DATA PROOF 160A Troubleshooting guide

1-2

OPERATING INSTRUCTIONS

AND

SERVICE MANUAL

LOW THERMAL SCANNER

MODLES 160A, 164A, 320A

Copyright DATA PROOF 1984-1999

1177 S. De Anza Blvd., San Jose, CA 95129

Phone: (408) 865-1177, Fax: (408) 865-1166

www.DataProof.com

1-3

WARRANTY AND SERVICE

CERTIFICATION: Data Proof certifies that this product was tested and inspected and found

to meet its published specifications when it was shipped from the factory.

WARRANTY: This product is warranted against defects in materials and workmanship for a

period of one year from date of shipment. During the warranty period, Data Proof will, at its

option, either, either repair or replace products which prove to be defective.

SERVICE: For warranty service or repair this product must be returned to the factory. The

buyer shall prepay shipping charges to Data Proof and Data Proof shall pay surface shipping to

the buyer. Permission must be obtained from the factory for warranty repair returns.

LIMITATIONS: The forgoing warranty shall not apply to defects resulting from improper or

inadequate maintenance by the buyer, or unauthorized modifications or misuse.

Neither Data Proof or any of its employees shall be liable for any direct or indirect, special,

incidental or consequential damages arising out of the use of this product.

No other warranty is expressed or implied.

SAFETY PRECAUTIONS

This product has been designed and tested in accordance with IEC1010-1/EN61010-1

including amendment 1(1995) for insulation category II use. Use of this equipment in a

manner not specified may could result in personal injury.

AC POWER SOURCE: This product is intended to operate from an ac power source that

will apply not more than 264 V ac between either of the supply conductors and ground.

POWER CORD: Use only the power cord and connector appropriate for the voltage and plug

configuration in your country. The cord must contain a safety ground conductor and be

connected to a plug which has a connection to earth ground. Use only a power cord that is in

good condition.

FUSE:To avoid fire hazard use only the specified fuse. The fuse must be rated at 0.25

ampere/250 volts time-delay.

SIGNAL INPUT POWER: Signals applied to the input or output terminals must be limited to

levels deemed safe by the IEC/EN specifications. When applied voltages are above 30 volts,

the current source must limit the current to not more than 2 milliamps.

