Intamsys Funmat Pro 410 User manual

FUNMAT PRO 410 3D PRINTER

User Manual

Version: July 2, 2020

1

ONTENTS

1 SERVICE AND SUPPORT ................................................................................................................................ 1

1.1 SERVICE ................................................................................................................................................................. 1

1.2 SAFETY INSTRUCTIONS .......................................................................................................................................... 1

1.2.1 CLASSIFICATION OF HAZARDS .......................................................................................................................................... 1

1.2.2 POTENTIAL SAFETY HAZARD AREA .................................................................................................................................... 2

1.3 DOOR LOCK ........................................................................................................................................................... 2

1.4 ENVIRONMENTAL REQUIREMENTS ....................................................................................................................... 3

2 SETUP AND INSTALLATION ........................................................................................................................... 5

2.1 GENERAL INFORMATION ....................................................................................................................................... 5

2.1.1 ATTACHMENT TOOLS......................................................................................................................................................... 5

2.1.2 WORKING SPACE REQUIREMENTS..................................................................................................................................... 5

2.1.3 INSPECTION OF THE PRINTER'S NAMEPLATE .................................................................................................................... 5

2.2 MACHINE PREPARATION ...................................................................................................................................... 6

2.2.1 REMOVE PACKAGE ............................................................................................................................................................. 6

2.2.2 TAKE OUT THE ACCESSORIES ............................................................................................................................................. 7

2.2.3 RELEASE THE FIXATION OF XY AXIS .................................................................................................................................. 8

2.2.4 ADD LIQUID COOLANT ...................................................................................................................................................... 8

2.2.5 INSTALL THE PRINTING BUILDPLATE .................................................................................................................................. 9

3 SYSTEM COMPONENTS ............................................................................................................................... 11

