DDN Storage StorageScaler8460 User manual

DDN StorageScaler8460

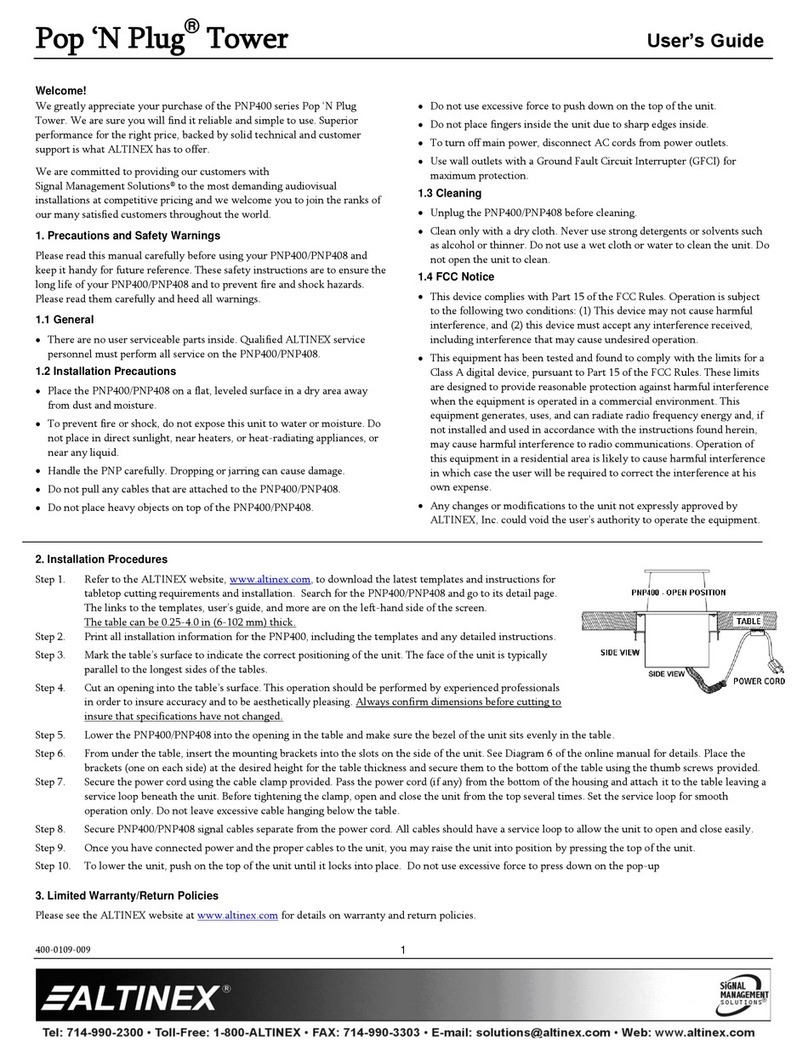

IBM Field Replacement Instructions.

Replacement Overview

Here is an overview of all the steps for installing a SS8460 system.

1. Safety

2. Preparation

3. Power down of the system.

4. Disconnect the SS8460 from the Storage Controllers or E pansion Enclosures.

5. Removal of Suspect SS8460 Chassis from Current Configuration.

6. Installation of New Replacement SS8460.

StorageScaler 8460 Replacement Instructions

1.0 Removal Preparation

1. Anti tip plate should have been installed at the time of rack instillation. If it is not

present, it must be installed prior to sliding any equipment forward out of the rack.

See figure 1 anti tip plate image. Ensure leveling pads are fully engaged to the floor

to prevent rack from moving during service activity.

Figure 1. Anti tip plate

.

