Datamatic Firefly User manual

DRAFT 1

DRAFT

©Datamatic, Ltd. 2000 - 2005

Version 2.8.2

FIREFLY

AMR SYSTEM REFERENCE

MANUAL

CONFIDENTIAL AND PROPRIETARY

2000-2004 By Datamatic, Ltd.

All Rights Reserved

3600 K Avenue

Plano, TX 75074

24-Hour Customer Support

(888) 326-5032 or (214) 540-5200

Internet: http://www.datamatic.com

THIS DOCUMENT CONTAINS THE TRADE SECRETS AND PROPRIETARY INFORMATION OF

DATAMATIC, LTD. NEITHER THIS DOCUMENT NOR ANY PART THEREOF MAY BE REPRODUCED

WITHOUT THE EXPRESS WRITTEN CONSENT OF DATAMATIC, LTD., NOR SHALL ANY INFORMATION

CONTAINED HEREIN RELATING TO THE FUNCTIONING OF THE ELECTRONIC METER READING

SYSTEM BE DISCLOSED TO ANYONE WHO DOES NOT HAVE A NEED TO KNOW THE CONTENTS AND

UNDER NO CIRCUMSTANCES SHOULD THIS INFORMATION BE DISCLOSED TO ANY PERSON NOT

EMPLOYED BY THE UTILITY WITHOUT THE EXPRESS WRITTEN CONSENT OF DATAMATIC, LTD.

DRAFT 3

DRAFT

©Datamatic, Ltd. 2000 - 2005

Table of Contents

Chapter 1: System Overview ................................................. 5

System Features................................................................................................5

FIREFLY AMR System Features...................................................................5

Interfacing Options .................................................................................5

Meter Options ...............................................................................................5

Installation Options........................................................................................6

Reading Methodologies ................................................................................6

Customized Programming Options................................................................6

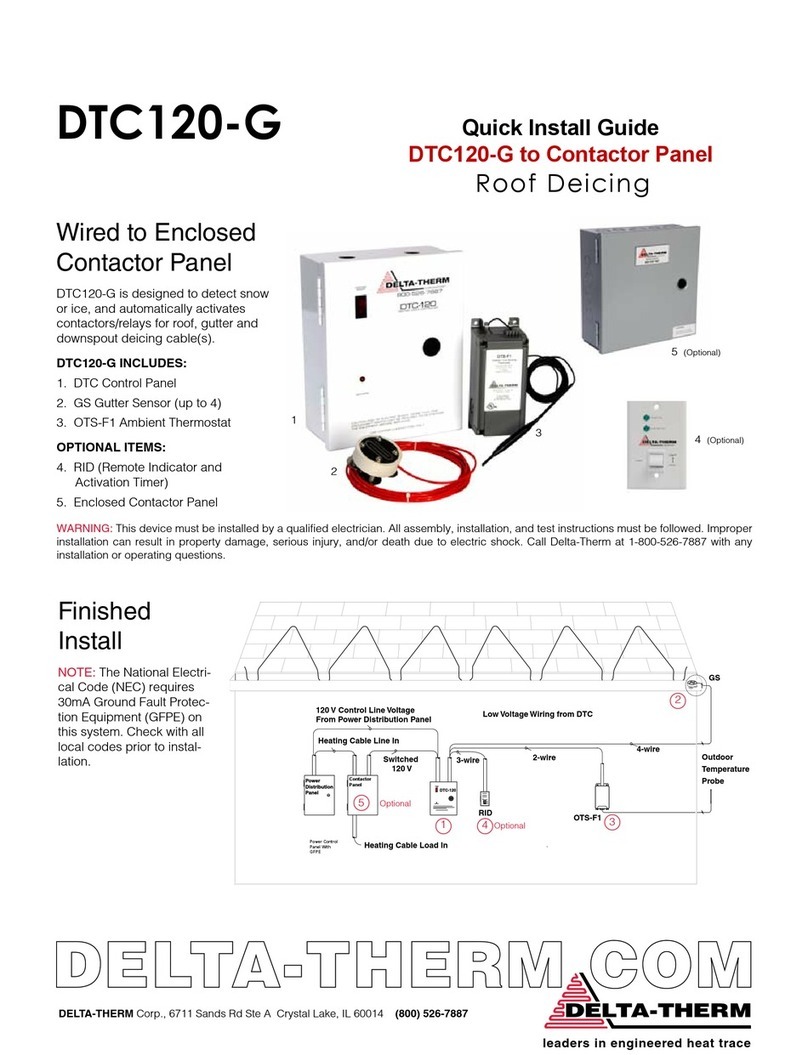

Equipment..........................................................................................................6

