DC Matic TL-900 User manual

Model TL-900

Safety and Use Manual

24-30 VDC Powered

3/4 Inch Drive Impact Wrench System

Work Area Safety

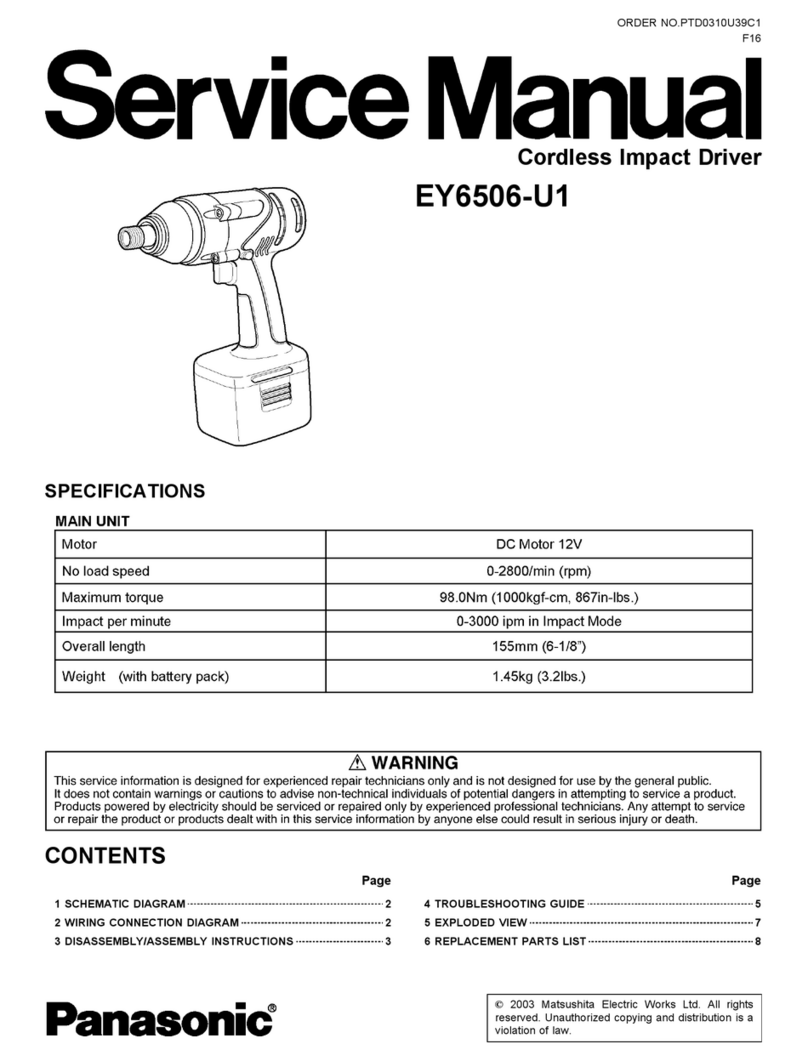

Keep work area clean and well lighted. Cluttered or dark areas invite accidents. Use the LED

light work light on the Model TL-900 (shown in Fig. 1) whenever possible to reduce injuries.

Do not operate the Model TL-900 in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Although the Model 900 incorporates safety measures that

enclose sparks, its exterior metal parts may create sparks that can ignite flammable materials.

Keep bystanders, children and visitors away while operating the Model TL-900. Distractions

can cause you to lose control.

Make sure vehicles are braked, chocked and stable.

Use extreme caution when working on or around a vehicle on a jack.

Electrical Safety

The Anderson quick connector ( shown in Fig. 1) on your Model TL-900 must match another

Anderson quick connector. Mismatched connectors create the risk of electrical shorting.

Make sure the cables, switches and power connector are in good working order

before making a secure connection. Damaged cables, plug, switches or receptacles will reduce

the amount of power available to the tool and potentially cause damage to it or the vehicle.

Do not immerse the Model TL-900 in standing water.

Do not abuse the power cables. Never use the cord for carrying, pulling or unplugging the

tool. Keep the cables away from sharp edges and moving parts.

Make sure the power cables are free from snags and tangles before operating the tool sys-

tem.

Personal Safety

Always stay alert and use common sense when operating the Model TL-900. Never operate

the tool while tired or under the influence of drugs, alcohol or medication. The Model TL-900

is a very powerful tool that can cause serious personal injury and property damage if not properly

used.

Use safety equipment. Always wear eye and ear protection. Safety equipment such as dust

masks, non-skid safety shoes, hard hat or hearing protection used for appropriate conditions will

reduce personal injuries.

Avoid accidental start up of the Model TL-900 by applying power only when ready to use. Un-

plug immediately when work is completed. Keep the trigger free from obstructions.

