Datakom DKG-705 User manual

Tel: +90-216 466 84 60

Fax: +90-216 364 65 65

DKG-705 AUTOMATIC MAINS FAILURE AND

REMOTE START UNIT

WITH PARALLEL TO MAINS

AND DUAL GENSET PARALLEL FEATURES

FEATURES

Automatic mains failure,

Remote start operation,

Engine control,

Generator protection,

Built in alarms and warnings,

Programmable analogue inputs: 4

Programmable digital inputs: 8

Programmable relay outputs: 7

I/O expansion capability,

LCD display 4 lines by 20 characters,

Periodic maintenance request indicator,

True RMS AC measurements,

Built-in exerciser,

Remote Start capability,

Statistical counters,

Event logging,

Field adjustable parameters,

Governor and AVR control outputs,

No break transfer,

Soft transfer,

Paralleling with the mains,

Peak lopping (peak shaving),

Load shedding,

Dual genset parallel with load sharing,

G-59 protections,

Remote monitoring (MS-Windows based),

RS-232 serial port,

Software downloadable from serial port,

Survives cranking dropouts,

Sealed front panel.

VERSION: 01.16 DATE: 20-02-2006

DATAKOM DKG-705 User’s Manual

705_USER.doc - 2 -

TABLE OF CONTENTS

Section

1. INSTALLATION

1.1. Introduction to the Control Panel

1.2. Mounting the Unit

1.3. Wiring the Unit

2. INPUTS AND OUTPUTS

3. DISPLAYS

3.1. Led Displays

3.2. Digital Display

3.3. Service Request Display

4. ALARMS

4.1. Shutdown Alarms

4.2. Load Dump Alarms

4.3. Warnings

5. MODES OF OPERATION

5.1. External switching of the operation mode

5.2. Remote start operation

6. SYNCHRONIZING WITH MAINS

6.1 Governor Control

6.2. AVR Control

7. LOAD TRANSFER MODES

7.1 Transfer with Interruption

7.2 No Break Transfer

7.3 Soft Transfer

8. PARALLELING WITH MAINS: PEAK LOPPING

9. DUAL GENSET PARALLEL OPERATION

10. PROTECTION FUNCTIONS FOR PARALLEL WITH MAINS

11. LOAD SHEDDING / DUMMY LOAD

12. WEEKLY OPERATION SCHEDULE

13. BUILT-IN EXERCISER

14. EVENT LOGGING

15. STATISTICAL COUNTERS

16. MAINTENANCE

17. SOFTWARE DOWNLOAD

18. PROGRAMMING

19. TROUBLESHOOTING

20. DECLARATION OF CONFORMITY

21. TECHNICAL SPECIFICATIONS

22. CONNECTION DIAGRAM

DATAKOM DKG-705 User’s Manual

705_USER.doc - 3 -

1. INSTALLATION

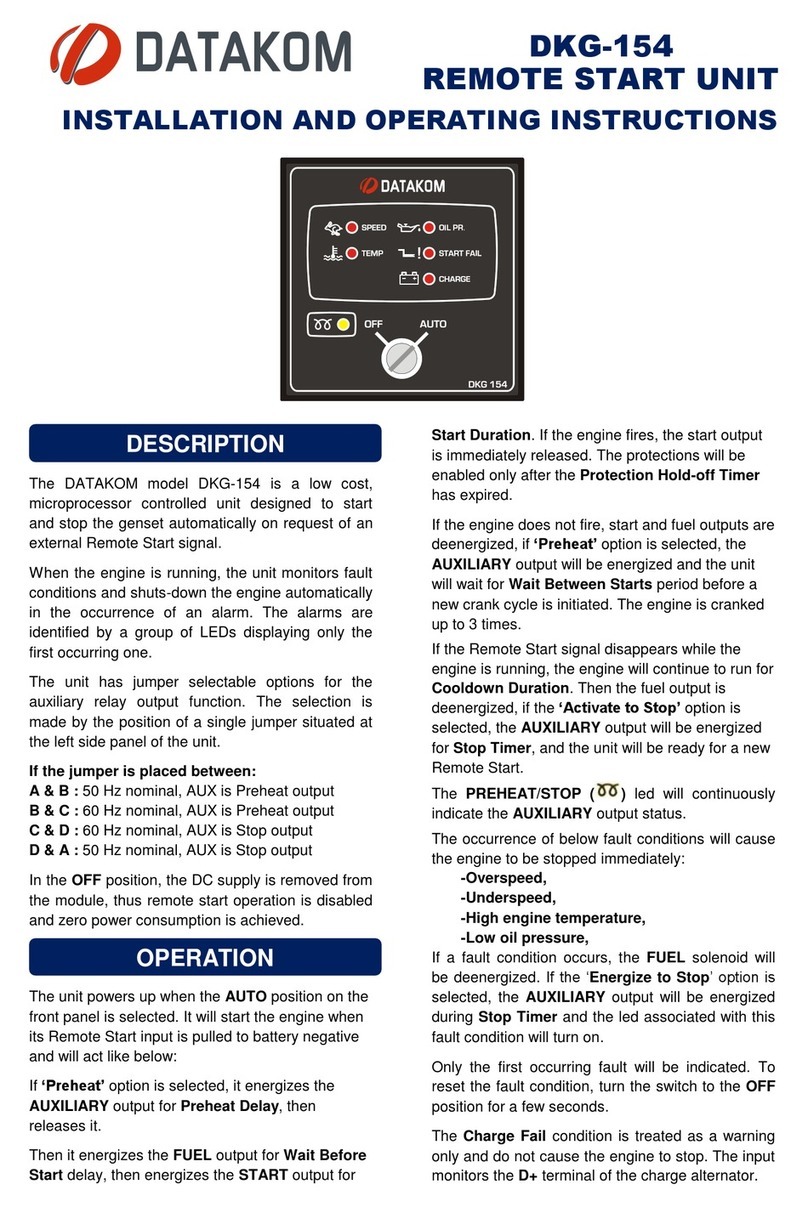

1.1 Introduction to the Control Panel

The DKG-705 is a control and protection unit used in gensets. The 4 lines by 20 characters LCD

display allows the visualization of many measured parameters. The unit is designed to provide user

friendliness for both the installer and the user. Programming is usually unnecessary, as the factory settings

have been carefully selected to fit most applications. However programmable parameters allow the

complete control over the generating set. Programmed parameters are stored in a Non Volatile Memory

and thus all information is retained even in the event of complete loss of power.

The measurable parameters are:

Mains voltage phase R to neutral

Mains voltage phase S to neutral

Mains voltage phase T to neutral

Mains voltage phase R-S

Mains voltage phase S-T

Mains voltage phase T-R

Mains current phase R (optional)

Mains current phase S (optional)

Mains current phase T (optional)

Mains frequency

Mains KW phase R (optional)

Mains KW phase S (optional)

Mains KW phase T (optional)

Mains KVA phase R (optional)

Mains KVA phase S (optional)

Mains KVA phase T (optional)

Mains KVAr phase R (optional)

Mains KVAr phase S (optional)

Mains KVAr phase T (optional)

Mains cosΦphase R (optional)

