Data Translation DT9840 Series User manual

DT9840 Series

UM-19197-T

User’s Manual

Title Page

Seventeenth Edition

August, 2013

Data Translation, Inc.

100 Locke Drive

Marlboro, MA 01752-1192

(508) 481-3700

www.datatranslation.com

Fax: (508) 481-8620

E-mail: [email protected]

Copyright © 2013 by Data Translation, Inc.

All rights reserved.

Information furnished by Data Translation, Inc. is believed to be

accurate and reliable; however, no responsibility is assumed by

Data Translation, Inc. for its use; nor for any infringements of

patents or other rights of third parties which may result from its

use. No license is granted by implication or otherwise under any

patent rights of Data Translation, Inc.

Use, duplication, or disclosure by the United States Government

is subject to restrictions as set forth in subparagraph (c)(1)(ii) of

the Rights in Technical Data and Computer software clause at 48

C.F.R, 252.227-7013, or in subparagraph (c)(2) of the Commercial

Computer Software - Registered Rights clause at 48 C.F.R.,

52-227-19 as applicable. Data Translation, Inc., 100 Locke Drive,

Marlboro, MA 01752.

Data Translation® is a registered trademark of Data Translation,

Inc.

All other brand and product names are trademarks or registered

trademarks of their respective companies.

Copyright Page

Radio and Television Interference

This equipment has been tested and found to comply with CISPR EN55022 Class A and

EN61000-6-1 (CE) requirements and also with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference, in which case the user will be required to correct the interference at his own

expense.

Changes or modifications to this equipment not expressly approved by Data Translation

could void your authority to operate the equipment under Part 15 of the FCC Rules.

Note: This product was verified to meet FCC requirements under test conditions that

included use of shielded cables and connectors between system components. It is important

that you use shielded cables and connectors to reduce the possibility of causing interference

to radio, television, and other electronic devices.

Canadian Department of Communications Statement

This digital apparatus does not exceed the Class A limits for radio noise emissions from

digital apparatus set out in the Radio Interference Regulations of the Canadian Department of

Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques dépassant les limites

applicables aux appareils numériques de la class A prescrites dans le Règlement sur le

brouillage radioélectrique édicté par le Ministère des Communications du Canada.

FCC

Page

5

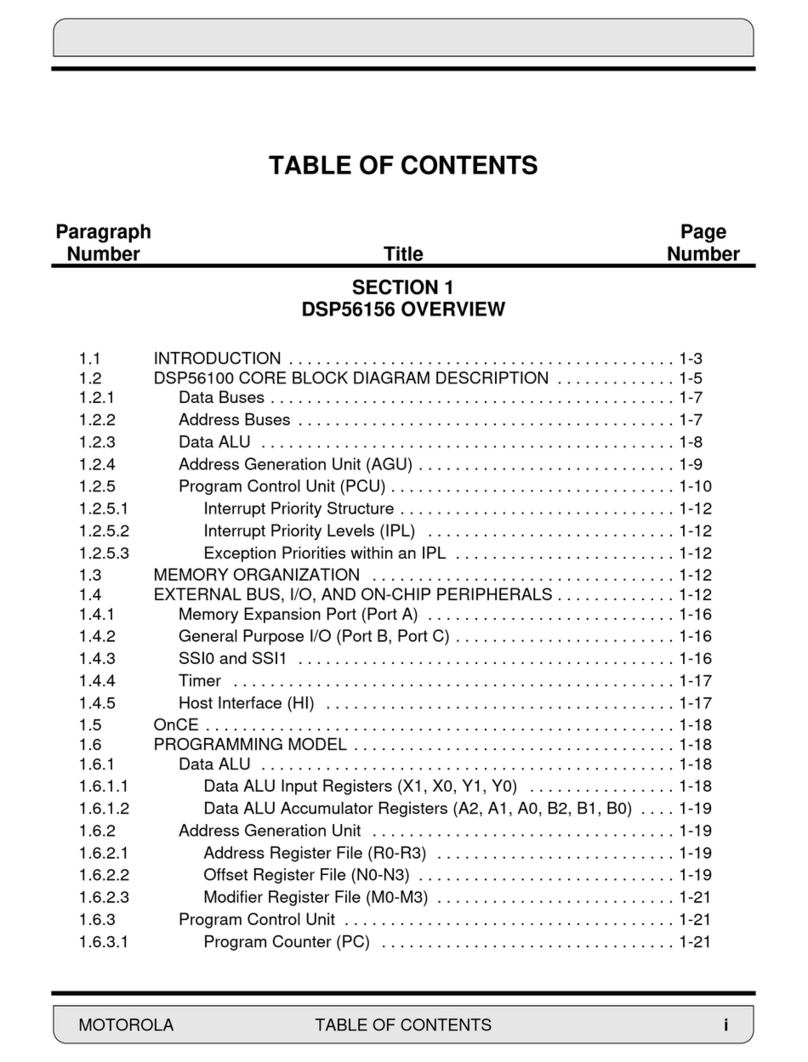

Table of Contents

About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

How this Manual is Organized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Conventions Used in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Related Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Where to Get Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 1: Principles of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

System Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Clock Sources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Internal Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

DT9841, DT9841E, and DT9841-VIB Internal Clock . . . . . . . . . . . . . . . . . . . . . 15

DT9842/2 and DT9842/8 Internal Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

External Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

DT9841, DT9841E, and DT9841-VIB External Clock . . . . . . . . . . . . . . . . . . . . . 16

DT9842/2 and DT9842/8 External Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Scalable Bus Master Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Operation Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Single-Value Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Single-Scan Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Multiple-Scan Input Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Function Generator Output Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Continuous Loop Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Scan Loop Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Block Loop Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

List Loop Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Triggers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Scalable Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Analog Input Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Analog Input Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

IEPE Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Input Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Input Range and Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Data Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Error Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table of Contents

Contents

6

Analog Output Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Analog Output Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Output Resolution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Output Range and Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Output Filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Data Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Error Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Digital I/O Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Digital I/O Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Interrupt On Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Counter/Timer Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

C/T Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

C/T Clock Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Internal C/T Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

External C/T Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Internally Cascaded Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Gate Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Edge Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Pulse Output Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Polarity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Period Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Pulse Width Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Counter/Timer Operation Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Standard Counting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Measure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Continuous Measure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Up/Down Counting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

One-Shot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Repetitive One-Shot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Chapter 2: Register Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

USB Bus/DSP Hardware Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Calibration and Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Setting Up the Xicor Potentiometers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Calibrating the Analog Input Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Calibrating the Analog Output Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Analog Input Subsystem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Analog Output Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Digital I/O Subsystem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Contents

7

Counter/Timer Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Counter/Timer Operation Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Count Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Event Counting Equations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Output Period/Frequency Equations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Output Pulse Width and Duty Cycle Equations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Counter Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Scalable Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Chapter 3: Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Using the DT9841 Calibration Utility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Calibrating the Analog Input Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Connecting a Precision Voltage Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Using the Auto-Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Using the Manual Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Calibrating the Analog Output Subsystem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Appendix A: Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Analog Input Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Analog Output Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Digital Input Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Digital Output Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Counter/Timer Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

External Clock Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

External Trigger Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Power, Physical, and Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Regulatory Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Connector Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

External Power Supply Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Appendix B: Connector Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

DT9841, DT9842/2, and DT9842/8 Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Connector J2 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Connector J3 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Connector J4 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Connector J6 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Connector J11 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Connector J12 and J13 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Connector J17 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Connector J18 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Connector J19 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Screw Terminal Block TB1 Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Contents

8

DT9841E Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Connector J1 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Connector J2 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Connector J3 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Connector J4 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Connector J6 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Connector J11 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Screw Terminal Block TB2 Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Screw Terminal Block TB3 Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Sleek Box Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Connector J1 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Connector J2 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Connector J19 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

EP358E Accessory Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Connector J202 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Connector J201 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

9

About this Manual

This manual describes the hardware features of the DT9840 Series modules.

Intended Audience

This document is intended for engineers, scientists, technicians, or others responsible for

using and/or programming the DT9840 Series modules for data acquisition operations in the

Microsoft®Windows®XP, Windows Vista®, or Windows 7 operating system. It is assumed

that you have familiarity with data acquisition principles and that you understand your

application.

How this Manual is Organized

This manual provides detailed information about the operation of the DT9840 Series modules.

It is organized as follows:

•Chapter 1, “Principles of Operation,” describes the system features and the features of the

analog input, analog output, digital I/O, and counter/timer subsystems.

•Chapter 2, “Register Description,” describes all the registers that are used to program the

DT9840 Series modules.

•Chapter 3, “Calibration,” describes the DT9841 Calibration Utility.

•Appendix A, “Specifications,” lists the specifications of the module.

•Appendix B, “Connector Pin Assignments,” shows the pin assignments for the connectors

and the screw terminal assignments for the module.

• An index completes this manual.

Conventions Used in this Manual

The following conventions are used in this manual:

• Notes provide useful information or information that requires special emphasis, cautions

provide information to help you avoid losing data or damaging your equipment, and

warnings provide information to help you avoid catastrophic damage to yourself or your

equipment.

• Items that you select or type are shown in bold.

About this Manual

10

Related Information

Refer to the following documents for more information on using the DT9840 Series modules:

•Benefits of the Universal Serial Bus for Data Acquisition. This white paper describes why USB

is an attractive alternative for data acquisition. It is available on the Data Translation web

site (www.datatranslation.com).

•DT9840 Series Getting Started Manual (UM-19199). This manual, included on the DT9840

Series Software CD, describes the how to install the DT9840 Series modules and related

software.

