DE-STA-CO MDE Series User manual

INSTALLATION MANUAL

MDE-SERIES INDEXDRIVES

MODELS

MDE600M

MDE700M

MDE900M

1

Contents

1IDENTIFICATION .............................................................................................................................................................. 3

2INSTRUCTIONS FOR USE .................................................................................................................................................. 6

3PRODUCT SAFETY ............................................................................................................................................................ 9

3.1 TRAINING OF THE PERSONNEL .............................................................................................................................................. 10

3.2 PRESENTATION OF SAFETY PRECAUTIONS................................................................................................................................ 10

3.3 SYMBOLS ON THE MACHINE ................................................................................................................................................. 11

3.4PERSONAL PROTECTIVE EQUIPMENT (PPE) ............................................................................................................................. 11

4MACHINE DESCRIPTION ................................................................................................................................................ 12

4.1 PRESENTATION AND IDENTIFICATION ..................................................................................................................................... 12

Figure 1 Unit.......................................................................................................................................................................... 12

Figure 2 Access ...................................................................................................................................................................... 12

4.2 INTENDED USE .................................................................................................................................................................. 13

4.3 FORESEEABLE IMPROPER USE ............................................................................................................................................... 14

4.4 DESIGN AND COMPONENTS OF THE MACHINE.......................................................................................................................... 15

Front and Top View ............................................................................................................................................................... 15

Section and Side View ........................................................................................................................................................... 16

Bill Of Materials .................................................................................................................................................................... 17

4.5 DESCRIPTION OF FUNCTION ................................................................................................................................................. 17

4.6 PLACES OF WORK OF THE OPERATING PERSONNEL .................................................................................................................... 17

4.7 HAZARD ZONES ................................................................................................................................................................. 18

4.8 SAFETY AND MONITORING INSTALLATIONS ............................................................................................................................. 20

4.9 WARNING DEVICES............................................................................................................................................................ 20

4.10 TECHNICAL DATA .............................................................................................................................................................. 20

Recommended Oil and Quantity ........................................................................................................................................... 21

Grease ................................................................................................................................................................................... 22

5TRANSPORT .................................................................................................................................................................. 22

5.1 TRANSPORTING MACHINE AND MACHINE PARTS..................................................................................................................... 22

5.2 UNPACKING ..................................................................................................................................................................... 23

5.3 HANDLING ....................................................................................................................................................................... 23

Markings and Weight............................................................................................................................................................ 24

Approved Transportation Equipment & Procedures ............................................................................................................. 24

Transportation Inside of Packaging ...................................................................................................................................... 24

Table 2 Approximate weights of MDE models with reducer ................................................................................................. 24

Transportation Outside of Packaging ................................................................................................................................... 25

Transportation Damage ........................................................................................................................................................ 25

Intermediate Storage ............................................................................................................................................................ 25

6INSTALLING AND COMMISSIONING .............................................................................................................................. 26

6.1 INSTALLATION AND CONNECTION.......................................................................................................................................... 26

Installation Safety Protocol ................................................................................................................................................... 26

Installation Prerequisites....................................................................................................................................................... 27

Installation of Unit ................................................................................................................................................................ 28

Installation ............................................................................................................................................................................ 28

Installing the Base Plate or Frame ........................................................................................................................................ 28

Attach Unit to Base-Plate...................................................................................................................................................... 29

Manual Adjustment of Unit................................................................................................................................................... 29

Installation of Additional Components.................................................................................................................................. 30

6.2 COMMISSIONING .............................................................................................................................................................. 31

2

6.3 SET-UP AND TOOLING......................................................................................................................................................... 31

Packaging Disposal ............................................................................................................................................................... 32

Recommissioning .................................................................................................................................................................. 35

7OPERATION ................................................................................................................................................................... 35

7.1 OPERATING AND DISPLAY ELEMENTS...................................................................................................................................... 35

7.2 OPERATION OF THE MACHINE .............................................................................................................................................. 36

8SERVICE AND MAINTENANCE ........................................................................................................................................ 37

8.1 CLEANING THE MACHINE..................................................................................................................................................... 38

8.2 PROCESS MEDIA ................................................................................................................... ERROR!BOOKMARK NOT DEFINED.