Mains cosΦphase S (optional)

Mains cosΦphase T (optional)

Mains total KW (optional)

Mains total KVA (optional)

Mains total KVAr (optional)

Mains total cosΦ(optional)

Gen voltage phase U to neutral

Gen voltage phase V to neutral

Gen voltage phase W to neutral

Gen voltage phase U-V

Gen voltage phase V-W

Gen voltage phase W-U

Gen current phase U

Gen current phase V

Gen current phase W

Gen frequency

Gen KW phase U

Gen KW phase V

Gen KW phase W

Gen KVA phase U

Gen KVA phase V

Gen KVA phase W

Gen KVAr phase U

Gen KVAr phase V

Gen KVAr phase W

Gen cosΦphase U

Gen cosΦphase V

Gen cosΦphase W

Gen total KW

Gen total KVA

Gen total KVAr

Gen total cosΦ

Synchronoscope phase angle

Voltage match U-R

Battery voltage,

Engine RPM

Coolant temperature

Oil pressure

Oil temperature

Fuel level

DATAKOM DKG-705 User’s Manual

705_USER.doc - 4 -

1.2 Mounting the Unit

The unit is designed for panel mounting. The user should not be able to access parts of the unit

other than the front panel.

Mount the unit on a flat, vertical surface. The unit fits into a standard panel meter opening of 188x140

millimeters. Before mounting, remove retaining steel springs from the unit, then pass the unit through the

mounting opening. The unit will be maintained in its position by the steel springs.

The DKG-705 is factory set for 24V-DC operation. If the unit is used in a 12V-DC system, the 12V

jumper terminals must be short-circuited.

Do not operate a 12V-DC unit with a 24V-DC system. This

may cause the destruction of the unit. Always disconnect

the voltage selector jumper of a stocked unit.

The engine body must be grounded for correct operation of the unit. Otherwise incorrect voltage and

frequency measurements may occur, resulting in faulty operation of the genset.

The output of the current transformers shall be 5 Amperes. The input current rating of the current

transformers may be selected as needed (between 50/5 and 5000/5 amps). Current transformer outputs shall

be connected by separate cable pairs from each transformer, to related DKG-705 inputs. Never use common

terminals or grounding. The power rating of the transformer should be at least 5 Watts. It is recommended to

use 1% precision transformers.

If analogue sensors (e.g. temperature, oil pressure, oil temperature or fuel level) are connected to

DKG-705, it is not possible to use auxiliary displays. If temperature or oil pressure displays are already present

on the generator control panel, do not connect the sensors to the DKG-705. The unit is factory programmed

for VDO type sensors. However if a different type of sensor is to be used, it is possible to recalibrate the unit.

The calibration process will be explained later in this document.

The programmable digital inputs are compatible with both ‘normally open’ and ‘normally closed’

contacts, switching either to BAT- or BAT+.

The charge alternator connection terminal provides also the excitation current, thus it is not necessary

to use an external charge lamp.

DATAKOM DKG-705 User’s Manual

705_USER.doc - 5 -

1.3 Wiring the Unit

WARNING: THE UNIT IS NOT FUSED.

Use external fuses for

Mains phases: R-S-T

Generator phase: U-V-W

Battery positive: BAT(+).

Install the fuses as nea

rly as possible to

the unit in a place easily accessible for the user.

The fuse rating should be 6 Amps.

WARNING: ELECTRICITY CAN KILL

ALWAYS disconnect the power BEFORE connecting the unit.