2. Remove Rack Door from hinges and set aside.

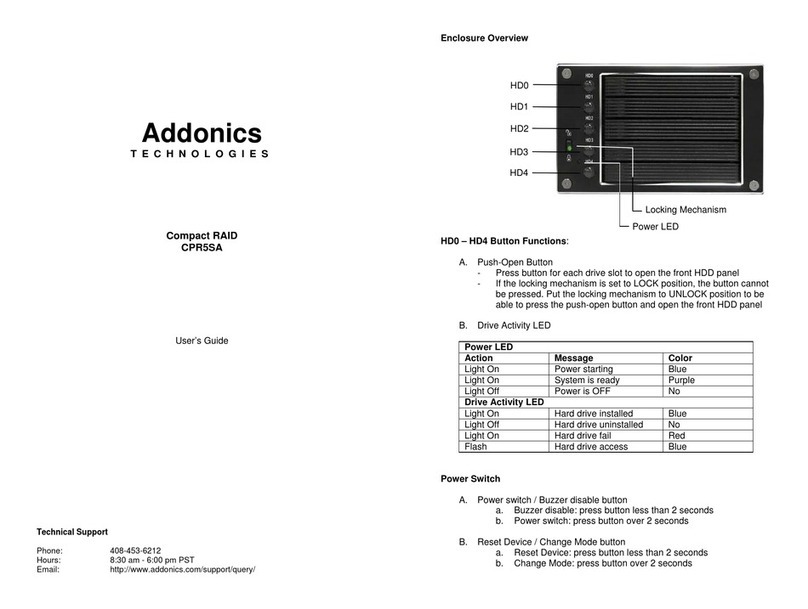

2.0.0 Single SS8460 Power Down Procedure

1. Stop all I/O to the SS8460.

2. Perform a “show subsystem summary” command and note any faults (not being

corrected by the enclosure replacement), total physical disks, pool state, virtual

disk state, and disk channel count.

3. Note either the failed enclosure’s ID or all the surviving enclosures ID’s with a show

enclosure command.

4. Shutdown controllers with a “shutdown subsystem” command. This will power

down the storage controllers.

5. Power down the SS8460 by turning off the switches on the PCMs. Figure 2

2.0.1 Multiple SS8460 Power Down Procedure

1. Stop all I/O to the SS8460 enclosures.

Formatted: Font color: Auto

2. Perform a “show subsystem summary” command and note any faults (not being

corrected by the enclosure replacement), total physical disks, pool state, virtual

disk state, and disk channel count.

3. Note either the failed enclosure’s ID or all the surviving enclosures ID’s with a

“show enclosure” command.

4. Shutdown controllers with a “shutdown subsystem” command. This will power

down the storage controllers.

5. Power down the master SS8460 by turning off the switches on the PCMs.

6. Power down the remaining e pansion enclosures by turning off the switches on

their PCMs. Figure 2

3.1 Disconnect the SS8460 from the storage controllers or

expansion enclosures.

Each SS8460 ships with two fully redundant PCMs. CAUTION: If power cable

replacement is required. Use only the power cables supplied with the enclosure.

Do NOT use another type of cord or e tension cords. If you require additional

power cables, please contact your DDN sales representative.

1. Verify that the power switch on both PCMs is in the OFF position (Figure 2).

2. Then disconnect the two power cables from rear of the SS8460. (Figure 3).

Figure 2

A Power and Cooling Module (PCM)

Figure 3.

SS8460 power ca les

3. Remove the SS8460 font bezel by positioning your hands as shown on

Figure 4 ON EACH SIDE of the bezel and gently pulling outward away from

the rack front and towards yourself.

Figure 4. Font Bezel

4. Remove the four screws (2 per side) that secure the SS8460 to the rack front.

Figure 5.

Figure 5.

Rack Securing Screws. 4 per SS8460

5. Use step ladders supplied with the FRU enclosure for upper rack U locations

as needed.

6. Verify that the cables and cable arm assemblies are such that cables won’t

get hung up and pulled on when the enclosure is removed.

7. Slide the enclosure out from the rack by pushing in the two release tabs on

front of the enclosure (Figure 6). Keep pulling until the enclosure locks and

you hear a clicking

.

The unit should now be out enough to open top covers.

Figure 6. Release Tab on Enclosure Front

8. Disconnect the SAS cables from the I/O modules. Disconnect the cable at the

highest position in the Cable Management Assembly CMA from the

innermost host port used on the I/O module (Figure 6). Then disconnect the

second cable to the ne t innermost host port used, working from the inside

toward the outside. Use Velcro to tie back in a safe place. Note that for SFA

subsystem installation, not all host ports are used on the I/O modules. Refer

to the cable maps given in the SFA OS User Guide to determine which host

ports are used

Figure 6. Ca le Positions in CMA

Figure 7 .CMA Cross Bar Removal

9. Remove the CMA cross bar on the rear panel of the enclosure by removing

two #10-32 screws as shown in Figure 7.

10. Repeat Step 1 above to remove the other CMA cross bar from the rack rear

panel of the enclosure.

4.0 Removal of Dis Modules and Enclosure

CAUTION :

Whenever handling disc modules ensure that the disk modules are at

room temperature before installing ore removing and powering up the SS8460.