ROADRUNNER Handheld Computer............................................................6

Key Descriptions.....................................................................................6

Keyboards............................................................................................10

Radio Frequency Receiving Unit (RFRU)....................................................11

Programming/Profiling Unit (PPU) for Water FIREFLYs..............................11

Programming/Profiling Unit (PPU) Cable.....................................................11

Config Tester (CT) for Water FIREFLYs......................................................11

FIREFLY Meter Interface Unit (MIU) – Water..............................................12

FIREFLY Optical Sensor.............................................................................12

Optical Sensor Tape Specification........................................................12

Installation Preparation.....................................................................................13

Installation Considerations..........................................................................13

Water FIREFLY Installation..............................................................................13

Installing the Optical Sensor-End FIREFLY.................................................13

Meter Preparation.................................................................................13

Background Check for Firmware Version 0210 and Prior Sensor

Firmware Versions Only .......................................................................14

Sensor Flap..........................................................................................14

Sensor Placement................................................................................14

Installing the Wire-end FIREFLY.................................................................15

Installing the Wire-end FIREFLY with a Logical Switch...............................16

Profile Data Extraction with Water FIREFLYs...................................................16

Electric FIREFLY MIU.................................................................................19

Meter Reading......................................................................................19

Demand Data.......................................................................................19

Profile Data...........................................................................................19

Power...................................................................................................19

Electric FIREFLY Specifications...........................................................20

Gas FIREFLY MIU......................................................................................21

Meter Reading......................................................................................21

Profile Data...........................................................................................21

Powering ..............................................................................................21

Gas FIREFLY Specifications ................................................................22

Profile Data Extraction for Gas and Electric FIREFLYs ....................................22

Viewing Profile Data in RouteSTAR MVP.........................................................24

Viewing ProfilePLUS Data via RouteSTAR MVP.........................................24

Viewing Data in ProfilePLUS.......................................................................27

Global Settings Menu ...........................................................................27

DRAFT

4 FIREFLY AMR REFERENCE MANUAL

DRAFT

©Datamatic.com, Ltd. 2000 - 2005

Appendix A: Glossary of Terms ...........................................37

Appendix B: Equipment Maintenance ....................................45

RMA Return Maintenance Authorization ..........................................................45

DRAFT 5

DRAFT

©Datamatic, Ltd. 2000 - 2005

FCC ID: ODYD740, ODYD2200, ODYD2212, ODYD2300,

ODYD2500, and ODYD3000 Datamatic, Ltd.

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

1) This device may not cause harmful interference, and

2) This device must accept any interference received, including

interference that may cause undesired operation.

Notice Specific to FCC ID: ODYD3000 Datamatic, Ltd.

This device must be professionally installed, below grade, in

a meter pit enclosure.

WARNING: These devices operate under Part 15 of the FCC rules.

Modifications to these devices not expressly authorized by

Datamatic, Ltd. may affect your ability to legally operate these

devices.

DRAFT

6 FIREFLY AMR REFERENCE MANUAL

DRAFT

©Datamatic.com, Ltd. 2000 - 2005

1

11

1

Chapter 1: System Overview

This document covers the setup and operation of the FIREFLY Radio Frequency

Automatic Meter Reading (AMR) system, used in conjunction with the RouteSTAR

Meter Reading System (RouteSTAR MVP).

All information presented herein assumes the installation and understanding of the

RouteSTAR MVP software and associated ROADRUNNER ruggedized, handheld

computers. Refer to the ROADRUNNER system manual and Training Guides for

additional information.

