DayTronic 5M78 User manual

The Model 5M78 is a single-channel conditioner of phase-sensitive carrier-amplifier

design. Intended for applications involving transformer-coupling to the transducer

bridge (as with rotary-transformer torque sensors), this conditioner can also be used in

conventional installations when high sensitivity is required or where the electrical

environment is especially noisy.Responding only to the modulated carrier frequency,

the 5M78 rejects extraneous voltages that can cause errors in DC systems,

particularly when there is a need to “blow up” a portion of the transducer range.

User-adjustable phase and symmetrycontrols are provided.

calibration resistor is 59 kilohms, 1% which is located internally to the 5M78 case.

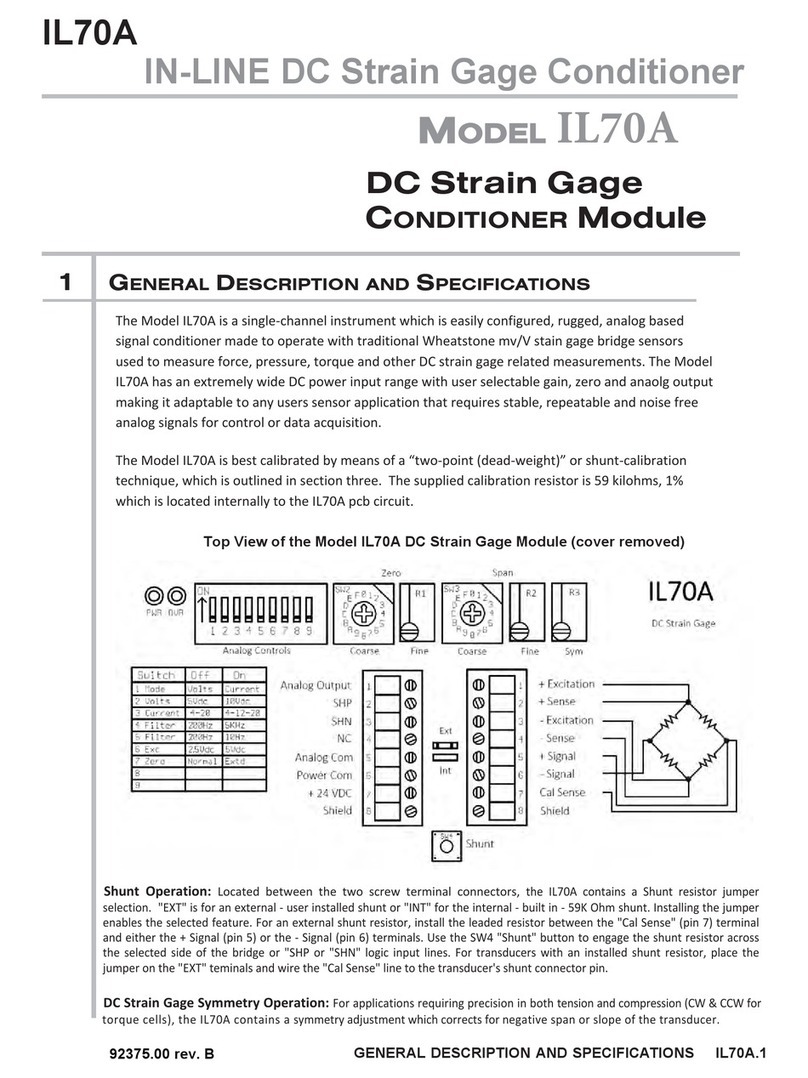

1GENERAL DESCRIPTION AND SPECIFICATIONS

Model 5M78 AC Strain Gage Module

Access switch settingsvia the front

panel of the 5M78 by gently pulling the

clear plastic cover (from the bottom

side) so the cover rotates open from

DIN AC Strain Gage Conditioner

MODEL 5M78

AC Strain Gage

CONDITIONERModule

5M78 1.A.1.5M78

GENERAL DESCRIPTIONAND SPECIFICATIONS 5M78.1

or without power to the unit. Once

completed, return the cover to the

View of Side Label of the Model 5M78 AC Strain Gage Module

the top. Use a small tool or finger to

place the switches to the left or right

position as you face the front of the

module. This process can be done with

original position.

AC Strain Gage Phase Operation

Due to the AC modulated aspects of the

5M78 AC Voltage excitation circuit, the 5M78

contains a "PHASE" adjustment which

aligns the transducer's return output signal

to the conditioner's demodulator. When

the demodulator is aligned properly through

calibration, maximum amplitude and

accuracy are achieved.