1-4

TABLE OF CONTENTS

SECTION I: GENERAL DESCRIPTION PAGE

1.1 DESCRIPTION 1-1

1.2 SPECIFICATIONS 1-2

1.3 REAR PANEL CONNECTIONS 1-3

1.4 REFERENCE STANDARD PROTECTION SYSTEMS 1-3

SECTION II: INSTALLATION PAGE

2.1 INITIAL INSPECTION 2-1

2.2 POWER REQUIREMENTS 2-1

2.3 LOCATION 2-1

SECTION III: OPERATION PAGE

3.1 FRONT PANEL CONTROLS AND INDICATORS 3-1

3.2 REAR PANEL CONNECTIONS 3-2

3.3 FRONT PANEL OPERATION 3-3

3.4 OPERATION VOLTAGE SELECTION 3-4

3.5 ADDRESS SELECTION 3-5

3.6 OPERATION FROM INTERFACE BUS 3-6

3.7 SAMPLE PROGRAMS 3-7

3.8 REMOTE LOCK 3-8

3.8 STANDARD PROTECTION FOR MULTIPLE SCANNERS 3-8

3.9 OPTION 3 SCANNER GUARD 3-8

SECTION IV: THEORY OF OPERATION PACE

4.0 INTRODUCTION 4-1

4.1 LATCHING RELAY 4-1

4.2 LOW THERMAL DESIGN 4-2

4.3 SCANNER CONFIGURATION 4-3

4.4 LOGIC CIRCUITS 4-3

4.5 PROTECTION FOR DEVICES CONNECTED TO SCANNER 4-3

4.6 PROCEDURE FOR MEASURING VOLTAGE REFERENCES 4-5

4.7 TEST RESULTS 4-7

1-5

SECTION V: MAINTENANCE AND TROUBLE SHOOTING PAGE

5.0 PERIODIC MAINTENANCE 5-1

5.1 UNSTABLE READINGS 5-1

5.2 RELAY FAILURES 5-1

5.3 LOCATING THE CHANNEL RELAYS 5-2

5.4 REPLACING RELAYS 5-2

SECTION VI: CIRCUIT DIAGRAMS PAGE

6.1 INTRODUCTION 6-1

6.2 ORDERING INFORMATION 6-1

321A SWITCH BOARD / DIAGRAM 6-3

160A SWITCH BOARDS / PARTS TABLE 6-4

164A SWITCH BOARDS / PARTS LIST 6-5

CONTROL BOARD PARTS LIST 6-6

CONTROL BOARD DIAGRAM 6-7

BUS INTERFACE PARTS LIST 6-8

BUS INTERFACE BOARD DIAGRAM 6-9

CLOSE CIRCUIT PARTS LIST 6-10

CLOSE CIRCUIT BOARD DIAGRAM 6-11

CLEAR CIRCUIT BOARD PARTS LIST 6-12

CLEAR CIRCUIT BOARD DIAGRAM 6-13

RELAY BOARD PARTS LIST 6-14

RELAY BOARD DIAGRAM 6-15

POWER SUPPLY CIRCUIT DIAGRAM 6-16

POWER SUPPLY PARTS LIST 6-17

DECLARATION OF CONFORMITY 6-18

1-1

SECTION 1

GENERAL INFORMATION

1.1 DESCRIPTION

Data Proof Low Thermal Scanners with extremely low thermal offsets are ideal for

automating precision measurements to sub-ppm accuracy. This versatile dual scanner has two

pairs of output lines which makes it suitable for a wide variety of uses. It can be used for

comparing voltage reference standards, as well as four-terminal measurements on resistance

devices.

Special care has been taken to minimize thermal offsets. The switches used are latching

relays requiring only a few milli-second pulse to actuate. Several systems are used to protect

the devices connected to the scanner from being damaged by operator error or scanner failure.

It can be operated from the front panel or by commands sent over the general purpose interface

bus.

LOW THERMAL SCANNER

DATA PROOF MODEL 320A

1-2

1.2 SPECIFICATIONS

NUMBER OF INPUTS

16 for Model 160A, 164A

32 for Model 320A

THERMOELECTRIC POTENTIALS **

20 nanovolts typical, 50 nanovolts maximum

SYSTEMATIC ERROR CONTRIBUTION FOR VOLTAGE COMPARISON **

Standard deviation less than 20 nanovolts

ENVIRONMENTAL LIMITS

Operating: 10oC to 40oC up to 80% relative humidity

Storage: -20oC to 65oC up to 95% relative humidity

** Note: Specifications apply only if temperature is stable within 1oC, free of drafts

and the relative humidity is below 70%. Warm scanner up for 2 hours min.

Measurement using the NIST 4x4 design with inputs properly shorted. (See NIST

Technical Note 430.)

SCANNER CONTROL

Local, using front panel push buttons

Remote, via IEEE-488 bus (interface included)

RELAY CONTACT RATINGS

Life: greater than 10,000,000 cycles at low levels

Initial contact resistance: 0.05 ohm maximum

Current: 100 milliamp maximum at 10 volts

Voltage switched: 100 volts maximum at 1 milliamp

Voltage non-switched*: 300 volts max. for cable inputs

Voltage non-switched*: 600 volts max. for terminal inputs

*CAUTION -reduce voltage before actuating relays.

NOTE: when applied voltage is above 30 volts, the current source must limit the

current to less than 2 milliamps to meet IEC 1010-1/EN61010-1 safety requirements.

SIZE

Length: 420 mm (16.5 in.)

Width: 451 mm (17.7 in.)

Height: 133 mm (5.2 in.)

WEIGHT

16 channel scanner: 10 kg (23 lb.)

32 channel scanner: 12 kg (27 lb.)

LINE POWER

100V, 115V-127V, 220V-230V, 240V all ±10%; 50-60 Hz

1-3

1.3 REAR PANEL CONNECTIONS

SCANNER INPUTS

Opt 1: Two meter (Six foot) cables. Untined solid

copper wire in groups of four pairs.