The RouteSTAR MVP system is designed to provide a fast, efficient method of

collecting meter reading data from a variety of sources. This includes FIREFLY AMR

meter readings as well as ProfilePLUS™historical usage data.

More specifically, utility meters are outfitted with FIREFLY Meter Interface Units

(MIUs) that transmit meter readings and associated information. Field personnel collect

these radio frequency readings via ROADRUNNERs equipped with an integrated Radio

Frequency Receiving Unit (RFRU) or ROADRUNNER Mobile.

Likewise, the MIUs provide a feature called ProfilePLUS to keep track of historical

usage data. This data helps solve billing disputes, and enable variable rate billing and

load management studies. ROADRUNNERs are used in conjunction with

Programming/Profiling Units (PPUs) for water FIREFLYs to extract this data on

demand.

System Features

FIREFLY AMR System Features

! ProfilePLUS: Usage data based on programmable interval setting.

! Quick and easy installation.

Interfacing Options

! 1. Optical “through-the-glass” sensor end.

! 2. Pulse or encoded wire-end.

DRAFT Chapter 1: System Overview 7

DRAFT

©Datamatic, Ltd. 2000 - 2005

! 3. Under-glass interfacing (electric meters).

! 4. Direct-mount to gas meters

Meter Options

Water Electric Gas

Pulse meters Single-Phase Meters Analog Index Meters

Encoded meters

Analog meters with one

sweep hand

Installation Options

Field installation in less than 10 minutes in most cases

! Above ground.

! Below ground: Pits, vaults, and basements.

Reading Methodologies

! Walk-by with the ROADRUNNER handheld.

! Drive-by with the ROADRUNNER Mobile system.

Customized Programming Options

! Programmable ID, communications, and profiling interval.

! Profiling capability: Interval consumption logging.

Equipment

ROADRUNNER Handheld Computer

Key Descriptions

There are two different types of keys on each keypad: data keys and function keys.

Data keys are the letter and number keys, A- Z and 0- 9. They are used to insert

data into the ROADRUNNER.

Function keys are labeled on the keyboard or the template. They are used to perform a

special procedure or function.

The SHIFT key shifts between the numeric and alphabetic keyboard on the

ROADRUNNER 860 and activates some of the function keys.

DRAFT

8 FIREFLY AMR REFERENCE MANUAL

DRAFT

©Datamatic.com, Ltd. 2000 - 2005

Note: Under the column for the ROADRUNNER X7, the following keys: #

##

#, $

$$

$,

%

%%

%, &

&&

&refer to the cursor pad located in the upper right corner of the keyboard. This

key groups together the four arrow keys, also called the direction keys.

Cursor Pad

Function ROADRUNNER

X7 ROADRUNNER

860

Menu

Displays the Main Menu [F1] [F1]

Contrast Up

Lightens the screen intensity when the APD is

displayed.

[FNCTN] [F4] #

##

#

Send

Initiates the communication procedure to

send/receive data to/from the MVP PC.

[F3] [F3]

Contrast Down

Darkens the screen intensity when the APD is

displayed.

[FNCTN] [F5] $

$$

$

Light

Turns the display backlight on/off. The light

will turn off automatically after approximately

2½ minutes of inactivity, to conserve power.

[FNCTN] [F3] [F5]

On/Off

Turns power on and off to the

ROADRUNNER. To conserve battery power,

the ROADRUNNER automatically turns itself

off after approximately 2 ½ minutes of non-

use.

[F1] / [FNCTN+F1] [ON/OFF]

Search

Initiates the Search function. [F2] [A]

Correct

Corrects entered data; used in conjunction with

other function keys to make corrections to

codes or messages.

[F4] [C]

End

Erases data in the current field, or acts as an

escape key, exiting a menu or function and

returning to the APD.

[FNCTN] [ESC] [END]

Skip

Enters a Skip Code in the reading field that

specifies the reason a reading was not entered.

[E] [E]

DRAFT Chapter 1: System Overview 9

DRAFT

©Datamatic, Ltd. 2000 - 2005

Trouble

Enters a Trouble Code, designating that an

unusual condition or problem exists at the

meter.

[F] [F]

Survey

Survey messages are displayed and allows the

meter reader to enter survey responses.