8.3 MAINTENANCE SCHEDULE................................................................................................................................................... 39

Gearmotor Check .................................................................................................................................................................. 41

MDE Lubrication.................................................................................................................................................................... 41

Oil Change Intervals .............................................................................................................................................................. 41

Recommended Oil and Quantity ........................................................................................................................................... 41

Grease ................................................................................................................................................................................... 42

8.4 TROUBLESHOOTING AND FAULT CORRECTION ......................................................................................................................... 42

Symptom: Indexer appears inaccurate.................................................................................................................................. 42

Symptom: Looseness in one dwell only ................................................................................................................................. 42

Symptom: Looseness in all dwells ......................................................................................................................................... 42

Symptom: Indexer is noisy..................................................................................................................................................... 43

Symptom: Premature wear of cam followers........................................................................................................................ 43

Symptom: Output movement is noisy and erratic................................................................................................................. 43

8.5 SPARE AND WEAR PARTS.................................................................................................................................................... 44

Spare Parts list ...................................................................................................................................................................... 44

Input Oil Seal Replacement Consideration ............................................................................................................................ 44

Cam Follower Replacement Consideration........................................................................................................................... 44

Input Shaft and/or Cam Replacement Consideration ........................................................................................................... 44

Follower Wheel and/or Output Bearing Replacement Consideration ................................................................................... 44

8.6 DISASSEMBLY ................................................................................................................................................................... 46

8.7 INSPECTION...................................................................................................................................................................... 46

8.8 OIL SEAL REPLACEMENT ...................................................................................................................................................... 47

Oil seal removal..................................................................................................................................................................... 47

Oil seal installation................................................................................................................................................................ 47

8.9 CAM FOLLOWER REPLACEMENT ............................................................................................................................................ 48

Cam follower cartridge removal ........................................................................................................................................... 48

Cam follower removal from cartridge ................................................................................................................................... 49

Cam follower installation into cartridge ............................................................................................................................... 49

Cam follower cartridge installation....................................................................................................................................... 50

9SHUTDOWN, STORAGE AND DISPOSAL ......................................................................................................................... 51

9.1 SHUTDOWN ..................................................................................................................................................................... 51

9.2 STORAGE CONDITIONS........................................................................................................................................................ 51

9.3 DISPOSAL......................................................................................................................................................................... 52

10. ANNEX ............................................................................................................................................................................. 53

Declaration of Incorporation................................................................................................................................................. 53

NORD DRIVESYSTEMS ........................................................................................................................................................... 54

SEW-EURODRIVE................................................................................................................................................................... 56

TL6615 EXTRACTION TOOL PAGE 1 OF 2 .............................................................................................................................. 57

TL6615 EXTRACTION TOOL PAGE 2 OF 2 .............................................................................................................................. 58

11. DECLARATION OF INCORPORTATION............................................................................................................................... 59

3

1 Identification

Product identification

Product

identification

Manufacturer:

DE-STA-CO CAMCO PRODUCTS

Street:

1444 SOUTH WOLF ROAD

City:

WHEELING, ILLINOIS 60090 USA

Tel.:

+1-847-459-5200

Fax:

+1-847-459-3064

E-mail:

Internet:

http://www.destaco.com

After-Sales Service

address:

Machine designation:

INDEX DRIVE MODEL

Type designation:

MDE-SERIES

Serial No.:

SEE NAME PLATE

Year of construction:

2015

Product No.:

SEE NAME PLATE

P.O. No.:

Order No.:

Sales:

DE-STA-CO Europe GmbH

Hiroshimastraße 2

61440 Oberursel

Germany

Manufacturer:

DE-STA-CO Camco Products

Industrial Motion Control, LLC

1444 South Wolf Road

Wheeling, IL 60090

USA

4

Document identification

Document

identification

Version:

1.0

Creation date:

IV 2015

Last revision:

NA

Product Identification

Product:

Model No.:

MDE600M, MDE700M MDE900M

Serial No.:

Year of construction:

2015

Sales:

DE-STA-CO Europe GmbH

Hiroshimastraße 2

61440 Oberursel

Germany

Manufacturer:

DE-STA-CO Camco Products

Industrial Motion Control, LLC

1444 South Wolf Road

Wheeling, IL 60090

USA

2.1 Justification for classification in accordance with the Machinery Directive

The products from the Automation division are divided into the following classes:

Index drive models.

