Datalogic Arex 420 User manual

Other Datalogic Barcode Reader manuals

Datalogic

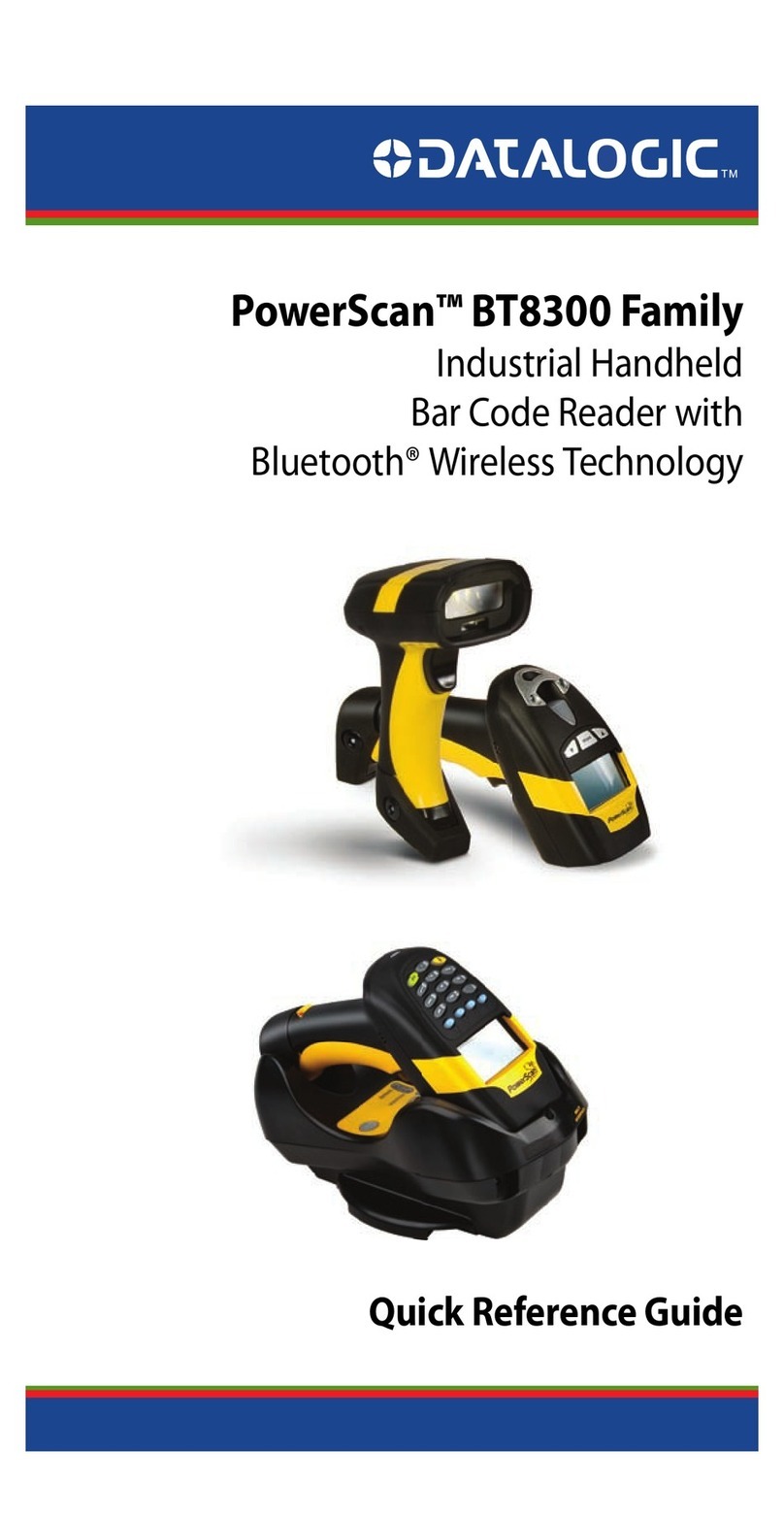

Datalogic PowerScan PD8530 User manual

Datalogic

Datalogic Magellan 1500i User manual

Datalogic

Datalogic QW2120 User manual

Datalogic

Datalogic Gryphon I GM440 Series Installation and operation manual

Datalogic

Datalogic QuickScan Lite QW2400 Installation and operation manual

Datalogic

Datalogic QuickScan QS6500BT User manual

Datalogic

Datalogic DSE0420 Quick setup guide

Datalogic

Datalogic DS6300 User manual

Datalogic

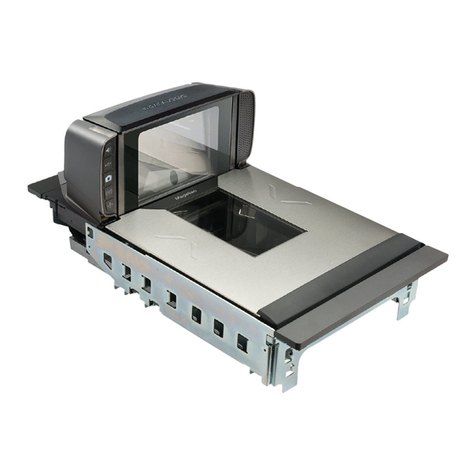

Datalogic MAGELLAN 8400 User manual

Datalogic