The Model 5M78's is calibrated by means of a “two-point (dead-weight)” or

shunt-calibration technique, which are outlined in section three. The supplied shunt

92342.00

WARNING

Death, serious injury, orfire hazard could result from improper connection of this instrument. Read and understand this

manual before connecting this instrument. Follow allinstallation andoperating instructions while using this instrument.

Connection of this instrument must be performed in compliance with the National Electrical Code (ANSI/NFPA 70-2014) of

USA and any additional safety requirements applicable toyour installation.

Installation, operation, and maintenance ofthis instrument must be performed by qualified personnel only. The National

Electrical Code defines a qualified person as “one who hasdemonstrated the skills and knowledge related to theconstruction

and operation of the electrical equipment and installations, and who hasreceived safety training on the hazards involved.”

Qualified personnel who work on or near exposed energized electrical conductors must follow applicable safety related

work practicesand procedures including appropriate personal protective equipment incompliance with the Standard for

Electrical Safety Requirements forEmployee Workplaces (ANSI/NFPA 70E-2012)of USA andanyadditional workplace safety

requirements applicable toyour installation.

ADVERTENCIA

Una conexión incorrecta de este instrumento puede producir lamuerte, lesiones graves y riesgo de incendio. Lea y entienda

este manual antes de conectar. Observe todas las instrucciones de instalación y operación durante elusode este

instrumento.

La conexión deeste instrumento a unsistema eléctrico se debe realizar enconformidad conelCódigo Eléctrico Nacional

(ANSI/NFPA 70-2014)de los E.E.U.U., además de cualquier otra norma de seguridad correspondiente a su

establecimiento.

La instalación, operación y mantenimiento de este instrumento debe ser realizada por personal calificado solamente. El

Código Eléctrico Nacional define a una persona calificada como "una que esté familiarizada con la construcción y operación del

equipo y con los riesgos involucrados."

El personal cualificado que trabaja encendido o acerca a los conductores eléctricos energizados expuestos debe seguir

prácticas y procedimientos relacionados seguridad aplicable deltrabajo incluyendo elequipo protector personal apropiado

en conformidad con elestándar para los requisitos deseguridad eléctricos para los lugares de trabajo del empleado (ANSI/

NFPA 70E-2012)de los E.E.U.U. y cualquier requisito de seguridad adicional dellugar de trabajo aplicable a suinstalación.

AVERTISSEMENT

Si l'instrument est mal connecté, lamort, desblessures graves, ou un danger d'incendie peuvent s'en suivre. Lisez

attentivement cemanuel avant de connecter l'instrument. Lorsque vous utilisez l'instrument, suivez toutes les

instructions d'installation etdeservice.

Cet instrument doit être connecté conformément auNational Electrical Code (ANSI/NFPA 70-2014)des Etats-Unis et à

toutes les exigences desécurité applicables à votre installation.

Cet instrument doit être installé, utilisé et entretenu uniquement par un personnel qualifié. Selon le National Electrical

Code, une personne est qualifiée si "elle connaît bien la construction et l'utilisation de l'équipement, ainsi que les dangers

que cela implique".

Le personnel qualifié qui travaillent dessus ou s'approchent desconducteurs électriques activés exposés doit suivre des

pratiques en matière et des procédures reliées par sûreté applicable de travail comprenant le matériel de protection

personnel approprié conformément à lanorme pour desconditions de sûreté électriques pour les lieux de travail des

employés (ANSI/NFPA 70E-2012)des Etats-Unis ettoutes les conditions de sûreté additionnelles de lieu de travail

applicables à votre installation.

WARNUNG

Der falsche Anschluß dieses Gerätes kann Tod, schwere Verletzungen oder Feuer verursachen. Bevor Sie dieses Instrument

anschließen, müssen Sie dieAnleitung lesen und verstanden haben. Bei derVerwendung dieses Instruments müssen alle

Installation- und Betriebsanweisungen beachtet werden.

Der Anschluß dieses Instruments muß in Übereinstimmung mit den nationalen Bestimmungen für Elektrizität (ANSI/NFPA

70- 2014)der Vereinigten Staaten, sowie allen weiteren, inIhrem Fall anwendbaren Sicherheitsbestimmungen, vorgenommen

werden.

Installation, Betrieb und Wartung dieses Instruments dürfen nur von Fachpersonal durchgeführt werden. In dem nationalen

Bestimmungen fürElektrizität wird einFachmann als eine Person bezeichnet, welche "mit der Bauweise und dem Betrieb des

Gerätes sowie den dazugehörigen Gefahren vertraut ist."