In accordance with the Machinery Directive 2006/42/EC, the above-mentioned products are classified as

incomplete machines according to Article 2g). This results in the necessity to produce the technical

documentation in accordance with Annex VII B and the declaration of incorporation in accordance with Annex

II B.

Justification for classification as an incomplete machine:

The machine as such does not fulfil a particular function.

The pneumatic/hydraulic/electric control system is not included in the scope of supply.

The machine is intended for incorporation into other machines or to be assembled with them.

5

There are no elementary protection devices at the man-machine interface

6

2 Instructions for Use

Purpose of the document

Purpose of

the document

The operating manual is intended to help the user familiarise himself with the machine

and its intended application possibilities. The operating manual contains important

information on the safe, proper and profitable operation of the machine. Observation

of this information will help avoid hazards, reduce repair costs and standstill times and

increase the reliability and service life of the machine.

Notes on precautionary measures to be taken by the machine owner:

Employ only personnel with the necessary qualification for the work in hand to

operate the machine.

Define clear responsibilities and authorities for the operating and maintenance

personnel.

Supplement the operating manual with rules derived from the national

occupational health and safety and environmental protection regulations (e.g.

work organisation).

Instruct the personnel to observe the operating manual and its additions, and

check compliance from time to time. Have one copy of the operating manual

available at the place of operation of the machine at all times!

Operate the machine only when it is in a technically safe condition, and take

measures to maintain this safety.

In addition to the operating manual, the binding accident prevention regulations

applicable in the country of operation and at the place of work must also be observed.

In addition, the acknowledged engineering rules for safe and proper working must be

observed.

7

Target groups

Target groups

a) The owner as superordinate legal entity is responsible for the intended use of

the machine and for the training and employment of the authorised persons. He

lays down the binding competencies and authorities of the authorised persons

for his company.

b) According to the latest Machinery Directive, the operating personnel are the

persons responsible for installation, operation, set-up, maintenance, cleaning,

repair or transport of machines.

c) A specialist is a person who thanks to his technical training, know-how and

experience is able to assess the assigned duties and to recognise potential

hazards. Furthermore, this person has know-how of the applicable regulations.

Only qualified specialists or such persons considered by the owner to be

capable are to be employed.

d) Trained/instructed persons are persons who have been instructed and

possibly trained in the assigned duty and in the potential dangers associated

with improper behaviour. The person has also been instructed about the

necessary protective devices and safety measures. Persons undergoing

training, instruction or familiarisation and persons undergoing general training

may only work under the constant supervision of an experienced person.

8

Target groups

Liability and warranty

Liability

and

warranty

All information and tips given in this operating manual are given to the

best of our knowledge and belief and on the basis of our experience

and findings to date. The original version of this operating manual was

drawn up in English and was examined technically by us. The

translation in the respective national/contract language was produced

by an acknowledged translation agency.

This operating manual was compiled with the greatest care. Should

you discover any gaps and/or errors, however, please inform us

accordingly in writing. Your suggestions for improvements will help us

in producing a user-friendly operating manual.

Reorders and copyright

Reorders

and

copyright

Further copies of this operating manual can be ordered from the

address shown under "Identification" in chapter 1. Please note that

further copies are subject to payment.

All rights are expressly reserved. Duplication or notification to third

parties in whatever form is not permitted without our written approval.

9

3 Product Safety

A basic precondition for the safe handling and trouble-free operation of this machine is thorough

knowledge of the fundamental safety precautions.

