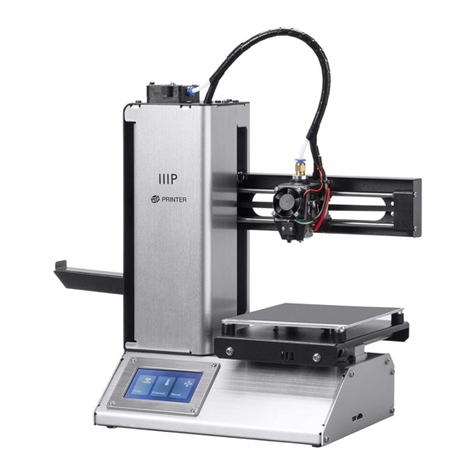

De Agostini Model Space Idbox pack 10 User manual

Pack 10

Compatible with

Windows 7 &8

Mac OS X

Anything you can

imagine, you

can make!

3D PRINTER

BUILD YOUR OWN

3D technology is

now available for

you at home!

254 255

All rights reserved © 2016

Published in the UK by

De Agostini UK Ltd,

Battersea Studios 2,

82 Silverthorne Road,

Battersea, London SW8 3HE

Published in the USA by

De Agostini Publishing USA, Inc.,

121 E. Calhoun Street,

Woodstock, IL 60098

Stage 41: Add the Z-axis and feeder motor

drivers, and the feeder motor cable

Stage 42: Connect up the power supply and

xittothehousing

Stage 43: Connect the X-, Y- and Z-axis limit

switches to the driver board

Stage 44: Attach two brackets to the housing and

add a linear bush to the modelling table

Stage 45: Add a second linear bush

to the table

WARNING: Not suitable for children under the

age of 14. This product is not a toy and is not

designed or intended for use in play. Items may

vary from those shown.

Thenextvedetailedandeasy-to-followstagesofconstructionforyour3Dprinter.

Assembly Guide 263-279

User Guide Section 1: Download, install and congure

Repetier-Host for the idbox

In this new section of Build Your Own 3D Printer,youwillndouthowto

download and install the software that you need to control the printer. You will

alsoseehowtosetupthesoftwaresoyoucanprintoutyour3Dles

successfully. Plus, how to connect the printer to your computer.

User Guide 255-262

CONTENTS PACK 10

3D PRINTER

BUILD YOUR OWN

TM

www.model-space.com

266-270

271-275

276-277

278-279

263-265

254 255

User Guide

User Guide Section 1:

Download, install and congure

Repetier-Host for the idbox

Repetier-Host is a free-to-use piece of

software that is employed around the

worldbypeoplewhoprintoutleson

a3Dprinter–lescreatedon,or

downloaded to, their computers. It can

be set up to work with a wide range of

3Dprintersandoncesetup–whichdoes

nottakeverylong–willmakeprinting

out3Ddesignseasy.Theset-upforthe

idbox is simple and straighforward, and

aftertherstinstallation,itwillnothave

to be done again.

1

In this section, you will download Repetier-Host–thesoftwarethatyourcomputeruses

to communicate with the idbox. You will then set up Repetieranditsbundled‘slicing’

software to work with your idbox.

1. Go to the Repetierwebsite(www.repetier.com)andclickontheFREEDOWNLOADlink.

There is lots of

useful information,

including pages

ofDocumentation,a

Troubleshooting section,

Tutorial pages and a Forum

on the Repetier website.