Make sure any attachments such as sockets, adapters and torque extensions are secured to

the tool’s square drive prior to operating the Model TL-900.

Do not overreach. Keep proper footing and balance at all times. Make sure cables are free

from snags and tangles when using the Model TL-900 off the ground.

Dress properly. Do not wear loose fitting clothing or jewelry. Make sure hair, clothing and

gloves are away from moving parts.

Keep your Model TL-900 handle clean from oil and grease. Holding a slippery handle will

make it difficult to safely control this powerful tool.

Tool Use And Care

Operate the Model TL-900 in 1 - 2 second long bursts. If the tool does not loosen the fastener

(nut or bolt) after (3) 1 –2 second bursts STOP and use other means to loosen the fastener.

Use only impact “rated” sockets. Non-impact sockets can break and cause

personal injury or property damage.

Always finger tighten fasteners before securing with the Model TL-900 to avoid cross-

threading.

Make certain that impact sockets are securely seated over the fastener prior to tightening or

loosening a bolt or nut.

Always use the correct size impact socket size. Incorrect sockets can damage the fastener or

slip off causing injury.

Always clean your Model TL-900 and all electrical connectors after use.

Operating Instructions

Hold the Model TL-900 firmly using both hands while operating it. Always wear safety gog-

gles or other approved eye protection. Heavy impacting can cause flying debris that can cause

permanent eye damage.

Sockets and fasteners can get hot during operation. Use protective gloves when handling them.

Do not operate the Model TL-900 for long periods of time. Vibration caused by the tool’s impact-

ing action may be harmful to your hands and arms. Use thick gloves to provide extra cushion and

limit exposure by taking frequent rest periods.

Operating Voltage

Your Model TL-900 requires a source of 24-30 VDC that is capable of providing 100 AMPS

(intermittent) to generate optimum impacting strength.

If you have a solid source of 24-30 VDC applied to your Model TL-900 and the impacting strength of the

tool seems sluggish or weak, please contact DC-Matic to obtain a return authorization (RMA) so we can

expedite the repair or replacement of your tool or arrange to have a new set of motor brushes sent to

you.

Thermal Protection/Cut Off

Your Model TL-900 is equipped with an internal, bi-metal thermostat that will shut-down the tool (kill the

trigger switch) when the tool becomes over-heated. Testing has revealed that this tool’s thermal

protection circuit will not activate if the Model TL-900 is used intermittently and allowed an adequate

amount of cool-down time between uses.

Note: When used in an ambient temperature of 90 degrees F the average amount of time needed for

the thermal protection circuit to re-set time is (30) minutes.

Control Box

Your Model TL-900 is equipped with a forward-positioned, 12-cluster LED work light (shown in Fig. 1).

The work light’s On/Off switch is located on the control box (shown in Fig. 3). To achieve the highest

degree of workplace safety always turn ON the work light when operating the Model TL-900 in a low or

no-light environment. The control box is “Factory Sealed” and must remain that way. Unauthorized

opening of the control box will void the tool’s warranty.

2

Input Power Connector

The Control Box that is part of your Model TL-900 is equipped with an Anderson Connector that is rated

for 175 amps of current. Before connecting your Model TL-900 make certain that this connector is free

of

debris and in good condition.

Impacting Mechanism

Your Model TL-900 is equipped with the highest quality, twin-hammer impacting mechanism (shown in

Fig. 1) It is factory lubricated and sealed so it is not necessary to service it in the field.

