Data Aire LonWorks dap4 User manual

Data Aire

dap4

LonWorks Interface Instructions

Data Aire, Inc.

230 West BlueRidge Ave.,

Orange, CA 92865

Document number: 600-000-966

April 2014

Revision 3.0

Dap4 LonWorks Interface Instructions

Document number 600-000-966 Ver. 3

2

Table of Contents

1. Introduction....................................................................................................3

2. Physical channels..........................................................................................3

3. Layout of the boards......................................................................................3

4. Meanings of the LEDs ...................................................................................3

5. Installation......................................................................................................4

6. Connection to the LonWorks® network .........................................................5

7. XIF and NXE file for dap4..............................................................................6

8. dap4 LonWorks Point list...............................................................................6

Dap4 LonWorks Interface Instructions

Document number 600-000-966 Ver. 3

3

1. Introduction

The dap4 LonWorks card (Data Aire P/N 160-700-020) is an optional network card

which allows the dap4 controller to be connected directly to a LonWorks®network.

The use of these boards requires knowledge of and experience with the LonWorks®

network installation and maintenance tools. The LonWorks card can be factory

installed or field installed.

2. Physical channels

The LonWorks card uses an Echelon®FTT-10 transceiver, approved for use on the

TP/FT-10 channel.

This channel has the following main characteristics:

Alllowing the connection of a maximum of 64 nodes for each network

segment;

The nodes can be connected without any restrictions in the topology: that is,

star, ring, on one bus only, or with any combination of these.

Communication speed: 78,125 kbps;

Maximum distance (Belden 85102 cable): 500m for connections between the

nodes with free topology.

