This manual covers the following topics:

Introduction................................................................................................................3

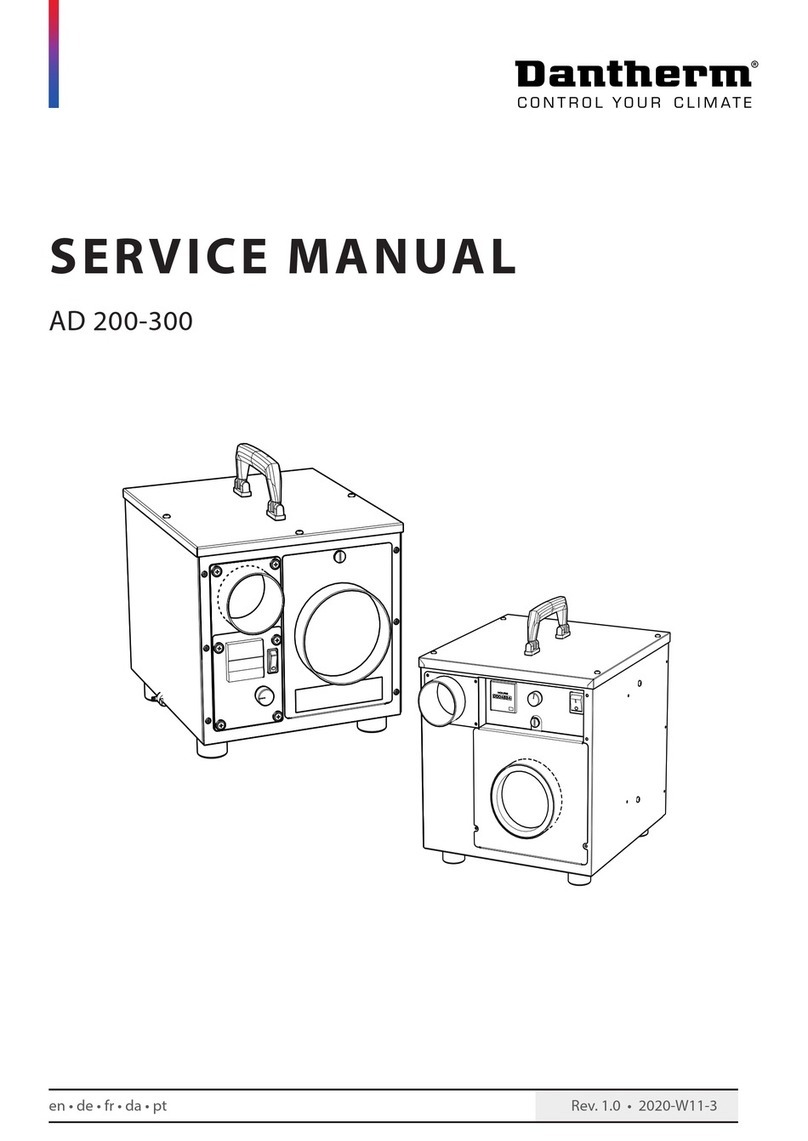

Overview..............................................................................................................3

General information .............................................................................................4

Product description.....................................................................................................5