[G] [G]

Interrogate

Begins user-selected FF interrogation method. [I] [I]

Special Message

Displays special messages, if present, which

have been sent from the Host. If used in

conjunction with the [ CORRECT ] key, a

special message may be entered or edited.

[J] [J]

Totals

Displays the total number of normal, demand,

checks and total devices in the route. Also

displays the total devices read, skipped, blank,

with trouble codes, failed audits and the route

number.

[K] [K]

New Meter

Adds a new meter to the current route. [L] [L]

Shift

On the X7, switches between upper and lower

case alpha characters. On the 860ES, switches

back and forth between the numeric function

mode and alpha mode.

[SHIFT]

Account Info

Displays the customer's name, address, account

number, and sequence number.

[N] [N]

Meter Info

Displays the device information associated

with the device record displayed on the APD.

Information includes meter number, meter

type, number of dials and number of decimals.

[O] [O]

Route Info

Displays route information including route

number, current date and time, meter reader ID,

total meters, total read, total skips, total blanks,

trouble codes, and failed audits. A second

screen contains vehicle information including

vehicle ID, and beginning and ending mileage.

[P] [P]

Clear

Erases data in the current field. [FNCTN] [DEL] [CLEAR]

Account Number

Displays the account number during a search,

correction, or view.

[Q] [Q]

DRAFT

10 FIREFLY AMR REFERENCE MANUAL

DRAFT

©Datamatic.com, Ltd. 2000 - 2005

Meter Number

Displays the meter number during a search,

correction, or view.

[R] [R]

Sequence Number

Displays the sequence number during a search,

correction, or view.

[S] [S]

Top

Scrolls through menus. Finds the beginning of

a route when used with the [ SEARCH ] key.

TIP: Press the [ SEARCH ] then the

[ TOP ] key to find the beginning of

the route.

#

##

#

[F2] #

##

#

[A] %

%%

%

Instruction

Displays the instruction message during a

search, correction, or view.

[T] [T]

Location

Displays the meter location during a search,

correction, or view.

[U] [U]

Read Type

Displays the meter read type during a search or

correction.

[V] [V]

Bottom

Scrolls through menus. Finds the end of a

route when used with the [ SEARCH ] key.

TIP: Press the [ SEARCH ] then the

[ BOTTOM ] key to find the end of

the route.

$

$$

$

[F2] $

$$

$

[A] &

&&

&

Blank

Displays blank devices during a search. [W] [W]

Constant

Displays the device constant during a search,

correction, or view.

[X] [X]

Previous Est

Displays the previous estimate for a device. [Y] [Y]

Repeat

Repeats the last search criteria entered. [F2] [ENTER] [A] [ENTER]

No

Responds "NO" to Yes/No questions. [ESC] [NO]

Space

Enters a space when typing in text. [SP] [SP]

DRAFT Chapter 1: System Overview 11

DRAFT

©Datamatic, Ltd. 2000 - 2005

Enter/Yes

Accepts entry of information typed in and is

the ‘Yes’ answer for Yes/No questions.

[ENTER] [ENTER]

FIREFLY Menu

Displays the FIREFLY Menu when the

ROADRUNNER application includes AMR.

[F5] [SHIFT] [I]

Backspace

Moves the cursor to the left one character and

erases the character.

[BKSP]

OR

%

%%

%

%

%%

%

Keyboards

ROADRUNNER 860 ROADRUNNER X7

DRAFT

12 FIREFLY AMR REFERENCE MANUAL

DRAFT

©Datamatic.com, Ltd. 2000 - 2005

Radio Frequency Receiving Unit (RFRU)

The ROADRUNNER Radio

Frequency Receiving Unit (RFRU)

receives and buffers radio readings,

then downloads them to the

ROADRUNNER handheld unit

when interrogated ("I" key).

The ROADRUNNER RFRU is an

integrated, internal unit, powered by

a rechargeable NiCad battery pack.

Programming/Profiling Unit (PPU) for Water FIREFLYs

The Programming/Profiling Unit

(PPU) is used to configure the MIUs,

and to extract ProfilePLUS

historical reading information.