3. Layout of the boards

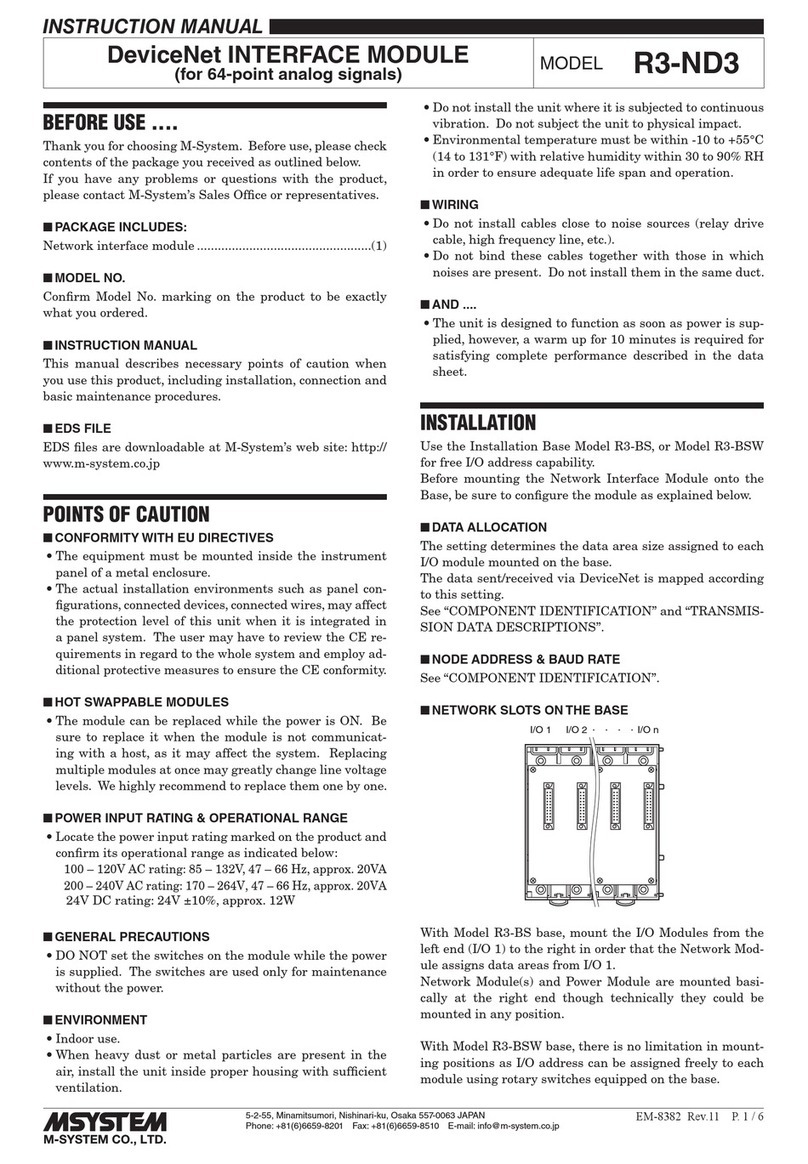

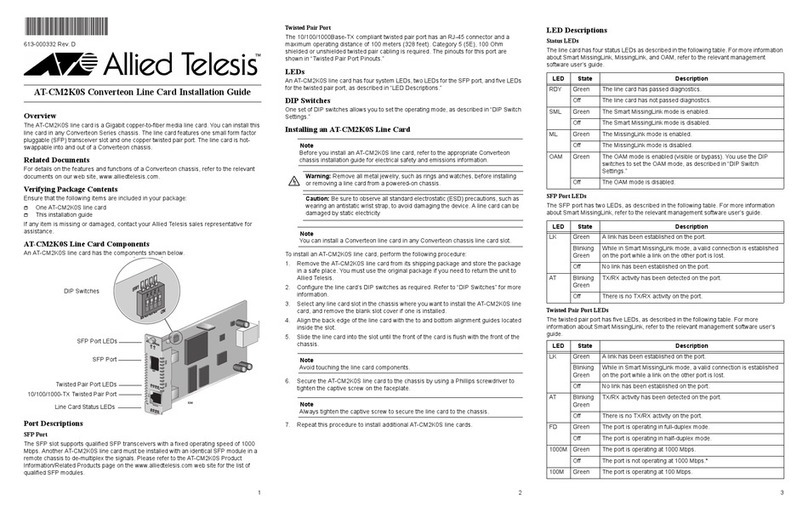

Fig. 1 – LonWorks card

1. Connector to the dap4 controller BMS card.

2. Terminal block for LonWorks® network (GND, A, B).

3. Service pin.

4. Green service LED.

5. Red fault LED.

For details on the activation of the service pin, see Connection to the LonWorks®network.

4. Meanings of the LEDs

The green service LED:

Signals the status of the node, as per the LonWorks®protocol:

Hardware fault: always ON or always OFF;

Node configured (normal operation): ½ second ON, then always OFF;

Node NOT configured: flashing at ½ Hz;

Node without software application: 1 second ON, 2 seconds OFF, then always OFF;

Node in continuous reset: flashing;

Remains on during the activation of the service pin;

Dap4 LonWorks Interface Instructions

Document number 600-000-966 Ver. 3

4

Remains on for one second when receiving a wink command via the network

(see Connection to the LonWorks® network).

The red fault LED:

Signals problems in the connection between the board and the dap4 controller.

WARNING

If the red LED comes on, make sure the instructions described under Installation have

been carefully followed. Network address must be greater than 1 (Use screw driver and

press button next to J3 connector to display the network address) and protocol must be

set to Lon on dap4 network config menu.

5. Installation

IMPORTANT WARNINGS: precautions in handling the board. Electrical damage

may occur to the electronic components as a result of electrostatic discharges from

the operator. Suitable precautions must be therefore be taken when handling these

components, specifically:

Before handling any electronic component or board, touch an earthed object

(simply not touching the component is not enough to prevent a spike, as static

electricity can produce a 10000V discharge, which can form an arc of about

1cm).

All materials must be kept inside their original package as long as possible. If

necessary, take the controller from its package and place it into antistatic

packaging, without touching the back of the board;

Absolutely avoid non-antistatic plastic bags, polystyrene or sponges;

Do not pass the electronic components or boards directly to other operators (to

prevent electrostatic induction and discharges).

Connect Lonworks card to the dap4 or Mini-dap4

With reference to Figs. 2- 5 below, insert the board in the dap4 or Mini-dap4 as

follows:

1. Disconnect the power supply to the controller.

2. Using a screwdriver, remove the BMS card cover (serial card cover on Mini-

dap4) (see Fig. 2).

3. With cutting nippers, remove the pre-cut plastic part from the cover, thus making

the opening for the 3-pin connector (see Fig. 3).