1) ALWAYS remove the plug connectors when inserting wires with a screwdriver.

2) ALWAYS refer to the National Wiring Regulations when conducting installation.

3) An appropriate and readily accessible set of disconnection devices (e.g.

automatic fuses) MUST be provided as part of the installation.

4) The disconnection device must NOT be fitted in a flexible cord.

5) The building mains supply MUST incorporate appropriate short-circuit backup

protection (e.g. a fuse or circuit breaker) of High Breaking Capacity (HBC, at

least 1500A).

6) Use cables of adequate current carrying capacity (at least 0.75mm

2

) and

temperature range.

DATAKOM DKG-705 User’s Manual

705_USER.doc - 6 -

2. INPUTS AND OUTPUTS

12V JUMPER: When this jumper is placed, 12V-DC operation is selected. Do not operate a 12V-DC unit with

a 24V-DC system. This may cause the destruction of the unit. Always disconnect the voltage selector jumper

of a stocked unit.

RS-232 SERIAL PORT: This connector provides serial data input and output for various purposes like

software update, remote monitoring, remote control, remote programming, etc.

EXTENSION CONNECTOR (OPTIONAL): This connector is intended for the connection of input and output

extension modules. The optional relay extension module provides 8 programmable 16A relay outputs. The

DKG-705 allows the use of up to 2 I/O extension modules.

Term Function Technical data Description

1 GENERATOR CONTACTOR Relay output, 10A-AC

This output provides energy to the generator

contactor. If the generator phases do not have

acceptable voltage or frequency values, the

generator contactor will be de-energized. In

standard genset applications, in order to

provide extra security, the normally closed

contact of the mains contactor should be

serially connected to this output. In ‘no break

transfer’ or ‘parallel with mains’

applications, this output will drive directly the

generator contactor.

2 U

3 V

4 W

Generator phase

inputs, 0-300V-AC

Connect the generator phases to these inputs.

The generator phase voltages upper and

lower limits are programmable.

5 GENERATOR NEUTRAL Input, 0-300V-AC Neutral terminal for the generator phases.

6 MAINS NEUTRAL Input, 0-300V-AC Neutral terminal for the mains phases.

7 T

8 S

9 R

Mains phase inputs,

0-300V-AC

Connect the mains phases to these inputs.

The mains voltages upper and lower limits are

programmable.

10 MAINS CONTACTOR Relay output, 10A-AC

This output provides energy to the mains

contactor. If the mains phases do not have

acceptable voltage or frequency values, the

mains contactor will be de-energized. In

standard genset applications, in order to

provide extra security, the normally closed

contact of the generator contactor should be

serially connected to this output. In ‘no break

transfer’ or ‘parallel with mains’

applications, this output will drive directly the

mains contactor.

DATAKOM DKG-705 User’s Manual

705_USER.doc - 7 -

Term Function Technical data Description

11 CURR_W+

12 CURR_W-

13 CURR_V+

14 CURR_V-

15 CURR_U+

16 CURR_U-

Current transformer

inputs, 5A-AC

Connect the generator current transformer

terminals to these inputs. Do not connect the

same current transformer to other units than

DKG-705 otherwise a unit fault will occur.

Connect each terminal of the transformer to

the unit’s related terminal. Do not use

common terminals. Do not use grounding.

Correct polarity of connection is vital. If the

measured power is negative, then change the

polarity of each 3 current transformers. The

rating of the transformers should be the same

for each of the 3 phases. The secondary

winding rating shall be 5 Amperes. (For ex.

200/5 Amps).

17 COOLANT TEMP. SENSOR Input, 0-5000 ohms Analogue temperature sensor connection. Do

not connect the sensor to other devices.

18 OIL PRESSURE SENSOR Input, 0-5000 ohms Analogue oil pressure sensor connection. Do

not connect the sensor to other devices.

19 FUEL LEVEL SENSOR Input, 0-5000 ohms Analogue fuel level sensor connection. Do not

connect the sensor to other devices.

20 OIL TEMP. SENSOR Input, 0-5000 ohms Analogue oil temperature sensor connection.

Do not connect the sensor to other devices.

Term Function Technical data Description

21 PROGRAM LOCK Digital input This input is used to prevent unwanted

modification to programmed values. If this

input is left open, program values can be

modified via the front panel buttons, but if this

input is connected to battery- it will not be

possible to change the program values.

22 DIGITAL INPUT-7

23 DIGITAL INPUT-6

24 DIGITAL INPUT-5

25 DIGITAL INPUT-4

26 DIGITAL INPUT-3

27 DIGITAL INPUT-2

28 DIGITAL INPUT-1

29 DIGITAL INPUT-0

Digital inputs These inputs have programmable functions,

selectable from a list via the program menu.

Each input may be driven by a ‘normally

closed’ or ‘normally open’ contact, switching

either battery+ or battery-. The effect of the

switch is also selectable from a list. See

PROGRAMMING section for more details.

DATAKOM DKG-705 User’s Manual

705_USER.doc - 8 -

Term Function Technical data Description

30 GROUND O VDC Power supply negative connection.

31 CHARGE Input and output Connect the charge alternator’s D+ terminal

to this terminal. This terminal will supply the

excitation current and measure the voltage of

the charge alternator.