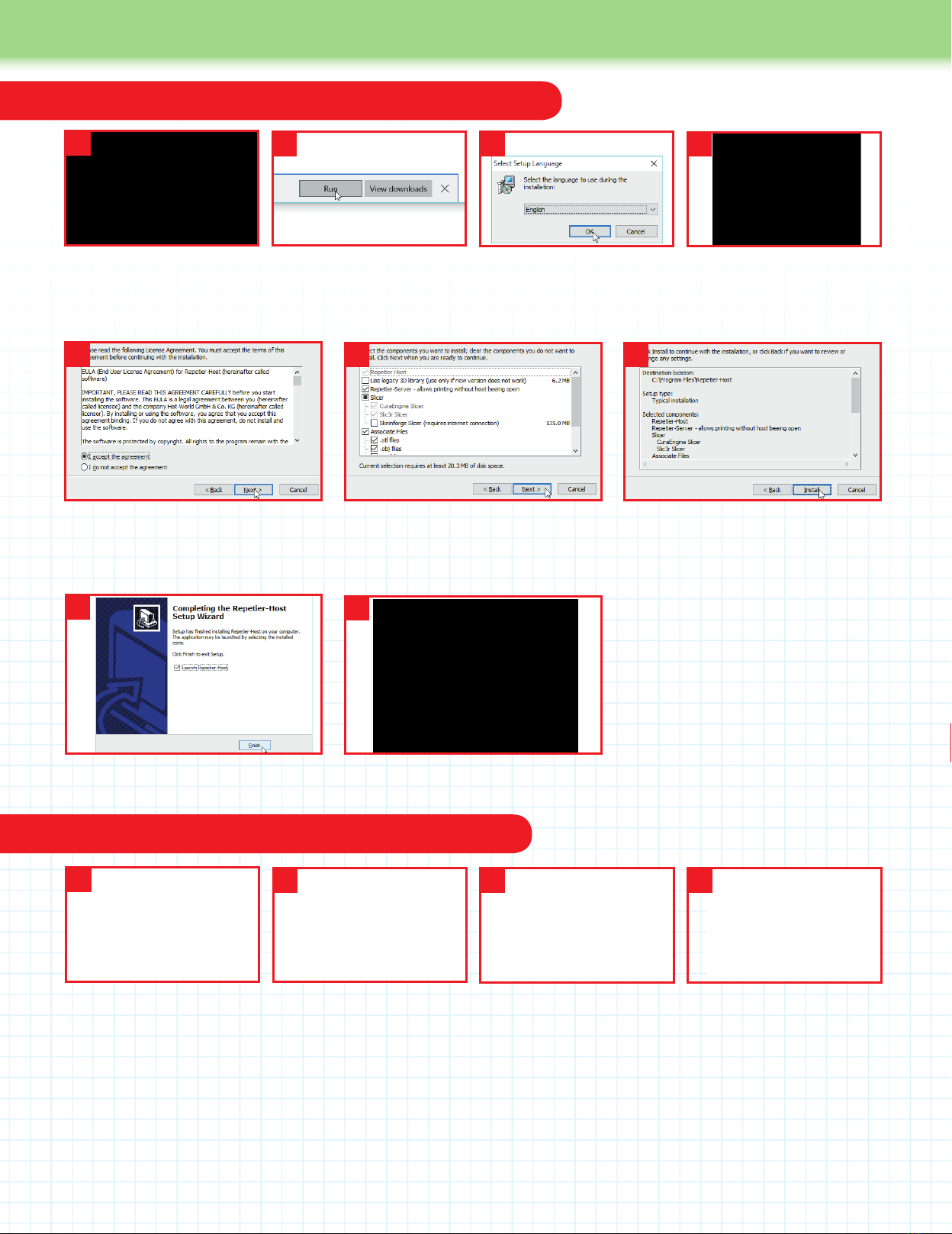

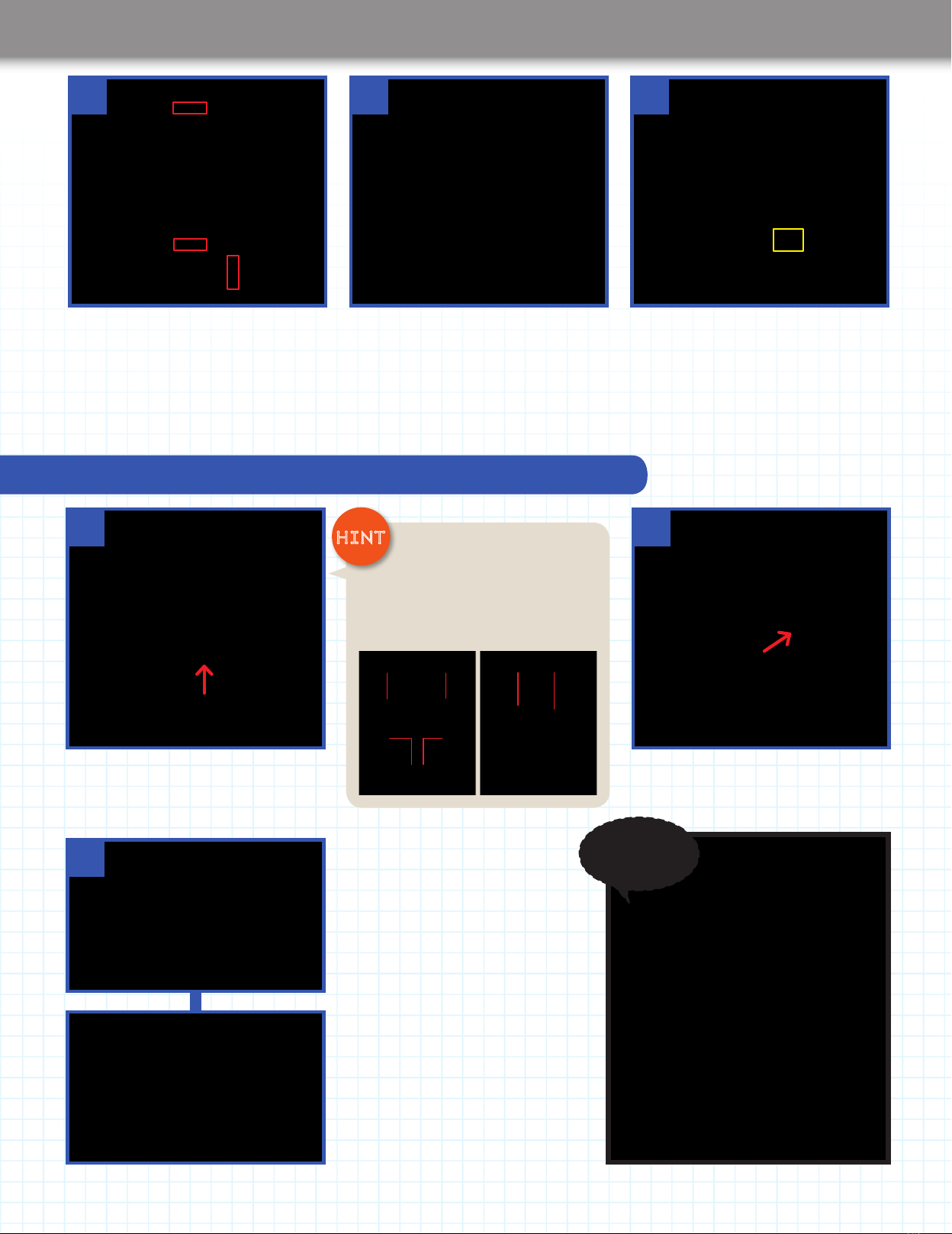

Preparing to download Repetier-Host

Computer compatibility

3. When you click on this, you

willseethe‘Downloadnow’

page, where you can chose the

version of Repetier-Host

for the operating system

on your computer.

2.You’llbetakentoapage

where you are invited to make

a donation to support the

development of this free-to-use

software. If you do not want to

donate right now, scroll down the

page and you will see a link that

says‘Downloadwithoutdonation’.

2

3

Please check the

specicationofthePCyou

want to connect to the idbox

to see if it is suitable. Below

istheminimumspecications

fortheOperatingSystem

(OS):

Windows 7 or higher

MACOSXorhigher

With older PCs, you may run

into problems, such as slicing

taking a very long time or

the computer crashing when

large or complex objects are

being printed.

256 257

User Guide

Download and install on a Mac

Download and install on a Windows PC

5. In the next dialog window, accept the

LicenseAgreementandclickonNext.The

‘SelectDestinationLocation’dialognow

appears: click Next on it.

6.Onthe‘SelectComponents’dialog

(above)–unchecktheoptiontoinstall

Repetier-Server, then click Next. Click

Next on the Select Start Menu Folder.

1.Onthe‘Downloadnow’

page, click on the link for the

latest version of Repetier-Host

for Windows.

4. This takes you to the

Repetier-Host Setup Wizard.

Click Next to start it.

13

5

2. When it has downloaded,

click Run at the bottom of the

page. Click Yes to allow the app

to make changes to your PC.

2

3. Inthe‘SelectSetup

Language’dialogthat

appears, choose English,

andclickonOK.

6 7

ClickNextonthe‘SelectAdditionalTasks’

dialog.Onthe‘ReadyToInstall’dialog

(above) click on Install. Files will then be

installed on your computer.

8.OntheCompletingtheRepetier-Host

Setup Wizard dialog, click on Finish.

9. The program will launch, showing a

window like the one above.

1. Onthe‘Downloadnow’

page, click on the link for the

latest version of Repetier-Host

for Mac. It will download into

yourDownloadsfolder.When

thedownloadhasnished,

ndtheleinyourDownloads

folder and double-click on it.

4. The program will launch,

showing a screen similar to the

one shown here.

13

8

4

2. A window opens on the

desktop with the Repetier-

Host Mac.app icon in it. In the

Finder, open the Applications

folderviatheGomenu.Drag

the icon into this folder. When

it has copied, double-click its

icon in the Applications folder.

2

3. If the program does not

open, right click (or ctrl click)

on its icon in the Applications

folderandselectOpenfromthe

menu of options that appears.

In the dialog box that then

appears(above),selectOpen.

9

4

256 257

User Guide

Fromthispointon,theUserGuideinstructionsassumethatyouhavenished

constructionoftheidbox.Do notproceedifyouhavenotnishedtheidbox.

Connecting the idbox to your computer

Connecting the power cable

Connecting the idbox to your computer and connecting the power cable

BeforeyoucongureRepetier-Host to work with your idbox, you have to connect the idbox to your

computer using the USB cable. Before you plug in the mains cable to the idbox, there are a couple

of things that have to be done, so do not plug in until you have done these.

Connect the PC and the idbox using the included USB cable.

(Donotpluginthepowercableoftheidboxatthispoint.)Insert

the smaller USB B-type connector into the socket on the right

side of the idbox and the larger USB A-type connector into a

USB port on the PC.

The idbox does not have a power switch, so connecting the

USBcablewillautomaticallyturnontheidbox’scircuitboard.

The circuit board takes its power from the PC via the USB cable

and does not require power from the power plug, which supplies

power to the motors, heater, etc.

The circuit board should be automatically recognised after

plugging in the USB cable. If an error occurs, please recheck

the USB connection, reinstall the driver (if you are using a PC

running Windows) and restart your PC.

Ifthereareerrorsintheassemblyorconguration,

there is a chance that the idbox might suddenly begin

moving when the power cable is connected. If the

idbox suddenly starts moving after inserting the power cable,

immediately remove the power cable. The use of an extension

socket with an on/off switch is recommended.

Donotpluginthepowercableatthispoint.Pleasewait

until after you have followed the instructions set out under

theheading‘Connectingthepowercable’,below.

CAUTION!

CAUTION!