Qualifiziertes Personal, das anbearbeiten oder herausgestellte angezogene elektrische Leiter sich nähern, mußanwendbare

Sicherheit bezogener Arbeit Praxis und Verfahren einschließlich passende persönliche schützende Ausrüstung gemäß dem

Standard für elektrische Sicherheitsauflagen für Angestellt-Arbeitsplätze (ANSI/NFPA 70E-2012)derVereinigten Staaten

und alle zusätzlichen Arbeitsplatzsicherheitsauflagen folgen, dieauf Ihre Installation anwendbar sind.

Safety Precautions

The following safety precautions must be followed whenever any type of voltage or current connection is being made to the

instrument.

oBefore connecting to electric circuits or pulse initiating equipment, open their related breakers or disconnects. It is

recommended NOT TO install any connection of the instrument on live power lines. Only Qualified Service personnel that

have demonstrated the abilities and received the proper safety training are capable of connecting to live circuits.

oConnections must be made to the instrument first, then connect to the circuit to be monitored.

oWear proper personal protective equipment, including safety glasses and insulated gloves when making connections to

power circuits.

oHands, shoes and floor must be dry when making any connection to a power line.

oBefore each use, inspect all cables for breaks or cracks in the insulation. Replace immediately if defective.

oIf the equipment is used in a manner not specified in this user’s guide, the protection provided by the equipment may be

impaired.

Medidas de seguridad

Las medidas de seguridad siguientes deberán observarse cuando serealice cualquier tipo de conexión al instrumento.

οCuando se haga conexiones a circuitos eléctricos o a equipo de activación por pulso, deberá abrirse sus respectivas cajas

de seguridad. NO deberá hacerse ninguna conexión del instrumento en líneas eléctricas bajo tensión.

οLas conexiones deberán hacerse primero al instrumento y, luego, al circuito a ser monitorizado.

οAl hacer conexiones a circuitos eléctricos, deberá utilizar anteojos y guantes protectores.

οSus manos, zapatos y elpiso deberán estar secos entodo momento en que sehaga una conexión a un cable eléctrico.

οVerifique que launidad esté DESACTIVADA antes de conectar sondas en el panel posterior.

οPrevio a cada uso, deberá verificarse que los cables no estén rotos y que elmaterial aislante no tenga rajaduras.

Reemplace de inmediato cualquier parte defectuosa.

Mesures de Sécurité

Les mesures de sécurité suivantes doivent être prises chaque fois qu’un type de connexion quelconque est effectué

sur l’instrument.

οOuvrir les disjoncteurs correspondants lors d’une connexion à descircuits électriques ou à deséquipement de génération

d’impulsions. NE PAS effectuer de connexion d’instrument sur deslignes électriques sous tension.

οUne fois toutes les connexions de l’instrument effectuées, connecter aucircuit à contrôler.

οPorter deslunettes de protection et desgants isolants pour effectuer desconnexions aux circuits électriques.

οS’assurerque les mains, les chaussures et le sol soient secs lors de connexions à une ligne électrique.

οS’assurer que l’unité est ÉTEINTE avant de connecter les sondes au panneau arrière.

οInspecter tous les câbles, avant chaque utilisation, pour s’assurer que les isolants ne sont pascoupés ou fendus.

Remplacer immédiatement tous les équipements défectueux.

Sicherheitsvorkehrungen

Die folgenden Sicherheitsvorkehrungen sind immer dann zu befolgen, wenn eine Verbindung zum Instrument hergestellt wird.

οÖffnen Sie beim Anschluß an elektrische Stromkreise oder Impulsauslösungseinrichtungen die entsprechenden

Unterbrecher. Es dürfen KEINE Anschlüsse an das Instrument unter stromführenden Spannungsleitungen montiert

werden.

οDie Verbindungen müssen zuerst am Instrument und danach an der zu überwachenden Schaltung hergestellt werden.

οTragen Sie Schutzbrillen und Isolierhandschuhe, wenn Sie Anschlüsse an den Stromkreisen vornehmen.

οHände, Schuhe und Fußboden müssen trocken sein, wenn Sie Anschlüsse an den Stromkreisen durchführen.

οStellen Sie sicher, daß das Gerät AUSgeschaltet ist, bevor Sie an der rückwärtigen Konsole Meßfühler anschließen.

οPrüfen Sie vor jedem Gebrauch alle Kabel auf Bruchstellen und Risse in der Isolierung. Wechseln Sie schadhafte Kabel

sofort aus.

Standard Accessories

Standard

accessories The following table lists the 5M standard accessories.