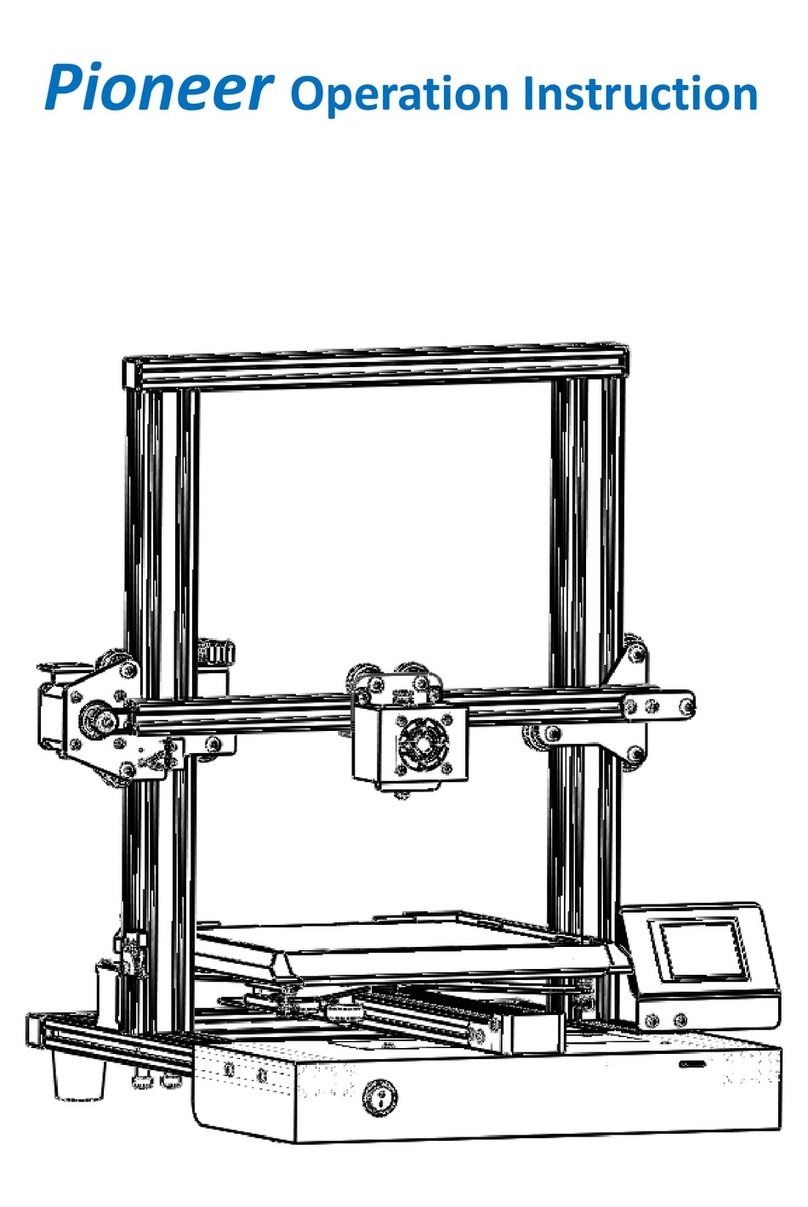

3.1 OVERVIEW OF THE PRINTER ................................................................................................................................ 11

3.2 TOP DOOR SUBASSEMBLY .................................................................................................................................. 12

3.3 PRINTING CHAMBER SUBASSEMBLY ................................................................................................................... 13

3.4 MATERIAL CHAMBER SUBASSEMBLY .................................................................................................................. 13

3.5 PRINTING HEAD SUBASSEMBLY .......................................................................................................................... 14

3.6 XY AXIS SUBASSEMBLY....................................................................................................................................... 15

3.7 Z AXIS SUBASSEMBLY ......................................................................................................................................... 16

3.8 CASTERS .............................................................................................................................................................. 16

4 USER INTERFACE ........................................................................................................................................... 17

2

4.1 OVERVIEW ........................................................................................................................................................... 18

4.1.1 STATUS BAR ...................................................................................................................................................................... 19

4.1.2 NAVIGATION BAR ............................................................................................................................................................. 21

4.1.3 DISPLAY AREA ................................................................................................................................................................... 21

4.2 PRINT INTERFACE ................................................................................................................................................ 21

4.2.1 MAIN STATE AREA ............................................................................................................................................................ 22

4.2.2 AUXILIARY STATE AREA .................................................................................................................................................... 23

4.2.3 CONTROL AREA ................................................................................................................................................................ 24

4.3 TUNING INTERFACE ............................................................................................................................................. 26

4.4 INCHING INTERFACE ............................................................................................................................................ 26

4.5 MATERIAL INTERFACE ......................................................................................................................................... 27

4.5.1 NOZZLE SETTING AREA .................................................................................................................................................... 28

4.5.1 MATERIAL MANAGEMENT INTERFACE ............................................................................................................................ 28

4.6 SYSTEM INTERFACE ............................................................................................................................................. 29

4.7 OTHER INTERFACES ............................................................................................................................................. 31

4.7.1 REMOTE PRINTING INTERFACE ........................................................................................................................................ 31

4.7.2 WIRED NETWORK IP SETTING INTERFACE ...................................................................................................................... 31

4.7.3 WIRELESS NETWORK IP SETTING INTERFACE ................................................................................................................. 32

5 PRINTER OPERATION .................................................................................................................................... 36

5.1 BASIC USER OPERATIONS ................................................................................................................................... 36

5.1.1 POWER ON THE PRINTER ................................................................................................................................................. 36

5.1.2 POWER OFF THE PRINTER ................................................................................................................................................ 37

5.2 MATERIAL, MATERIAL CHAMBER AND NOZZLE ................................................................................................. 37

5.2.1 MATERIAL LOADING ......................................................................................................................................................... 37

5.2.2 MATERIAL UNLOADING ................................................................................................................................................... 39

5.2.3 MATERIAL EDITING ........................................................................................................................................................... 40

5.3 REPLACEMENT OF NOZZLE OR MATERIAL .......................................................................................................... 41