Organisational measures

Keep the operating manual available at the place of operation of the machine and in a legible condition at

all times!

a) Supplement the operating manual to include provisions to cover specific company aspects (e.g.

supervisory and reporting obligations, work organisation, work processes, personnel employed,

and fire alarm and firefighting possibilities, operation of fire extinguishers).

b) Supplement the operating manual to include binding local provisions on accident prevention and

environmental protection (e.g. handling of hazardous substances, disposal of operating and/or

ancillary media, provision/wearing of personal protective equipment)!

c) Instruct all personnel to observe the operating manual!

d) If the personnel discovers faults or hazards, the owner or his representative must be informed

immediately.

Technically safe condition

a) Keep all safety and hazard signs on and around the machine complete and in a legible condition!

b) Do not make any modifications, attachments or alternations to the machine that could impair safety

without consultation/agreement with the manufacturer/supplier. This applies also to the installation

and setting of safety devices and valves, and for welding on load-bearing parts.

c) Do not make any program changes to the software of programmed control systems!

Major modifications to the machine and/or program changes may

invalidate the EC Declaration of Conformity!

d) Observe intervals prescribed by law or in the operating manual for recurring tests/inspections and

the replacement intervals for safety-critical components!

e) Spare parts must satisfy the technical requirements stipulated by the manufacturer. This is always

guaranteed with OEM spare parts.

f) Be sure to have appropriate workshop equipment available for carrying out independent service

and maintenance work.In addition to this operating manual, the information and tips contained in

the suppliers' documentation (see Annex) must also be observed!

10

3.1 Training of the Personnel

Training of

the personnel

Personnel selection and qualification

a) Work on and with the machine may only be carried out by reliable personnel.

Observe the statutory minimum working age!

b) Employ only qualified or at least trained personnel. Give the necessary

instructions and check from time to time that only authorised personnel are

working on/with the machine!

c) Clearly define the responsibilities and authorities of the personnel for operation,

set-up, maintenance and repair!

d) Allow persons undergoing training, instruction or an apprenticeship to work on

the machine only under the supervision of an experienced person.

e) Work on the electrical equipment of the machine may only be carried out by an

electrician or by trained persons under the instruction and supervision of an

electrician. For safety reasons, the rules of electrical engineering must be

observed.

f) Work on gas and heating installations may only be carried out by appropriately

qualified personnel.

g) Only experienced and qualified personnel may be allowed to work on hydraulic

and pneumatic installations!

3.2 Presentation of safety precautions

HAZARD SYMBOLS

SYMBOL

DEFINITION

Indicates a hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

Indicates a situation which, if not avoided, could result in damage to the unit,

equipment, or environment.

11

Adhere to subsequent SAFETY PROTOCOLS throughout this document, and

observe all HAZARD SYMBOLS.

Accessibility to the unit presents/increases the hazard of human error. It is

therefore recommended that accessibility is kept to a minimum during all life-

phases of the unit.

3.3 Symbols on the Machine

Symbols on

the machine

Electric shock hazard

3.4 Personal Protective Equipment (PPE)

Personal

protective

equipment

(PPE)

The personal protective equipment (PPE) described below must be provided by the

machine owner and be worn by the responsible operating personnel when working

with the machine.

