3

1SAFETY AND WARNINGS

!WARNING!

Electric Shock Hazard

Read and follow the safety and warnings outlined in this installation

instructions guide before operating this appliance.

Failure to do so can result in death, electric shock, fire or injury

topersons.

!WARNING!

Cut Hazard

Take care – panel edges are sharp. Failure to use caution could result in

injury or cuts.

!WARNING!

This appliance is top-heavy and must be secured to prevent the

possibility of tippingforward.

To ensure that the appliance is stable under all loading conditions,

theanti-tip bracket and fittings supplied must be installed according

tothe following installation instructions by a professional installer.

Please follow the installation steps below to ensure your appliance is installed and

operatescorrectly.

Power

To ensure that the appliance is not accidentally switched off, connect your refrigerator to its

own isolating switch. Do not plug in any other appliance at this isolating switch.

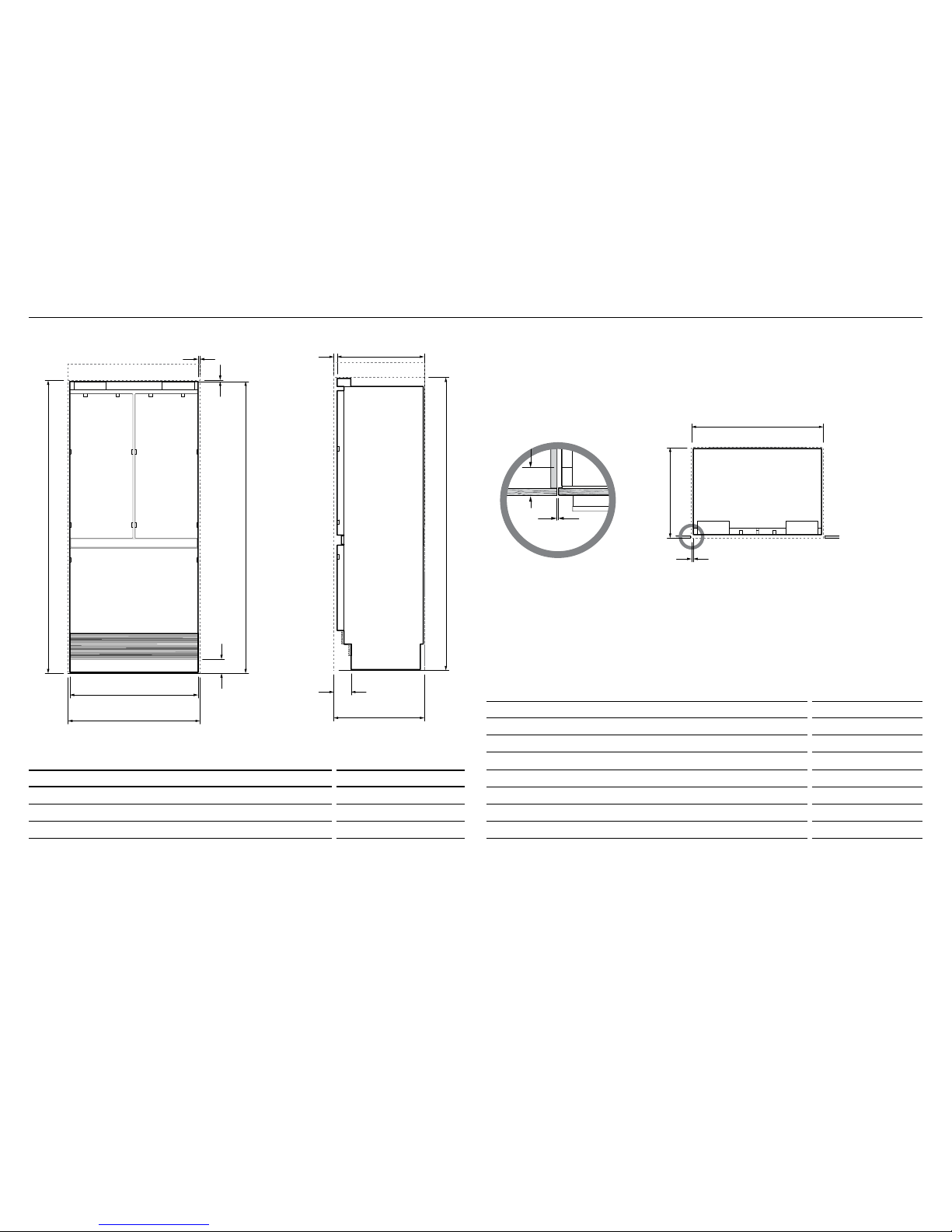

For power requirements, please refer to the information on the serial plate. This is located

atthe front right-hand side of the drawer when open.

It is essential that the appliance is properly grounded (earthed).

Connect the appliance to the electrical supply (115VAC, 60 Hz) with the fitted plug and lead.

Follow the National Electrical Code and all local codes and ordinances when installing

thisproduct.

Warning: Ground Fault Circuit Interrupters (GFCI) may trip during normal operation of your

refrigerator and interrupt the power supply. The use of a GFCI is not recommended with

thisproduct.