•DT9840 Series DSP Library User’s Manual (UM-19591). This manual, included on the

DT9840 Series Software CD, describes how to write a DSP program for the DT9840 Series

modules.

•DT9840 Series Host Communication Library User’s Manual (UM-19593). This manual,

included on the DT9840 Series Software CD, describes how to write a host application

program that communicates with the DSP program running on the DT9840 Series

module.

• Documentation for Code Composer StudioTM Integrated Development Environment (IDE)

from Texas Instruments.

• Documentation for Texas Instruments TMS320C6713 DSP processor.

• Microsoft Windows XP, Windows Vista, or Windows 7 documentation.

• Microsoft Visual Studio documentation.

• USB 1.1 and USB 2.0 specifications on the USB web site (http://www.usb.org).

Where to Get Help

If you have difficulty using a DT9840 Series module, Data Translation’s Technical Support

Department is available to provide technical assistance.

To request technical support, go to our web site at http://www.datatranslation.com and click

on the Support link.

When requesting technical support, be prepared to provide the following information:

• Your product serial number

• The hardware/software product you need help on

• The version of the CD you are using

• Your contract number, if applicable

If you are located outside the USA, contact your local distributor; see our web site

(www.datatranslation.com) for the name and telephone number of your nearest distributor.

11

1

Principles of Operation

System Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Analog Input Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Analog Output Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Digital I/O Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Counter/Timer Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Chapter 1

12

DT9840 Series modules provide simultaneous analog I/O, digital I/O, and counter/timer

operations on the USB bus. The hardware design features an embedded Texas Instruments

TMS320C6713 DSP processor that manages I/O functions on the module. This 300 MHz

processor provides float-point functionality and supports standard programming tools from

Texas Instruments, including Code Composer Studio.

Data Translation provides a library of DSP functions that you can use within a standard Code

Composer program to access the functionality of the DT9840 Series modules, as well a library

of communication functions that you can use to communicate between a DT9840 Series

module and a Windows-based host program. Refer to the DT9840 Series DSP Library User’s

Manual and DT9840 Series Host Communications Library User’s Manual for more information

about the functions included in these libraries. For maximum flexibility, you can also program

your own digital signal processing tasks at the DSP-level, if you wish.

Currently, the DT9840 Series consists of the DT9841, DT9841E, DT9841-VIB, DT9842/2, and

DT9842/8 modules. Table 1 describes the differences among the modules.

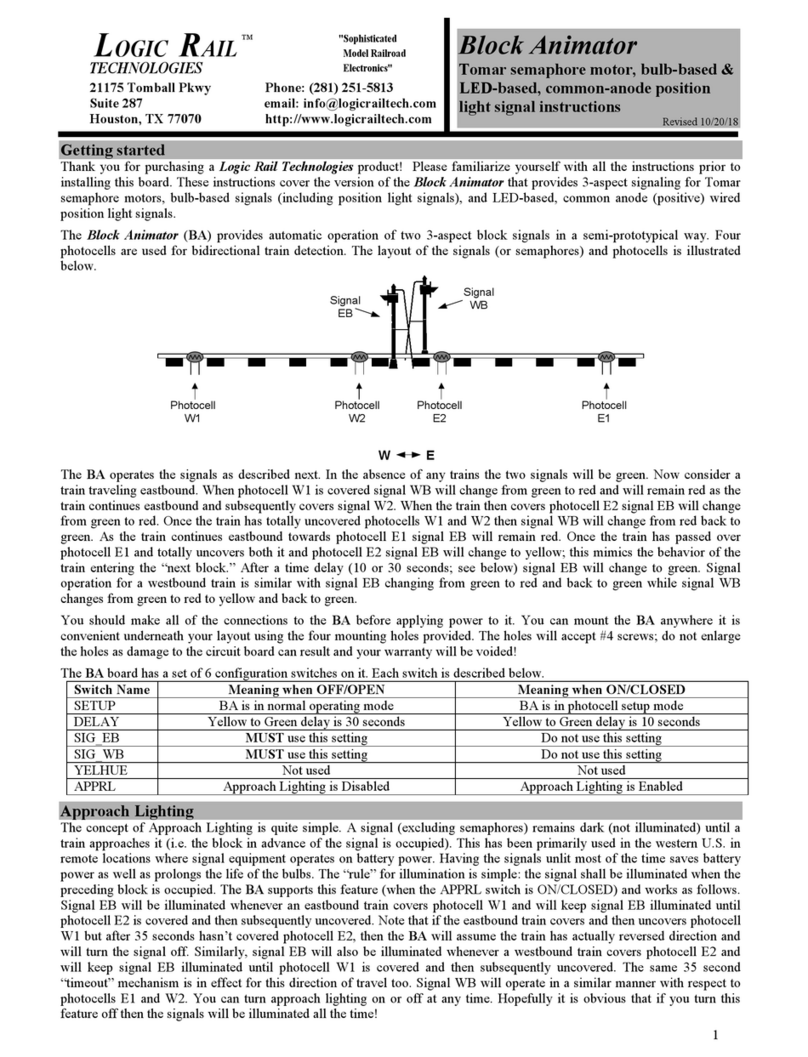

This chapter describes the operation of the DT9840 Series modules from a hardware

perspective. Figure 1 shows a block diagram of the DT9840 Series hardware architecture to

frame the discussion in this chapter. Note that bold entries indicate signals you can access.