Opt 2: Low thermal binding posts. Tellurium copper,

gold flashed per MIL-G-45204.

OUTPUT LINES

Four low thermal binding posts

Line A

Line B

Line A common

Line B common

INTERFACE BUS

24 pin IEEE-488 connector, CINCH No. 57-20240

FUSE

0.25 ampere/250 volts time-delay

REFERENCE STANDARD PROTECTION

Screw terminals connected to open collector TTL logic circuit. Terminal

goes low (0 volts) when any relay is closed, and goes high (5 volts through 10

kohm) when all relays are open. This line can be connected in parallel with other

scanners cascaded in a large system to protect standards from being shorted

together. Two systems are provided, one for line A and one for line B.

1.4 REFERENCE STANDARD PROTECTION SYSTEMS

Three systems are used to help protect standards from being damaged due to

scanner failure or operator error. These systems are described briefly below. See Theory

of Operation Section for complete description.

a. The relays are driven from a decoder so that only one output circuit can be

activated for any possible input combination.

b. Contacts on each relay are connected so that all input lines must be open before

power is available to close a relay.

c. Two push-buttons must be depressed at the same time to actuate any relay.

Requires two hands to operate.

1-4

(Blank Page)

2-1

SECTION 2

INSTALLATION

2.1 INITIAL INSPECTION

This instrument was carefully inspected both mechanically and electrically before

shipment. It should be free of mars and scratches and in perfect electrical order upon receipt.

Unpack the instrument and retain the shipping container until the instrument has been

inspected for damage in shipment. If in-shipment damage is observed, notify the carrier and

obtain authorization for repairs before returning the instrument to the factory.

2.2 POWER REQUIREMENTS

The instrument is shipped with a three wire line cord and must be connected to a

grounded 50 to 60 Hz ac power source. Transformer taps are available for operation at the

following line voltages: 100V, 115V-127V, 220V-230V, 240V all ±10%. Line voltage

selection is accomplished either by changing the line selector on the rear panel or changing

jumpers on the power transformer depending on the scanner model. The jumper connections

are shown on the power supply diagram.

WARNING: BEFORE SWITCHING ON THIS INSTRUMENT, THE

PROTECTIVE TERMINAL OF THIS INSTRUMENT MUST BE CONNECTED TO A

PROTECTIVE EARTH CONTACT. THE POWER LINE CORD SUPPLIED WILL

PROVIDE THE PROTECTIVE GROUNDING WHEN INSERTED INTO A SOCKET

OUTLET PROVIDED WITH AN EARTH CONTACT. THE PROTECTIVE ACTION

MUST NOT BE NEGATED BY THE USE OF AN EXTENSION CORD OR ADAPTOR

WITHOUT A PROTECTIVE GROUNDING CONDUCTOR.

2.3 LOCATION

To insure optimum performance, the scanner should be installed in an area having

reasonably constant temperature, no strong electrostatic or magnetic fields, and a minimum

amount of vibration. The unit should not be located near heating or cooling vents or in direct

sunlight. Such locations can cause sudden temperature changes resulting in generation of

thermal errors in the measurements. A cloth can be placed over the binding posts on the rear

panel (and at the connections to your devices) to shield it from drafts to further reduce thermal

errors.

2-2

(Blank Page)

