DaSeDa Electronics HM-75A User manual

Manual

Digital Feeder Controller : HM-75A/710A

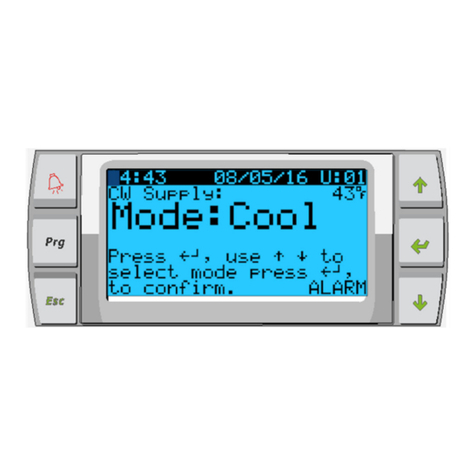

1. HM-75A / 710A controller front configuration

1. Data display window: Displays frequency, voltage, parameter, error code, etc. in numeric or text

2. RUN LED: It lights up during RUN, blinks during pause, and turns off at STOP.

3. Feed Back LED: It is ON when Feed Back ON and Sensor is connected.

Flickering when setting the vibration amount reference value, ON while the constant amplitude function is operating.

4. RUN Key: Pressing RUN key for a short time.

5. Volume: Used to change voltage / frequency / parameter value. Press repeatedly to select frequency / voltage repeatedly

6. STOP Key: Short press to stop the operation (STOP), press this button to initialize the controller when POWER ON. (See initializing the controller)

7. Selector: Frequency / Voltage / Parameter, etc. For setting menu selection, parameter value is displayed when button is pressed, and value can be changed by volume (1).

8. Power Key: Controller power switch.

9. Frequency LED: On when frequency is set.

10. Volt LED: On when voltage is set.

11. Slow Start LED: On when parameter Slow Up / Down time is set.

12. Sensor LED: On when parameter related to sensor is set. (Number of Sensors, On / Off Delay Time, NO / NC)

13. Ext Input LED: On when parameter related to external input is set. (On / Off Delay Time, NO / NC)

14. Feed Back LED: Turns on when setting parameters related to vibration such as constant amplitude control and constant amplitude time.

15. Ext Volume LED: Turn on when using external volume ON / OFF.

2. Power and feeder connection

- Internal connectors AC1 and AC2 are internally connected to each other and can be used to supply power to other controllers

Is a power connection method when two additional controllers are connected.

- Ground the feeder.

3. External input

- Used for operation and stop with external input.

- Control method is as follows.

3-1. Contact control method 3-2. TR control method

3-3. Voltage control method

E-nc

stop

driving

stop

driving

OPEN

12~24V

0 V

Condition E-no

driving

stop

driving

stop

Direct

connection

(3-1, 3-2)

Voltage input

(3-3)

CLOSE

4. External input 2CHANNEL

'- The output voltage can be controlled in two ways by the 2CHANNEL input. (You have to go to V2 ON in Paris Meter.)

- V1 if there is no input, V2 if there is input

4-1. Contact control method 4-2. TR control method

5. External volume

Function to control output voltage by applying volume or voltage to external terminal

5-1. Volume control method

5-2. Voltage control method

Do not exceed 5V DC

6. Sensor operation control

- The HM-75A / 710A controller can be operated / stopped by an external sensor.

- One to three sensors can be used depending on parameter setting.

6. Sensor operation control 6-2. When using two sensors

7. Vibration sensor

- In order to maintain constant vibration amplitude during operation, attach a vibration sensor to the feeder

Set the constant amplitude control ON in the parameter setting.

7-1. How to connect vibration sensor

Vibration sensor should be connected to its own product. (Third-party products are not allowed.)

8. DATA communication

- Transmit controller status and control data by external data communication with external control device (PLC, computer ..).

- Communication method is 485 method. Up to 32 cables can be connected to one communication cable. (Refer to communication manual)

- Connect to SERIAL on one line.

- Each HM-75A controller has two communication connectors, which are internally connected to each other in parallel,

For convenient connection.

- The communication cable uses shielding wire with three wires.