For more detailed, register-level information, refer to Chapter 2 starting on page 45.

Table 1: DT9840 Series Modules

Models

Analog

Inputs

Converter

Type Resolution

Sampling

Rate

Analog

Filtering

Analog

Outputs

Scalable

Bus

DT9841 8DIa

a. DI refers to differential mode and SE refers to single-ended mode. For differential inputs only, you can configure the

termination resistance in software on a channel-by-channel basis.

Delta-Sigma 24-bitb

b. The input signal range is ±10 V.

200 Hz to

100 kHz

Ye s c

c. Software-selectable output filters of 5 kHz and 20 kHz are available.

2d

d. Software-selectable output ranges of ±10 V and ±2.5 V are available.

Ye s

DT9841-VIBe

e. The DT9841-VIB supports IEPE functions on the analog input channels. The DT9841-VIB module has two 8-bit digital

I/O ports, where the standard DT9841 product has three 8-bit digital I/O ports.

8SEaDelta-Sigma 24-bitb200 Hz to

100 kHz

Ye s c2dYe s

DT9841E 2DIaDelta-Sigma 24-bitb200 Hz to

100 kHz

Ye s c2dNo

DT9842/2 8SEaSuccessive

Approximation

16-bitb0 Hz to

100 kHz

No 2f

f. The output signal range is ±10 V.