5.3.1 REPLACEMENT OF NOZZLE .............................................................................................................................................. 41

5.3.2 MATERIAL CHANGE BEFORE PRINTING ........................................................................................................................... 42

5.3.3 PAUSE TO CHANGE MATERIAL ........................................................................................................................................ 43

5.3.4 REPLENISH MATERIAL AFTER STARVED FEEDING ALARM ............................................................................................... 43

5.4 BASIC PRINTING OPERATIONS ............................................................................................................................ 43

5.4.1 PREPARE THE PRINTER ..................................................................................................................................................... 43

5.4.2 IMPORT THE PRINT FILE INTO THE PRINTER .................................................................................................................... 44

3

5.4.3 LOAD THE PRINT FILE ....................................................................................................................................................... 45

5.4.4 PRINTING PROCESS .......................................................................................................................................................... 46

5.4.5 SETTING OF PRINTING PARAMETERS ............................................................................................................................... 47

5.4.6 PRINTING ALARM ............................................................................................................................................................. 47

5.4.7 PAUSE THE PRINTING ....................................................................................................................................................... 48

5.4.8 CEASE THE PRINTING ....................................................................................................................................................... 48

5.4.9 AFTER THE COMPLETION OF PRINTING .......................................................................................................................... 48

5.5 CHANGE DEFAULT SETTINGS OF THE PRINTER ................................................................................................... 49

5.5.1 CHANGE THE SYSTEM DATE AND TIME ........................................................................................................................... 49

5.5.2 ENABLE/DISABLE THE FUNCTION OF ALLOWING NETWORK REMOTE ACCESS ............................................................ 50

5.5.3 ENABLE/DISABLE WIFI AUTO-RECONNECT .................................................................................................................... 50

5.5.4 ENABLE/DISABLE DEVELOPER MODE .............................................................................................................................. 50

5.5.5 ENABLE/DISABLE USB PRINTING MODE ......................................................................................................................... 50

5.5.6 LOCK THE FRONT DOOR AND CAP ................................................................................................................................. 51

5.5.7 LIQUID COOLER CONTROL .............................................................................................................................................. 52

5.5.8 ENABLE MOTOR................................................................................................................................................................ 52

5.6 PRINTER STATE.................................................................................................................................................... 53

5.6.1 TEMPERATURE AND HUMIDITY STATE ............................................................................................................................. 53

5.6.2 MATERIAL STATE .............................................................................................................................................................. 53

5.6.4 STATE OF LIQUID COOLING SYSTEM ............................................................................................................................... 54

5.6.4 SOFTWARE VERSION ........................................................................................................................................................ 54

6 LEVELING AND CALIBRATION ................................................................................................................... 55

6.1 MANUAL LEVELING AND XYZ CALIBRATION ..................................................................................................... 55

6.1.1 MANUAL LEVELING .......................................................................................................................................................... 56

6.1.2 Z CALIBRATION ................................................................................................................................................................. 56

6.1.3 XY CALIBRATION .............................................................................................................................................................. 57

6.2 AUTO LEVELING AND XYZ CALIBRATION ............................................................................................................ 59

6.2.1 AUTO LEVELING ................................................................................................................................................................ 60

6.2.2 Z CALIBRATION ................................................................................................................................................................. 61

6.2.3 XY CALIBRATION .............................................................................................................................................................. 61

6.3 CALIBRATION OF MATERIAL WEIGHT ................................................................................................................. 61

6.4 CALIBRATION OF THE CLAMP FORCE OF EXTRUDER ........................................................................................... 62

7 MAINTENANCE ................................................................................................................................................. 65

4

7.1 INSPECTIONS BEFORE EACH PRINT ..................................................................................................................... 65

7.1.1 INSPECT THE PRINTING BUILDPLATE ............................................................................................................................... 65

7.1.2 EMPTY THE PRINTING CHAMBER ..................................................................................................................................... 65