32 RELAY-6 (FUEL RELAY) Output 10A/28VDC This relay is normally used for fuel solenoid

control. It is internally connected to terminal 31

for supplying the charge alternator’s excitation

current.

33 RELAY-2 (CRANK RELAY) Output 10A/28VDC This relay has programmable function,

selectable from a list. However it is generally

used as engine crank output.

34 BATTERY POSITIVE +12 or 24VDC The positive terminal of the DC Supply shall

be connected to this terminal. The unit

operates on both 12V and 24V battery

systems, depending on the voltage selection

jumper. Do not operate a 12V-DC unit with a

24V-DC system. This may cause the

destruction of the unit. Always disconnect

the voltage selector jumper of a stocked unit.

35 RELAY-7 (STOP RELAY) Output 10A/28VDC

36 RELAY-1 (PREHEAT) Output 10A/28VDC

37 RELAY-3 (ALARM RELAY) Output 10A/28VDC

These relays have programmable functions,

selectable from a list.

Term Function Technical data Description

38 CURR_R+

39 CURR_R-

40 CURR_S+

41 CURR_S-

42 CURR_T+

43 CURR_T-

Current transformer

inputs, 5A-AC

Connect the mains current transformer

terminals to these inputs. Do not connect the

same current transformer to other units than

DKG-705 otherwise a unit fault will occur.

Connect each terminal of the transformer to

the unit’s related terminal. Do not use

common terminals. Do not use grounding.

Correct polarity of connection is vital. If the

measured power is negative, then change the

polarity of each 3 current transformers. The

rating of the transformers should be the same

for each of the 3 phases. The secondary

winding rating shall be 5 Amperes. (For ex.

200/5 Amps).

Term Function Technical data Description

44 MAGNETIC PICKUP

45 MAGNETIC PICKUP

Inputs, 0.5-70V

0-20KHz

Connect the magnetic pickup signal to these

inputs.

46 AVR CONTROL

47 AVR CONTROL

Output,

isolated resistor,

300-100,000 ohms.

AVR voltage control outputs. Connect to the

external adjust potentiometer terminals of the

AVR. The polarity is not important.

48 GOVERNOR CONTROL Output, 0-10VDC Connect this output to the terminal ‘J’ or ‘EXT’

of the speed governor.

DATAKOM DKG-705 User’s Manual

705_USER.doc - 9 -

3. DISPLAY

3.1 Led Displays

The DKG-705 has 12 leds, divided in 3 groups:

-Group_1: Operating mode: This group indicates the genset function.

-Group_2: Mimic diagram: This group indicates the current status of the mains and

genset

voltages and contactors.

-Group_3: Warnings and alarms: This group indicates the existency of abnormal conditions

encountered during operation.

Function Color Description

MAINS ON Green The LED will turn on when all 3 mains phase voltages

and the mains frequency are within the limits.

MAINS OFF Red The LED will turn on when at least one of the mains

phase voltages or the mains frequency are outside

limits.

GENERATOR Yellow The LED will turn on when all 3 generator phase

voltages are within the programmed limits.

LOAD GENERATOR Yellow It turns on when the generator contactor is activated.

LOAD MAINS Green It turns on when the mains contactor is activated.

LOAD TEST Yellow

TEST Yellow

OFF Green

AUTO Green

It turns on when the related operation mode is

selected. One of these LEDs is always on and

indicates which operation mode is selected.

If the operation of the genset is disabled by the

weekly operation schedule, then the AUTO led will

flash.

ALARM Red It turns on when an engine shutdown or load_dump

condition is occurred.

WARNING Red It turns on when an engine shutdown or load_dump

or warning condition is occurred.

SERVICE REQUEST Red Engine periodic maintenance request indicator. It

turns on when the preset engine hours or time

duration after previous service has elapsed.

DATAKOM DKG-705 User’s Manual

705_USER.doc - 10 -

3.2 Digital Display

The digital display is of LCD type, with 4 lines by 20 characters.

It shows:

-The software version and release date,

-The genset status,

-Measured parameters,

-Alarm information,

-Date and time,

-Service counters,

-Statistical counters,

-Logged events,

-Program parameters.

During power on, the display shows the software version and the release date for 1 seconds.

The display has basically two modes:

-Normal operation,

-Programming mode.

The programming mode will be explained later in this document.

The display is driven by a menu system. The display has many different screens, divided into 3

main groups.

The navigation between different screens in a group is made with the MENU button. Holding the

MENU button pressed for 1 second makes the display to switch to the next group.

During operation, the DKG-705 will switch automatically between different screens, displaying

each time the most important screen for the given situation.

If an alarm or warning occurs during operation other then programming mode, the display will

automatically switch to ALARM LIST position. The MENU button will not allow to switch to other modes.

To enable display navigation, press ALARM MUTE button.

The display has a backlight illumination feature. The backlight turns on with the depression of

any button. It turns off after 1 minute to allow power economy. Also note that the backlight will turn off

during engine cranking.