Description Part Number

Manual & Operating instruction Resource CD

5M78 SPECIFICATIONS

Measurement Range:

Adjustable 0.5 mV/V to 5.0 mV/V; nominal full-scale

Excitation: 3.28 kHz; Nominal 2.77 Vac rms, sensed

Transducer Types:

Conventional 4-arm strain gage bridges, typically transformer

Amplifier

Normal - Mode Range : ±1.5 Vrms operating; ± 8V without instrument damage

Input Impedance : Differential > 10 MΩ

Offset : vs. Temperature: ±30 ppm/°C; vs. Time: ±10 ppm/month

Gain Accuracy

: Limited only by calibration accuracy

Gain Stability

: vs. Temperature: ±30 ppm/°C; vs. Time: ±10 ppm/month

Filter

:3-pole modified Butterworth; 3 dB down at 10 Hz, 100 Hz or 650 Hz; selectable

Step-Response Settling Time (Full-Scale Output @ 10 Hz)

:

To 1% of final value: 0.08 sec; (0.008 sec @ 100 Hz) (0.0011 sec @ 650 Hz)

To 0.1% of final value: 0.095 sec; (0.0095 sec @ 100 Hz) (0.0016 sec @ 650 Hz)

To 0.02% of final value: 0.10 sec; (0.01 sec @ 100 Hz) (0.0014 sec @ 650 Hz)

5M78.1GENERAL DESCRIPTIONAND SPECIFICATIONS

5M78 AC Strain Gage Module

coupled - 120 to 10 k ohm

Analog Ouput

: selectable; ± 0 to 5, ± 0 to 10 Vdc, 4-12-20 or 4-20mA (20% over-range, voltage only)

Power Supply

: 11 - 28 Vdc regulated; 100 mAmax.

Operating Temperature

: -10 to +70 Degrees C, 5 to 95% relative humidity, non-condensing

Dimensions

Linearity

: better than ± 0.03% of full scale

Housing height [A] : 114.5 mm

Housing depth [B] : 99 mm

Housing width [C] :22.5 mm

7 ,

2 , 2

0 , 3

2 0

,

2 2

3 6

3 ,

Optional DIN Power Rail Connector Model 5M-PCON

A

BC7

Dimensional drawing

N/A

N/A

N/A

DC POWER

5

4

3

2

1

POWER COMMON

N/C

N/C

N/C

DC POWER

5

4

3

2

1

POWER COMMON

DIN Power Connection (top)

2TRANSDUCER CONNECTIONS

The Model 5M78 I/O CONNECTIONS are via non-removable screw terminals which will

accept wire sizes from AWG 12 to 26. NOTE: The recommended transducer

cabling would be eight wire, individually shielded, twisted pair - wired as indicated (Fig. 1)

Sense lines must be connected at the transducer (as recommended) or at the 5M78

screw terminals - as a minimum. Table 2 denotes screw terminal assignments

Table 2 Model 5M78 Pin Assignments

I/O Connector Conditioner

PinScrewTerminal Line

Number Terminal Label Function

Top Rear 1 1 + EXC +EXCITATION

Top Rear 2 2+ SEN + SENSE

Top Rear 3 3 - EXC - EXCITATION

Top Rear 4 4 - SEN - SENSE

Top Front 1 1+ SIG +SIGNAL Input

Top Front 2 2-SIG –SIGNAL Input

Top Front 3 3 CAL SEN CALIBRATION SENSE

Top Front 4 4

/// SHIELD

Bottom Front 1 1 Ano Out ANALOG Output

Bottom Front 2 2 SHP Shunt Positive

Bottom Front 3 3 SHN Shunt Negative n

Bottom Front 4 4 SYC SYNC - MASTER/SLAVE

TRANSDUCER CONNECTIONS 5M78.2

AC Strain Gage Conditioner Module 5M78

Bottom Rear 1 1 Acom Analog Common

Bottom Rear 2 2 Pcom Power Common

Bottom Rear 3 3 24 V 24 Vdc Power

Bottom Rear 4 4 /// SHIELD

SHIELD

Fig. 1 Model 5M78 Transducer Cabling

Top Input Connectors

(viewed from front)

Rear Terminals

Front Terminals

Front Terminals

Rear Terminals

Bottom Power & Signal Connectors

Analog Common

Power Common

24 Vdc Power Input

EXTRA WIRE

(paired with "CAL SENSE,"

UNCONNECTED at

Conditioner Connector)

+EXCITATION

–EXCITATION

CAL SENSE *

–SENSE

+SENSE

–SIGNAL

+SIGNAL

SHIELD

Master/Slave

Clock Sync Line

to/from other

modules

* CAL SENSE

when used with internal transducer

shunt resistor, wire CAL SENSE

line to transducer's CAL pin.

Internal Shunt resistor

must be shorted.