7.1.3 INSPECT NOZZLES ............................................................................................................................................................ 65

7.2 MAINTENANCE AFTER EACH PRINT .................................................................................................................... 65

7.2.1 CLEAN THE GLASS BUILDPLATE ....................................................................................................................................... 65

7.2.2 CLEAN AND REPLACE THE NOZZLE BRUSH ..................................................................................................................... 65

7.2.3 CLEAN THE CHAMBER ...................................................................................................................................................... 66

7.2.4 CLEAN THE NOZZLE ......................................................................................................................................................... 66

7.3 PERIODIC MAINTENANCE ................................................................................................................................... 66

7.3.1 CLEANSING OF THE FEEDING GEAR OF EXTRUDER ......................................................................................................... 66

7.3.2 MAINTENANCE OF MOVING PARTS ................................................................................................................................ 67

7.3.3 MAINTENANCE OF CHAMBER FILTER SCREEN ................................................................................................................ 67

7.3.4 MAINTENANCE OF FEEDING PIPE AND COOLING PIPE .................................................................................................. 67

7.3.5 LIQUID COOLANT ............................................................................................................................................................. 68

7.4 OTHERS ............................................................................................................................................................... 68

8 TROUBLESHOOTING ..................................................................................................................................... 69

1 SERVICE AND Support

1

1 Service and Support

The information in terms of service and support for FUNMAT PRO 410, as well as the safety information

and safety label position are provided in this chapter.

1.1 Service

Please contact INTAMSYS customer support for any problem not covered by this guide during your use of

the printer.

Region E-mail Tel.

Asia Pacific Support_APAC@intamsys.com +86-21-5846 5932

Europe, Middle East and Africa Support_EMEA@intamsys.com +86-21-5846 5932

North America / Latin America Support_America@intamsys.com +86-21-5846 5932

1.2 Safety Instructions

Following basic safety instructions are provided to ensure the safe installation, operation and

maintenance of INTAMSYS equipment, which shall not be regarded as the comprehensive safety

problems. FUNMAT PRO 410 Printer is a safe and reliable 3D printer in industrial grade. There is potential

hazard in the printer overhauling area.

1.2.1 Classification of hazards

It is recommended by INTAMSYS that all services should be executed by qualified personnel. All

personnel operating the printer or near by the printer shall understand the meaning of following hazard

classification used in this guide.

[HIGH VOLTAGE]: The sign of high voltage indicates the existence of high voltage. Be sure to keep away

from exposed circuits. It is suggested to take off all accessories.

[HIGH TEMPERATURE]: It indicates that the equipment is in high temperature. Take extra care when

working near by heated components. Be sure to wear the safety gloves provided in the attachment tools.

The temperature of printing nozzle in the printer can reach up to 500℃.

The temperature of printing buildplate in the printer can reach up to 160℃.

The temperature of chamber in the printer can reach up to 90℃.

1 SERVICE AND SUPPORT

2

[PINCH POINT]: It indicates that you may have a risk to pinch hand between two objects. There are one

or multiple objects moving in your working area.

1.2.2 Potential safety hazard area

The following components and areas have been highlighted as having potential safety hazard. Failure to

follow the safety procedure will cause system fault or problem in reliability.

Nozzle

[HIGH TEMPERATURE] Warning: During the heating of nozzle, please be sure to wear the safety gloves

when maintaining the nozzle or working in the chamber.

Printing buildplate

[HIGH TEMPERATURE] Warning: During the heating of hot bed, please be sure to wear the safety gloves

when taking off the buildplate glass or working in the chamber.

Chamber

[HIGH TEMPERATURE] Warning: During the heating of chamber, please be sure to wear the safety

gloves when working in the chamber.

XY movement frame

[PINCH POINT] Warning: Do not wear tie, loose clothes or hanging ornament when working near by any

moving component of the printer.

Take extra care when maintaining such moving components.

Z-axis buildplate

[PINCH POINT] Warning: Do not wear tie, loose clothes or hanging ornament when working near by any

moving component of the printer.

