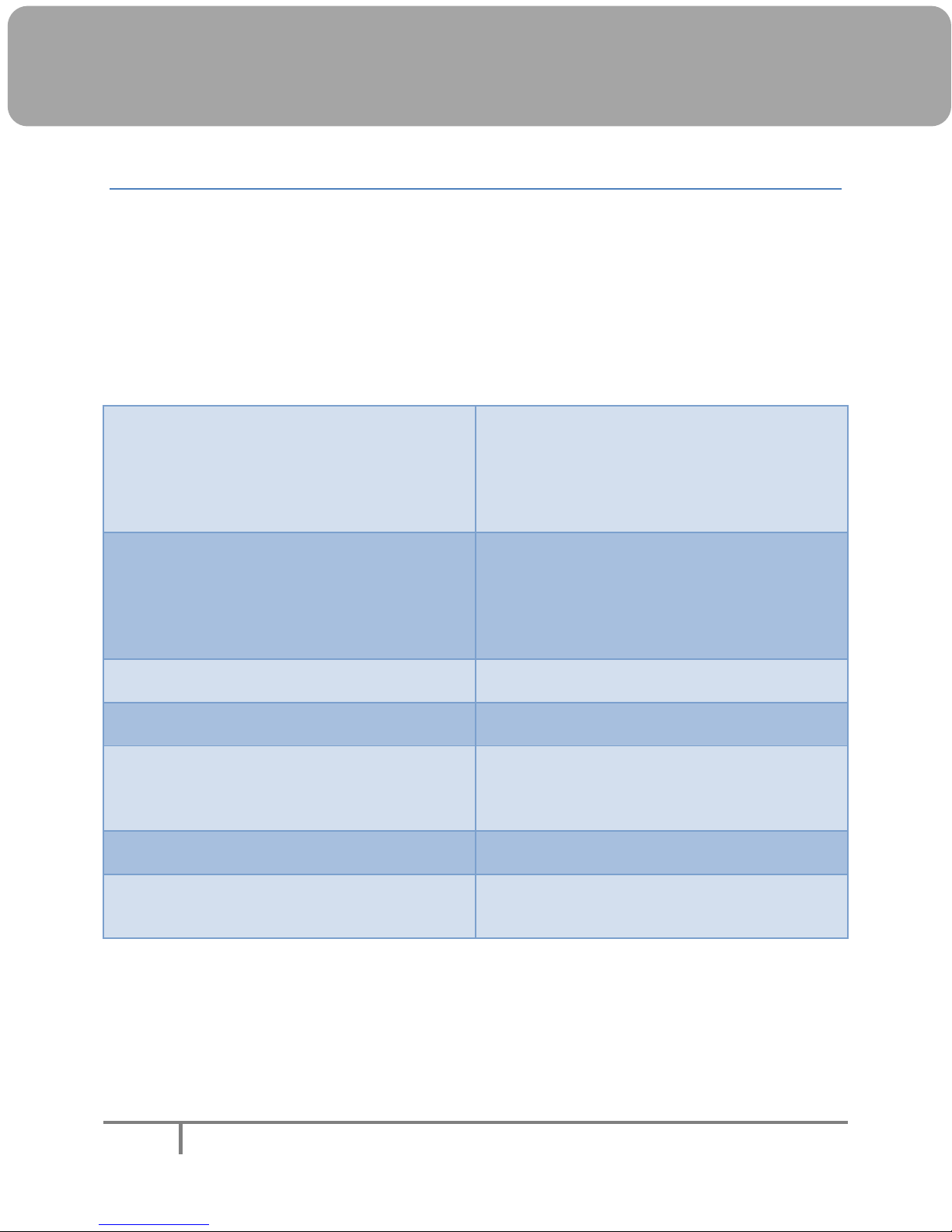

The following chart briefly describes some of the basic heavy machinery used in a fabrication

shop. The type of machinery in each shop will differ according to individual needs, and

state/federal requirements for safety.

(Bridge Saw)

This is the most important piece of equipment.

Bridge saws will cut full slabs of material with

greater accuracy, precision, and speed than

conventional hand tools. Bridge saws can have

many different options ranging from manual to

CNC Machine Computer Numerically Controlled (CNC)

Technology.

The CNC mill (router) uses digital templates or

measurements to automatically cut out, profile,

and polish the perimeter of a piece and internal

cutouts such as sink holes, etc.

Line Polisher

(Single Head)

Machine designed to profile and polish edges in a

straight line only.

Line Polisher

(Multi Head)

Similar function as the single head polisher but it is

capable of much higher production rates.

Overhead gantries and jib booms facilitate the

movement of material around the shop and the

ability to load pieces on the machines without the

necessity of forklifts in space prohibitive areas.

Water Treatment A system of pumps, filters and settlement tanks

used for the recirculation of shop water.

Air Compressor Used to supply machines and pneumatic hand

tools with sufficient air pressure and volume to

operate efficiently.