3 GENERAL DESCRIPTION AND CALIBRATION

The Model 5M78 is useful in applications involving tranformer coupling to the strain gage

bridge (for example, rotary transformer torque sensors) and in certain appications that require high

sensitivity with optimum signal-to-noise characteristics. Carrier amplifiers offer higher sensitivity

than dc amplifiers and, since they respond only to the modulated carrier frequency, they reject certain

extraneous voltages that can cause error in dc systems. These error sources include thermocouple

or galvanic voltages in the cable-connector system, homopolar voltages from rotating machinery,

low-frequency pickup, and 1/f noises of various origin.

Calibration of the 5M78 is accomplished by the conventional shunt technique, using an internally

(or externally) installed calibration resistor, or via the "dead-weight" method.

Calibration Resistor. If a fixed resistor is shunted across one arm of a strain

gage bridge, it produces an unbalance equivalent to that of a particular value of

mechanical input. If this Equivalent Input value is accurately known, it can be used

as a reference point for shunt calibration of the system. Upon completion of

installation of the transducer and its associated cabling, the user can:

Perform an overall dead weight calibration using a precisely known

value of mechanical input. The calibration can then be transferred to the

installed calibration resistor for convenience in subsequent checking.

Replace the installed calibration resistor with one (or an equivalent

resistance value) supplied by the transducer manufacturer to achieve a

precisely known Equivalent Input allowing the instrument sensitivity to

be adjusted correctly.

Determine the Equivalent Input value for the installed calibration resis-

tor, knowing the transducer sensitivity, and adjust the instrument sen-

sitivity accordingly.

A one percent 59-kilohm calibration resistor is installed in the 5M78 at the factory.

The installed resistor can usually be used even though the transducer calibration

data mentions some other resistance value. In Section 4of this manual, the tech-

niques described above are demonstrated. If, however, the installed value of the

calibration resistor is not appropriate for the transducer and measurement range to

be used, the 59-kilohm resistor should be replaced at this time. The calibration

resistor is mounted on terminals located internally to the 5M78 conditioner's

printed-circuit board. It can be accessed by removing the instrument case (Fig. 5).

Note: A variety of Rotary Transformer Torque Transducers are supplied

with the appropriate calibration resistor integral to the transducer. When this type

of transducer is used it will be necessary to place a short across the 59-kilohm

resistor internal to the instrument. The transducer calibration resistor can be appropri-

ately connected to the 5M78 calibration circuit via the transducer cabling. Refer to

cabling diragam section of this manual in the area of CAL SENSE.

7

(1)

(2)

(3)

Calibration 5M78.3

3. CALIBRATION (cont.)

This section contains the instructions for calibrating the 5M78. Included is a

functional description of the instrument front-panel (see Figure 2). To perform

calibration, proceed as follows.

Turn power ON to the 5M78 DC Power input terminal (11 to 28 Vdc input)

The front-panel indicator should light green to indicate the application of

dc power. Allow 10 minutes of warmup for stabilization of transducer

characteristics. Open the protective, clear plastic, front cover of the unit.

Set the Coarse Zero and Span controls to the marked label position (<, Min>).

Position the front panel switches to the desired settings for the application.

Refer to Figure 2 for details. If using Shunt method, refer to step (k).

(b)

(a)

(c)

the Coarse and Fine SPAN controls. If not, adjust the Symmetry control

to obtain the negative Equivalent Input value.

If dead weight calibration is not practical and the transducer calibration

data is unknown, the Equivalent Input value for the factory-installed

calibration resistor can be approximated

mv/v sensitivity rating of the transducer

known.

as follows, assuming that

and the bridge resistance

the

are

13

(m)

With the transducer unloaded, adjust the Coarse Zero control and the Fine Zero

control until the desired analog output is achieved. If greater zero authority is

desired, place the front panel Switch 7 - "Zero Adj" to the extended range. This will allow

the user to obtain 100% zero offset control. The Normal postion of switch 7 allows

for approximately 25% Zero authority.

(d)

the Coarse and Fine SPAN controls. If not, adjust the Symmetry control

to obtain the negative Equivalent Input value.

If dead weight calibration is not practical and the transducer calibration

data is unknown, the Equivalent Input value for the factory-installed

calibration resistor can be approximated

mv/v sensitivity rating of the transducer

known.

as follows, assuming that

and the bridge resistance

the

are

13

(m)

Load the transducer in the positive direction with a convenient dead weight value

(greater than one half of full scale). Adjust Coarse Span for a nominal corresponding output.

Adjust the PHASE control, until a maximum output value is obtained. (Once set for your

transducer, this PHASE ADJUSTMENT step need not be repeated unless a change in

cable length – or transducer – is required). Unload the sensor and re-Zero as needed.

(e)

(f) If the calibration will utilized a known "dead-weight", re-load the sensor and adjust the

Coarse and Fine Span controls for the expected analog output value. Unload - Zero and

Load - Span operations may need to be repeated for analog output precision.