3-1

SECTION 3

OPERATION

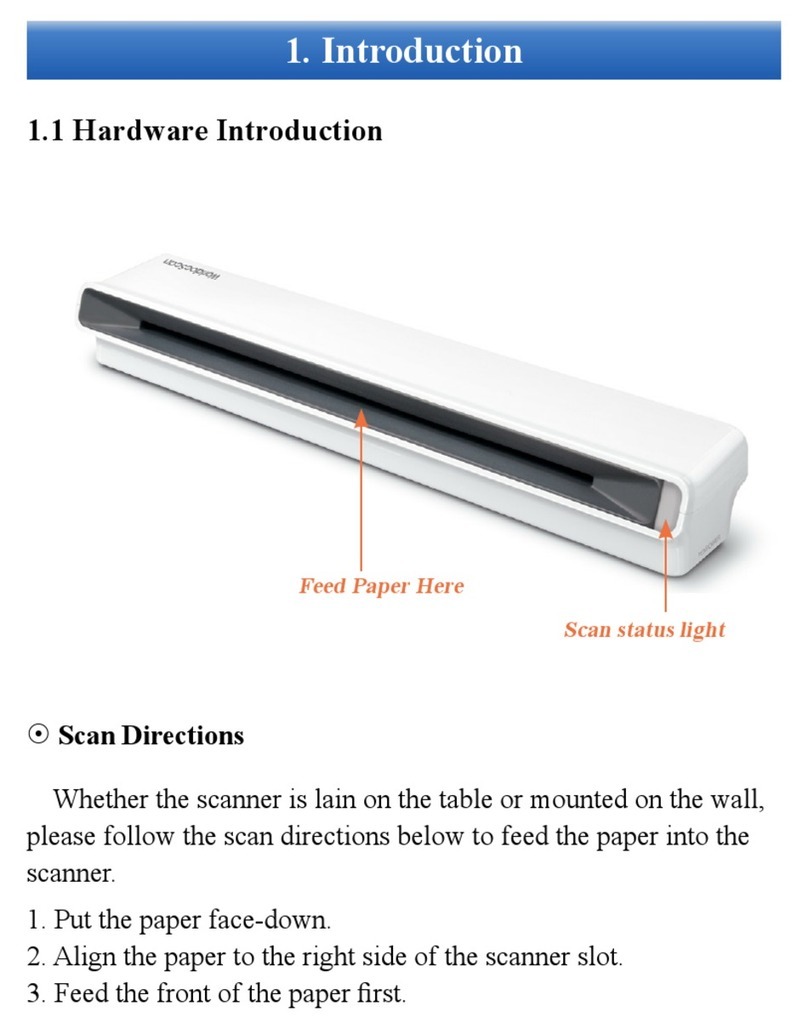

3.1 FRONT PANEL CONTROLS AND INDICATORS (Model 320A shown)

1. Line POWER on/off switch

2. LINE A push-button -when depressed will cause any relay on the A line to be cleared.

3. LINE B push-button -when depressed will cause any relay on the B line to be cleared.

4. Numbered relay control push-buttons -when depressed at the same time that either the A

LINE or the B LINE push-button is down will cause the corresponding relay to close.

5. LINE A lights -indicates which LINE A relay is closed.

6. LINE B lights -indicates which LINE B relay is closed.

7. REMOTE light -is illuminated when the scanner is in bus control. The front panel push-

buttons are inoperative.

8. LOCAL Light -is illuminated when the scanner is in front panel (local) control.

9. LOCAL push-button (if equipped) -returns scanner to local.

3 61

5 87 942

3-2

3.2 REAR PANEL CONNECTIONS (Model 320A option 2 is shown)

1. SCANNER INPUTS -Terminal inputs, opt 2 (shown)

Connect red terminals to positive leads of units under test and negative leads to black

terminals. Numbers correspond to front panel relay numbers.

1. SCANNER INPUTS -Cable inputs, opt 1 (not shown)

Cable lines are in groups of four pairs. The relay numbers are shown on the color code

chart at the end of each cable. The lines in cable with red band are to be connected to

the unit positives. Connect the unit negatives to the lines with the black band.

2. LINE A OUTPUT positive -Connect to positive terminal of measuring system.

3. LINE A OUTPUT COM -Connect to Line B output com for voltage comparisons.

4. LINE B OUTPUT positive -Connect to negative terminal of measuring system.

5. LINE B OUTPUT COM -Connect to Line A output com for voltage comparisons.

6. GND -Connected to chassis at relay isothermal box.

5V Max

to

DATA PROOF

SUNNYVALE, CA U.S.A.

17 18

20

29 30 31 32

OUTPUT LINES

PROTECT

GP-IB BUS

~Line: 50-60Hz 27VA Max

~Fuse: (250V) 250mAT

GND COM A B

A

B

19

MODEL NO.