Don’t put anything on the bottom of the chamber.

1.3 Door lock

The sensor is used to transmit the state of chamber front door and top door. For safety reason, the

chamber front door and top door must be closed before the chamber is heated or the X/Y/Z motor starts

working. The electromagnetic lock can ensure that the chamber door and cap are firmly closed when the

printer is executing the printing operation.

1 SERVICE AND Support

3

1.4 Environmental Requirements

• The printer is for indoor use only.

• The condition of air quality with excessive solid particles (conductive or non-conductive) may

cause damage to the system.

• The system operating temperature shall be kept between 15°C and 30°C (59°F to 86°F), and the

relative humidity shall be kept between 30% and 70% (non-condensate).

• The system storage temperature shall be kept between 0°C and 35°C (32°F to 95°F), and the

relative humidity shall be kept between 20% and 90% (non-condensate).

•

•

• Please take attention that changes or modification not expressly approved by the party

responsible for compliance could void the user’s authority to operate the equipment.

•

• This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions:

• (1) This device may not cause harmful interference, and

• (2) This device must accept any interference received, including interference that may

cause undesired operation.

• This equipment complies with FCC radiation exposure limits set forth for an uncontrolled

environment. This equipment should be installed and operated with minimum distance

20cm between the radiator & your body.

• This device complies with Industry Canada licence-exempt RSS standard(s). Operation is

subject to the following two conditions:

• (1) this device may not cause interference, and

• (2) this device must accept any interference, including interference that may cause

undesired operation of the device.

• Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils

radioexempts de licence. L'exploitation est autorisée aux deux conditions suivantes :

• (1) l'appareil ne doit pas produire de brouillage, et

• (2) l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le

brouillage est susceptible d'en compromettre le fonctionnement.

1 SERVICE AND SUPPORT

4

• This equipment complies with FCC/IC RSS-102 radiation exposure limits set forth for an

uncontrolled environment. This equipment should be installed and operated with minimum

distance 20cm between the radiator & your body.

• ce matériel est conforme aux limites de dose d'exposition aux rayonnements, FCC /

CNR-102 énoncée dans un autre environnement.cette eqipment devrait être installé et

exploité avec distance minimale de 20 entre le radiateur et votre corps.

2 SETUP AND Installation

5

2 Setup and Installation

The basic setup and installation of FUNMAT PRO 410 are described in this chapter.

2.1 General Information

2.1.1 Attachment tools

Please check the attachment tools in the packing list. These attachment tools are the frequently used

tools in printing and spare parts in maintenance of the printer.

2.1.2 Working space requirements

It is the guide for installation site preparation, which can ensure the efficient and safe preparation of

related facilities to install the printer.

Figure 2.1 Space for installation and maintenance(Unit:mm)