Group

Screen

Description Contents

1 1 Mains parameters Genset status

Voltage R (or RS), current R, Mains Frequency

Voltage S (or ST), current S

Voltage T (or TR), current T

1 2 Mains parameters Genset status

Voltage RS (or R), current R, Mains Frequency

Voltage ST (or S), current S

Voltage TR (or T), current T

1 3 Basic genset parameters

Genset status

Voltage U (or UV), current U, Genset Frequency

Voltage V (or VW), current V, Genset Active Power (KW)

Voltage W (or WU), current W, Genset Power Factor (cosΦ)

1 4 Basic genset parameters

Genset status

Voltage UV (or U), current U, Genset Frequency

Voltage VW (or V), current V, Genset Active Power (KW)

Voltage WU (or W), current W, Genset Power Factor (cosΦ)

DATAKOM DKG-705 User’s Manual

705_USER.doc - 11 -

Group

Screen

Description Contents

1 5 Engine parameters Engine rpm, Battery Voltage

Coolant Temperature, Fuel Level

Oil Temperature, Oil Pressure

1 6 Genset power Genset Active Power (KW) , Genset Frequency

Genset Apparent Power (KVA), Genset Power Factor

(cosΦ

ΦΦ

Φ)

Genset Reactive Power (KWr)

1 6 Alarm list If no alarm exists this screen will display ‘END OF ALARM

LIST’. Existing alarms, load_dumps and warnings will be

displayed as one screen for each entry. Switching to the

next entry will be made with the MENU button.

Group

Screen

Description Contents

2 1 Genset phase U parameters Phase to Neutral Voltage, Phase Active Power (KW)

Phase Current , Phase Apparent Power (KVA)

Phase Power Factor, Phase Reactive Power (KWr)

2 2 Genset phase V parameters Phase to Neutral Voltage, Phase Active Power (KW)

Phase Current , Phase Apparent Power (KVA)

Phase Power Factor, Phase Reactive Power (KWr)

2 3 Genset phase W parameters Phase to Neutral Voltage, Phase Active Power (KW)

Phase Current , Phase Apparent Power (KVA)

Phase Power Factor, Phase Reactive Power (KWr)

2 4 Synchronoscope Governor Output (%)I AVR Output(%)

Voltage RU, Phase Angle (degrees)

Phase U Voltage, Genset Frequency

Phase R Voltage, Mains Frequency

2 5 Soft transfer parameters Remaining Duration

Governor Output (%), AVR Output(%)

Genset Active Power (KW), Gen. Reactive Power (KWr)

Target Active Power (KW), Target React. Power (KWr)

2 6 Date, time, engine hours Date, Time

Engine Hours Run

2 7 Service display Time to Service

Engine Hours to Service

2 8 Total power counters Total Genset Active Power (KW-h)

Total Genset Apparent Power (KVA-h)

Total Genset Reactive Power (KWr-h)

2 9 Statistical counters Total Engine Cranks

Total Genset Runs

Total Genset on Load

2 10 Mains phase R parameters Phase to Neutral Voltage, Phase Active Power (KW)

Phase Current , Phase Apparent Power (KVA)

Phase Power Factor, Phase Reactive Power (KWr)

2 11 Mains phase S parameters Phase to Neutral Voltage, Phase Active Power (KW)

Phase Current , Phase Apparent Power (KVA)

Phase Power Factor, Phase Reactive Power (KWr)

2 12 Mains phase T parameters Phase to Neutral Voltage, Phase Active Power (KW)

Phase Current , Phase Apparent Power (KVA)

Phase Power Factor, Phase Reactive Power (KWr)

Group Screen

Description Contents

3 1…32 Event logging This group comprises 32 screens, each screen

displaying one recorded event, starting from the most

recent one.

DATAKOM DKG-705 User’s Manual

705_USER.doc - 12 -

3.3 Service Request Display

This led is designed to help the periodic maintenance of the genset to be made consistently.

The periodic maintenance is basically carried out after a given engine hours (for example 200 hours),

but even if this amount of engine hours is not fulfilled, it is performed after a given time limit (for example 365

days).

The SERVICE REQUEST led has no effect on the genset

operation.

The DKG-705 has both programmable engine hours and maintenance time limit. The engine hours is

programmable between 0 and 2500 hours with 10-hour steps (P_624), the time limit is programmable between

0 and 2500 days with 10 day steps (P_625). If any of the programmed values is zero, this means that the

parameter will not be used. For example a maintenance period of 0 days indicates that the DKG-705 will

request maintenance only based on engine hours. There will be no time limit. If the engine hours is also

selected as 0 hours this will mean that the SERVICE REQUEST display will be inoperative.

The remaining engine hours and the remaining time limit are kept stored in a non-volatile memory and

are not modified by power supply failures. The remaining engine hours and time to service may be checked on

the LCD display. (group_2, screen_7)

When the engine hours OR the time limit is over, the SERVICE REQUEST led (red) will start to flash.

To turn off the led, select programming mode, enter factory password and set the parameter_600 to 1, then

check the remaining time and engine hours to service using group_2, screen_7.

DATAKOM DKG-705 User’s Manual

705_USER.doc - 13 -

4. ALARMS

Alarms indicate an abnormal situation in the generating set.

The alarms are divided into 3 priority level:

1- SHUTDOWN ALARMS: These are the most important alarm conditions and cause:

-The genset contactor to be released immediately,

-The engine to be stopped immediately,

-The alarm relay output to operate,

-The ALARM led to turn on,

-The LCD display to switch to alarm display mode (except when programming).