The PPU creates a "positive snap"

interface with the MIU for

hands-free operation, and when

cabled to the ROADRUNNER

handheld, enables communication.

The PPU is powered with one 9-volt

battery.

Programming/Profiling Unit (PPU) Cable

A cable is used to connect the PPU to a ROADRUNNER for programming and

extraction of profile data from a Water FIREFLY.

DRAFT Chapter 1: System Overview 13

DRAFT

©Datamatic, Ltd. 2000 - 2005

Config Tester (CT) for Water FIREFLYs

The Config Tester (CT) is similar to

the PPU. It is a stand-alone device

for resetting the FIREFLY to

dormant and factory configurations.

Once coupled with the MIU and

activated, there are three lights

which display the status:

Yellow = Updating

Green = Successful

Red = Unsuccessful

FIREFLY Meter Interface Unit (MIU) – Water

The FIREFLY Meter Interface Unit

(MIU) tracks and transmits reading

data. Each MIU includes

ProfilePLUS which tracks and

stores over 1,700 of the most recent

readings. For example, the MIU can

be configured to record 72+ days of

hourly consumption readings,

enabling the resolution of billing

complaints.

The FIREFLY signal includes the

meter number, meter reading, battery

voltage, tamper flag, and a leak

indicator.

The FIREFLY MIU is powered with a 3.6-volt lithium chloride D-cell battery.

Material: Polycarbonate

Construction: Ultrasonic welding

Temperature Rating: Sensor-end: -10°C to +43°C

Wire-end: -40°C to +85°C

Radio communications: 916.5 MHz

Radiated power: .75 mW

DRAFT

14 FIREFLY AMR REFERENCE MANUAL

DRAFT

©Datamatic.com, Ltd. 2000 - 2005

FIREFLY Optical Sensor

The FIREFLY MIU uses a unique and

highly sophisticated optical sensor unit

to track meter activity. An infrared

strobe is integrated into the sensor and

generates its own light, regardless of

ambient conditions. The sensor is

oriented so that the register needle

approaches the sensor from the cable

side and perpendicular to the cable.

The indicators on the top side of the

sensor need to be aligned with the

passing sweep hand. As the needle

sweeps past the sensor, it changes the

light reflected back from the meter

face, and an incremental count is

registered.

The Optical Sensor is affixed to the

meter face using a high-bond adhesive

tape. Specifications for the tape follow.

Optical Sensor Tape Specification

Manufacturer 3M.

Material Acrylic Foam-Closed Cell.

Thickness .045 inch.

Color White/gray.

Release Liner .002 inch clear polyester.

Application Temp 32°+ Fahrenheit.

Curing 24-96 hours.

Peel Adhesion Test 18lb. per square inch (to stainless at room temp).

ASTM B-3330.

D-897.

Tensile Strength 110 lbs. per square inch.

Static/Sheer Test At 72 degrees – 1250 lbs.

(Slide pressure) At 150 degrees – 500 lbs.

Temperature Tolerance 300 degrees.

Pressure Activated 16 lbs.

DRAFT Chapter 1: System Overview 15

DRAFT

©Datamatic, Ltd. 2000 - 2005

Installation Preparation

Installation Considerations

1. Signal distance varies depending on the location of the MIU. FIREFLYsinstalled

above-ground generally transmit the greatest distance.

2. The material of a pit or vault lid affects the transmission range. For example, a

transmitter has a greater range sending from a pit with a plastic lid than a cast iron

lid.

3. Lids with holes of a diameter of roughly 1 3/4 inches make it possible to mount the

FIREFLY MIU through the lid. This can increase transmission range significantly.

4. Complete field installation of an MIU takes 5-10 minutes, depending on the meter

location and mounting application.

5. If the lid has a hole for the unit, use the

cap and wing nut assembly (“lid lock”

pictured at right). Ensure that enough

space exists between the box lid and

the ground for the unit to sit. If not,

remove some of the dirt from the

bottom of the box. Do not over-

tighten lid locks.