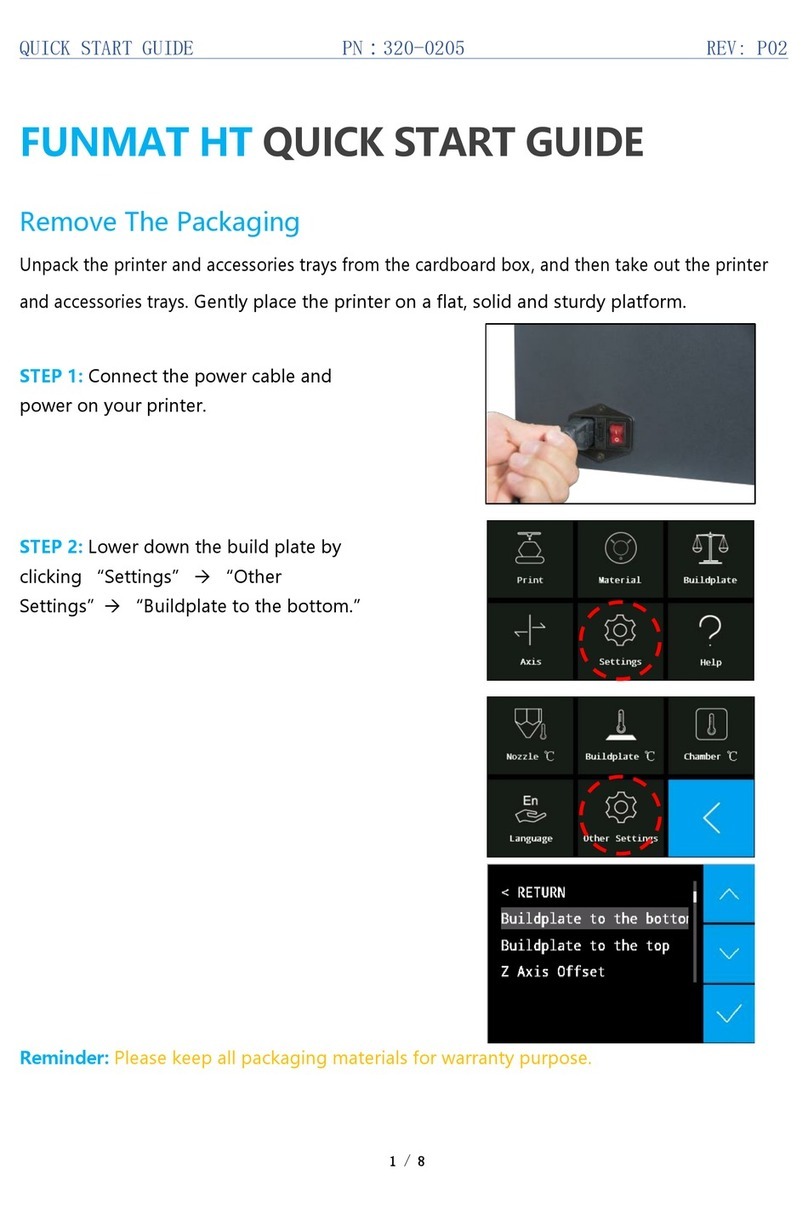

2.1.3 Inspection of the printer's nameplate

Identify your printer by following figure.

2 SETUP AND INSTALLATION

6

Figure 2.2 Printer nameplate

Model designation: It lists the product name, the model number and power requirement of the printer. The

nameplate also lists the related certification information and the company information of INTAMSYS.

Serial number: It lists the serial number of the printer, which will be provided to agent or INTAMSYS for

requesting services, so that the service personnel can quickly identify the configuration of your printer.

2.2 Machine Preparation

2.2.1 Remove package

Step 1: Please remove the screws on wooden case with wrench having a 8mm sleeve. Remove the

packing cases on the top and around, and take off the fixing band, foam and packaging film on the

printer;

Step 2: Take out the wooden plate placed at the bottom of the printer, and fix it as two slope structures

with cross screwdriver. Based on the printer's wheel span, place the slope structures close to the

printer's bottom tray, and make them closely contact with the tray;

Step 3: There are four casters installed at the bottom of the machine. Clockwise rotate the knobs above

the casters to make the casters in movable state, and push the machine slowly onto floor along

the slope. Where any caster is too tight to be rotated by fingers, the spanner in packing case may

be used to help rotating (the spanner is in accessory box);

Step 4: In the process of printing, the movement of the printer's XY axis in high speed causes vibration of

machine, thus impacting the printing quality. To avoid the impact of machine vibration on printing

quality, please be sure to lock the 4 casters at the bottom of the printer. Anticlockwise rotate the

knobs above the casters to make the casters in fixed state.

2 SETUP AND Installation

7

Figure 2.3 Diagram for package removal

2.2.2 Take out the accessories

Step 1: Connect the power cable to the power socket on the back of the printer, and then turn on the

power switch besides the power socket to make the power switch in ON (I) position;

Step 2: Press the round start button on the right of the panel. Turn to the screensaver mode after the

machine is started up. Click any place on the screen to quit the screensaver mode.