It’snowtimetoconnecttheidboxtoyourcomputerusingtheUSBcable.Ifyouareusingacomputerrunning

Windows,youhavetodownloadandinstalladriver–softwarethatconnectsaPCtoexternaldevices,suchas

printers like the idbox. Mac computers come with the driver pre-installed.

IfconnectingaWindowsPCtotheidbox,downloadArduinoIDE

version 1.0.6 from the website:

https://www.arduino.cc/en/Main/OldSoftwareReleases#previous

Click on the Windows Installer link and follow the instructions to install

the driver. If even after installing Arduino 1.0.6, you have trouble

connectingthePCtotheidbox,downloadandinstallArduinoIDE

version 1.0.5 (available on the same web page). Version 1.0.6 (or

1.0.5) are the recommended versions. Any other versions of the

Arduinodrivershouldbeusedattheuser’sdiscretion.

1. Check that there is at least 5mm of space between the

nozzle and the table (the table and nozzle may be farther apart

depending on the assembly). If the gap is too small, turn the

cup ring on the Z-axis (the silver cylinder) anticlockwise to

lower the table. If the power cable is already connected, the

table will not be movable by hand. Unplug the power cable,

and then operate the table by hand.

2. Move the head by hand toward the centre of the table.

When moving the head by hand, hold it with both hands and

moveitcarefully.AswiththeZ-axisbefore,itwillbedifcultto

move by hand if the power cable is already plugged in. If the

power cable is already plugged in, unplug the power cable

and then operate the head by hand.

Installing the driver software (Windows only)

Before you plug in the power cable

Donotpluginthepowercableuntilafterperformingthetwoproceduresdescribedbelow.Onlyplugitinwhenspecicallyinstructedto

do so. When you plug the power cable into the idbox, this sends power to the various motors and the heater.

After you have performed the procedures described in the box

‘Beforeyoupluginthepowercable’shownleft,youmaynowplug

one end of the power cable into the back side of the idbox and

the other end into a power outlet. (If using an extension cable with

switched sockets, plug the extension cable into a power outlet and

switch on the socket.) When you turn on the power, the head fan

should activate and there should be no sudden movements of the

table or the head.

258 259

User Guide

Before you can use Repetier-Hosttocontroltheoutputfromyouridbox,youhavetoconguretheprogramsoitknowshowtocommunicate

withtheidbox.Itneedstoknowtheidbox’sbedsize,therangeofthemovementsitsprinterheadcandoandthetemperaturesettingsfor

thenozzle.Thesesettingsonlyneedtobeenteredonce.ThewaytosetupRepetiertoworkwithyourcomputerisshownbelow,rstfora

Windows computer and then for a Mac. After this, you check that the computer and idbox are connected properly.