Wear protective gloves

Wear safety shoes

Wear ear protectors

Wear a safety helmet

12

4 Machine Description

4.1 Presentation and Identification

Presentation

and

identification

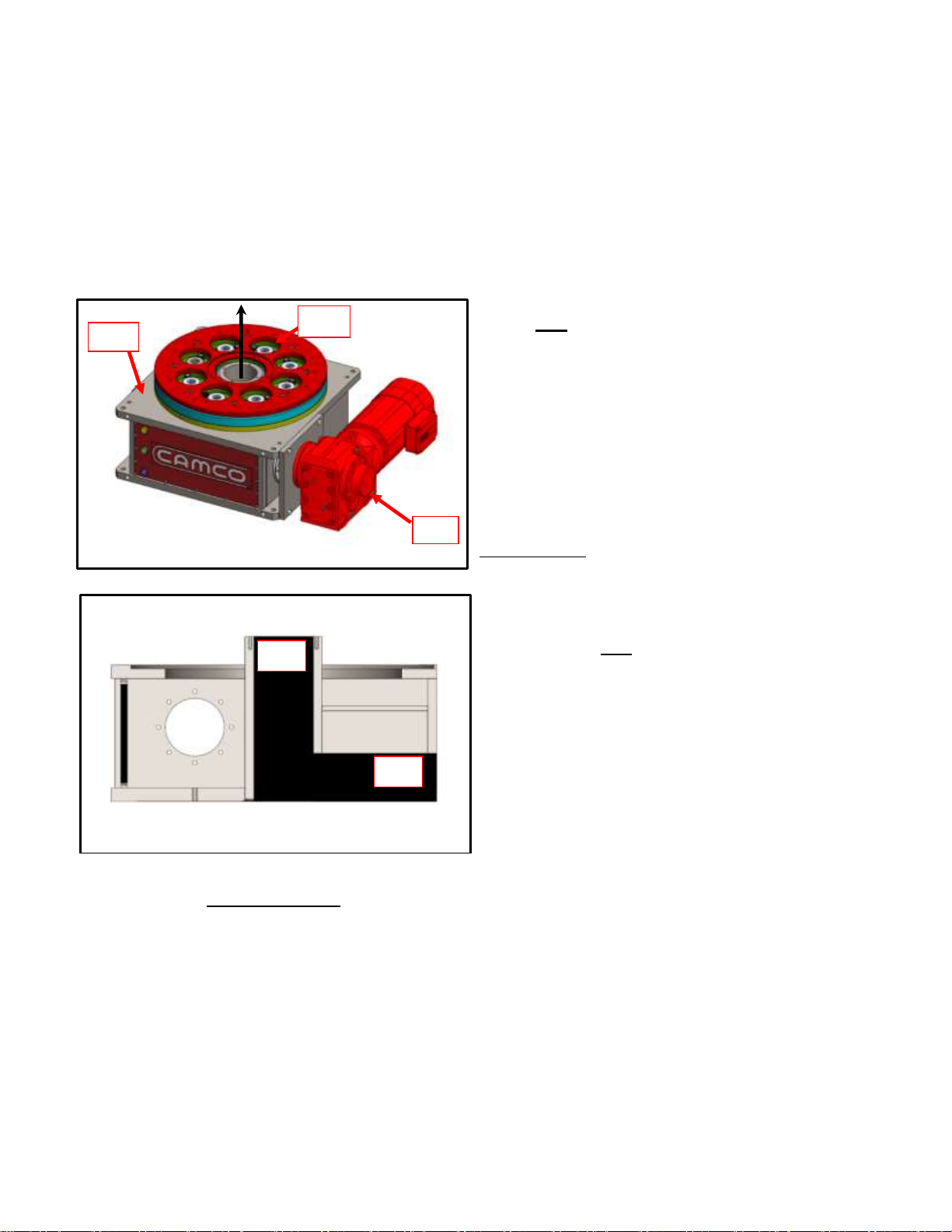

General view of the machine

The unit consists of the

following main components

(FIGURE 1)

01. Housing: Machined Housing

Weldment, Cover Plate

02. Output Assembly: Follower-

Wheel, Dial Plate, Output bearing

03. Input Assembly: Cam, Cam-

Shaft, Reducer Mounting plate,

Gear motor with brake.

Figure 1 Unit

04. Center-Bore: Allows passage

of wires, robotics and various

tooling through unit.

05. Allows for Table-Top or

Trunnion (optional) mounting with

mounting holes placed on front

and bottom faces of housing.