2- LOAD DUMP ALARMS: These conditions cause:

-The genset contactor to be released immediately,

-The engine to be stopped after the cooldown cycle,

-The alarm relay output to operate,

-The ALARM led to turn on,

-The LCD display to switch to alarm display mode (except when programming)

3- WARNINGS: These conditions cause:

-The alarm relay output to operate,

-The WARNING led to turn on.

Most of the alarms are of LATCHING type. Even if the alarm condition is removed, the alarms will stay

on and disable the operation of the genset.

The existing alarms may be canceled by pressing one of the operating mode buttons (LOAD TEST /

TEST / OFF / AUTO) or by pressing the ALARM MUTE button twice.

If the ALARM MUTE button is pressed, the alarm relay output will be deactivated; however the

existing alarms will persist and disable the operation of the genset.

Most of the alarms have programmable trip levels. See the programming chapter for settable alarm

limits.

The digital inputs are programmable and may be set to provide a large variety of alarms and warnings.

See the programming chapter for digital input programming.

The alarms may be cancelled either by pressing any of the front panel mode selection buttons or by a

change in external mode force inputs.

DATAKOM DKG-705 User’s Manual

705_USER.doc - 14 -

4.1 Shutdown Alarms

Definition Source Description

Low Oil Pressure Switch Digital Input

High Eng.Temp.Switch Digital Input

Emergency Stop Digital Input

Low Coolant Level Digital Input

Alternator High Temp. Digital Input

High Oil Temp. Digital Input

Overload Digital Input

Low Fuel Level Digital Input

Battery Charger Fail Digital Input

Spare Alarm 7 Digital Input

Spare Alarm 6 Digital Input

Spare Alarm 5 Digital Input

Spare Alarm 4 Digital Input

Spare Alarm 3 Digital Input

Spare Alarm 2 Digital Input

Spare Alarm 1 Digital Input

These shutdown alarms are set depending on the digital input

settings. The related program parameters are P_700 to P_776.

Gen Under-Frequency Phase U Set if the genset frequency goes under the Low Frequency

Shutdown (P_516) limit for Frequency Timer (P_520) period.

Gen Over Frequency Phase U Set if the genset frequency goes over the High Frequency

Shutdown (P_518) limit for Frequency Timer (P_520) period.

High Battery Voltage Battery Set if the battery voltage goes over the High Battery Voltage

Shutdown (P_610) limit.

Low Fuel Level Analog In. Set if the fuel level measured from analog input goes under the Low

Fuel Level Shutdown (P_608) limit.

High Oil Temperature Analog In. Set if the oil temperature measured from analog input goes over the

High Oil Temperature Shutdown (P_606) limit.

High Coolant

Temperature

Analog In. Set if the coolant temperature measured from analog input goes

over the High Coolant Temperature Shutdown (P_604) limit.

Low Oil Pressure

Measured

Analog In. Set if the oil pressure measured from analog input goes under the

Low Oil Pressure Shutdown (P_602) limit.

Fail To Stop Internal Set if the engine is not stopped before the expiration of the Stop

Timer (P_505).

Fail To Start Internal Set if the engine has not started after Start Attempts (P_504)

number of attempts.

Genset Low Voltage U-V-W Set if any of the genset phase voltages goes under the Generator

Low Limit (P_514) voltage.

Genset High Voltage U-V-W Set if any of the genset phase voltages goes over the Generator

High Limit (P_515) voltage.

Slave Unavailable (dual

genset mode)

Serial

Comm.

Set if a shutdown or load dump alarm has occurred in the slave

genset and Single Genset Load Enable parameter (P_A32) is set

to 0.

Gen Phase Sequence

Fail

U-V-W Set if the generator phase sequence is not correct. This alarm may

be cancelled also by programming the Ignore Phase Order

parameter (P_A06) to 1.

Low Engine Speed Magnetic

Pickup

Set if the engine rpm goes under the Low rpm Shutdown (P_613)

limit. If the Crank Teeth Count (P_619) is set to ‘0’, this alarm will

be disabled.

High Engine Speed Magnetic

Pickup

Set if the engine rpm goes over the High rpm Shutdown (P_615)

limit. If the Crank Teeth Count (P_619) is set to ‘0’, this alarm will

be disabled.

Communication Lost

(dual genset mode)

Serial

Comm.

Set if the serial communication between Master and Slave gensets

is interrupted and Single Genset Load Enable parameter (P_A32)

is set to 0.

DATAKOM DKG-705 User’s Manual

705_USER.doc - 15 -

4.2 Load Dump Alarms

Definition Source Description

Low Oil Press.Switch Digital Input

High Eng.Temp.Switch Digital Input

Emergency Stop Digital Input

Low Coolant Level Digital Input

Alternator High Temp. Digital Input

High Oil Temp. Digital Input

Overload Digital Input

Low Fuel Level Digital Input

Battery Charger Fail Digital Input

Spare Alarm 7 Digital Input

Spare Alarm 6 Digital Input

Spare Alarm 5 Digital Input

Spare Alarm 4 Digital Input

Spare Alarm 3 Digital Input

Spare Alarm 2 Digital Input

Spare Alarm 1 Digital Input

These load dump alarms are set depending on the digital input

settings. The related program parameters are P_700 to P_776.

Gen Reverse Power Internal Set if the genset consumes active power (KW) from the mains and

this power goes over the Reverse Power Load Dump (P_618)

limit.