4. Insert the LonWorks card in the corresponding plug-in connector, initially holding

it diagonally and then making sure it is properly inserted and pushed up against

the two plastic supports on the case of the dap4 (see Fig. 4);

5. Close the cover again, aligning the connector on the card with the hole made in

the cover (see Fig. 5).

6. Reconnect the power supply to the controller; if the BMS 1 communication port

has been set to use the Lon protocol, the red LED on the board will come on for

a few seconds and then will go off immediately, indicating correct operation.

Dap4 LonWorks Interface Instructions

Document number 600-000-966 Ver. 3

5

Fig. 2 Fig. 3

Fig. 4 Fig. 5

6. Connection to the LonWorks®network

The physical connection to the LonWorks®network is performed using the connector

with removable terminals fitted on the board, according to the Echelon®instructions

and specifications. For further information on installation, maintenance, the cross-

section and type of cable, refer to the LonWorks®literature.

Important Note: Data Aire Dap4 Lon interface uses a Carel Lonworks card; if there is

existing equipment provided by others that uses the same Carel Lonworks card then

the device interface file (XIF) of dap4 must be manually loaded during the

commissioning process otherwise Lon network may use an incorrect device interface

template on dap4 that leads to erroneous data.

Service pin

To activate the service pin, simply momentarily short-circuit the two pins on the

board (see Fig. 1 and no.3) with the tip of a screwdriver or a similar tool.

The service pin must only be activated during the installation of the node. When

the pin is activated, the node sends a broadcast message over the LonWorks®

network, containing the information required for identification. There is sticker on

the card to indicate the Lon card neuron ID, this neuron ID can be used to

manually commission the card if service pin does not work.

After you can commission the card and the red LED is lit, reset the dap4 (power off then

back on). The Red LED should go off after dap4 starts up. If dap4 does not get reset

after commissioning, the erroneous data may appear.

WINK event

A generic supervisor can send the WINK command to a specific node on the

LonWorks®network. This generates an event that the application on the specific

node can respond to with any action decided by the programmer.

Dap4 LonWorks Interface Instructions

Document number 600-000-966 Ver. 3

6

In this specific case, the service LED on the interface comes on for one second,

thus making it possible to check the correct operation of the connection between the

interface and LonWorks® network.

7. XIF and NXE file for dap4

The XIF and NXE for dap4 can be downloaded from Data Aire website for

commissioning the dap4.

http://www.dataaire.com, go to System Controls/ dap4.

8. dap4 LonWorks Point list

Note: Read = NVO, write = NVI, some parameters can be read and written, in this

case these parameters have separate NVO point for read (monitor) and NVI point for

write a new value.

Description Read/

Write Variable Name Data

Type LONworks SNVT

Temperature of return air R Ret_Air_Tmp A nvoReturnTemp 105

Maximum Return air temp in

last 24hrs R Maximum A nvoHiTempHistory 105

Minimum Return air temp in last

24hrs R Minimum A nvoLoTempHistory 105

Temperature setpoint R/W Temp_Setpoint A nvoTempSetpoint /

nviTempSetpoint 105

Temperature of chilled water R CW_Tmp A nvoWaterTemp 105

Temperature of discharge air R Disch_Air_Tmp A nvoDischTemp 105

Value of the analog input 1 R Opt1_Analog A nvoOpt1_Analog 8

Value of the analog input 2 R Opt2_Analog A nvoOpt2_Analog 8

Value of the analog input 3 R Opt3_Analog A nvoOpt3_Analog 8

Value of the analog input 4 R Opt4_Analog A nvoOpt4_Analog 8

Lower limit alarm of discharge

air temp Write

only Disch_Air_Lo_SP I nviLoDiscLimit 105

Relative humidity displayed as

xx% R Humidity_dis I nvoHumidity 8

Cooling Stages On = Cooling

stages are currently on This

point applies to DX unit only

R Stages_On I nvoCoolStagesOn 8

Number of heat stages running R Heaters_On I nvoHeatStagesOn 8

Maximum humidity in last 24hrs R Maximum I nvoHiHumHistory 8

Minimum humidity in last 24hrs R Minumum I nvoLoHumHistory 8

Dap4 LonWorks Interface Instructions

Document number 600-000-966 Ver. 3

7

Description Read/

Write Variable Name Data

Type LONworks SNVT

Cooling Utilization Over Last

Hour -Percentage of cooling is

used in the last hour of

operation; this point applies to

DX unit.