Do-It–Yourself Motor Brush Set Replacement

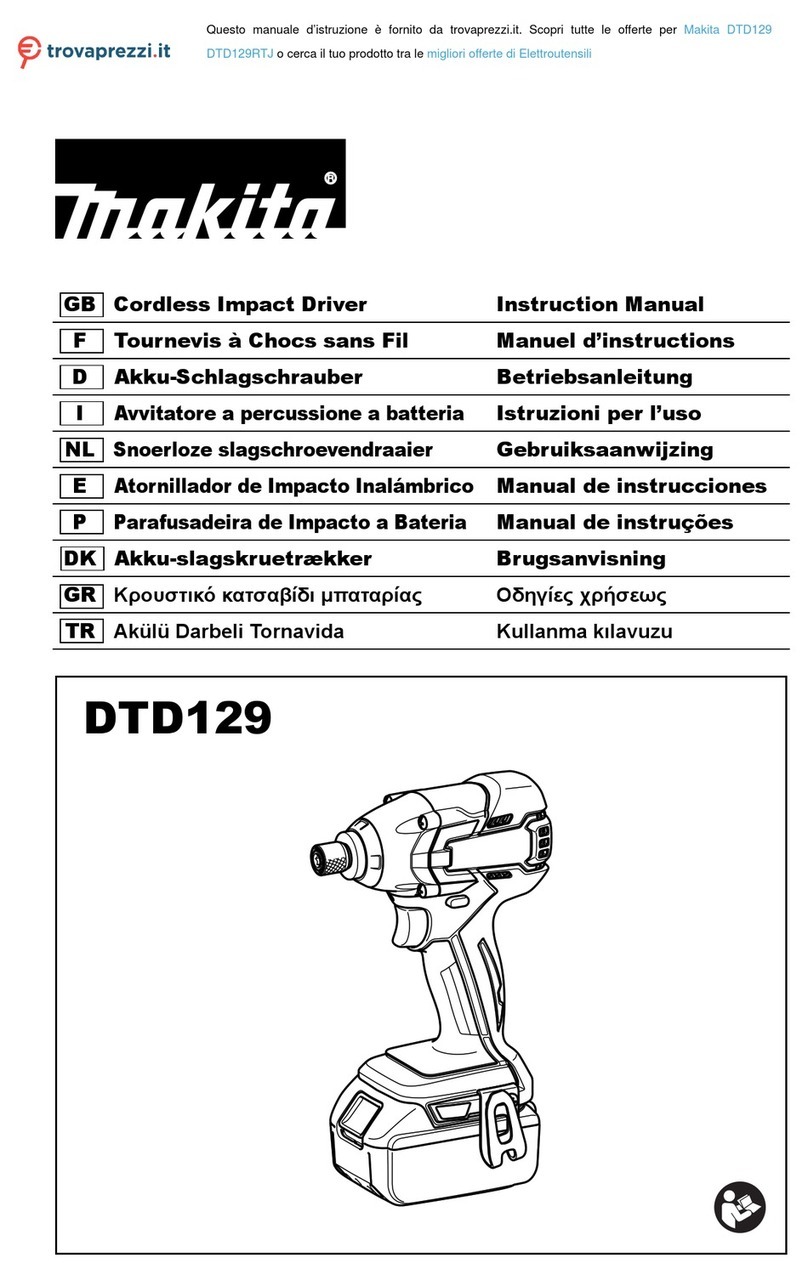

Your Model TL-900 is equipped with (4) external brush ports that will allow you to quickly and

easily replace your initial set without having to remove the 24 VDC motor from the tool’s plastic housing.

Each brush can be removed and replaced by using a standard flat-blade screw driver in minutes (shown

in Fig. 2).

Repairs

To achieve the highest degree of user safety and tool reliability, all repairs (excluding brush set

replacement) to your Model TL-900 must be performed by an authorized repair location. Please contact

DC-Matic Enterprises, Inc. for immediate support of your Model TL-900 and for proper product return

(RMA) instructions or to purchase a replacement brush set.

Returns

Each returned product must first be issued a RMA (returned merchandise authorization) by DC-Matic

Enterprises, Inc. Do not ship your tool back without a company issued return authorization

(RMA). To request an RMA call toll-free 1-(866)-419-5602

Note: Returned units must be shipped transportation prepaid to DC-Matic’s designated repair facility

noted on the RMA.

Warranty

DC-Matic Enterprises will repair or replace, without charge, any portion of your Model TL-900 tool

if a defect or failure was proved to be caused by faulty material or workmanship for a period of

ONE FULL YEAR from the date of purchase. Proof of purchase date is required for all

warranty claims. Warranty DOES NOT provide repair or replacement if it is determined that any

portion of the tool system failed due to abuse or when repairs were made or attempted by any

one other than “authorized” repair facility personnel. Please take the time to register your Model

900 using the mail-in Warranty Registration Card included in this packet or register the tool

online at www.dcmatic.com

Note: Each Model TL-900 has a manufacturer’s ID plate with serial number affixed to the bottom

of the tool’s Control Box ( shown in Fig. 4) for Warranty Verification purposes.