Note: With sensor unloaded, activate & record "SHP" value for furture calibration verification.

If the calibration will utilize the "Shunt" calibration method, refer to step (k).

recommended calibration resistor.

the Coarse and Fine SPAN controls. If not, adjust the Symmetry control

to obtain the negative Equivalent Input value.

If dead weight calibration is not practical and the transducer calibration

data is unknown, the Equivalent Input value for the factory-installed

calibration resistor can be approximated

mv/v sensitivity rating of the transducer

known.

as follows, assuming that

and the bridge resistance

the

are

13

(g)

(m)

Calibration 5M78.3

the Coarse and Fine SPAN controls. If not, adjust the Symmetry control

to obtain the negative Equivalent Input value.

If dead weight calibration is not practical and the transducer calibration

data is unknown, the Equivalent Input value for the factory-installed

calibration resistor can be approximated

mv/v sensitivity rating of the transducer

known.

as follows, assuming that

and the bridge resistance

the

are

13

(m) the Coarse and Fine SPAN controls. If not, adjust the Symmetry control

to obtain the negative Equivalent Input value.

If dead weight calibration is not practical and the transducer calibration

data is unknown, the Equivalent Input value for the factory-installed

calibration resistor can be approximated

mv/v sensitivity rating of the transducer

known.

as follows, assuming that

and the bridge resistance

the

are

13

(m)

If the transducer is to be also used in the negative realm, load the

transducer in the negative direction with the same dead weight value as

used in step (f) and confirm that the dead weight reading obtained is the

same, but negative polarity, as that of step (f). If not, see steps (i) thru (j).

A Symmetry adjustment is provided to compensate for transducers

that do not have symmetrical sensitivity characteristics. This

adjustment is factory set assuming symmetrical characteristics. If step

(h)indicates that a field adjustment is necessary, proceed as follows.

recommended calibration resistor.

the Coarse and Fine SPAN controls. If not, adjust the Symmetry control

to obtain the negative Equivalent Input value.

If dead weight calibration is not practical and the transducer calibration

data is unknown, the Equivalent Input value for the factory-installed

calibration resistor can be approximated

mv/v sensitivity rating of the transducer

known.

as follows, assuming that

and the bridge resistance

the

are

13

(h)

(i)

(m)

With the transducer loaded as in step (f), adjust the Symmetry control (right

above the PHASE control adjustment) to obtain a dead weight reading equal to

that obtained in step (f).

If dead weight calibration is not practical and the transducer manufac-

turer has supplied a calibration resistor (or resistor value), install the

recommended calibration resistor. See Fig. 5

(j)

(k)

Perfom steps (b) thru (e). Now activate the SHUNT POSITIVE (SHP) terminal

and adjust the SPAN controls until the instrument output is equal to the Equivalent

Input value simulated by the installed resistor. Shunt is performed at zero load.

If a negative Equivalent Input value is also provided on the calibration sheet

of the transducer under calibration, activate the SHUNT NEGATIVE (SHN) terminal.

Confirm that the negative value can also be obtained. If necessary, adust the SYMMETRY

control to obtain the negative Equivalent Input value as listed on the calibration

document. The SYMMETRY control has approximately 7% authority, full scale.

If dead weight calibration is not practical and the transducer calibration

data is unknown, the Equivalent Input value for the factory-installed

calibration resistor can be approximated

mv/v sensitivity rating of the transducer

known.

as follows, assuming that

and the bridge resistance

the

are

(l)

(m)

where X=Equivalent Input, % of full scale

R

b=bridge resistance, ohms

K =transducer sensitivity, mV/Vfull scale

R

c=calibration resistance, ohms (59 kinstalled)

Sample Calculation: Assume that K =3.000 mV/Vfor a 5000-pound loadcell

(fullscale) with a bridge resistance of 350 ohms.

49.4% of full scale =2472 pounds

X = 25000 Rb

K Rc

X = 59000 x 3

25000 x 350 =

ring, one unit can be designated the master, and the remaining units can be driven

from the oscillator contained in the master unit. The remaining units are designated

as slave instruments. To perform master/slave wiring, refer to Figure 4.

3. CALIBRATION (cont.)

Calibration 5M78.3

Note: Above calculation is useful in applications involving non - star bridge shunt calibration strain gage

bridges (for example DC bridges, and slip ring type torque sensors). Rotary transformer type sensors

which use star bridge shunt circuit will not equate properly and the sensor's published calibration

data should be referenced.

b

c

Remote Calibration Check. The instrument can be placed in the calibration mode

(positive or negative) by shorting terminals Power Common and SHP for positive or SHN for

negative on the lower I/O connector. Figure 4 indicates two methods of remotely

entering the calibration mode (external switch, or push button control). The

Remote Cal function provides a convenient method of periodically monitoring

calibration of the instrument in the positive or negative realm.