R Comp_duty I nvoCoolUtlz 8

Heating Utilization Over Last

Hour -Percentage of heating is

used in the last hour of

operation

R Heat_duty I nvoHeatUtlz 8

Humidifier Utilization Over Last

Hour -Percentage of humidifier

is used in the last hour of

operation

R Hum_duty I nvoHumUtlz 8

Compressor 1 Runtime -This

point applies to DX unit with one

compressor -high

R C1_Hours_H I nvoC1_Hours_H 8

Compressor 1 Runtime -This

point applies to DX unit with one

compressor -low

R C1_Hours_L I nvoC1_Hours_L 8

Compressor 2 Runtime -This

point applies to DX unit with

dual compressor - high

R C2_Hours_H I nvoC2_Hours_H 8

Compressor 2 Runtime -This

point applies to DX unit with

dual compressor - low

R C2_Hours_L I nvoC2_Hours_L 8

Heater 1 Runtime - high R Ht1_Hours_H I nvoHt1_Hours_H 8

Heater 1 Runtime - low R Ht1_Hours_L I nvoHt1_Hours_L 8

Humidity upper limit alarm Write

only Hum_Hi_SP I nviHiHumLimit 8

Upper limit alarm of return air

temp Write

only Ret_Air_Hi_SP I nviHiTempLimit 105

Humidity setpoint R/W Hum_setpoint I nvoHumSetpoint /

nviHumSetpoint 8

CW valve open % (0-100% with

10% increment) R CW_disp I nvoValve 8

Chilled Water Utilization Over

Last Hour - This applies to

Chilled water or Energy saver

units.

R WtrVlv_duty I nvoChillUtlz 8

Humidifier Runtime - high R Hum_Hours_H I nvoHum_Hours_H 8

Humidifier Runtime - low R Hum_Hours_L I nvoHum_Hours_L 8

Blower Runtime - high R Blower_Hours_H I nvoFan_Hours_H 8

Blower Runtime - low R Blower_Hours_L I nvoFan_Hours_L 8

Dap4 LonWorks Interface Instructions

Document number 600-000-966 Ver. 3

8

Description Read/

Write Variable Name Data

Type LONworks SNVT

CW Fan speed (%) sent via

BMS Write

only CW_Fan_Speed_bms I nviCW_Fan_Speed 8

DX Fan speed (%) sent via

BMS Write

only DX_Fan_Speed_bms I nviDX_Fan_Speed 8

Heater 2 Runtime - high R Ht2_Hours_H I nvoHt2_Hours_H 8

Heater 2 Runtime - low R Ht2_Hours_L I nvoHt2_Hours_L 8

Heater 3 Runtime - high R Ht3_Hours_H I nvoHt3_Hours_H 8

Heater 3 Runtime - low R Ht3_Hours_L I nvoHt3_Hours_L 8

Chilled Water Runtime - This

applies to chilled water units

only - high

R CW_Hours_H I nvoCW_Hours_H 8

Chilled Water Runtime - This

applies to chilled water units

only - low

R CW_Hours_L I nvoCW_Hours_L 8

Zone Airflow Setpoint kcfm

(Enter Total airflow

setpoint/100)

