04

•About Fluorinated Gases

-This heat pump unit contains fluorinated gases. For specific information on the type of gas and the amount, please refer to the

relevant label on the unit itself. Compliance with national gas regulations shall be observed.

- Installation, service, maintenance and repair of this unit must be performed by a certified technician.

- Product uninstallation and recycling must be performed by a certified technician.

- If the system has a leak-detection system installed, it must be checked for leaks at least every 12 months. When the unit is checked

for leaks, proper record-keeping of all checks is strongly recommended.

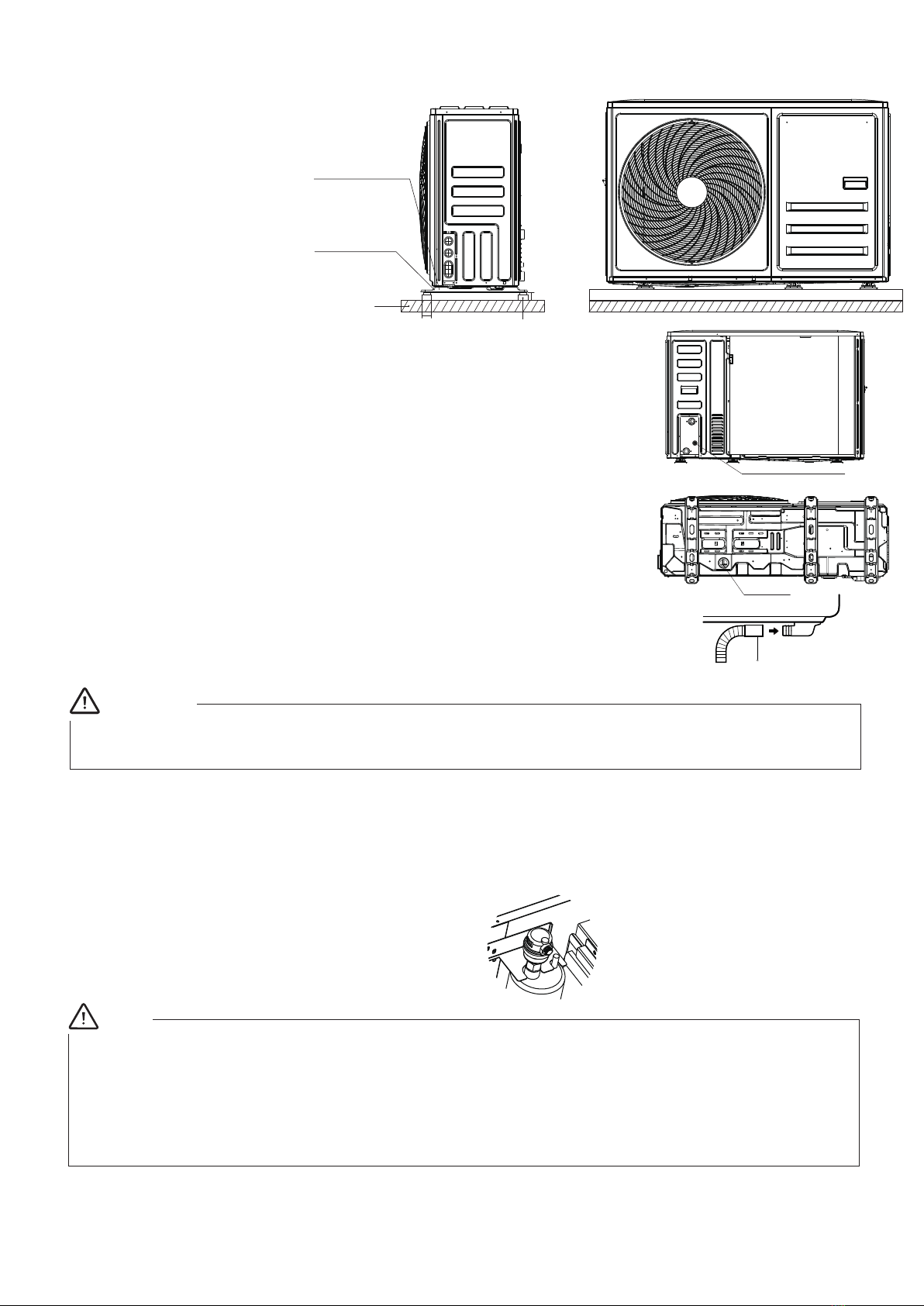

• Ground the unit.

• Grounding resistance should be according to local laws and regulations.

• Do not connect the ground wire to gas or water pipes, lightning conductors or telephone ground wires.

• Incomplete grounding may cause electric shocks.

- Gas pipes:Fire or an explosion may occur if the gas leaks.

-Water pipes:Hard vinyl tubes are not effective grounds.

- Lightning conductors or telephone ground wires:Electrical threshold may rise abnormally if struck by a lightning

bolt.

• Install the power wire at least 3 feet (1 meter) away from televisions or radios to prevent interference or noise. (Depending on the radio

waves, a distance of 3 feet (1 meter) may not be sufficient to eliminate the noise.)

• Do not wash the unit. This may cause electric shocks or fire. The appliance must be installed in accordance with national wiring

regulations. If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or similarly qualified persons in

order to avoid a hazard.

• Do not install the unit in the following places:

- Where there is mist of mineral oil, oil spray or vapors. Plastic parts may deteriorate, and make them become loose or water leakage.

- Where corrosive gases (such as sulphurous acid gas) are produced. Where corrosion of copper pipes or soldered parts may cause

refrigerant to leak.

- Where there is machinery which emits electromagnetic waves. Electromagnetic waves can disturb the control system and cause

equipment malfunction.

- Where flammable gases may leak, where carbon fiber or ignitable dust is suspended in the air or where volatile flammables such as

paint thinner or gasoline are handled. These types of gases might cause a fire.

- Where the air contains high levels of salt such as near the ocean.

- Where voltage fluctuates a lot, such as in factories.

- In vehicles or vessels.

- Where acidic or alkaline vapors are present.

• This appliance can be used by children 8 years old and above and persons with reduced physical, sensory or mental capabilities or lack

of experience and knowledge if they are supervised or given instruction on using the unit in a safe manner and understand the hazards

involved. Children should not play with the unit. Cleaning and user maintenance should not be done by children without supervision.

• Children should be supervised to ensure that they do not play with the appliance.

• If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a similarly qualified person.

• DISPOSAL: Do not dispose this product as unsorted municipal waste. Collection of such waste separately for special treatment is

necessary. Do not dispose of electrical appliances as municipal waste, use separate collection facilities. Contact your local government

for information regarding the collection systems available. If electrical appliances are disposed of in landfills or dumps, hazardous

substance can leak into the groundwater and get into the food chain, damaging your health and well-being.

•The wiring must be performed by certified person technicians in accordance with national wiring regulation and this circuit diagram. An

all-pole disconnection device which has at least 3mm separation distance in all pole and a residualcurrent device(RCD) with the rating

not exceeding 30mA shall be incorporated in the fixed wiring according to the national rule.

• Confirm the safety of the installation area ( walls, floors, etc. ) without hidden dangers such as water, electricity, and gas before

wiring/pipes.

• Before installation, check whether the user's power supply meets the electrical installation requirements of unit ( including reliable

grounding, leakage, and wire diameter electrical load, etc. ). If the electrical installation requirements of the product are not met, the

installation of the product is prohibited until the product is rectified.

• Product installation should be fixed firmly. Take reinforcement measures when necessary.

NOTE

CAUTION