9. Connection of operation synchronous output signal

9-1. Operation synchronous contact signal

- This controller has a function to give synchronization signal to control other external controller.

When stopping or pausing, the contact signal is sent to 8, 9, and the contact signal is output to 9, 10 during operation.

This can be used as an operation / stop signal for another controller (HOPPER, etc.).

- The figure below shows a connection diagram between a hopper (HOPPER) and a ball (BOWL) controller.

9-2. AC220V output for SOL drive

10. How to operate the controller

10-1. Power on / off method

This controller is a push (push) type, not a lock type.

With the AC cord plugged in

To turn on the power first, press and hold the power switch (for about 1 second)

The power turns on while it is on.

To turn off the power Turn on the power switch while the power is on in the same way

Press and hold for about 1 second to turn off the power while the display is enlarged.

In the ideal state, the button is not operated and the output is not output.

10-2. Initialize the controller

DSD_75A can initialize various parameters by button operation.

After turning off the power and holding down the "stop" button and pressing the power button to turn on the display

The power button can be released, but the "stop" button is held down for 3 seconds.

On the display

All values are initialized while flashing 3 times.

10-3. Parameter change prevention setting and cancellation

The DSD_75A controller can be set to lock the system so that it can not change various parameters such as frequency and voltage.

It is possible to prevent the setting value from being changed unintentionally when the button in use is mistakenly touched.

OFF is set in initialization. If it is set to OFF, the parameter can be changed, but if it is .

ON, the setting value will not be changed even if the volume is turned.

- To set ON, press the "RUN" button for 3 seconds while the power is on

The display flashes for 3 seconds to prevent the parameter change and turn the volume

The left-hand side flashes for 3 seconds, indicating that the current lock is in progress.

- To release the lock device again, press the "RUN" button for 3 seconds

The display flashes for 3 seconds to release the lock

You can change the parameters

10-3. Parameter setting menu

You can select the parameter change menu by turning the selector.

Turn the selector to the right

Frequency -> voltage 1 -> slow up -> slow down -> number of sensors -> sensor polarity -> sensor on delay ->

Sensor off delay -> external input polarity -> external input on delay -> external input off delay -> external volume on / off

-> Constant amplitude control on / off -> Constant amplitude control time -> Voltage 2 on / off -> Voltage 2 -> Communication id setting

-> Automatic frequency setting -> Controller version display.

Turning to the left selects the opposite.