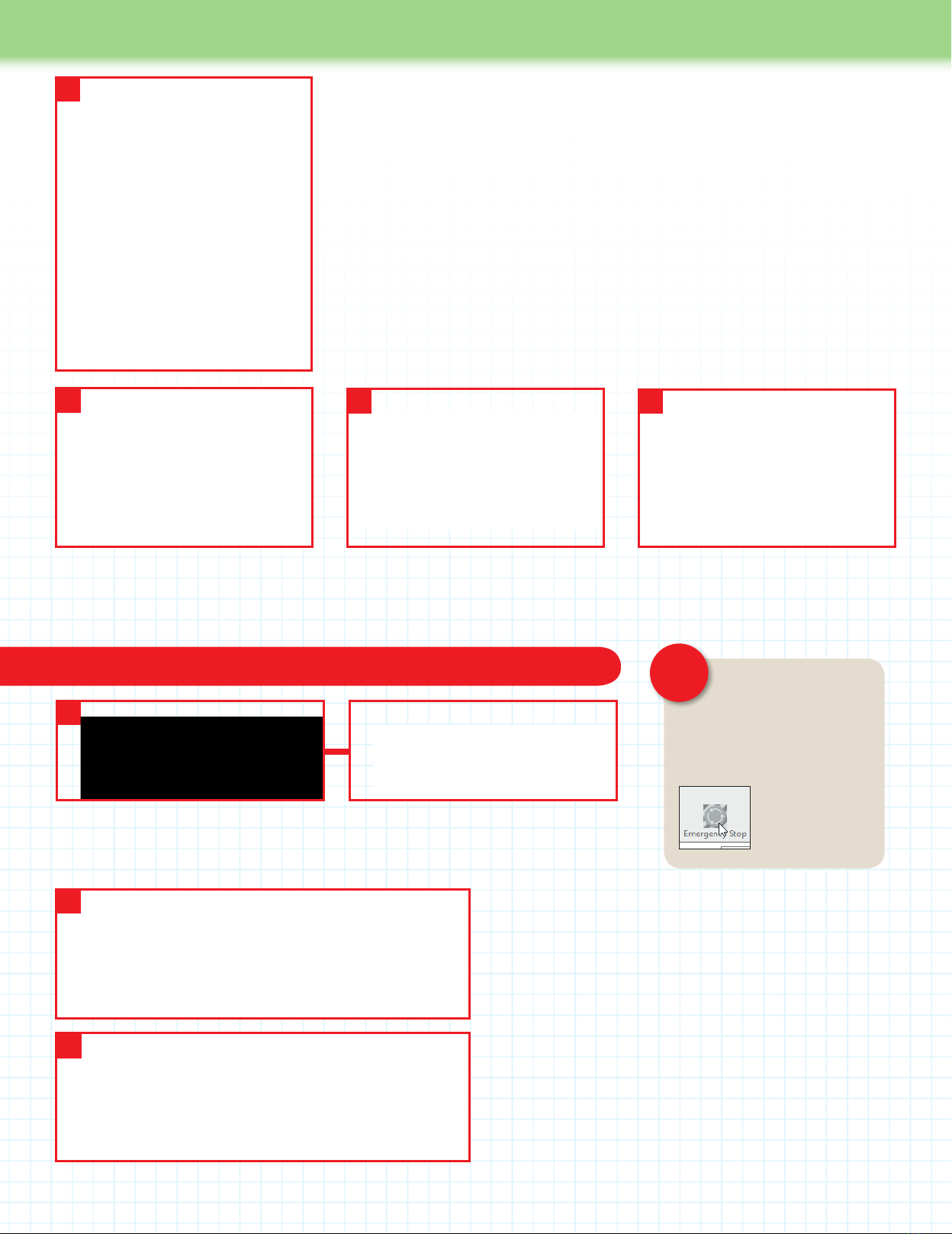

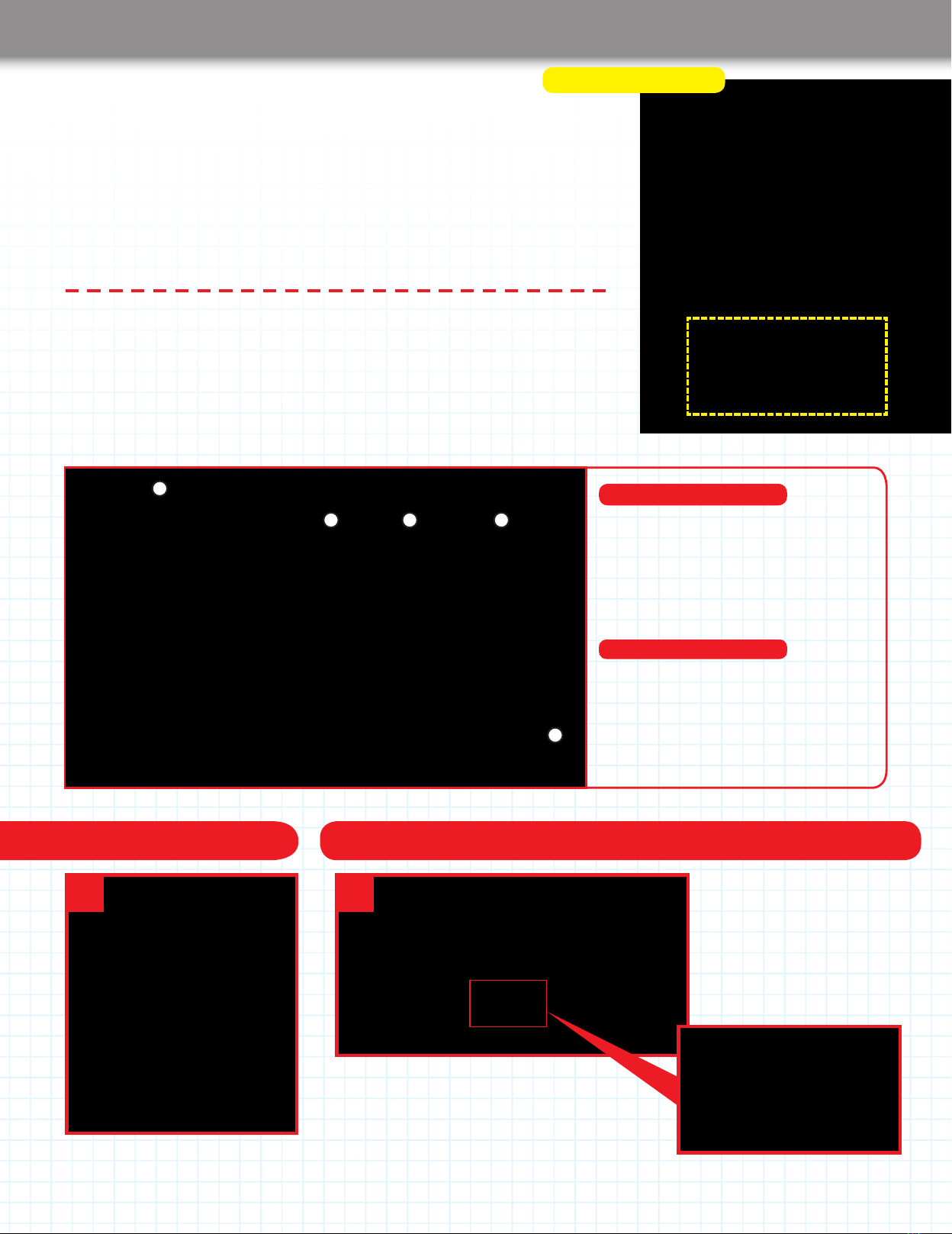

Congure Repetier-Host for a Windows computer

3. Next, you set the number of extruders

and the nozzle size and so on. Click the

Extruder tab. The idbox has a single

extruder, so select 1. The diameter of the

nozzle supplied with the idbox is 0.4mm,

soenterthatasthevaluebyDiameter.

SETTINGS

Number of Extruder: 1

Diameter: 0.4

1. Click the Printer Settings button

onthetoprightofthewindow.Once

the Printer Settings window is open,

click the Connection tab and enter the

values as shown in the image on the left

and in the SETTINGS text on the right.

This procedure should be performed

with as few devices attached to the PC

aspossible.Dependingontheprecise

congurationofyourhardwareand

software, you might also see the setting

for Reset on Connect. If so, set it to

DTRlow->high->low.Thesettingfor

Communication timeout can be left at

the default value.

SETTINGS

Connector: Serial Connection

Port: Auto (If this does not work, test

each of the other options in sequence)

Baud Rate: 115200

Transfer Protocol: Autodetect

Reset on Emergency: Send emergency

command and reconnect

Receive Cache Size: 63

1

3

22. Now click the Printer tab and enter the

values shown in the image on the left

and in the SETTINGS text on the right.

The values here are the recommended

values for the idbox when printing using

PLA.‘DefaultExtruderTemperature’

shouldbesetto220℃,and‘Default

HeatedBedTemperature’shouldbe

setto60℃.Theactualtemperaturesfor

printing will be determined by the printing

temperature upon the start of printing.

Even though the idbox does not have

aheatedbed,youcansetthe‘Default

HeatedBedTemperature’hereanyway.

SETTINGS

Travel Feed Rate: 4800 [mm/min]

Z-Axis Feed Rate: 200 [mm/min]

Manual Extrusion Speed: 2, 20 [mm/s]

Manual Retraction Speed: 5 [mm/s]

Default Extruder Temperature:220℃

Default Heated Bed Temperature: 60℃

Park Position: X:0 Y:0 Z:0

Add to comp. printing time: 10%

Othercheckboxes:(seeimage,left)

Conguring Repetier-Host to work with the idbox

The printer settings that Repetier-Host uses are chosen by selecting a name entered

for the Printer at the top of the Printer settings window. They are stored every time you

clickonOKorApply.Tocreateanewsetofprintersettings,enteranewprintername

in‘Printer’andclickApply.Thenewsettingswillhavewhateverthecurrentvaluesareinthe

PrinterSettingswindow.Youcanthenchangethemifyouwant,andthenclickOK.