Water FIREFLY Installation

Installing the Optical Sensor-End FIREFLY

Meter Preparation

1. Remove meter box lid.

2. Survey the meter, checking lid, hole depth, and overall cleanliness.

3. Check for meter disqualifications and enter the corresponding skip code.

4. Clean excess dirt from meter lid, exposing meter number and verify it with the

account on the ROADRUNNER.

5. Flip lid back and pre-clean meter face/lens using Fast Orangenon-pumice cleaner

and a cloth or cotton swab to remove residue.

6. Clean meter face/lens with 99% isopropyl alcohol and a NEW lint-free cotton swab.

Note: Use Isopropyl rubbing alcohol, 99% by volume. Lower

concentrations do not clean or evaporate as well and adversely affect the

sensor-to-meter bond.

DRAFT

16 FIREFLY AMR REFERENCE MANUAL

DRAFT

©Datamatic.com, Ltd. 2000 - 2005

7. Re-wipe the surface of the meter lens with a clean, new cotton swab each time until

the swab comes up clean, and the clean lens squeaks when wiped.

8. After cleaning, ensure that the lens is completely dry; allow time for the alcohol to

evaporate

Background Check for Firmware Version 0210 and Prior

Sensor Firmware Versions Only

1. Connect the ROADRUNNER to the FIREFLY via the PPU.

2. On the ROADRUNNER 860 Press SHIFT I to display the FIREFLY main menu

and on the ROADRUNNER X7 press F5 .

3. For 0210 and prior sensor firmware versions, Press A to begin testing the FIREFLY

optics. For 0211 and future sensor firmware versions go to the Sensor Placement

section below.

Verifying

Sensor Placement

Background: 181

Status: [Success]

Test Again?

Y/N

The values shown are in decimal and the test keys on Power Level 2 (P2). A successful

test and sensor target placement is achieved when the P2 value is 60 or greater.

*After completing the sensor background test, determine if another alcohol cleaning is

needed on the register face prior to installation of the sensor.

Sensor Flap

Within each case of FIREFLYs, 24 rubber Sensor Flaps are included for every

installation. Utilizing these Sensor Flaps insures a stable environment during the

calibration process.

Sensor Placement

1. Insert sensor cable through sensor flap.

2. Remove the adhesive backing from the high-bond tape on the Optic Sensor face.

3. Install sensor to the location of the best background according to the background

check (for 0210 and prior sensor firmware version FIREFLYs).

DRAFT Chapter 1: System Overview 17

DRAFT

©Datamatic, Ltd. 2000 - 2005

4. Orient the sensor so the water meter needle approaches the sensor from the cable side

and perpendicular to the cable. There are indents on each side of the sensor base that

are to be in line with the needle when it passes.

5. Attach the sensor to the water meter lens

surface.

6. Since the 3M tape provides a pressure

sensitive seal, the installer must apply

16 lbs. of pressure to the MIU sensor

immediately after attaching to the lens

surface. The next step is to maintain

constant pressure for a minimum of 60

seconds.

Tip: Palm the sensor and lean

onto it to apply the

appropriate pressure.

7. A full cure on the seal is achieved in 24 - 96 hours. Do not touch, pull, move, or

handle the sensor in any way during this period.

8. Apply approved adhesive around the sensor to seal it completely in case the pit fills

with water prior to the 24 - 96 hour cure time, or if the meter face is curved and not

flat.

Note: If the sensor is initially misplaced, do not attempt to remove the

sensor by twisting the sensor body. A fully cured sensor requires

breaking the seal at the adhesive tape joint with a flat tool such as a

screwdriver. Insert the screwdriver between the aluminum base and

meter lens and twist.

9. Mount the FIREFLY MIU to an appropriate wall, stake or through hole in meter

box/vault lid with the threaded neck pointing up.

If using a stake, bury the stake in the ground adjacent to the meter register at least 6

inches. The platform area of the pole needs to face inward.

Position the MIU on the pole platform.

Attach the MIU to the pole with the binding material, such as a zip tie (14”).

If utilizing a lid lock, make certain NOT to over tighten the FIREFLY within the

lock. Also be sure to never rest the weight of the lid on the FIREFLY.