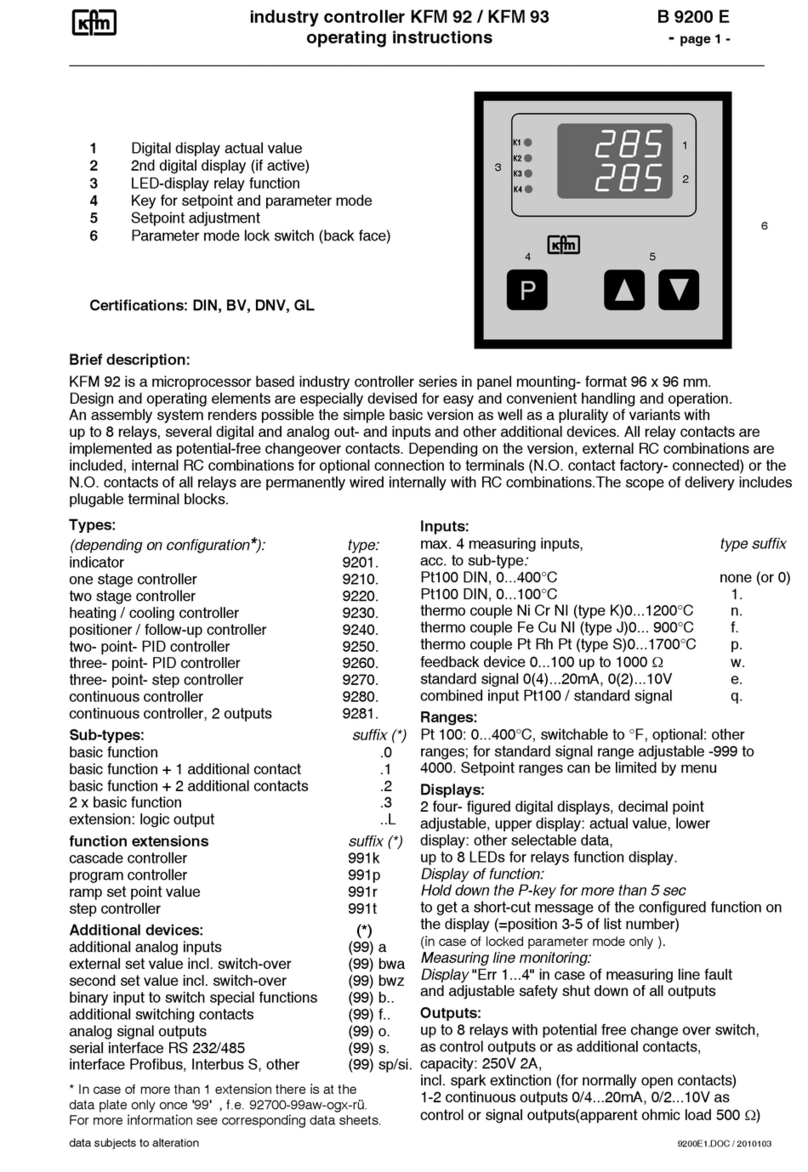

menu Setting range Initial value Menu LED

Display Show menu Pressing the selector button or

Show setting value when turning

Frequency 40 ~ 400Hz

(

0.1Hz unit

)

120Hz Frequency

Volt 1 0 ~ 200V

(

0.1V 단

위

)

100V Volt

slow up 0 ~ 3sec

(

0.1sec unit

)

0.1 sec Slow Start

slow down 0 ~ 3sec

(

0.1sec unit

)

0 sec Slow Start

Number of used sensors 1 ~ 2 1 EA Sensor

Sensor polarity setting no,nc no Sensor

sensor

on dela

y

0 ~ 60sec

(

0.1sec unit

)

0.1 sec Sensor

센서

off dela

y

0 ~ 60sec

(

0.1sec unit

)

0.1 sec Sensor

External input

Polarit

y

settin

g

no,nc no Ext Input

Ext input

on dela

y

0 ~ 60sec

(

0.1sec unit

)

0 sec Ext Input

Ext input

off dela

y

0 ~ 60sec

(

0.1sec unit

)

0 sec Ext Input

Vibration control

on

/

off on, off off Feed Back

Vibration Width

Control time

10 ~ 1000

(

10 unit

)

300 Feed Back

External volume on, off off Ext Volume

V2 on/off on, off off Volt

Volt 2 0 ~ 200V

(

0.1V unit

)

50V Volt

Communication ID setting 0 ~ 32

(

0 = off

)

off

frequency

Automatic setting

Selector button

Press to start.

Show product version

If there is no button or volume operation for 20 seconds after setting is completed, or when RUN or STOP button is pressed

The display shows the default output voltage.

"Volt LED ON"

11. How to operate the volume

When the parameter value is increased or decreased by the volume of HM-75A (frequency, voltage, DELAY TIME, etc.)

Change unit can be changed to 0.1 or 1.0.

The default is 0.1, and when you press the volume button, it becomes 1.0 units.

Every time you press the volume button again, 0.1 -> 1.0 -> 0.1 ...

In the display, the corresponding unit number flashes.

If you turn it left If you turn it right

0.1 unit

If it is 1.0 unit

11-2. Communication ID setting

The HM-75A is connected to an external device such as a computer via 485 communication to transmit data such as the status and parameters of the controller.

You can control the parameters and operation of the controller from an external device.

The communication method is 485 system. Up to 32 controllers can be connected to one external computer or control device.

You can connect and control at the same time.

To do this, you need to give an ID for each controller, so how to set the ID is explained.

Turn the selector to set it to "Communication ID setting" mode and set the ID to volume, or set the communication function

It can be stopped.

The setting value is 0 ~ 32, 0 is when communication function is not used ("oFF" is displayed)

However, if you connect multiple controllers together, you must set a different ID for each controller.

If there is a duplicate ID, the controller can not communicate.