258 259

User Guide

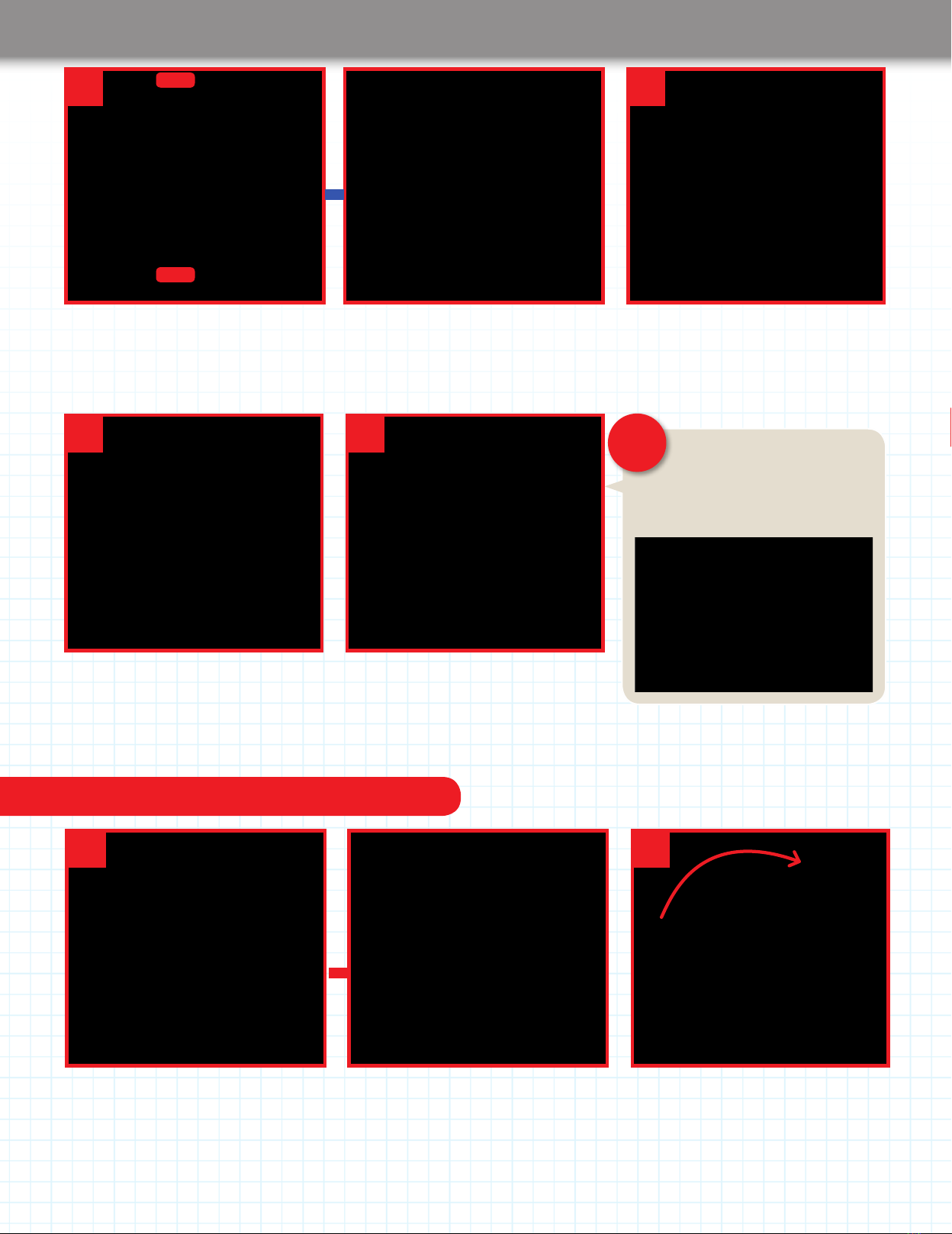

Congure Repetier-Host for a Mac computer

4.Clickonthe‘PrinterShape’tabto

enter information about the volume of

the space the idbox can print in. Where

settings are not shown on the right, the

default values can be used.

Onceallvalueshavebeenentered,

clickOKtosavethesettingsandclose

thewindow.ClickingOKwill

save the settings under whatever name

is entered at the top of the window

by‘Printer’.

SETTINGS

X Min: 0 X Max: 150 Bed Left: 0

Y Min: 0 Y Max: 130 Bed Front: 0

Print Area Width: 150 mm

Print Area Depth: 130 mm

Print Area Height: 100mm

4

11.Clickon‘Printersettings’atthetop

right of the Repetier-Hostwindow.Once

the‘Printersettings’windowisopen,click

the Connection tab and enter the values

as shown in the image on the left and in

the SETTINGS text on the right.

If multiple ports are available for

selection in the Port dropdown menu,

select any one for now. The values

available may not contain the one shown

in the image on the left, depending on

the Mac being used.

SETTINGS

Port: usbmodem****

(**** will change depending on the Mac

being used.)

Baud rate: 115200

Stop Bits: 1

Parity: None

Transfer Protocol: Autodetect

Receive cache size: 63

22. Click the Behaviour tab and enter the

values as shown in the image on the left

and in the SETTINGS text on the right.

The values here are the recommended

values for the idbox when printing using

PLA.‘DefaultExtruderTemperature’–

shouldbesetto220℃,and‘Default

heatedbedtemperature’shouldbeset

to60℃.Theactualtemperaturesfor

printing will be determined by the printing

temperature upon the start of printing.

Even though the idbox does not have

aheatedbed,youcansettheDefault

Heated Bed Temperature here anyway.

SETTINGS

Travel Feedrate: 4800 [mm/min]

Z Axis Travel Feedrate: 200 [mm/min]

Default Extruder Temperature:220℃

Default heated bed temperature:60℃

Number of Extruder: 1

Check Extruder & Heated bed

every 1 seconds

Dump area positon: X= 5 Y= 5

Z-min= 0

Add to comp. printing time: 10%

Othercheckboxes:(seeimage,left)

260 261

User Guide

3

4. You now save the new settings and

give them a new name. Click the Add

button on the top row of the Printer

Settings window.

4

5. A dialog box appears. Enter a new

name, such as idbox, and click Create.

56

6. Click the OK button at the bottom of

the Printer Settings window.

Check the connection between the computer and the idbox If at any point from now

on, the idbox goes out

of control, press the

Emergency Stop button (Windows

version is shown, but Mac version

is virtually identical) to immediately

terminate all

movement. If the

idbox still does not

stop, unplug the

power cable.

CAUTION!

1

1. To check that the software on your computer is ‘talking’ to the idbox, click on the red

Connect button at the top left of the screen. The Windows version is shown above left and

the Mac version above right.

2. Attempting to connect to printer. Connection opened.

If the connection is successful, a message similar to the

one above should be visible in the log. The version shown is

for Windows, but is similar on the Mac. If you can’t see any

message, click on Toggle Log (Windows) or Load G-Code

(Mac). These are close by the Connect button at the top left

of the screen (See above).

3. There could be several reasons why you see an error

message. The USB cable might not be plugged in properly, the

correct driver (Windows) might not be installed or the wrong

Port might have been chosen in the Printer settings. Check

that the USB cable is in OK, reinstall the driver and restart your

Windows PC. Alternatively, select a different port on the Mac or

Windows PC and try each one until one of them works.

2

3

Attempting to connect to printer. Couldn’t open port for device

If a message like this appears, there is a problem with the connection.

idbox

3. SET THE PRINTABLE AREA

Now click on the Dimension tab to enter

information about the volume of the

space the idbox can print in. Use the

values as shown in the image on the left

and in the SETTINGS text on the right.

SETTINGS

Home X: x min

Home Y: y min

Home Z: z max

X Min: 0 [mm] X Max: 150 [mm]

Y Min: 0 [mm] Y Max: 130 [mm]

Printer type: Classic Printer

Print Area Width: 150 [mm]

Bed Front: 0 [mm]

Print Area Depth: 130 [mm]

Bed Left: 0 [mm]

Print Area Height: 100 [mm]