Ye s

DT9842/8 8SEaSuccessive

Approximation

16-bitb0 Hz to

100 kHz

No 8fYe s

Principles of Operation

13

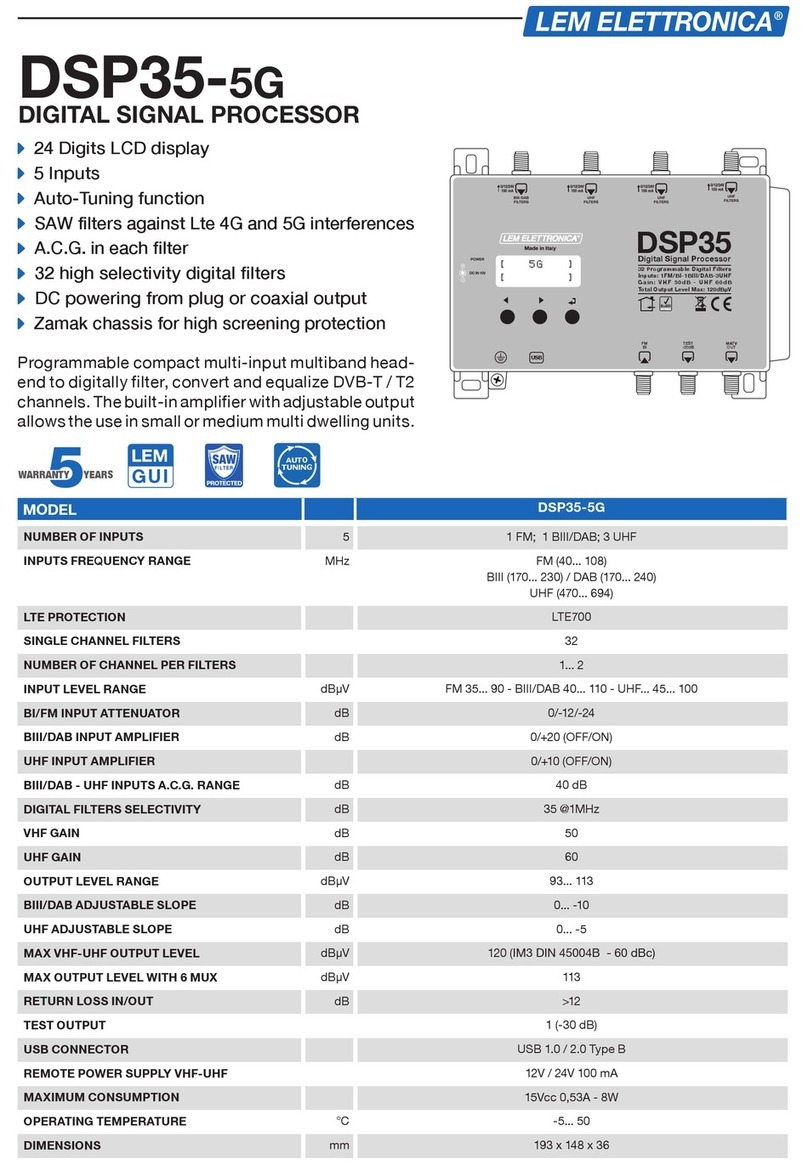

Figure 1: Block Diagram of the DT9840 Series Modules

USB Interface

Input FIFO

ID ROM

128 Kx8

SRAM

500 V Isolation Barrier

Isolated

DC to DC

Converter

External

+5 V Power

@ 6 A

HINT_L

16-Bit HPI

Address/

Data

4 Control

INT

Logic

Up to 24

Digital I/O

Lines and

3 Counter/

Timers

Programmable

Clock

External Clock

and Trigger

2 or 8

Analog

Inputs

2 or 8, 24-Bit

Delta-Sigma

or 8, 16-Bit Successive

Approximation A/Ds*

DSP

L2 Memory

256 KBytes

32 M x 32

SDRAM

2 or 8

DACs*

Reset

Rd_Wr_L

Isolation

Interface

16-Bit HPI

Address/Data

8 Ch

Data** A/D Clock

D/A Serial

Data

4 Control

INT 6 A/D Done

Reset

Rd_Wr_L

HINT_L

A/D and D/A

Data

JTAG

16-bit Scalable Bus 16-bit Scalable Bus

INT 4 (occurs

with A/D Trig, Ctr

Over, Dig

Change, SB

Done, or A/D or

D/A Error)

Serial Port

(1 - McBSP)

INT 5 D/A

Ready

INT 7 SB

FIFO

Control

Logic

* The DT9841 and DT9841-VIB features 8, 24-bit A/Ds and

2, 24-bit DACs.

The DT9841E features 2, 24-bit A/Ds and 2, 24-bit DACs.

The DT9842/2 features 8, 16-bit A/Ds and 2, 16-bit DACs.

The DT9842/8 features 8, 16-bit A/Ds and 8, 16-bit DACs.

**This is serial on the DT9841,

DT9841E, and DT9841-VIB, and parallel

on the DT9842/2 and DT9842/8.

1 M x 16

Flash RAM

The DT9841-VIB

has 16 digital I/O

lines.

FIFO

Chapter 1

14

System Features

The DT9840 Series modules provide the following system-level features:

• Memory, described below

• Clock sources, described on page 14

• Conversion modes, described on page 17

• Triggers, described on page 20

• Connections for multiple modules, described on page 21

• LEDs, described on page 22

Memory

All DT9840 Series modules provide 128 MB of onboard SDRAM and 2 MB of flash memory.

Flash memory is divided into two sections: a single 64 KB block is reserved for user data; the

remaining memory (2 MB – 64 KB) is reserved for storing a DSP program

You can download a program into SDRAM using the DT9840 Series Download Utility,

described in the DT9840 Series Getting Started Manual, and then run and debug the program.

Once you have debugged the program, you can store it in flash memory using the DT9840

Series Flash Download Utility, described in the DT9840 Series Getting Started Manual. This

allows the DSP program to run automatically each time the DT9840 Series module is powered

on, autonomously from the PC.

If desired, you can also copy a user data fie into flash memory using the DT9840 Series Flash

Download Utility. By copying a user data into flash, you can ensure that valuable information,

such as configuration information or collected data, persists across power cycles, even if the

DT9840 Series module loses power or is turned off.

Notes: Only one DSP program can be running on a module at one time. In addition, only one

user data file can be stored in flash memory at a time. However, you can overwrite the flash

memory up to one million times with a new or modified DSP program or data file, if you

wish.

Each DT9840 Series module also requires a CDB file for proper operation. Refer to the

DT9840 Series DSP Library User’s Manual for more information on CDB files.

Clock Sources

DT9840 Series modules support the following sample clock sources:

• Internal clock, described below

• External clock, described on page 16

• Scalable Bus master clock, described on page 16

Principles of Operation

15

Internal Clock

The internal clock has a 36 MHz time base for the DT9841, DT9841E, and DT9841-VIB

modules and an 18 MHz time base for the DT9842/2 and DT9842/8 modules. Conversions

start on a high-to-low transition after a rising edge of the internal calibration signal.

Use software to specify the internal clock source and the frequency at which to pace the input

and output operations and to start the sample clock. For the DT9841, DT9841E, and

DT9841-VIB, the sampling frequency ranges from 200 Hz to 100 kHz. For the DT9842/2 and

DT9842/8, the sampling frequency ranges from 0 Hz to 100 kHz.

Note: According to sampling theory (Nyquist Theorem), specify a frequency that is at least

twice as fast as the input’s highest frequency component. For example, to accurately sample a

20 kHz signal, specify a sampling frequency of at least 40 kHz to avoid aliasing.