Gen Excess Power Internal Set if the genset power (KW) supplied to the load goes over the

Excess Power Load Dump (P_617) limit for Overcurrent / Excess

Power Timer (P_511).

Alternator Overcurrent Internal Set if at least one of the genset phase currents goes over the

Overcurrent Limit (P_510) for Overcurrent / Excess Power

Timer (P_511).

DATAKOM DKG-705 User’s Manual

705_USER.doc - 16 -

4.3 Warnings

Definition Source Description

Low Oil Press.Switch Digital Input

High Eng.Temp.Switch Digital Input

Emergency Stop Digital Input

Low Coolant Level Digital Input

Alternator High Temp. Digital Input

High Oil Temp. Digital Input

Overload Digital Input

Low Fuel Level Digital Input

Battery Charger Fail Digital Input

Spare Alarm 7 Digital Input

Spare Alarm 6 Digital Input

Spare Alarm 5 Digital Input

Spare Alarm 4 Digital Input

Spare Alarm 3 Digital Input

Spare Alarm 2 Digital Input

Spare Alarm 1 Digital Input

These warnings are set depending on the digital input settings. The

related program parameters are P_700 to P_776.

Synchronization Fail Internal Set if the phase and voltage synchronization is not successful

before the expiration of Synchronization Fail Timeout (P_A07).

Gen Under-Frequency Phase-U Set if the genset frequency goes under the Low Frequency

Warning (P_517) limit for Frequency Timer (P_520) period.

Gen Over-Frequency Phase-U Set if the genset frequency goes over the High Frequency

Warning (P_519) limit for Frequency Timer (P_520) period.

High Battery Voltage Internal Set if the battery voltage goes over the High Battery Voltage

Warning (P_611) limit.

Low Fuel Level Analog

Input

Set if the fuel level measured from analog input goes under the Low

Fuel Level Warning (P_609) limit.

High Oil Temperature Analog

Input

Set if the oil temperature measured from analog input goes over the

High Oil Temperature Warning (P_607) limit.

High Coolant

Temperature

Analog

Input

Set if the coolant temperature measured from analog input goes

over the High Coolant Temperature Warning (P_605) limit.

Low Oil Pressure

Measured

Analog

Input

Set if the oil pressure measured from analog input goes under the

Low Oil Pressure Warning (P_603) limit.

Mains Phase Sequence

Fail

R-S-T Set if the mains phase sequence is not correct and Ignore Phase

Order (P_A06) parameter is ‘0’.

Charge Failure Charge

input

Set if the Charge input (terminal_31) is pulled to battery negative

when the engine is running.

Low Battery Voltage Internal Set if the battery voltage goes under the Low Battery Voltage

Warning (P_612) limit.

AVR Control Fail Internal Set if the AVR control output has gone to the low or high limit

value for 1 second.

GOV Control Fail Internal Set if the GOV control output has gone to the low or high limit

value for 1 second.

Low Engine Speed Magnetic

Pickup

Set if the engine rpm goes under the Low rpm Warning (P_614)

limit. If the Crank Teeth Count (P_619) is set to ‘0’, this warning will

be disabled.

High Engine Speed Magnetic

Pickup

Set if the engine rpm goes over the High rpm Warning (P_616)

limit. If the Crank Teeth Count (P_619) is set to ‘0’, this warning will

be disabled.

DATAKOM DKG-705 User’s Manual

705_USER.doc - 17 -

Definition Source Description

Parallel Mains Fail Internal This general warning is set if any of the protection functions have

detected a mains failure during parallel with mains operation.

Mains Reverse Power Internal In parallel with mains operation and after the parallel check

timeout delay (P_A23) has elapsed, this warning will be set if the

mains power is negative and over the reverse power limit defined in

P_A24.

Mains Frequency Fail R In parallel with mains operation and after the parallel check timeout

delay (P_A23) has elapsed, this warning will be set if the mains

frequency is out of the limits defined in P_522 and P_523 for 4

consecutive cycles.

No Mains Frequency R In parallel with mains operation and after the parallel check timeout

delay (P_A23) has elapsed, this warning will be set if the mains

frequency disappears for more than 2,5 periods.

ROCOF (df/dt) Fail R In parallel with mains operation and after the parallel check timeout

delay (P_A23) has elapsed, this warning will be set if the mains

frequency change exceeds the limit defined in P_A25 for 4

consecutive cycles.

Vector Shift (df/dt) Fail R In parallel with mains operation and after the parallel check timeout

delay (P_A23) has elapsed, this warning will be set if the phase of

the mains measured on last 2 cycles jumps over the limit defined

in P_A26 on the phase measured on last 4

th

and 5

th

period.

Communication Lost

(dual genset mode)

Serial

Comm.

Set if the serial communication between Master and Slave gensets

is interrupted and Single Genset Load Enable parameter (P_A32)

is set to 1.

DATAKOM DKG-705 User’s Manual

705_USER.doc - 18 -

5. MODES OF OPERATION

The modes of operation are selected either by pushing the front panel keys or using the external mode

select inputs. External inputs override the front panel selection. If none of the external inputs is active, the unit

resumes to the mode selected by the front panel. Following selected mode, the DKG-705 will have different

behavior.

OFF: In this mode, the mains contactor will be energized if mains phase voltages and frequency are within the

programmed limits. The engine will be stopped.