260 261

User Guide

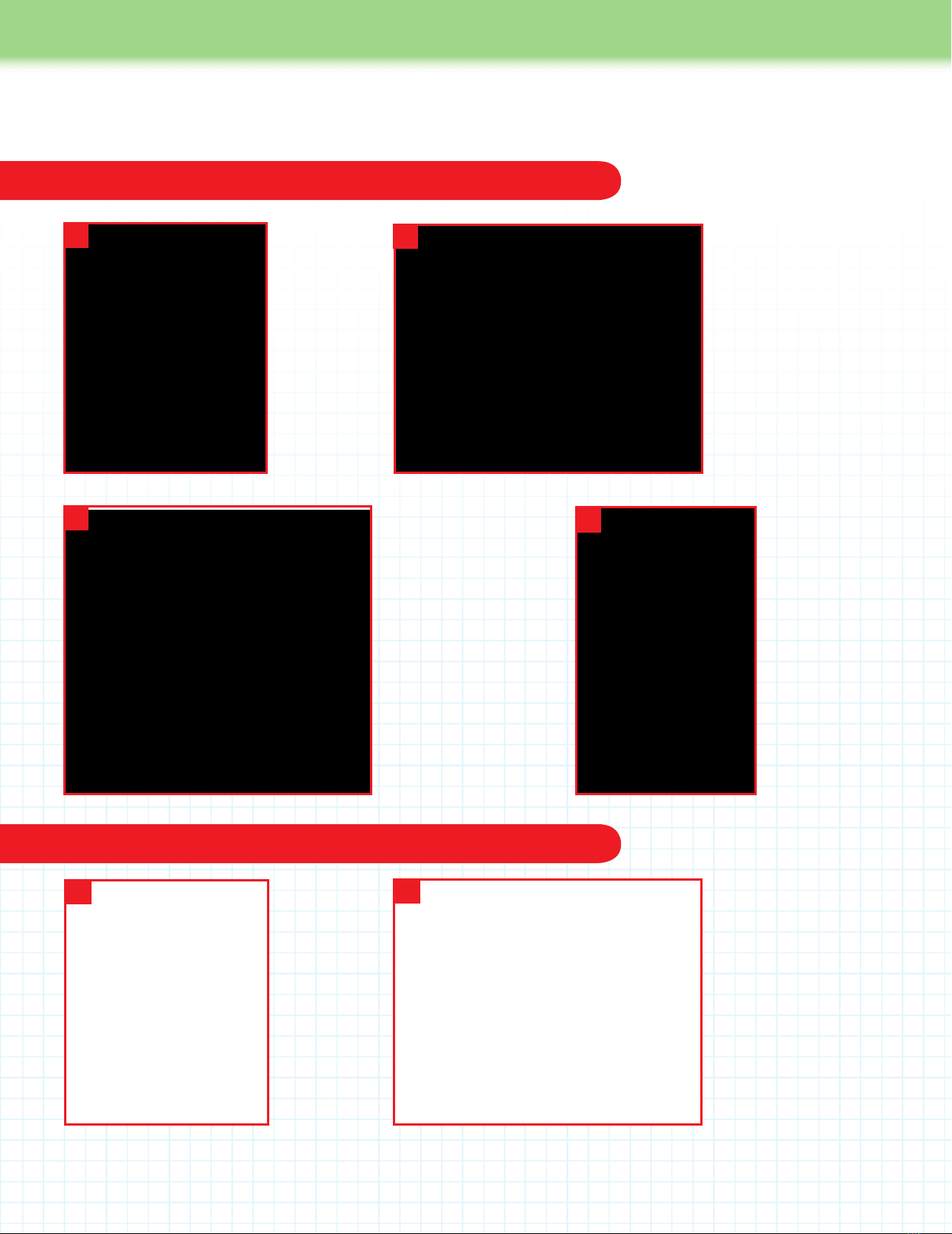

Setting up the CuraEngine slicer for Windows computers

Setting up the Slic3r slicer for Mac computers

Setting up the slicing software for the idbox

Toconvert3Ddataintothecommandsthatcontrola3Dprinter(G-code),youuseaprogramcalledaslicer.Repetier-Host has

different slicers included with it. We will use CuraEngine for Windows and Slic3r for Mac computers.

1.Open

Repetier,

and click on

the Slicer tab

near the top

right of the

screen. Select

CuraEngine

from the drop-

down list by

Slicer: and

then click the

Conguration

button.

2.Ontheleftofthescreen,

select the Print, then Speed

and Quality tabs. Enter the

values shown in the image

on the left for both the

Speed and Quality sections.

The values entered for the

speed determine the speed

of the movement of the

head when printing using

CuraEngine, and the values

for the Quality determine

the height of each layer

when printing.

3. Click the Filament tab

to enter the details of the

lament.(Detailshereare

forPLA.)Notethesetting

by Temperature will change,

dependingonthelament

you are using. To save

settingsforalament,

clickthe‘Saveas…’button

near the top of the pane,

and enter a name for the

lament,suchasPLA,then

clickOKtosaveit.Ignore

the settings in the Cooling

section, as the idbox does

not use them.

12

34. The settings

can be selected

on the right of

the screen. If you

have not changed

the name of the

settings, these

will show as

Defaultin‘Print

Conguration’,

0.2mmin‘Quality’

andDefaultin

‘Extruder1:’.

4

1. Click the

Slicer tab in

the Repetier

window to

open the Slicer

panel, then

clickCongure

to open the

conguration

window for

Slic3r.

12.Underthe‘PrintSettings’

tab,clickon‘Layersand

perimeters’inthepanelon

the left. Enter the values

as shown in the image on

the left for the two settings

shown under SETTINGS

below.

SETTINGS

Layer height: 0.2 mm

First layer height:

0.2 mm or %

2

262 263

Assembly Guide

User Guide

262 263

3. Click on Speed in the panel on the

left and enter the values as shown

in the image on the left and under

SETTINGS below.

To save the Print Settings, click

theoppydiskicononthetopleft

of the window. In the dialog box that

appears,enteraname,suchas‘test

print’,thenclickOK.

SETTINGS

Perimeters: 30 mm/s

Small perimeters: 30 mm/s or %

External perimeters:

70% mm/s or %

Inll: 60 mm/s

Solid inll: 60 mm/s or %

Top solid inll: 50 mm/s or %

Support material: 60 mm/s

Bridges: 60 mm/s

Gap ll: 20 mm/s

Travel: 130 mm/s

First layer speed: 30% mm/s or %

All the values under Acceleration

control (advanced) are set to

0 mm/s2

4. Click on the Filament Settings

tab, and on Filament in the panel on

the left. Enter the values as shown

in the image on the left and under

SETTINGS right. The values under

Temperature used here are for

PLAandwillneedtobechanged

dependingonthetypeoflament

you use. Save the settings as

you did in Step 3 above, this time

enteringanamesuchasPLA.

SETTINGS

Diameter: 1.75 mm

Extrusion multiplier: 1

Extruder: First layer: 220 Other

layers: 220

Bed: First layer: 0 Other layers: 0

7. Click the close button on the top left of the Slic3r window, to return to

Repetier. To use the settings, select the names you used for them in the three

eldsoutlinedinredintheimageontheleft.Thenamesoftheeldsare:

Print Settings:

Printer Settings:

Extruder 1:

6. Click Extruder 1 in the panel on

the left sidebar. Enter the values as

shown in the image on the left and

under SETTINGS below. Save the

settings as you did in Step 3

above, this time entering a name,

such as idbox.

SETTINGS

Nozzle diameter: 0.4 mm

Extruder offset: x: 0 y: 0 mm

Length: 1 mm (zero to disable)

Lift Z: 0 mm

Speed: 30 mm/s

Extra length on restart: 0 mm

Minimum travel after retraction:

2 mm

Retract on layer change: (check)

Wipe while retracting: (leave

unchecked)

(‘Wipewhileretracting:’mightnotbe

visible, depending on the version of

Slic3r that you have installed.)

Length: 10 mm (zero to disable)

Extra length on restart: 0 mm

5. Click on the Printer Settings tab, and

then on General in the panel on the left.

Enter the values as shown in the image

on the left and under SETTINGS below.

SETTINGS

Bed size: x: 150 y: 130 [mm]

Printer center: x: 75 y: 65 [mm]

Z offset: 0 [mm]

G-code avor: RepRap (Marlin/

Sprinter)

(If the exact above option shown by

‘G-codeavor’aboveisnotoffered,

select one that includes RepRap.)

Use relative E distances: (leave

blank)

Extruders: 1 (Number of nozzles)

Use rmware retraction: (leave

unchecked)

(Theoptiontoalterthe‘Usermware

retraction:’settingmightnotbevisible

depending on the version of Slic3r

that you have installed.)

Vibration limit: 0 Hz

3

4

5

6

7

Your 3D Printer User Guide will be continued in the next pack!

262 263

Assembly Guide

262 263

Stage 41: Add the Z-axis and

feeder motor drivers, and

the feeder motor cable

The two motor drivers you add to the

driver board this time are identical to

each other and also to the two you added

in Stage 39. This time the motor drivers

are for the Z-axis and feeder motors.

Remember to make sure they are fully

seated and that they are plugged in

the right way round. You then secure

the feeder motor cable to the housing

and plug it into the driver board. Finally,

connect your PC to the circuit board

using the USB cable.

1: Motor drivers x 2

2: Feeder motor cable (650mm) x 1

3: Cable ties x 4

4: USB cable x 1

Stage 41 Components

In this stage, you add the Z-axis motor driver to the driver board, then add the feeder

motor driver before plugging the feeder motor cable into the driver board.

You will need

Ruler

Marker pen

Scissors

PC to connect to idbox via USB cable

Parts to have ready

1 2

Get ready the printer housing and

turn it so that the front is facing you.