Master/Slave Connections. When more than one 5M78 is being used in a measurement

setup (instruments are closely mounted or the transducer cabling is in a common conduit

or raceway), beat frequencies may be produced from the 3-kHz oscillators used in

the instruments to develop the excitation. To prevent beat frequencies from occur-

ring, one unit can be designated the master, and the remaining units can be driven

from the oscillator contained in the master unit. The remaining units are designated

as slave instruments. To perform master/slave wiring, refer to Figure 7.

3. CALIBRATION (cont.)

Switch 1 - Mode - selects current (I) or voltage analog output

Switch 2 - Volts - selects +/- 5 or +/- 10 Vdc when mode is voltage

Switch 3 - Current - selects 4-12-20 or 4-20mA when mode is current

Switch 4 - Filter - selects 650 Hz or 100 Hz at 3 db, for 100 Hz switch 5 must be set to the right

Switch 5 - Filter - selects 10 Hz or 100 Hz at 3 db, for 100 Hz switch 4 must be set to the right

Switch 6 - Sync - selects excitaton clock to slave from a master module or to be master

Switch 7 - Zero Adj. - selects extended (100%) or normal (25%) zero authority

Switch 8 - Aux Output - selects SYNC terminal output for use by other linked modules

Coarse Zero - 16 position switch adjustment for stepped zero balance control

marked for calibration default position

Fine Zero - 18 turn potentiometer for fine zero balance control

Coarse Span - 16 position switch adjustment for stepped gain contr ol

marked for calibration default position

Fine Span - 18 turn potentiometer for fine gain - span control

Symmetry - adjust the negative output span to be equal to the positive output

Phase - adjustment for phasing the AC modulated signal to its highest level at load

Over Range - indicates when the analog output is 2% greater than mode selected

Power - indicates the power input voltage is ON

Fig. 2 Front Panel Settings and Indicators

Calibraton 5M78.3

or in the AUX position for raw - uncalibrated analog gained voltage output

4. VERIFICATION OF NORMAL OPERATION

It is the purpose of this section to aid the user in determining, in the event of a

malfunction to which the Model 5M78 is suspected of contributing, whether the

instrument is functioning normally or whether it is the source of the observed

trouble. In the event the unit requires repair, the user may also contact the

factory Service Department or the local Daytronic Representative for assistance.

Daytronic service information is located on the last page of this document.

If the instrument is suspected of faulty operation, follow the steps below.

(a) If the unit is totally inoperational (front-panel power indicator does not

light), check the primary power input terminals for proper connection.

Input power can be from 11 to 28 Vdc and will draw less than 2 watts.

If properly connected, the front panel Green LED will be illuminated. Before

reapplying power, visually inspect the power supply and the input power

connections for any discrepancy which could have caused the overload.

(b)

If the transducer has some preloading, the BALANCE controls may not

allow successful zeroing of the instrument output. This condition can be

remedied by connecting a resistor (50 k-200 krange, metal-film type)

from the +Signal terminal of the transducer to the + or –Excitation Sense

terminals. The Excitation terminal to which the connection is made is

determined by the direction of the loading or off-zero reading.

(c) The inability to balance correctly,where the instrument output reads

totally off scale and the BALANCE controls have no authority,can very

likely be the result of a damaged or defective transducer or cable. This

possibility can be confirmed (or eliminated) by substituting a transducer

and cable known to be in good condition or by simulating a balanced

transducer, using either a commercially available transducer simulator

or the simple star bridge arrangement shown in Figure 7. The star bridge

simulates a conventional four-arm bridge in an exact condition of bal-

ance. To construct a star bridge,connect four 10% carbon resistors as

shown in Figure 5. Use 180-ohm resistors to simulate a 350-ohm bridge

and use 56-ohm resistors to simulate a 120-ohm bridge. Neither the

resistor values nor temperature characteristics are critical since the

balance condition of a star bridge is not determined by the resistance

I<

Figure 7. Star Bridge Construction

20

values. Solder two resistors together, then solder the remaining two

resistors together. Next, connect the two junctions together using a

separate wire as shown. There is a good reason for this method of

construction, and it should be followed. Connect the substitute or simu-

lated transducer to the instrument I/O connector using a short 4-wire

cable configuration as shown in Figure 4. Attempt to balance the substitute

simulated transducer. If conditions now appear to be normal, the transducer

or cable is at fault. If the previous difficulties persist, the 5M78 is faulty.