SERIAL NO. 320A Opt.2

725

HI

LOW

HI

LOW

~ 100V 115V / 127V

~ 220V 230V / 240V

100

220

120

240

3 4 5 6

7 8

9

10 11 12 13 14

15 16

21 22 23 24 25 26 27 28

INPUT LINES

1 2

6 7 853 2 4

91 10

!

All Lines 600V pk Max to

3-3

7. PROTECT CIRCUIT -Connect to same terminals on other scanners. Provides

protection for standards in a multiple scanner system. See Section 3.9 for details.

8. INTERFACE BUS -IEEE-488 bus connector used to connect scanner to controller.

9. FUSE -Use 0.25 amp, Type 3AG slow blow.

10. AC LINE INPUT -AC Power connector IEC Type with offset pin connected to chassis.

3.3 FRONT PANEL OPERATION

The scanner must be in local mode (LOCAL light on) to operate from the front panel. If

the REMOTE light is on, press the LOCAL push-button or turn power off and then on to

reset.

To connect one of the channel inputs to LINE A proceed as follows:

a. Press and hold down the LINE A push-button. This will cause any previously closed

relay on the A LINE to be cleared.

b. Press the numbered push-button corresponding to the input to be connected. This

will cause the relay to actuate connecting the input line to the A output and also turn

on the appropriate light.

c. To actuate a LINE B relay repeat the above process except hold down the LINE B

push-button.

NOTE:The push-buttons can be depressed in either order and the end result will be the same;

that is, any previously closed relay will be opened and the desired relay will be closed. The

important thing is that two push-buttons must be pressed for any relay to close.

3-4

3.4 OPERATION VOLTAGE SELECTION

The scanner can be operated at 100, 120, 230 or 240 Volt AC line voltage. The following

explains how to change the voltage settings and the fuse.

Four possible voltage settings are available as shown on the Power Entry Module cover shows

(IOOV, 12OV, 230V or 24OV). The white pin in one of these holes indicates the present

voltage setting for the scanner. (The 120 Volt AC setting is shown above.) If this setting does

not match the voltage available at your site, then it must be changed before powering on the

scanner. Sites with 220 Volts line power should select 230 V.

Follow the steps below to change a fuse or convert the operating voltage of a scanner.

1. Set the scanner power switch to the OFF position (down).

2. Disconnect the power line cord from the AC wall outlet and from the power cord

receptacle on the power entry module.

3. Inserted a small flat bladed tool into the slot at the left edge of the cover and carefully pry

the cover off the fuse cavity.

4. Grasp the white plastic voltage select board use with a small pair of pliers and pull straight

outward until the voltage select board unseats from the power entry module cover to

change the voltage setting. Hold the board so that you can read the four voltage selection

labels (100, 120, 23O and 240) imprinted on the board. Move the voltage indicator pin to

the opposite side of the board from the desired voltage label. Be sure to seat the pin in the

notch provided on the board's edge. Install the voltage select board so that it is fully seated

in the voltage select cavity (the label side toward the fuse cavity).

5. Change the fuse if necessary. Carefully replace the power entry module cover making sure

the voltage indicator pin is seated properly in the appropriate hole.

3.5 ADDRESS SELECTION

100 V

120 V

230 V

240 V

3-5

The IEEE-488 bus address of the scanner is selected by the “DIP” switches located on

the interface board under the top cover. The five switches labeled 1 through 5 are used to

select a unique address. The scanner normally leaves the factory with the switches set to a bus

address of 24. Switch No. 6 is used to lock the scanner in remote only. The following table

lists the address codes and corresponding switch settings:

ASCII Code Character Address Switches 5 Bit

Decimal

Listen Talk A5 A4 A3 A2 A1 code

SP @0000000

!A0000101

"B0001002

#C0001103

$D0010004

%E0010105

&F0011006

`G0011107

(H0100008

)I0100109

*J0101010

+K0101111

`L0110012

−M0110113

.N0111014

/O0111115

0P1000016

1Q1000117

2R1001018

3S1001119

4T1010020

5U1010121

6V1011022

7W1011123

8X1100024 FACTORY

9Y1100125 SETTING

:Z1101026

;{1101127

<\1110028

=}1110129

>~1111030

TABLE 3-1 BUS ADDRESS

6 5 4 3 2 1

Position 1

away from board

Remote Lock

switch Address 24 shown

Interface Board

Position 0

towards board

3-6

3.6 OPERATION FROM INTERFACE BUS

The interface circuit is designed to accept coded data sent over the bus to actuate the

relays. To operate with the bus the scanner must be set to a usable address and must be

connected to the controller using a 24 pin IEEE-488 cable (not supplied).

The scanner was set at the factory for bus address 24. All the examples that follow

assume 24 as the address. The address can be easily changed if necessary by means of a “DIP”

switch on the interface board located under the top cover. Refer to paragraph 3.6 for the

procedure to change the bus address.

To actuate a relay the bus interface must first receive the correct address, then a three

character ASCII code designating the relay, and then a carriage return/line feed. For example

using an HPBASIC computer, the statement:

OUTPUT 724;”AO1”

would cause any relay on LINE A to be cleared, and then relay number 1 to be closed.

In this example

7 is the controller IO address,

24 is the scanner address and

A01 is the code for relay 1 on line A

To clear both lines use the following HPBASIC commands:

OUTPUT 724;”AOO”

WAIT .2

OUTPUT 724;”BOO”

Note that each actuation must be a separately addressed statement. For example, the

following is not valid:

OUTPUT 724;”AOO”,”BOO” —NOT VALID—

Note also that a delay of at least 200 milliseconds must occur between any two

actuations to allow the relays to complete their operation.

3-7

3.7 SAMPLE PROGRAMS

The following program will exercise the scanner relays 1 through 16 and leave both

lines clear. This program is for HPBASIC computers with the scanner address set to 724.

10 ! SCANNER TEST

20 DIM Relay$[32]

30 Relay$=”01020304050607080910111213141516”

40 FOR I = 1 TO 16

50 OUTPUT 724;”A”&Relay$[2*I-1,2*I] ! CLOSES A RELAY

60 WAIT .5

70 OUTPUT 724;”B”&Relay$[2*I-1,2*I] ! CLOSES B RELAY

80 WAIT .5

90 NEXT I

100 OUTPUT 724;”A00” ! CLEARS LINE A

110 WAIT .2

120 OUTPUT 724;”B00” ! CLEARS LINE B

130 END

Note: A Wait of at least 200 milliseconds is required between relay actuations to allow time

for the relay circuits to actuate.

The second program example has exactly the same result as the first program listed above

but uses string output statements. The formatted output statement is used to assure the first

character that the scanner sees (after the address) is the line code and the next two characters are

the relay code.

10 ! SCANNER TEST

30 FOR I = 1 TO 16

40 OUTPUT Code$ USING “A,ZZ”;”A”,I ! SETS CODE

50 OUTPUT 724; Code$ ! CLOSES A RELAY

60 WAIT .5

70 OUTPUT Code$ USING “A,ZZ”;”B”,I ! SETS CODE

80 OUTPUT 724; Code$ ! CLOSES B RELAY

90 WAIT .5

100 NEXT I

110 PRINT “A00” ! CLEARS A RELAY

120 WAIT .2

130 PRINT “B00” ! CLEARS B RELAY

140 END

3-8

3.8 REMOTE LOCK

The push-buttons can be locked out when it is desired to prevent tampering from the

front panel. Position No. 6 of the “DIP” switch located on the Interface printed circuit board is

used to lock the scanner in remote only. if the switch is the “O” position (towards the PC

board) the REMOTE light will be on and the front panel push-buttons will not operate. The

scanner can be actuated only by the bus in the usual manner. The scanner address must still be

used in the output command to actuate the relays.