The actual frequency that the module can achieve may be slightly different than the frequency

you specified due to the accuracy of the clock (0.01% for the DT9840 Series). You can

determine the actual clock frequency using software.

DT9841, DT9841E, and DT9841-VIB Internal Clock

On the DT9841, DT9841E, and DT9841-VIB modules, the value that you specify for the

internal clock frequency is multiplied by 512 internally to set the oscillator on the module. The

resulting signal from the oscillator is then divided by 2 to provide a clock signal to the A/D

and D/A converters that is oversampled 256 times and has a 50% duty cycle. For example, if

you specify an internal clock frequency of 100 kHz, internally the module sets the oscillator to

51.2 MHz then divides the resulting signal by 2 to provide a 25.6 MHz signal with a 50% duty

cycle to the A/D and D/A converters.

In addition, if you specify a sampling frequency between 200 Hz and 5 kHz, the DT9841,

DT9841E, and DT9841-VIB modules automatically filter the data using decimation and

interpolation filters. Refer to the DT9840 Series DSP Library User’s Manual for more

information on how these filters are implemented.

Once the sample clock is started, the DT9841, DT9841E, and DT9841-VIB modules require 37

clock pulses before the first conversion is completed (at 100 kHz, this delay is 370 μs).

Thereafter, the data is converted without delay (at 100 kHz, sampling occurs every 10 μs). This

initial delay is required by the filtering algorithms of the A/D and D/A converters.

DT9842/2 and DT9842/8 Internal Clock

Because the DT9842/2 and DT9842/8 use successive-approximation A/D converters and

provides no inherent filtering, no initial delay occurs (like on the DT9841, DT9841E, and

DT9841-VIB). Therefore, the converter always runs as fast as possible (at 100 kHz, sampling

occurs every 10 μs).

Internally, the DT9842/2 and DT9842/8 hardware divides the 18 MHz time base by a 32-bit

value to achieve the closest rate to the sampling rate you requested.

Chapter 1

16

External Clock

An external clock is useful when you want to pace acquisitions at rates not available with the

internal sample clock or when you want to synchronize a DT9840 Series module with other

devices in your system.

For the DT9841E module, connect the external clock to pin 23 of connector J1. For all other

modules, connect the external clock to the Ext Clk BNC input on the module. Use software to

specify the external clock source and to start the sample clock. Conversions start on a

high-to-low transition of the external clock signal after a rising edge of the internal calibration

signal.

DT9841, DT9841E, and DT9841-VIB External Clock

For the DT9841, DT9841E, and DT9841-VIB, ensure that the external clock source has a 50%

duty cycle. The resulting frequency of the external clock input is equal to the frequency of the

external clock signal that you connected to the module divided by 256 (this division is done

internally by the module), and must be in the range of 200 Hz to 100 kHz. For example, if you

need a sampling frequency of 100 kHz, use an external clock source with a frequency of

25.6 MHz.

Once the external clock is started, the DT9841, DT9841E, and DT9841-VIB modules require 37

clock pulses before the first conversion is completed (at 100 kHz, this delay is 370 μs).

Thereafter, the data is converted without delay (at 100 kHz, sampling occurs every 10 μs). This

initial delay is required by the filtering algorithms of the A/D and D/A converters.

DT9842/2 and DT9842/8 External Clock

Because the DT9842/2 and DT9842/8 use successive-approximation A/D converters and

provide no inherent filtering, no initial delay occurs (like on the DT9841, DT9841E, and

DT9841-VIB). Therefore, the resulting frequency of the external clock input is equal to the

frequency of the external clock signal that you connected to the module.

Scalable Bus Master Clock

Note: The Scalable Bus is not supported by DT9841E modules.

Use the Scalable Bus Master Clock source only if you are using the Scalable Bus to connect

multiple modules and you want to synchronize their operation. Refer to page 21 for more

information on Scalable Bus operations.

In this configuration, the clock, internal trigger, and reset signals are provided to the slave

modules from the master DT9840 Series module through the Scalable Bus. You can configure

the master module to use either an internal or external clock source. The Ext Clk BNC

connector on the slaves is not used.

Principles of Operation

17

Operation Modes

DT9840 Series modules support the following operation modes:

• Single value, described below

• Single scan, described on page 17

• Multiple scan input, described on page 18

• Function generator output, described on page 18

• Continuous loop operations (scan loop, block loop, and list loop), described on page 19

Single-Value Operations

Use software to perform a single-value operation. A DT9840 Series module acquires one value

from a specified channel or outputs one value to a specified channel on the next pulse of the

sample clock, and then stops. Triggers are ignored.

You can acquire data from an analog input channel, digital input line, or counter/timer

channel.

You can output data to either an analog output channel or a digital output line.

Single-Scan Operations

Use software to perform a single-scan operation. A DT9840 Series module acquires one input

scan record and/or outputs one output scan record on the next pulse of the sample clock, and

then stops. Triggers are ignored.