Turn the selector Press the selector button Change the volume to the desired value.

Set to communication ID setting mode. Turning the volume (Setting range: 0 ~ 32)

0 case

10 cases

11-3. Automatic frequency setting

The automatic frequency setting function allows the controller to find the optimum resonance point when the resonance point of the vibrator is unknown.

It is a convenient function.

First, you need to have a vibration sensor, set the proper voltage after connecting the vibrator, and proceed.

If there is no vibration sensor or the output voltage is set too low, the resonance point can not be found.

Turn the selector Press the selector button to start. Basic display after completion

Set to frequency automatic setting mode. As the display rotates

Tells you that it is working

`

The automatic frequency setting is about 6 minutes. If you press the "STOP" button, it will stop.

You can only stop with the STOP button, but not other buttons.

12. Protection and Notification Features

This product is designed to protect the product if an error occurs due to user's carelessness or environmental factors.

The protection function operates and an error code is displayed on the display window.

The following explains the error code and its countermeasures according to the error code.

Error display

- Turn off the power, remove the cause of overheating,

Wait a certain amount of time and use.'

- Turn off the power and remove the cause of the overcurrent.

- Needs repair.

Above

EEPROM Write Error

Over Heat Error (Over Heat)

Internal heat sink overheated

Over current error (Over Current)

Capacity over current flow or load side

short

How to cope

13. Product Features and Specifications

HM-75A HM-710A

How to set up

Setting range

How to set up

Setting range

5 A 10 A

Panel manipulation

Analog input

External volume control

Ambient temperature

Ambient humidity

weight 1.25Kg 2.4Kg

Appearance 68(W) X 100(D) X 147(H) 98(W) X 100(D) X 147(H)

Specifications

Over-current, over-temperature operation stop and error indication

Natural air cooling

0 ~ 40'C

10 ~ 90%

Terms of Use

Cooling system

485 communication control

Output voltage control with external volume connection

V1 / V2 selection operation by external input (2-step control)

V2 on / off setting from menu.

3 terminal (COM, NC, NO) contact output

Slow Up Timer: 0.0 ~ 3.0sec, 0.1sec unit

Slow Down Timer: 0.0 ~ 3.0sec, 0.1sec unit

Voltage, Frequency, Parameter READ / WRITE

Data change input prohibition function (when RUN key is pressed for 3 seconds)

Display voltage, frequency, parameter and error code

RUN,Feed-Back,

Parameter item display (frequency, voltage, sensor, external input, etc.)

On / off control by external input

Voltage input control (+12 ~ + 24V)

Output voltage control with DC 0 ~ 5V input

On Delay Timer setting: 0.0 ~ 60.0sec, 0.1sec unit

Off Delay Timer setting: 0.0 ~ 60.0sec, 0.1sec unit

Pause / Move in RUN state

Change input settings: no, nc

Up to 3 sensors can be used. (3 sensor input terminals)

On Delay Timer setting: 0.0 ~ 60.0sec, 0.1sec unit

Off Delay Timer setting: 0.0 ~ 60.0sec, 0.1sec unit

Sensor power: DC12V

RUN,STOP Key

Feed-back control by vibration sensor

Automatic frequency setting function

Input polarity setting (no, nc)

Communication function

Protection function

AC 90 ~ 260 (50Hz/60Hz)

Turn volume right and left, external volume, 0 ~ 5V control signal

0 to 200 V (unit 0.1 V)

Turn volume right or left

40 to 400 Hz (unit: 0.1 Hz)

Operation synchronization signal

Soft Start

Soft Stop

Con

trol

Met

hod

Disp

lay

7 -Segment

PWM method

Operation status LED (Red)

Full digital control by microcomputer

Parameter LED (green)

Memory function

OVF

Sensor input

Pause

Control

External input

on / off

Control

driving

stop

Control

Access restrictions

Rated input

Item

Vibration Width Control

2CH selection control

amplitude

Control

volt

frequency

Maximum capacity

Driving method

Control method

Out

put

Met

hod

14. Outline drawing

14-1. HM-75A Outline Drawing

14-2. HM-710A Outline Drawing

This manual suits for next models

1

Table of contents