It is recommended that the disks are allowed at least two hours at installation

and thirty 30 minutes after power down to acclimate to room temperature.

Figure 8 shows the layout of disks in the SS8460. The disk layout may also be

found inside the cover of the enclosure. Refer to Appendi B for information on

zoning configuration.

1. Prepare an area such as a table located in close pro imity to the SS8460 you

are working on for placement and temporary storage of the removed disc

modules. NOTE: It is highly recommended that each disc module and blank

be labeled with its current installed location within the SS8460 prior to

removal.

2. Store the drives in an area so that they remain acclimated to room

temperature. Drives and new replacement enclosure must be acclimated to

the same room temperature before drives can be reinstalled into the

replacement enclosure.

Figure 8 . Disk Module

Layout

3. Swing up both cover release handles to disengage the locks (Figure 9). Lift

up the cover. The cover is equipped with constant torque hinges which allow

the door to remain in place at any open position and prevent it from being

dropped.

Figure 9. Cover Release Handles

When removing the disk modules:

- Create a more balanced load by evenly distributing the disk modules among the

enclosures

- Always remove the rows from back to front.

Note that disks with similar rotational speeds are placed in the same row if a

mi ture of disk technologies are populated into one enclosure, for optimal

performance, the best loading order from back to front will be:

- SAS disks, SATA disks, then SSD

- - 3.5" HDD, then 2.5" HDD or smaller

-

Note : To ensure proper airflow through the enclosure, the SS8460 requires that any

empty disk slot to be filled with a blank module.

4. On the disk module, press the latch to release the handle (Figure 10).

Figure 0. Release Latch on Disk Module

5. Carefully slide the module from the disk slot (Figure 11).

Figure . Removing Disk Modules

6. Repeat Steps 4 and 5 above to remove all the remaining disks and blank

modules.

5.0 Removal of Suspect SS8460 C assis from Current Configuration.

1. Carefully position the lift tool in front of the rack (Figure 12) and raise the load

plate up under the enclosure to be removed so that the load plate is now

supporting the enclosure. Ensure the foot brake is applied and secure in position

Figure 13

Figure 2. Proper Lift tool Place in Front of the Rack

F

igure 3 Foot break lock / unlock mechanism

2. Carefully disengage the enclosure rails from the rack rails and slide the rack rail

back into the rack (Figure 14a and 14b). The SS8460 Enclosure is now

dismounted from the rack. Adjust Load plate up and down as necessary for ease

of enclosure removal.

Figure 4a Detach Enclosure Rail from Rack Rail (Right Side)

Figure 4b

3. Re Use the packaging material from the new replacement unit to repack the

suspect unit for proper return.

6.0 Installation of New Replacement SS8460

6.01 Installation Overview

1. Unpack the SS8460 system.

2. Rack mount the SS8460 and install cable management assembly. Refer to

Appendi A for physical dimensions and weight of the SS8460.

3. Install the disk modules.

4. Connect the SS8460 to the storage controllers or e pansion enclosures.

5. Power up the system.

6.0.2 Unpac ing the SS8460

Your SS8460 ships with the following:

- SS8460 enclosure

- Two power cables

- Rack-mounting hardware

- Cable management hardware

- SS8460 user documentation CD

- Disk modules

- Blank modules (if ordered)

Before you unpack your SS8460, inspect the shipping containers for damage. If

you detect damage, report it to your carrier. Retain all bo es and packing

materials in case you need to store or ship the system in the future.

Perform the following steps:

1. Open the top of the bo . Inspect for damage.

2. Remove all the components from the packaging, inspect the SS8460

chassis and all components for signs of damage. If you detect any

problems, contact DataDirect Networks Customer Service as soon as

possible. Then place the components on an anti-static surface until you are

ready to use them.

3. There are two nylon lifting straps that are used to remove the enclosure

assembly from the bo (Figure 15). A forklift or other mechanical lifting

device is highly recommended to remove the unit and to place on the IBM

lift tool.

Figure 5 Unpacking the SS8460

6. If you are installing the enclosure in a rack: a) Ensure that you have these tools

available: • Phillips screwdriver • Bubble level b) Arrange for assistance during

installation c) Ensure ahead of time that you have chosen a suitable location for the

enclosure or rack assembly.

7. Ensure that the area around the enclosure or rack assembly has sufficient cooling

and space around the unit to access cabling.