AUTO: It is used for genset and mains automatic transfer. If at least one of the mains phase voltages or the

mains frequency is outside limits, the mains contactor will be deactivated.

The diesel will be started for programmed times after the wait period. When the engine runs, the crank relay

will be immediately deactivated. The engine will run without load during engine heating period. After this, if

alternator phase voltages and frequency are within limits, the unit will wait for the generator contactor period

and the generator contactor will be energized.

When all the mains phase voltages and the mains frequency are within the limits, the engine will continue to

run for the mains waiting period. At the end of this period the generator contactor is deactivated and the mains

contactor will be energized. If a cooling period is given, the generator will continue to run during cooling period.

At the end of the period, the fuel solenoid will be de-energized and the diesel will stop. The unit will be ready

for the next mains failure.

If the operation of the genset is disabled by the weekly schedule, then the AUTO led will flash, and the

operation of the genset will be as in the OFF mode.

LOAD TEST: It is used to test the genset under load. Once this mode is selected, the engine will run and the

load will be transferred to the genset. The genset will feed the load indefinitely unless another mode is

selected.

TEST: It is used to test the generator when the mains are on, or keep the generator waiting in the emergency

backup mode. The operation of the generator is similar to the AUTO mode, but the mains contactor will not be

deactivated if the mains are not off. If the mains are off, mains contactor will be deactivated and the generator

contactor will be activated. When the mains are on again, a changeover to the mains will be made, but the

engine will be kept running unless another mode is selected. The emergency backup operation may be

prohibited using the program parameter P_629.

5.1 External Switching of the Operation Mode

The Mode of operation of the unit may also be selected by external inputs instead of front panel keys.

For this, at least one of the digital inputs should be programmed as an input to force one of the 4 operating

modes. The corresponding input’s P_7x0 parameter should be set to 18, 19, 20 or 21. The mode selection

signal may be a NO or NC contact, switching to either battery positive or battery negative. These selections

are made using parameters P_7x5 and P_7x6.

The external selection input has a higher level of priority than the front panel keys. Thus if the

operating mode is forced by the external input, this will override the selection made by the front panel keys.

However, when the external selection signal goes off, the unit will resume to the mode selected by the front

panel keys.

If a front panel mode selection key is pressed while the external mode select input is active, then the

key selection will be stored and when the external selection signal goes off, the unit will resume to this mode.

DATAKOM DKG-705 User’s Manual

705_USER.doc - 19 -

5.2. Remote Start Operation

The unit offers the possibility of REMOTE START mode of operation. In this mode the mains

phases are not monitored. If the REMOTE START signal is present then the mains will be supposed to fail,

inversely if the REMOTE START signal is absent, then mains voltages will be supposed to be present. The

front panel mimic diagram’s mains LEDs will reflect the status of the REMOTE START input.

Any of the digital inputs may be programmed as a REMOTE START input. For this the

corresponding input’s P_7x0 parameter should be set to 23. The REMOTE START signal may be a NO or NC

contact, switching to either battery positive or battery negative. These selections are made using parameters

P_7x5 and P_7x6.

DATAKOM DKG-705 User’s Manual

705_USER.doc - 20 -

6. SYNCHRONIZING WITH MAINS

The DKG-705 offers the possibility of synchronizing the genset with the mains.

The synchronization comprises frequency, phase and voltage matching features.

The synchronization properties of the unit are adjusted with program parameters.

These parameters are reserved for factory and qualified installation

personal use and must not be modified by end users or non-qualified

service personal. Otherwise severe damage may occur!

6.1 Governor Control

The frequency and phase matching is made by controlling the engine’s governor module. The

DKG-705 compares the mains phase R with the genset phase U. If the engine does not have a speed

governor it is not possible to make frequency or phase control.

The GOV output (terminal 45) is an analog voltage output of 0-10 VDC. The output impedance is

180 ohms.

The functions of the GOV output are controlled by programmed parameters:

P_A02 GOV Control Enable: This parameter enables/disables the activation of the governor control

output. If governor control is disabled, the output will always stay at the rest level defined by P_A13.

P_A03 GOV Reverse Polarity: In normal polarity, the governor control voltage increases in order to

increase the engine speed. If reverse polarity is selected the governor control voltage decreases in order to

increase the engine speed.

P_A13 Governor Start: This is the rest value of the governor control output. Always set this value to 128,

which is the mid-course, and then adjust the engine speed from the speed governor. However, if needed,

engine speed adjustment may be made through this parameter. Do not forget that, if this parameter is

modified, the adjustment range will be reduced.

P_A15 Frequency Lock Gain: This parameter defines the reaction speed of the governor output to phase

differences between genset and mains phases during synchronization. The standard value for this

parameter is 32. But it must be readjusted for the engine during manufacturing. If this parameter is too

high, a phase oscillation may occur. If it is too low, the phase locking will have a lazy behavior.

Table of contents

Other Datakom Remote Starter manuals

Popular Remote Starter manuals by other brands

ATD Tools

ATD Tools 5928 owner's manual

Firstech

Firstech CM6200 installation manual

RED FUEL

RED FUEL SL161 owner's manual

Directed Electronics

Directed Electronics SmartStart 5000-series owner's guide

Audiovox

Audiovox Prestige 128-7852A owner's manual

Tactical technologies

Tactical technologies TX-500 operating instructions