Have a look at the driver

board and the diagram,

left–makesureyou

know where to plug in the

Z-axis motor driver and

the feeder motor driver.

Locatethefeedermotor

cable plug, below.

Z-axis motor driver

goes here

Feeder motor driver

goes here

Feeder motor cable plug

123 4

Stage 41 Assembly Area

264 265

Assembly Guide

264 265

3

4

Hold one of the motors drivers as shown and plug it into the position for the Z-axis motor driver (see

previous page, Step 2). Make sure that the circular structure on the driver is aligned as shown above.

Holdthedriverparalleltothedriverboardwhileyouplugitinslowlyandrmlyuntilitisinalltheway.

Now plug the other motor driver into the position for the feeder motor driver. Again, press

rmlywhileholdingitparalleltothedriverboarduntilitisfullyinserted.

Plug the motor drivers into the driver board

Ensure the driver motors are not

at an angle to the driver board and

that the pins are all the way in.

Make sure that the

circular element on

the top of the motor

driver is on the left when

viewed with the front of the

housing facing you.

Be careful not to touch

this element.

Make absolutely certain that

the motor drivers are correctly

plugged in, with their pins in the

correct sockets and the circular structures

to the left.

Failure to

do so might

result in

reduring

operation of

the printer.

Circular element

Attach the feeder cable to the housing, then plug it into the driver board

5 6

With a marker pen, make a mark on the

feeder motor cable 12cm in from the end

of the cable, measuring from the smaller

(motor end) connector.

Turn the housing so the rear panel is facing you. Put a cable tie through each of the four

sets of holes outlined in red in the image above left. Align the tie at the top right with the

mark on the feeder motor cable and, with the motor end socket on the right, tighten the

cable tie around the cable. Trim off the excess cable tie with scissors.

Align with

12cm mark

CAUTION!

CAUTION!

264 265

Assembly Guide

264 265

789

At the other three cable tie positions

(outlined in red, above), use the cable ties

to secure the feeder motor cable and the

spiraltubetothehousing.Whenyou’ve

done up each cable tie, trim off the excess

with scissors.

Pass the feeder motor cable through

the hole in the casing to the left of the

noiselter.

Turn the housing so the front is facing you.

Untwistthefeedermotorcableyou’vejust

passed into the housing (if necessary) and

plug the connector into the pins (outlined

in yellow, above) on the motor board for

the feeder motor cable.

The Z-axis motor and feeder motor

drivershavebeenttedtothedriver

board and the feeder cable has

been plugged into the driver board.

There are two different connectors

on the USB cable supplied this

time. The smaller, squarer one is

the B-type and is plugged into the idbox.

Thewider,atteroneistheA-type,andthis

is plugged into the USB port on a computer.

Check the power supply from a computer to the circuit board

10

12

11

With the right side of the printer facing you,

plug the B-type connector of the USB cable

into the USB port on the circuit board.

The circuit board is powered

via the USB cable by your computer.

When you connect the USB cable

to your computer you should see a

green light come on on the circuit

board (lower photo). Check this, then

remove the USB cable and keep it

safe.

With your computer turned on, plug the

A-type USB connector into a USB port on

the computer.

Plug in

Plug in

USB

symbol

B type B type

A type A type

Stage

nished

266 267

Assembly Guide

266 267

The power supply has no fewer than

nine terminals to which you attach cables

in this stage. After wiring up the power

supply, you attach it to the inside of the

base of the housing and connect it to the

thick power cables, the fan cables and

thenoiselter.Makesureyoufollowthe

instructions carefully and be sure to check

over your assembly so you can be certain

that the cables are all connected properly.

This is extremely important, as if the

cables are not correctly wired up, there is

a real danger that the printer will fail when

the power is switched on.

Parts to have ready Set the input voltage to 230V (for UK)

1

The printer housing.

1: Power supply x 1

2: Power lines x 2

3: Earth wire x 1

4: Power supply wires for the fans x 2

5: M3 truss head screws x 4

Stage 42 Components

In this stage, you will wire up the power supply, then attach it to the housing. After that,

connect up more of the wiring inside the housing. It is vital to get the wires connected

properly, so take care as you do it.

You will need

Phillips screwdriver size 1

Phillips screwdriver size 2

Stage 42: Connect up the power

supply and x it to the housing

Stage 42 Assembly Area

1

2 3 4

5

2

There is a switch on the side of the power supply

where you can select the input voltage from the

mainstothepowersupply.FortheUK,makesure

it is switched to 230V and not 115V.

Incorrect

266 267

Assembly Guide

266 267

Connect up the nine screw terminals on the power supply

Plug the second of the two yellow power

lines into the terminal with the letter N

above it and tighten the screw.

Plug the green Earth cable into the

terminal with the Earth symbol above it

and tighten the screw.

Plug the black wire for the fan power supply

line into the fourth terminal from the left,

whichhasCOMaboveit.Putthepinkwire

into the seventh terminal, which has +V

above it. Tighten the screws.

567

Black

wire

Pink

wire

Earth symbol

3

There are nine screw terminals on the end of the power supply. Use a size 2 Phillips screwdriver to

loosen them all before you start attaching cables.

9 screw

terminals

Gap when

screw is

loosened

When you insert

the Y-shaped end of a cable

into a screw terminal, do it so

the crimp mark is uppermost

so it goes in securely.

4

Plug the Y-shaped end of one of the yellow power lines into the terminal on the left with the

letterLaboveit.Tightenthescrewoftheterminalwiththescrewdriver.

Plug in

Crimp

mark

268 269

Assembly Guide

268 269

Attach the power supply to the housing

12 13

Passthepowersupplythroughthefrontpanel(you’llhavetoangleittogetitthrough).

Make sure the cables do not go under the power supply, and beware of damaging the

housing while you manoeuvre the power supply.

With the front panel facing you, rotate

the housing by 90 degrees so it lies on

its right panel. Support the power supply

while you do this.

Rotate by 90

degrees

8 9

Turn the housing so its left side is facing you. Place the power supply as shown, so it is

to the right of the housing. Pass the rightmost of the two thick pink power cables from

the driver board through the opening in the front panel of the housing and plug it into the

rightmost terminal of the power supply, which has +V above it, and tighten the screw.

Pass the second thick pink cable from the

driver board through the hole in the front

panelandplugitintothepowersupply’s

eighth terminal from the left, which has a

+V above it, and tighten the screw.

Left

Right

It is very important that the wires

connected to the power supply

are in the correct terminals. Check

particularly that the pink and black wires are

in the correct positions as shown below.

10 11

Take the rightmost of the two thick black

cables from the driver board and plug it

into the sixth from the left of the power

supply’sterminals,whichhasCOMabove

it, and tighten the screw.

Take the other thick black cable from

the driver board and plug it into the

fthfromtheleftofthepowersupply’s

terminals,whichhasCOMaboveit,

and tighten the screw.

CAUTION!

268 269

Assembly Guide

268 269

17 18

Hold the power supply in position with one hand so that the four screw holes in its

underside align with the screw holes in the bottom panel (ringed in red). Insert an 8mm

M3trussheadscrewintoeachofthescrewholesandscrewtheminwithyourngers.

Plug the connector of the green Earth wire

onto the central, upper metal pin on the

noiselter.

Tuck the four thick power cables (two black, two pink) into the bottom of the housing, as

shown above left and above right. If you unplug any of the connectors from the driver

board while you do this, make sure you get them back into the correct locations.

Tighten all four of the screws with a size 1

Phillips screwdriver.

When tidying the thick power

cables to the bottom of the

housing, unplug the motor cables

one at a time and plug them back in as

soon as you can to avoid mixing them up.