8. When installing disk modules, allow them to acclimate to room temperature prior to

installation. Disks should be stored at room temperature for at least two hours prior

to use.

6.0.3 Installing the SS8460 in a Rac

The SS8460 enclosure is designed to fit within a 4U rack space. Follow these steps to

mount the enclosure in your rack:

1. Ensure that you have these rack mount components: • Rack rails (one left, one

right) • Rail installation hardware (screws, screw plates, shelf locking brackets)

2. Remove the enclosure rails from the right and left side of the enclosure. If rails

were shipped with the replacement unit you may instead, pull the enclosure rail out

of the rack rail until it is fully e tended. Then press the locking tab down to release

the enclosure rail (Figure 15a and B). Press the locking tab on the middle rail and

push it back into the rack rail. Repeat for the other rack rail.

Figure 5a Detach Enclosure Rail from The Right and Left Sides (Right Side shown) or

remove from suspect unit. SS8460 Rail (Right Side)

Figure 15 b

3. Attach the enclosure rails to each side of chassis by positioning the rails

over the keyhole tabs, and slide the rails into place. The rails are marked

“R” (right) and “L” (left) viewing from the front of the enclosure. Do not

e change the enclosure rails. Secure each rail using seven #8-32 flat head

screws (Figure 15b).

4. With the new replacement SS8460 in place on the lift tool carefully position

the lift tool in front of the rack (Figure 12) and raise the load plate up under

the enclosure to be removed so that the load plate is now supporting the

enclosure. Ensure the foot brake is applied and secure in position Figure

13.

5. Position the lift tool shelf and new replacement SS846 to the proper height

to enable alignment of enclosure rails and rack rails and slide the rear

alignment blocks on to the rack rails to align the enclosure properly with the

rack rails.

6. Carefully engage the enclosure rails into the rack rails and slide the

enclosure in until the enclosure rail tabs “click” into place. The SS8460

enclosure is now mounted in the rack (Figure 16).

Figure 6. Enclosure installed in Rack

7. Carefully reinstall all drives removed in previous steps by sliding the module

into a disk slot until it contacts the baseboard and begins to engage the

handle (Figure 11). Press down on the handle until it latches which will cam

the module into place.

8. Reconnect the SAS cables, CMA cross bars.

9. Verify that the power switch on both PCMs is in the OFF position Figure 2.

10. Reinstall Power cables removed in previous steps. Figure 3.

6.0.4 Single SS8460 Power up Procedure

1.

Turn the switch on each PCM to the ON position.

2.

Wait appro imately 1 minute for all the disks to become ready.

3.

Power on and boot the storage controllers.

4.

Verify and set zoning if necessary

a. Note lines 11 and 12 from the output of “show enclosure X all”

where X is inde of the replacement enclosure

b. For 1-5 shelf configurations, the zoning should be:

i. Zones: 2

ii. Zoning Configuration: 1

c. For ten or greater shelf configurations the zoning should be:

i. Zones: 1

ii. Zoning Configuration: 0

d. If the enclosure zoning is incorrect (normally set by the factory with

one zone) then issues the following commands against the

enclosure:

i. “Set enclosure X zoning Y” (where X is enclosure inde and

Y is 0 or 1)

ii. “Set enclosure X restart” (see inde from previous step)

iii. Issue “show enclosure + 60”. Wait until response is TRUE,

and then hit return to stop the output.

iv. Show enclosure X all (verify zoning change took affect)

5. Perform a show subsystem summary command and note any faults (not

being corrected by the enclosure replacement), total physical disks, pool

state, virtual disk state, and disk channel count.

6.0.5 Multiple SS8460 Power up Procedure

CAUTION : The power up order is critical for each of the e pansion enclosures

to properly be seen by the previous unit in the chain. For systems with

e pansion enclosures attached, the enclosure last in the chain should be

powered up first, followed by the other enclosures with the master unit being

turned on last.

1. Turn the switch on each PCM supply to the ON position.

2. Wait appro imately 1 minute for all the disks to become ready.

3. Power on and boot the storage controllers.

4. Verify and set zoning if necessary

a. Note lines 11 and 12 from the output of “show enclosure X all”

where X is inde of the replacement enclosure

b. For 1-5 shelf configurations the zoning should be:

i. Zones: 2

ii. Zoning Configuration: 1

c. For ten or greater shelf configurations the zoning should be:

i. Zones: 1

ii. Zoning Configuration: 0

Table of contents