Figure 2.4 Power switch and startup button

Step 3: The accessory box is under the printing buildplate in the chamber. Click "Axis" button to enter into

the interface, and then click "Home Z". After the printing buildplate rises, all accessory boxes can

be taken out.

2 SETUP AND INSTALLATION

8

Figure 2.5 Power switch and startup button

2.2.3 Release the fixation of XY axis

Step 1: Press the round start button on the right of the panel to shut down the printer. Gently pull the right

side of the front door, open the printer's front door, and then open the top door upwards;

Step 2: The fixed block on X axis guideway is used for ensuring the steadiness of the nozzle device

during transportation. Unscrew the two bolts on the fixed block with a 4mmsocket head wrench

(the socket head wrench is placed in the accessory box box) to take off the X axis fixed block;

Step 3: On the linear guideway on the left side, upwards drag the buckle to take out the Y axis left fixed

block;

Step 4: In power-off state, gently push the printing head towards the left on X axis direction to leave

sufficient operating space, and take out the Y axis right fixed block by same method.

Figure 2.6 Positions of fixed blocks on XY axis

2.2.4 Add liquid coolant

Step 1: Remove the charge coverplate on the back of the machine with 2mm socket head wrench (the

2mm socket head wrench is placed in the accessorybox).

Step 2: It can be seen that one end of the charge pipe is fixed on a support by the buckle. Press the

buckle to pull out one end of the liquid adding pipe.

Step 3: Unscrew the screw cap of charge pipe and insert funnel (the funnel is in the spare accessory box).

There is a scale observation window on the left side of the charging inlet. Inject 750~950ml of

liquid coolant via the funnel (it is suggested to add water-free liquid coolant for automobile engine

to reduce the erosion and the generation of incrustation, and colored liquid coolant is

1

2

2 SETUP AND Installation

9

recommended for easier observation).

Step 4: After charging, screw down the screw cap of charge pipe, put the charge pipe back and install the

coverplate.

Figure 2.7 Position of charging inlet and method to charge

2.2.5 Install the printing buildplate

Step 1: In the "Axis" interface, click the key "Home XYZ".

Step 2: Select the option "100mm" in the "Move steps" above, then click "Z↓" (no more than 3 times) and

adjust the printing buildplate to a position convenient for the installation of printing buildplate.

Step 3: Install the printing buildplate according to the direction as shown on the label on printing buildplate,

make the four magnet blocks on the glass be placed into the corresponding magnet holes, and

gently press the four magnet blocks with hand to confirm the magnet blocks are fully placed in the

magnet holes.

Figure 2.8Buildplate descending method

1

2

3

2 SETUP AND INSTALLATION

10

Figure 2.9Buildplate glass installation direction

3 SYSTEM COMPONENTS

11

3 System Components

The system components of FUNMATPRO 410 are described in this chapter, to help users better

understanding the composition principle of the printer, and knowing about the functions of each part.

3.1 Overview of the Printer

The visible parts of the printer from appearance are shown as following figure. Among them, the right

lateral plate, left lateral plate, and back lateral plate are all dismountable, which are used for the

maintenance of internal components; the top door and front door shall be in closed state and be locked by

electromagnetic lock in the process of printing; the material chamber can been seen by opening the lower

door, which is opened by "pushing and bouncing".

Figure 3.1 Front view of the printer

Top door

Switch Button

Right lateral plate

Printing chamber

Lowerdoor/ Material

chamber

Touch screen

user interface

Front door /

Printing

observation window

3 SYSTEM COMPONENTS

12

Figure 3.2 Rear view of the printer

3.2 Top Door Subassembly

By pushing up the top door, the printing state can be observed, and it is also convenient for the

maintenance of XY rack and printing head component.

Release the electromagnetic lock to push up the top door, where the top door is supported by air spring.