An input scan record consists of the following information:

• Eight analog input values corresponding to analog input channels 0, 1, 2, 3, 4, 5, 6, and 7.

For the DT9841, DT9841E, and DT9841-VIB, these are 24-bit values; for the DT9842, these

are 16-bit values.

Note: The DT9841E supports only two analog input channels (0 and 1). Therefore, values

for channels 2 through 7 in the input scan record should be ignored.

• One 24-bit value corresponding to all the digital input lines. For the DT9841-VIB, only

16-bits (ports 0 and 1) are accessible.

• One 32-bit value containing the state of the digital input lines. For the DT9841-VIB the

least significant 16-bits of this 32-bit value correspond to the digital inputs of port 0 and

port 1. On all other DT9840 Series modules, the least significant 24-bits of this 32-bit value

correspond to the digital inputs of port 0, port 1 and port 2.

• Three 32-bit values corresponding to counter/timer channels 0, 1, and 2.

Chapter 1

18

An output scan record consists of the following information:

• For the DT9841, DT9841E, and DT9841-VIB, two 24-bit values corresponding to analog

output channel 0 and 1. For the DT9842/2, two 16-bit values corresponding to analog

output channel 0 and 1. For the DT9842/8, eight 16-bit values corresponding to analog

output channels 0 to 7.

• One 24-bit value corresponding to all the digital output lines.

Multiple-Scan Input Operations

Use software to perform a multiple-scan input operation. When it detects a trigger event, the

DT9840 Series module acquires a specified number of input scan records, and then stops. An

input scan record is acquired on each pulse of the sample clock.; refer to page 17 for more

information on input scan records.

This is a synchronous operation; therefore, you cannot perform any other operation while this

operation is in process.

Function Generator Output Operations

Use software to start a function generator output operation. When it detects an initial trigger,

the DT9840 Series module outputs a buffer that contains a specified number of output scan

records. Refer to page 17 for more information on output scan records.

The module continuously outputs the data in the output scan records from the buffer in

memory to the analog output channels and/or digital output lines on each pulse of the sample

clock. Once the operation is started, the DSP is not used.

When you are finished outputting the data, use software to stop the operation.

Continuous Loop Operations

DT9840 Series modules support three types of continuous loop operations:

• Scan loop operations, described below

• Block loop operations, described on page 19

• List loop operations, described on page 19

The most appropriate mode depends on your application.

Use scan loop mode in control loops and other applications where you need to acquire a

sample on every tick of the sample clock and process the data as soon as possible. This mode

is less efficient than block loop and list loop operations, but allows more timely access to the

data.

Block and list loop operations process data in blocks. Your program gets called only when an

entire block of data has been acquired. These modes are more efficient than scan loop, but give

less frequent access to the incoming data.

Principles of Operation

19

Block and list loop operations are very similar in operation. The main difference is that block

loop uses only two block buffers, which are automatically allocated and managed, while list

loop uses a linked list of as many buffers as you want, but your program must allocate and

free each buffer appropriately.

Scan Loop Operations

Use software to start a scan loop operation. When it detects a trigger event, the module

continuously acquires an input scan record and/or outputs an output scan record on each

pulse of the sample clock, until you stop the operation. Refer to page 17 for more information

on input and output scan records.

The sample rate is determined by the frequency of the sample clock and is the rate at which a

single input scan record is acquired and a single output scan record is output; refer to page 14

for more information on the sample clock.

Block Loop Operations

Use software to start a block loop operation. When it detects a trigger event, the module

continuously acquires input blocks and/or outputs output blocks until you stop the

operation.

Each input block consists of the following information:

• Input scan records; refer to page 17 for more information on input scan records

• The number of scans in each block

• A flag that indicates whether or not the block is full

• A pointer to the next block

Each output block consists of the following information:

• Output scan records; refer to page 17 for more information on output scan records

• The number of scans in each block

• A flag that indicates whether or not the block is full

• A pointer to the next block

List Loop Operations

To perform a list loop operation, use software to allocate a linked list of input and/or output

blocks, and start the list loop operation. When it detects a trigger event, the module acquires

lists of input blocks and/or outputs lists of output blocks. Each list contains a specified

number of input and/or output blocks. Refer to page 19 for more information on input and

output blocks.

You can specify whether to stop the operation when the number of blocks have been filled (for

an input operation) or emptied (for an output operation) or whether to continue the operation

starting by overwriting the first block in the list.

When you are finished acquiring and/or outputting data, you can use software to stop a

continuous operation and free the previously allocated memory.

Chapter 1

20

Triggers

A trigger is an event that occurs based on a specified set of conditions. Using software, you

can specify these conditions by selecting one of the following trigger sources:

•Software trigger – The trigger event occurs immediately when you start the operation

(the computer issues a write to the module to begin conversions).