3

1

Environmentally Sealed Work Light

On / Off Rocker Switch

Fig. 1

Fig. 4

Mfr. Serial # Plate

Forward-Reverse

Rocker Switch

Control Box

8 Foot Long

Power Cord

175 Amp Anderson Quick Connector

Forward-Mounted Control

Brush Cap

Trigger Switch

12-Cluster LED

Work Light

3/4 Inch Drive-Twin-Hammer

Impact Assembly With Snap-

Ring Retainer

Solid Brass Brush Retainer Cap /PlugBrush

Port Cap

Replacement Brush

Standard Flat-Blade

Screw Driver

Fig. 3

Fig. 2

Control Box

4

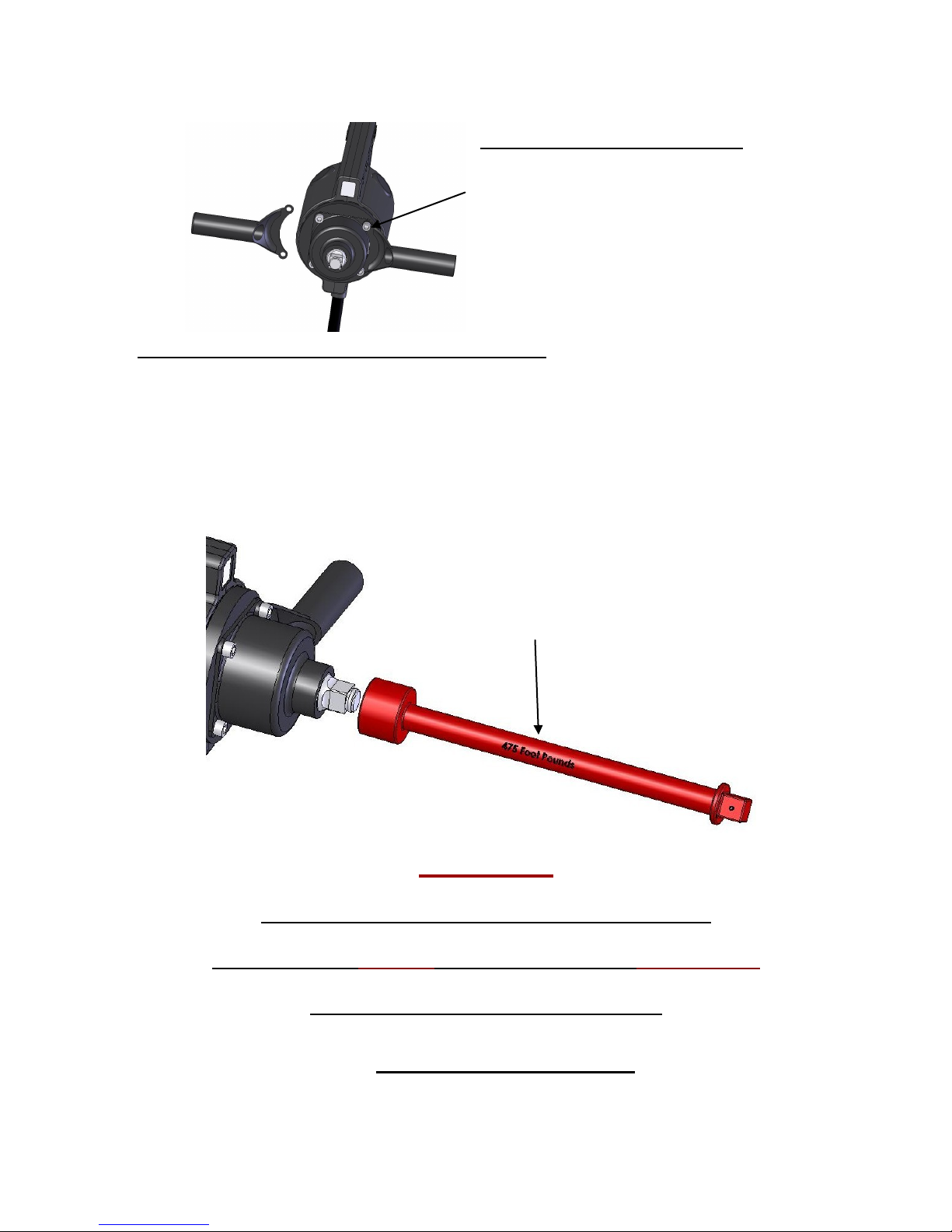

Fig. 5

Properly Controlling Output Impacting Torque

DC-Matic Enterprises, Inc. markets (4) individual 3/4 inch drive “torque limiting

extensions” calibrated at 175, 250, 350 and 475 foot pounds. When attached to the

Model TL-900 a burst of (2) seconds of tool run time will yield an output (impacting

torque) limited within the range (plus or minus 10 %) that is marked on the extension. It

must be noted that a longer than (2) second burst will yield a greater amount of

impacting torque.

WARNING

Excluding the do-it-yourself replacement of motor

brushes, please DO NOT attempt to repair your Model TL-900.

Doing so will void the tool’s WARRANTY.

Fig. 6

475 Foot Pound

Torque Limiting Extension

By removing the (4) allen-head cap screws

that secure the hammer assembly to the

tool, the stabilizing handle can be moved

to the other side as shown.

Stabilizing Handle Placement

5

www.dcmatic.com

Table of contents

Popular Impact Driver manuals by other brands

Sealey

Sealey CP400LI instructions

Haussmann Xpert

Haussmann Xpert PNT104-B Operator's manual

Parkside

Parkside PDSSE 450 A1 Translation of the original instructions

Ryobi

Ryobi R18IDBL Original instructions

Paoli Avvitatori

Paoli Avvitatori RED DEVIL 2.0 street legal Operating and maintenance manual

DeWalt

DeWalt DCF911 manual