Location

Your refrigerator should not be located in direct sunlight or next to any heat generating

appliance such as a cooktop, oven or dishwasher.

Your product is fitted with front and rear rollers designed for moving the product in

forwards and backwards direction.

Avoid moving the product in a sideways direction as this may damage the rollers or the floor

covering/surface.

Plumbing

Your product must be installed by a qualified appliance installer as incorrect plumbing can

lead to water leaks.

DCS by Fisher & Paykel Appliances does not accept responsibility for damage (including

water damage) caused by faulty installation or plumbing.

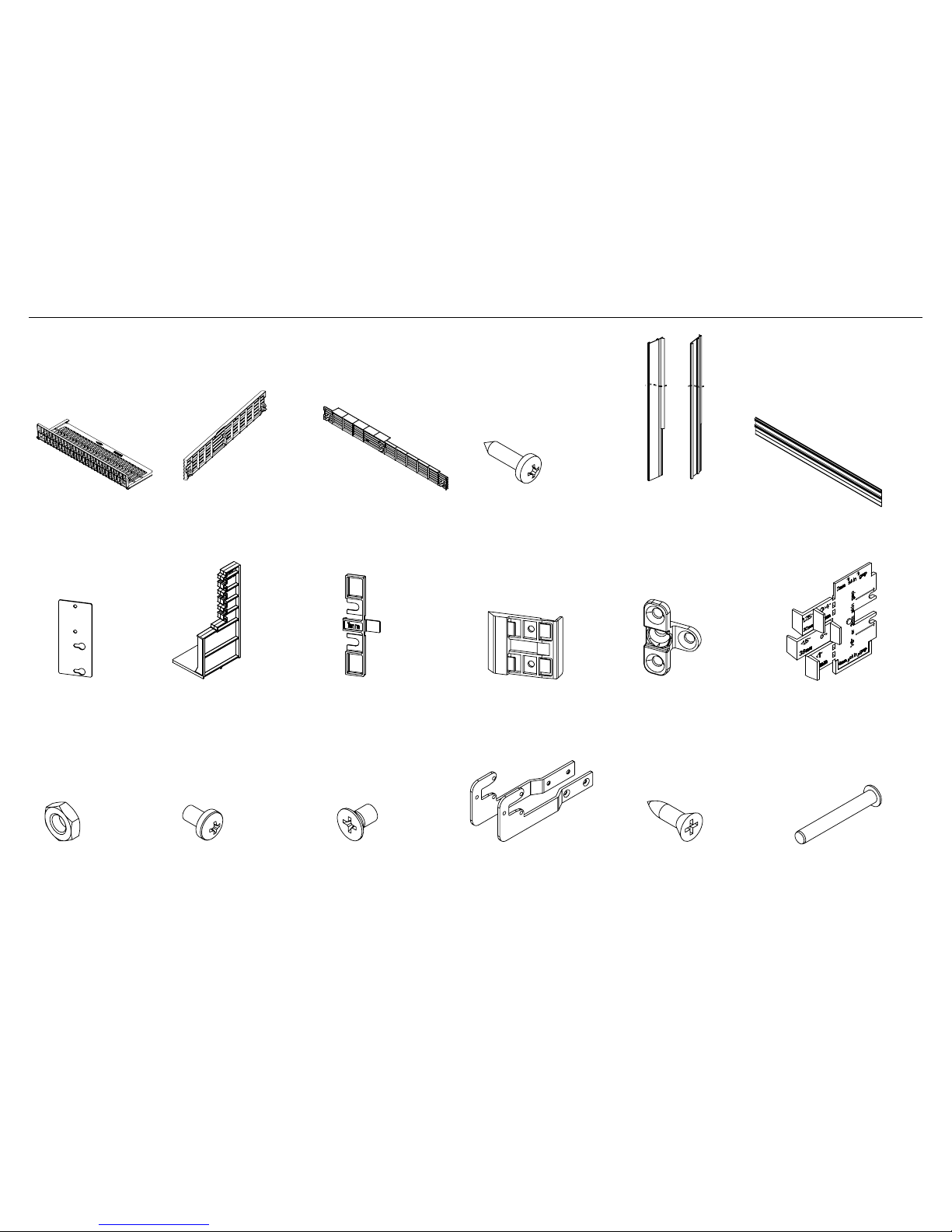

Door panel set

The standard appliance does not include a door panel set.

When designing custom door panels, these are only available for non-Water dispensing models.

To complete the integrated appliance for non-Water dispensing models the customer should

supply their own custom door panel set. All the hardware required to mount the door panel

sets to the refrigerator doors is supplied.

DCS by Fisher & Paykel door panel sets are available (Stainless steel door panels, model

numbers: RD3680C, RD3680CU, RD3684C and RD3684CU), and can be purchased through

your DCS by Fisher & Paykel dealer.

IMPORTANT!

SAVE THESE INSTRUCTIONS

The models shown in this installation guide may not be available in all markets and are subject to change at any time. For current details about model and specification availability in your country, please go to

our website www.dcsappliances.com or contact your local DCS by Fisher & Paykel dealer.

2BEFORE INSTALLATION