Contact Switch

(NO)

NOT PUSHED = Logic 1 (Shunt not enabled)

PUSHED = Logic 0 (Shunt is enabled)

Push Button

(NO)

11 - 28VDC

POWER

SUPPLY

SHIELD

Fig. 3 Shunt Connections

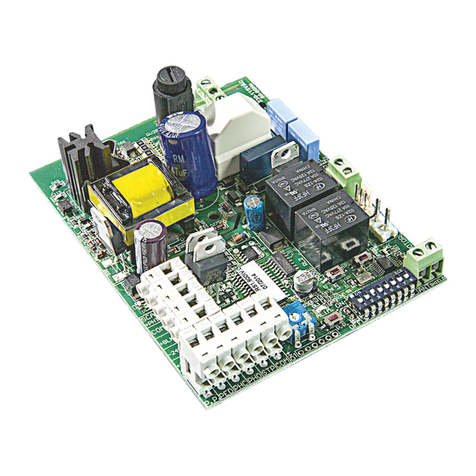

Fig. 4 Star Bridge

Shunt Resistor

Fig. 5 Internal Shunt Location

The internal 59k Ohm shunt resistor is located

inside the 5M78 housing. To replace this resistor,

remove the spring and DIN Clip located on

rear of the case. Use a flat head screw driver to

separate the top and bottom of the case, typically

starting at the front connector positions. The

resistor is soldered to two terminal post as

shown in the diagram. Unsolder and resolder

the replacment shunt resistor or "short" for sensors

with internal shunt resistors. Reassemble the housing

and DIN clip. Ensure rear grounding clip and front

Master 5M78 Module

(Switch 6 to Master)

Additional 5M78 Module

Additional 5M78 Module

(Switch 6 to Slave)

(Switch 6 to Slave)

Fig. 7 Master / Slave Wiring

Master / Slave Connections

When more than one 5M78 is being used in the

same measurment setup, beat frequencies can be

produced by the excitation clock oscillator. To

prevent this, the user should declare one of the

5M78 units as a Master via switch 6 on the front

panel. The other units should be switched to Slave

and wired as shown with the SYC terminals

connected and a separate Power Common wire.

If the units share a common power supply, the

P com terminal should be connected at the modules.

Shunt Reference

Fig. 6 Internal Shunt Reference Solder Connections

The 5M78 internal shunt resistor is referenced

from + Signal to either + Sense for Shunt positive (SHP)

or - Sense for Shunt negative (SHN) when

activated via the terminals per Fig. 3. Provisions have

been incorporated to reference Common instead of

+ Signal for sensors that require this feature. To

accomplsih this, unsolder the "S" connection and

make a solder bridge across "C" to the middle pad as

shown in adjacent layout. Reassemble the

housing and DIN clip. Ensure rear grounding clip

and front cover are in place.

cover are in place.

5M78 AC Strain Gage Conditioner Module

Product Warranty and Repair

Daytronic Corporation warrants its products to be free from defects in material and

workmanship, under normal and proper use in accordance with our instructions,

for the period of time specified below. Our liability under such warranty or in

connection with any other claim relating to the products shall be limited to, at our

option, the repair or replacement of any products or parts or components thereof

which are returned to us freight prepaid and which are defective in material or

workmanship or the refund of the purchase price to the Buyer.

Before returning a product or products for any reason, the

customer must call Daytronic Customer Support Services at

ALL EQUIPMENT TO BE REPAIRED OR REPLACED UNDER WARRANTY MUST BE

RETURNED TO THE FACTORY.

. Once the customer has provided the

necessary information and has been assigned a specific RMA, the product(s) in question

may be returned to Daytronic by shipping it

Daytronic Corp. , 1000 New Durham Road, Edison, New Jersey 08818

ANY PRODUCT FOUND TO BE DAMAGED THROUGH CUSTOMER NEGLIGENCE OR MIS-

USE MAY BE EXCLUDED FROM ANY AND ALL POLICIES CONTAINED IN THIS DOCUMENT.

(937) 866-3300

to request a

RETURN MATERIAL AUTHORIZATION (RMA)

Daytronic CorporationDayton OH USA

wwwwww..ddaayyttrroonniicc..ccoomm

Table of contents

Other DayTronic Control Unit manuals

Popular Control Unit manuals by other brands

CNC Router Parts

CNC Router Parts CRP800 Retrofit Guide

DOLD

DOLD SAFEMASTER RK 5924 operating instructions

Microsoft

Microsoft 1925 quick start guide

Viessmann

Viessmann EM-EA1 extension Installation and service instructions for contractors

Hansen

Hansen HCK4-2 Specifications, Applications, Service Instructions & Parts

Siemens

Siemens SITRANS PCS 7 Function manual