Write

only ZM_Airflow_SP I nviZone_Air_Setp 8

Water under floor alarm R Floor_Wtr_alm D Alarm_1 . Bit0 83

No air flow alarm R Air_Flow_alm D Alarm_1 . Bit1 83

Dirty filter from digital input R Filter_alm D Alarm_1 . Bit2 83

Alarm from humidifier digital

input R Humidifier_alm D Alarm_1 . Bit3 83

Temperature of return air above

firestat alarm set point R Firestat_alm D Alarm_1 . Bit4 83

One or more comps has short

cycled R Shortcycle_alm D Alarm_1 . Bit5 83

Loss of power requires manual

reset of alarm R PwrUp_alm D Alarm_1 . Bit6 83

Sensor is out of range R Humidity_fail D Alarm_1 . Bit7 83

Sensor is out of range R Ret_Air_fail D Alarm_1 . Bit8 83

Maintenance Schedule Due

alarm R Maint_alm D Alarm_1 . Bit9 83

High pressure alarm R C1_HP_alm D Alarm_1 . Bit10 83

Low pressure alarm R C1_LP_alm D Alarm_1 . Bit11 83

High pressure alarm R C2_HP_alm D Alarm_1 . Bit12 83

Low pressure alarm R C2_LP_alm D Alarm_1 . Bit13 83

Smoke detected from digital

input R Smoke_alm D Alarm_1 . Bit14 83

No water flow alarm R Wtr_Flow_alm D Alarm_1 . Bit15 83

Sensor is out of range R Disch_Air_fail D Alarm_2 . Bit0 83

Temperature of return air above

alarm set point R RA_Tmp_hi_alm D Alarm_2 . Bit1 83

Dap4 LonWorks Interface Instructions

Document number 600-000-966 Ver. 3

9

Description Read/

Write Variable Name Data

Type LONworks SNVT

Temperature of return air below

alarm set point R RA_Tmp_lo_alm D Alarm_2 . Bit2 83

Humidity above alarm set point R Hum_hi_alm D Alarm_2 . Bit3 83

Humidity below alarm set point R Hum_lo_alm D Alarm_2 . Bit4 83

Fan overload R Fan_Overload D Alarm_2 . Bit5 83

Local alarm #1: See tag inside

door =Optional alarm. External

alarm input required

R SeeTag_cust_alm1 D Alarm_2 . Bit6 83

Local alarm #2: See tag inside

door =Optional alarm. External

alarm input required

R SeeTag_cust_alm2 D Alarm_2 . Bit7 83

Local alarm #3: See tag inside

door =Optional alarm. External

alarm input required

R SeeTag_cust_alm3 D Alarm_2 . Bit8 83

Local alarm #4: See tag inside

door =Optional alarm. External

alarm input required

R SeeTag_cust_alm4 D Alarm_2 . Bit9 83

Standby pump on: Check

primary pump -Optional alarm.

Pump failure input signal

required

R Stdby_Pump_On D Alarm_2 . Bit10 83

Alarm: UPS power on: Check

main power -Optional alarm.

External alarm input required

R Ups_On_alm D Alarm_2 . Bit11 83

Custom alarm #1 -Optional

alarm. External alarm input

required. Factory programmed

custom message required

R Cust_msg_Sw1 D Alarm_2 . Bit12 83

Custom alarm #2 -Optional

alarm. External alarm input

required. Factory programmed

custom message required

R Cust_msg_Sw2 D Alarm_2 . Bit13 83

Custom alarm #3 -Optional

alarm. External alarm input

required. Factory programmed

custom message required

R Cust_msg_Sw3 D Alarm_2 . Bit14 83

Dap4 LonWorks Interface Instructions

Document number 600-000-966 Ver. 3

10

Description Read/

Write Variable Name Data

Type LONworks SNVT

Custom alarm #4 -Optional

alarm. External alarm input

required. Factory programmed

custom message required

R Cust_msg_Sw4 D Alarm_2 . Bit15 83

Humidifier stopped due to

custom alarm switch R HumSw_Inhibit D Alarm_3 . Bit0 83

Heat inhibited due to custom

switch alarm condition R Heat_inhibit D Alarm_3 . Bit1 83

Reheat and humidification

inhibited from operation R Rht_Hum_inhibit D Alarm_3 . Bit2 83

Temperature of discharge air

below alarm set point R Disch_Tmp_lo_alm D Alarm_3 . Bit3 83

Manual override: Check bypass

switches - Standard alarm.

Manual override switch is on

R Override_Alm D Alarm_3 . Bit4 83

High condensation from digital

input R Condensation_alm D Alarm_3 . Bit5 83

Unit in standby, all functions

held off - Optional alarm.

Control input signal required

Factory setting required

R Unit_In_Standby D Alarm_3 . Bit6 83

Cooling operation inhibited by

BMS R/W BMS_Cooling_inhibit D nvoBMSCool_In /

nviBMSCool_In 95

Heat inhibited due to bms R/W BMS_Heat_inhibit D nvoBMSHeat_In /

nviBMSHeat_In 95

Humidifier operation inhibited by

BMS R/W BMS_Humidifier_inhibit D nvoBMSHum_In /

nviBMSHum_In 95

Inhibit fan by bms R/W Fan_Inhibit_bms D nvoBMSFan_In /

nviBMSFan_In 95

Supervisor (BMS) On-Off. Show

the state OFFbyBMS in main

mask (1: Off; 0: On)

R/W Superv_Off D nvoSuperv_Off /

nviSuperv_Off 95

BMS-heartbeat is to confirm the

communication with BMS.