Where the opening angle is greater than the critical angle, the support moment of air spring will be greater

than the gravity moment of the top door, which can keep the top door in its opening position. Where the

opening angle of the top door is less than the critical angle, the air spring does not have sufficient support

moment yet, and the top door will fall down freely. Therefore, when opening the top door, please note to

not release your hand when the door opening angle is less than the critical angle, and release hand when

you feel the top door is supported by sufficient force from the air spring.

The user interaction area is under the top door, including the touch screen, USB interface, button switch.

Users can control the printed piece and obtain the information about machine state through the touch

screen. The USB on the left side is onlyused for printingviacomputer.

The USB on the right side is used for printing by plugging in USB flash disk. The button switch is used for

normal switching on and off, and emergency shutdown.

Caster

Mounting screw

Left lateral plate

Back lateral plate

Power interface / Switch

Liquid observation

window

3 SYSTEM COMPONENTS

13

Figure 3.3 Diagram for top door

opening angle

Figure 3.4 Diagram for user operating Area

3.3 Printing Chamber Subassembly

The front door can be pulled out from the right side through releasing the electromagnetic lock by screen

operation, and then it can be seen that following components are included in the printing chamber: front

door, hot bed, dual nozzle component, brass wire brush, electromagnetic lock, magnet, door sensor,

heating and heat maintaining component, etc.

When the printing chamber is heating, please do not touch the stainless steel bottom plate and lateral

plates to avoid scald as they are in high temperature.

The four leveling rotary knobs under the hot bed are used for the manual leveling of the printing

buildplate.

Figure 3.5 Diagram for front door

opening mode

Figure 3.6 Printing chamber

3.4 Material Chamber Subassembly

The material chamber contains two material rolls on the right and left, of which normally model materials

are installed on left material roll and the support materials are installed on the right material roll. There is

Pull

here to

open

the door

Leveling knob

Build plate

Electromagnetic

lock

Magnet

Dual nozzle

Brush

Door sensor

ON/OFF

switch

Air spring

USB-Disk

For USB

printing via PC

3 SYSTEM COMPONENTS

14

weight sensor on each material roll. An alarm will be given on the screen when the weight of materials

arelower than the materials required by printing. There is heating device in the material chamber, which

can be used for auxiliary drying of material chamber, and the maximum temperature of material chamber

can reach up to 70°C. To ensure the dryness of materials, the slide door of material chamber shall be kept

in closed state all the time. The sliding door are held closed by magnetic force when it is in closed state.

To replace materials or do troubleshooting, the sliding door can be opened by pushing it forward slightly,

and the light will be enabled automatically with the opening of chamber.

Figure 3.7 Material chamber

3.5 Printing Head Subassembly

The printing head subassembly is used for fusing wire, and forming the required model on the printing

glass plate in combination with the movement of XYZ axis. The subassembly contains two nozzles, of

which the left nozzle is used to print model material and the right nozzle is used to print support material in

normal cases. The left and right nozzle can be switched by the up and down movement of the right nozzle,

and only one nozzle will execute the printing at one time.

There is also feeding state monitoring sensors (each one on the left and right respectively) on the printing

head subassembly, which will alarm for abnormal material feeding. Refer to Chapter 5 for the loading and

unloading of materials.

Door of material Chamber

Sliding door

Auxiliary feeding

Filament existing sensor

Filament roll

Door sensor

Weight sensor

Light

Other manuals for Funmat Pro 410

2

Table of contents

Other Intamsys 3D Printer manuals

Intamsys

Intamsys FUNMAT HT User manual

Intamsys

Intamsys FUNMAT HT User manual

Intamsys

Intamsys FUNMAT PRO 310 User manual

Intamsys

Intamsys FUNMAT HT User manual

Intamsys

Intamsys FUNMAT PRO User manual

Intamsys

Intamsys FUNMAT PRO User manual

Intamsys

Intamsys FUNMAT PRO 310 User manual

Intamsys

Intamsys Funmat Pro 410 User manual

Intamsys

Intamsys Funmat Pro 410 User manual