3.9 STANDARD PROTECTION FOR MULTIPLE SCANNERS

The protection feature can be extended to multiple scanners in a large system by means

of the rear panel PROTECT terminals. The protection circuit prevents more than one relay on

either the A Line or the B Line from being closed at the same time which prevents standards

from being shorted together. Each relay has a contact which closes when the relay is in the

open position. These contacts must all be closed (relays open)for the logic circuit to allow a

close pulse to be sent out. This protection can be extended to more than one scanner in a large

system by connecting the PROTECT terminals together. Both the A and B PROTECT

terminals are connected to an open collector TTL gate on the control board. When all relays

are open the terminal will be high (5 volts through 10 kohm), and when any relay is closed the

terminal will be low (near 0 volts) . Connecting either terminal to COM will prevent any relay

on that line from being activated.

To extend this protection feature when two or more scanners are used in a system,

connect all PROTECT A terminals together, all PROTECT B terminals together, and all

PROTECT COM terminals together.

3.10 OPTION 3 SCANNER GUARD

Option 3 scanners have both a high and low guard. The high guard surrounds the

potential and current leads to the high end of the resistor. A separate low guard surrounds the

leads to the low end of the resistor. The guard shields are switched along with the current and

potential lines. The guard is carried through shielded cables from the resistor, through the

scanner and to the output cables and requires an external source to be driven. Each guarded

cable has a white and a black lead. The white and black leads are identical so either could be

used as the current or potential circuit. The guard circuit is switched to chassis ground when

the channel is not connected.

4-1

SECTION 4

THEORY OF OPERATION

4.0 INTRODUCTION

Data Proof Low Thermal Scanners with extremely low thermal offsets are ideal for

automating precision measurements to sub-ppm accuracy. This versatile dual scanner has two

pairs of output lines which makes it suitable for a wide variety of uses. It can be used for

comparing voltage reference standards, as well as four-terminal measurements on resistance

devices.

4.1 LATCHING RELAY

The device that makes this scanner possible is a sensitive latching relay originally

manufactured for the telephone industry. The major problem with conventional relays is the

thermal offset voltage caused by the heat generated by the current in the relay coil. With this

latching relay a short pulse of only 10 milliseconds is all that is required to toggle the contacts

from one side to the other. Thus the heat generated is negligible. The relays are attached to

the boards with spring clips so that they can be easily removed for replacement if necessary

FIGURE 4.1 LATCHING

RELAY ARRANGEMENT FIGURE 4.2 LATCHING

RELAY CONSTRUCTION

4-2

Figure 4.1 shows how the relay is arranged. Figure 4.2 shows the construction

details. The gold fingers attached to the relay armature make contact to gold pads on printed

circuit boards. A permanent ceramic magnet holds the armature in place against one of the two

pole pieces. If the coil on the side opposite is energized, the armature will toggle so that it is

held against the other pole piece. once the armature has toggled the current in the coil can be

removed. This requires less than ten milliseconds.

The relays used in the scanner have 3-pole, 2-throw bifurcated contacts. The contacts

short out parallel traces on the printed circuit board connecting the channel inputs to the output

lines. A third contact provides current to a light on the front panel to indicate which relay is

closed.

4.2 LOW THERMAL DESIGN

Special care has been taken to minimize thermal offsets. The switches used are latching

relays requiring only a short pulse to actuate, and thus no self-heating occurs. Gold plated

fingers on the relay armature make direct contact to hard gold pads on special circuit boards.

Relays make connection by shorting together adjacent pads on the board with pairs of

contacts. Thus any thermal emf caused by a contact is canceled out by the nearly equal thermal

emf generated by the other half of the pair.

Switching assemblies with eight relays to a PC board are housed in a heavy machined

aluminum box. This isothermal enclosure helps to maintain a uniform temperature at each of

the relay contacts.

FIGURE 4.3 SCANNER CONFIGUATION

The printed circuit edge connectors carry only the relay coil and panel light circuits. All

the channel input lines are soldered to the relay boards directly to prevent the thermal and noise

voltages caused by connectors.

VOLTMETER

LOW LINES

UP TO 16 OR 32

VOLTAGE

STANDARDS

B LINES

A LINES

This manual suits for next models

2

Table of contents