Note: If you are using the Scalable Bus to connect multiple modules and you want to use

an internal trigger to trigger the master and slave modules, no extra wiring is required.

The internal trigger signal is provided to the slave modules through the Scalable Bus

cables and connectors. Refer to page 21 for more information on using the Scalable Bus.

•External trigger – The trigger event occurs when the module detects a low to high

transition on the TTL-level signal connected to the external input of the module. For the

DT9841E module, connect the external trigger to pin 24 of connector J1. For all other

modules, connect the external trigger to the Ext Trig BNC on the module. This trigger

asserts EXT_INT4 for processing.

Note: If you are using the Scalable Bus to connect multiple modules and you want to

externally trigger the master and slave modules at the same time, you must supply an

external trigger signal to the master and each slave module using external wiring. The

external trigger signals is not provided through the Scalable Bus cable and connectors.

Refer to page 21 for more information on using the Scalable Bus.

When the DT9840 Series module detects the specified trigger event, the input and/or output

operation starts at the clock frequency of the specified clock source.

Figure 2 illustrates acquisition using an external trigger source. In this example, an input scan

record is acquired on each pulse of the selected clock source when the external trigger event

occurs.

Figure 2: Acquisition Using an External Trigger

The module detects a low-to-high transition on the

TTL-level signal attached to the Ext Trig BNC. Data

is acquired on each pulse of the sample clock.

Scan 1

Scan 2

Scan 3 Scan 4

Scan 5

Scan 6 Scan 7

Scan 8

Scan 9

Sample

Clock

This manual suits for next models

5

Table of contents

Popular Signal Processor manuals by other brands

West Mountain Radio

West Mountain Radio CLRstereo ClearSpeech operating manual

Euphonix

Euphonix DF64 Digital Frame manual

Radial Engineering

Radial Engineering JDI Duplex user guide

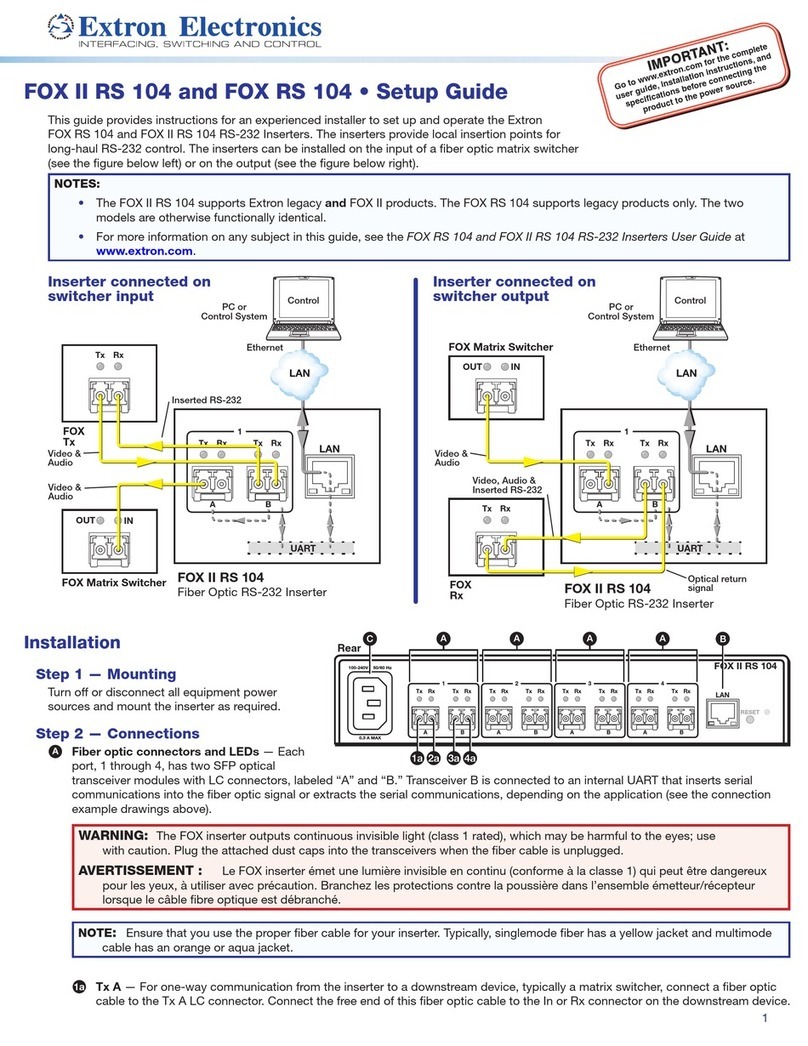

Extron electronics

Extron electronics FOX II RS 104 Setup guide

BSS Audio

BSS Audio Prosys PS-8810 user manual

CYP

CYP CPLUS-V11SE8 Operation manual