10. Place sensor flap over sensor, insuring a snug fit.

11. Program the MIU and set to "AutoCAL".

12. Prior to leaving, take an RF read.

Installing the Wire-end FIREFLY

1. Connect FIREFLY wire-end to meter contacts using Posi-lock connector or Gel caps.

DRAFT

18 FIREFLY AMR REFERENCE MANUAL

DRAFT

©Datamatic.com, Ltd. 2000 - 2005

2. Use approved method specified in the Training Guide for wire connections.

3. Mount the FIREFLY to an appropriate wall, stake, or through hole in the meter box /

vault lid.

4. If using a stake, bury the stake in the ground adjacent to the meter register at least 6

inches. The platform area of the pole needs to face inward.

5. Position the MIU on the pole platform.

6. Position the FIREFLY MIU with the threaded neck pointing up.

7. Attach the MIU to the pole with the binding material.

Note: Do not connect a multi-meter, probe or other interrogating device

to the FIREFLY wires. Doing so may cause the unit to globally reset,

erasing all programmed data!

Installing the Wire-end FIREFLY with a Logical Switch

The FIREFLY Logical Switch MUST be handled with care at all times. A drop or shock

of any kind could affect the performance of the Logical Switch.

Use the following instructions to install FIREFLYs:

1. Set Reading Mode to RV Mode.

Clean the Register

2. Clean the register with a rag to make sure there is no mud or dirt that would get

caught between the collar and glass.

Attach the Logical Switch to the Register

3. Place the Logical Switch on the register and secure with the two screws attached on

the switch.

Profile Data Extraction with Water FIREFLYs

When extracting profile data for an account loaded on the ROADRUNNER, always

enter the meter reading prior to profile extraction. With an RF-enabled

ROADRUNNER, utilize the Read and Verify function. With non-RF

ROADRUNNERs, enter the read manually.

Note: If extracting profile data for an account not loaded on the

ROADRUNNER, collecting the meter reading is not necessary.

Attach the 9-pin end of the Datamatic-supplied cable to the PPU and the other end to the

top port of the ROADRUNNER 860 or the side port of the ROADRUNNER X7.

Remove the rubber plug from the side of the MIU, uncovering the infrared port.

Make sure the optical windows for both the PPU and MIU are clean and unobstructed.

Snap the PPU onto the MIU and turn the PPU power on.

DRAFT Chapter 1: System Overview 19

DRAFT

©Datamatic, Ltd. 2000 - 2005

Note: When the PPU is not in use, it MUST be switched to the OFF

position, to prolong battery life.

! From the meter record, on the ROADRUNNER 860 press SHIFT I or F5 on the

ROADRUNNER X7 to access the FIREFLY Menu.

Or,

! Press F1 , 4, then 6to access the FIREFLY Menu.

! Choose 5Profile Extract from the FIREFLY Menu.

—FIREFLY Config—

1.Templates

2.Program FF

3.Program Indiv Param

4.Current Settings

5.Profile Extract

5.Profile Extract5.Profile Extract

5.Profile Extract

6.Set Reading Mode

7.Enter AutoCAL

8.Exit AutoCAL

9.Test RF Reception

A.TEST OPTICS

B.Diagnostics

C.Options

D.Captue Config

E.AutoCAL Rules

F.Clr Zero/Sat Evt

The ROADRUNNER extracts the profile data from the MIU.

Receiving Interval

Data

Progress

XX %

Please Standby

The process takes up to 60 seconds with water FIREFLYs and 2 minutes on electric or

gas.

DRAFT

20 FIREFLY AMR REFERENCE MANUAL

DRAFT

©Datamatic.com, Ltd. 2000 - 2005

After data has been successfully validated, the following screen displays:

____________________

Interval Data

Successfully Read

____________________

If data is of invalid length, or has corrupt values, this message is displayed:

____________________

Invalid Interval

Data Length

____________________

This is followed by a prompt to retry extraction:

Would you like

to retry extraction?

Y/N

If “Yes” is selected, the Receiving Interval Data screen is re-displayed with the

percentage indicator starting at 0%. Profile extraction restarts from the beginning. If the

user selects “No”, profile extraction exits to the current APD.

Table of contents