Datalogic Gryphon I GBT4100 User manual

Datalogic

Datalogic PowerScan 9501-AR Series Installation and operation manual

Datalogic

Datalogic MAGELLAN 1400I User manual

Datalogic

Datalogic F725-E SERIES User manual

Datalogic

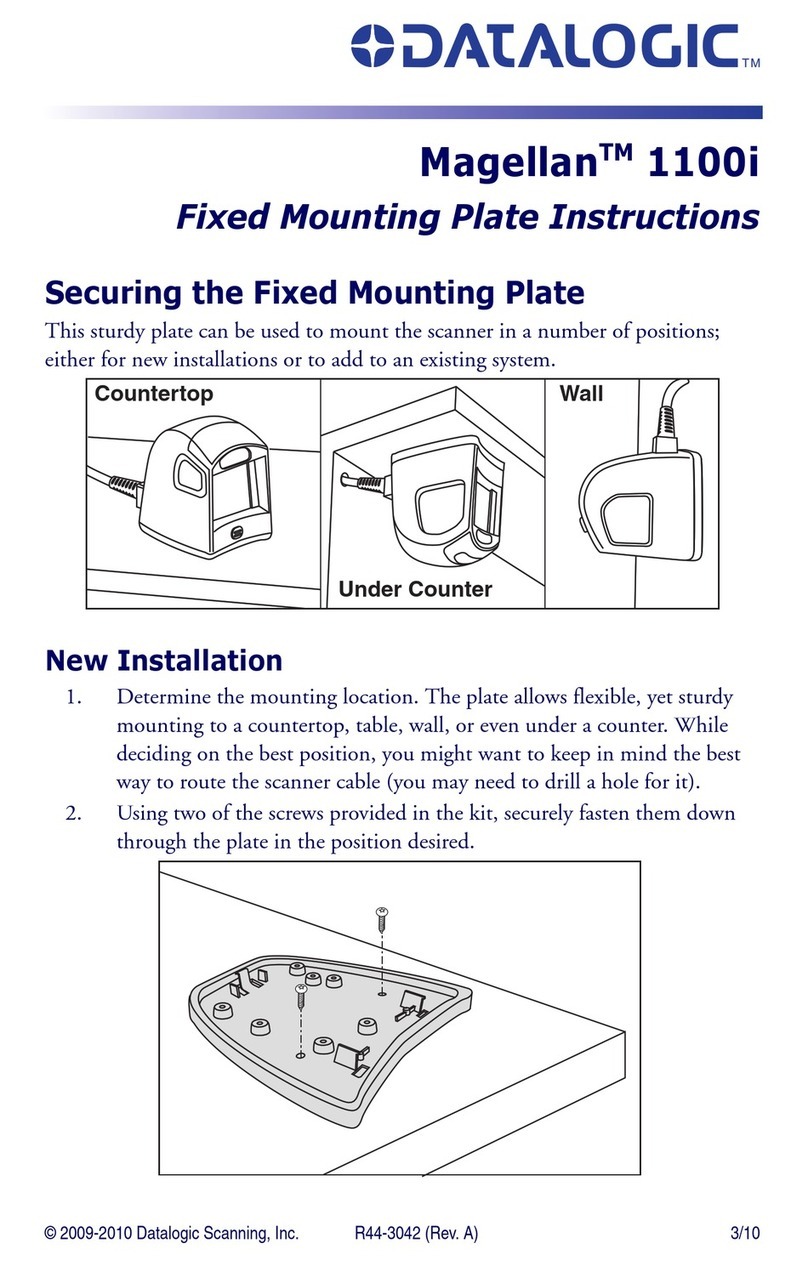

Datalogic Magellan 1100i OEM Use and care manual

Datalogic

Datalogic PowerScan RF User manual

Datalogic

Datalogic DSM0400 Installation and operation manual

Datalogic

Datalogic Matrix 450 User manual

Datalogic

Datalogic GRYPHON BT100 User manual

Datalogic

Datalogic Gryphon D412Plus Installation and operation manual

Datalogic

Datalogic QuickScan QM21 1 Series User manual