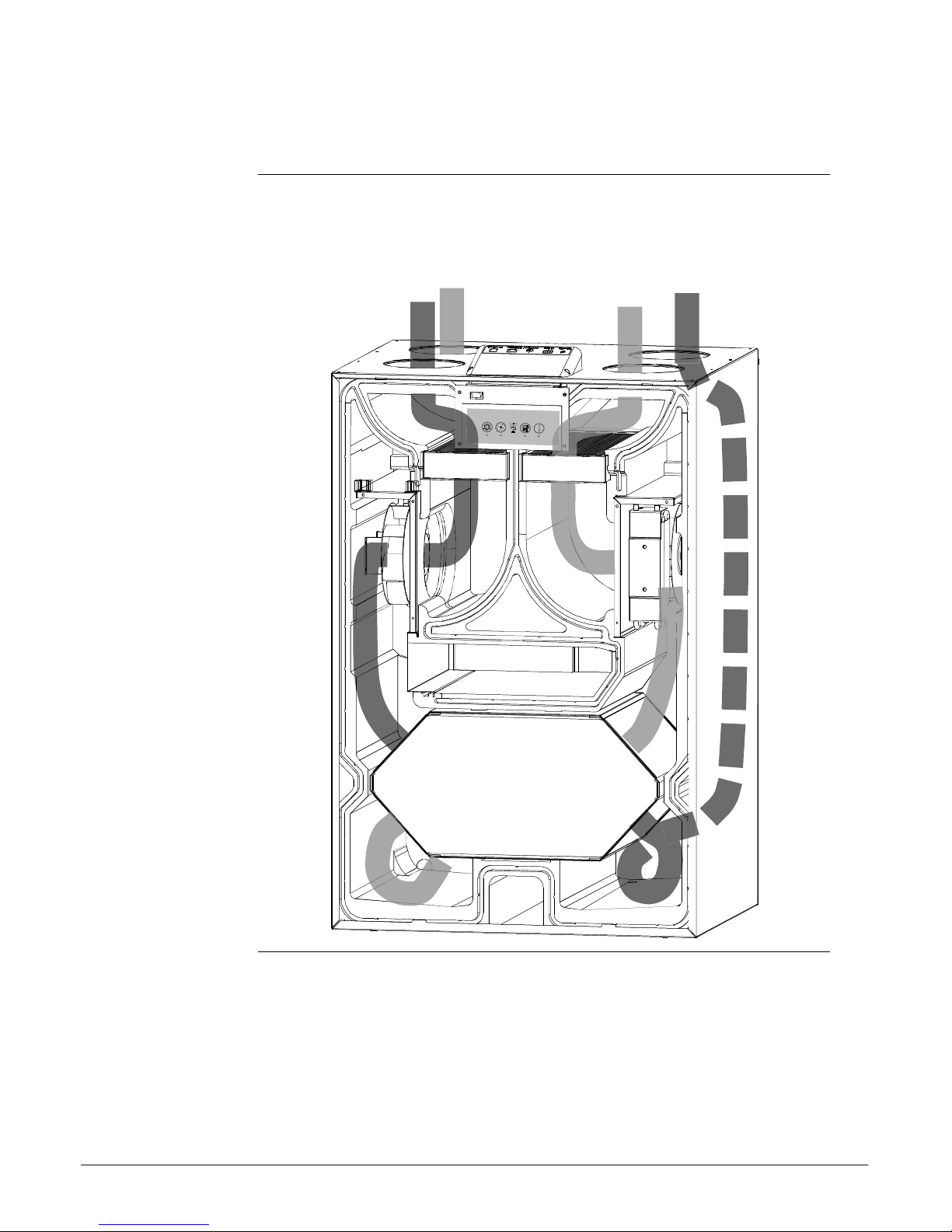

Overall description...............................................................................................5

Components description ......................................................................................8

Accessory description ........................................................................................10

Electronic control...............................................................................................11

System operation strategy..................................................................................14

Installation ...............................................................................................................15

Wall mounting....................................................................................................16

Water drainage...................................................................................................18

Connecting ducts...............................................................................................19

External connections..........................................................................................21

Swapping operation mode..................................................................................22

Initial calibration ................................................................................................24

Setting operation parameters .............................................................................25

Firmware update ................................................................................................26

User’s guide .............................................................................................................27

Overall ventilation functions...............................................................................28

Using the control panel ......................................................................................29

Using the LAN interface......................................................................................31

Service guide ............................................................................................................32

Overview............................................................................................................32

Preventive maintenance......................................................................................33

Error list ............................................................................................................36

Spare part list ....................................................................................................38

Technical information ...............................................................................................41

Technical data ...................................................................................................41

Wiring schematic................................................................................................42

Contact Dantherm..............................................................................................43