Connect the remaining cables

16

Turn the housing so its base is back on your work surface. Plug the two yellow power

supplylinesasshownaboveontothetwolowerterminalsofthenoiselter,whichisat

therearleftofthehousing.Pushthemallthewayon,rmlyyetgently.

Thenoiselterhas

threemetalpins.Ofthese,

two are side by side and have

a black cover to their bases.

These are the pins for the

power lines. The other pin is for

the Earth wire. Make sure you

plug the correct wires onto the

correct pins.

Earth

wire

Power

lines

14 15

Plug on

Plug on

270 271

Assembly Guide

270 271

The power supply terminals

have been wired up, and the

powersupplyhasbeenxed

inside the housing.

19

Take the connector for one branch of the fan power supply wires, and plug it into the connector for the fan at

the lower back right of the housing. (The connector leading to the fan can be connected to either branch.)

The fan power

connectors

are designed to be

put together so the

ribs on one side of the

smallerconnectorst

into the slots on the

larger connectors.

20

21

Plug the connector for the fan in the printer head into the connector on the other

branch of the power supply wires.

In the photo, you can see

where the various cables you

have connected up in this

stage run from and to. In the

next stage, more cables are

added, and the wiring is tidied

up with cable ties.

Slots Ribs

Correct

Incorrect

Stage

nished

270 271

Assembly Guide

270 271

Stage 43: Connect the

X-, Y- and Z-axis limit

switches to the driver board

When you insert the pins on the limit

switches into the connectors on the

ends of the cables, be sure to do this

carefully and not bend the pins. Make

sure you get the connectors in the

correct positions on the driver board.

Secure the limit switch cables using

ties supplied with this stage and others

attached to the housing in Stage 39. After

you have plugged the thermistor cable into

the driver board, tidy up the cables in the

bottom of the housing.

1:Limitswitchcablesx2

2: Cable ties x 6

3: Brackets x 2

4: M3 truss head screws (14mm) x 2

5: M3 washers x 2

6: M3 nuts x 2

Stage 43 Components

In this stage, you connect up the three limit switches to the driver board using the two

cables supplied with this stage and the one supplied with Stage 3. You will also plug in

the thermistor cable to the driver board and tidy up the cables.

Tools you will need

Scissors

Parts to have ready

1

Get ready the printer housing and the limit

switch cable that was supplied with Stage 3.

Stage 43 Assembly Area

1

2

3

4

5

6

272 273

Assembly Guide

272 273

2 3

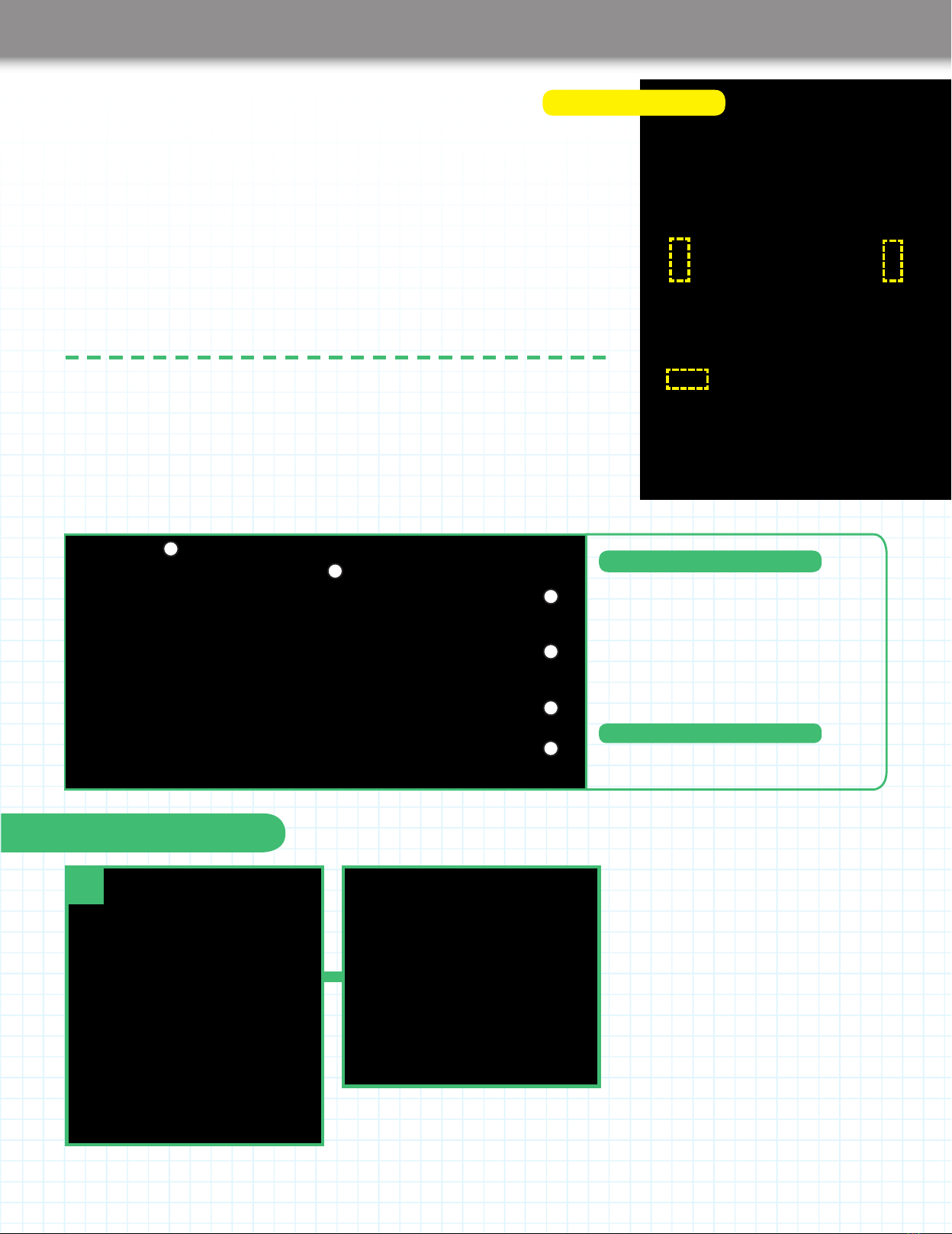

The Z- and X-axis limit switches are at the rear

and the Y-axis limit switch is on the right.

ConnecttheX-axislimitswitchrst.Turnthecable’s

connector so that you can see the side where the

metal parts show. Plug it in carefully from below until

justthebasesoftheswitch’spinsarevisible.

Connect the cables to the limit switches

Plug in

The sides of the

connectors are

different. Make

sure you plug them in so

the metal parts show.

X-axis limit

switch

Metal shows

on this side

Z-axis limit

switch

Y-axis limit

switch

Pin

base

You must get

the connectors from the

limit switches plugged into

the correct sets of pins or

the printer will not operate

properly.Takecare!

6

Turn the printer housing so the front panel is facing you and

ndthelocationofthepinsforthelimitswitchcables,outlined

in yellow above, and shown in close-up on the right.

Connect the limit switch cables to the driver board

Z-axis

(6th column

from right)

Y-axis

(3rd column

from right)

X-axis

(1st column

on the right)

4 5

Now connect the Z-axis limit switch. Carefully

plug the pins on the switch into the sockets on

the connector, making sure the metal parts of

the connector are visible, as shown above.

Turn the printer housing so its left side is

facing you, and plug in the Y-axis limit switch

cable connector from below. Again, put in the

connector so its metal parts are showing.

Plug in

Plug in

Pins on switch

Pins on switch

Connector's metal parts

Connector's

metal parts

Connector's

metal parts

Table of contents