This variable must change at

least once every 5 minutes or

unit will revert on mode if it is

command to off

Write

only BMS_Heartbeat D nviBMS_Heartbeat 95

Table of contents

Other Data Aire Network Card manuals

Popular Network Card manuals by other brands

HP

HP Memory Modules user guide

ZyXEL Communications

ZyXEL Communications ZYWALL TURBO CARD user guide

Rosewill

Rosewill RC-NIC416Dual user manual

Huawei

Huawei Pocket WiFi 3G user manual

Socket

Socket 10/100 Ethernet CF Card user guide

MikroTik

MikroTik RouterBOARD 711UA-2HnD Quick setup guide and warranty information

Quanta Computer

Quanta Computer WMA1 user manual

MGE UPS Systems

MGE UPS Systems minislot 66244 user manual

Xerox

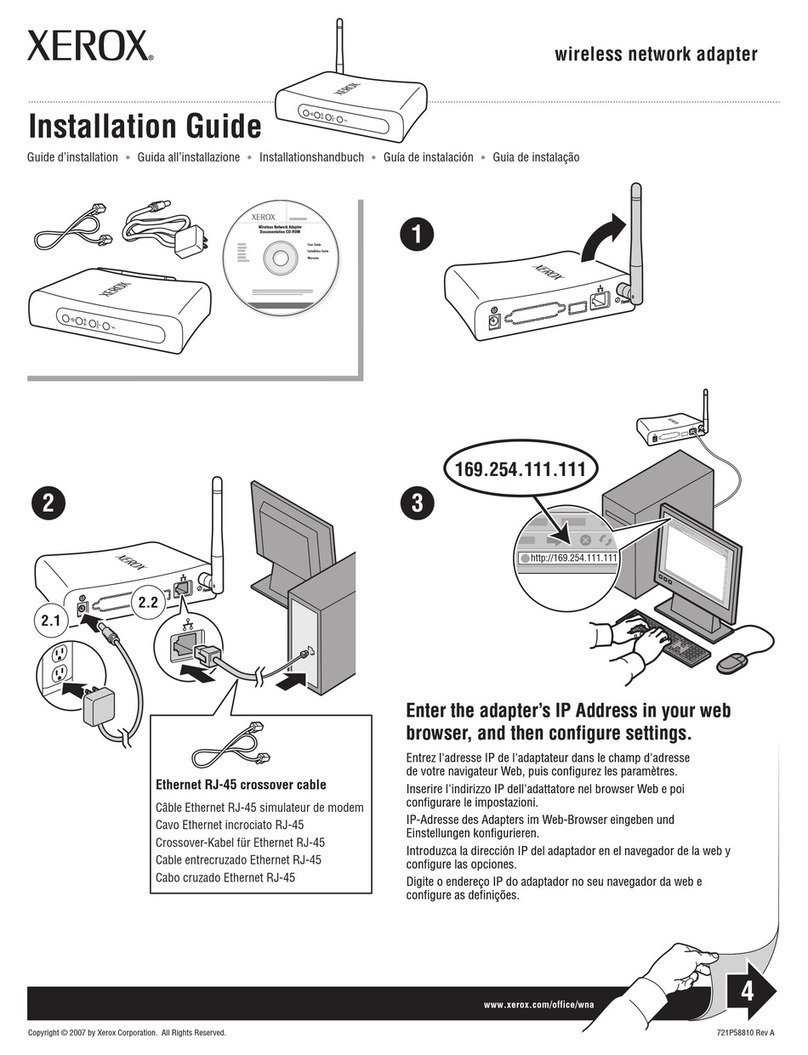

Xerox WNA-100 - Bridge installation guide

Allied Telesis

Allied Telesis CONVERTEON AT-CM2K0S installation guide

SUNRICH TECHNOLOGY

SUNRICH TECHNOLOGY N-480 user manual

Echelon

Echelon PCLTA-10 PC LonTalk Adapter 73401 product manual