01

02

01

03

02

Figure 2 Access

13

Presentation

and

identification

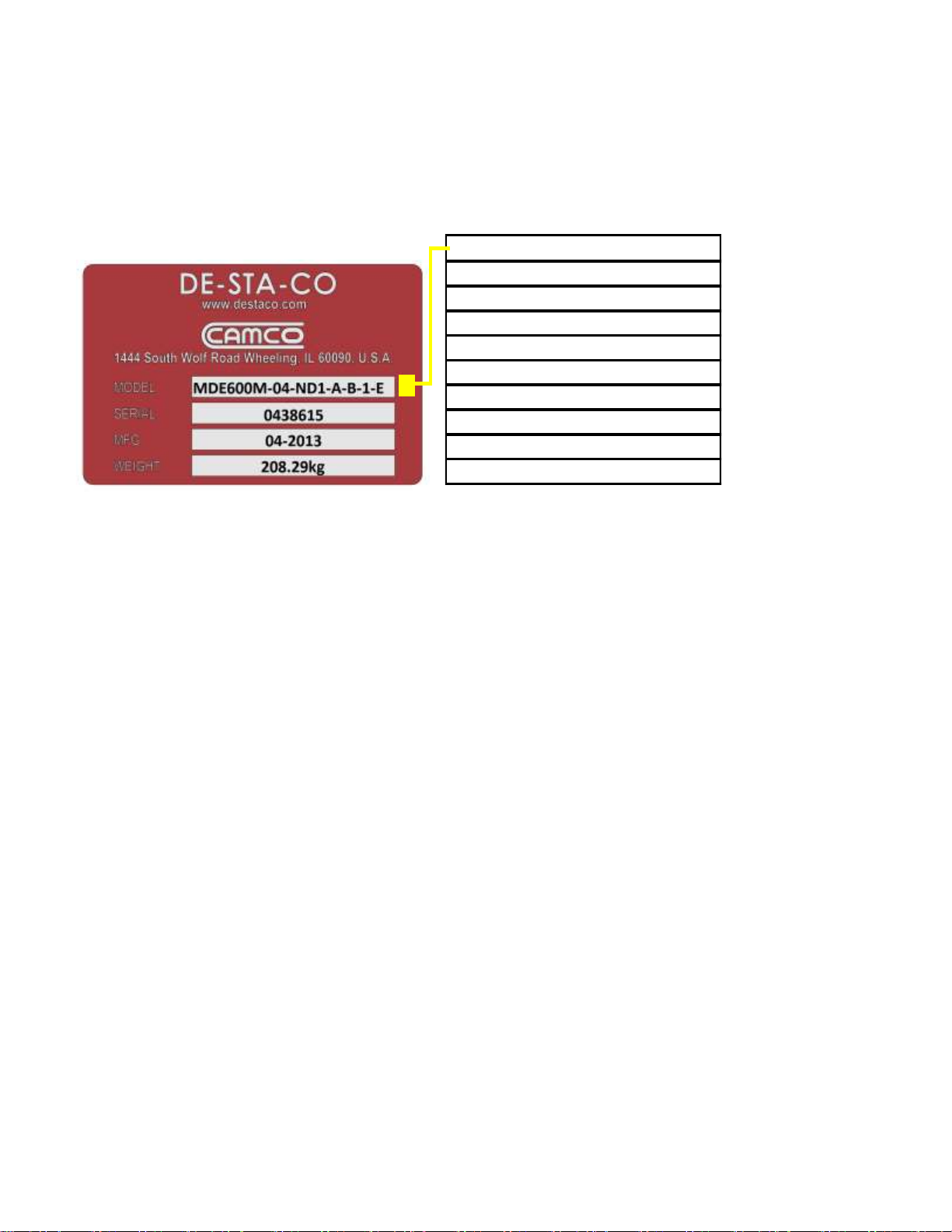

Identification of the machine

The following information can be found on the machine rating plate:

Company name with full address

DE-STA-CO CAMCO PRODUCTS

1444 SOUTH WOLF ROAD

WHEELING, ILLINOIS 60090 USA

Article No.: MDE600M : MDE700M : MDE900M

Year of construction: 2015

4.2 Intended Use

Intended

use

The machine has been built within the battery limits to the state-of-the-art and in

accordance with the acknowledged general safety engineering rules. Nevertheless

hazards can arise during its use for the life and limb of the operator or third parties and for

impairment to the machine and other assets.

The machine may only be operated for its intended when it is in a technically safe

condition, giving consideration to safety and the potential hazards, in accordance with the

operating manual! Have all malfunctions remedied immediately, in particular those which

could impair safety.

The machine is intended exclusively for the purpose described in chapter 4.5 "Description

of function". Any other or further use constitutes an improper use. The

MDE600M-04-ND1-A-B-1-E

MDE: MODEL FAMILY (MDE SERIES)

600: MODEL DIAL SIZE (600mm)

M: MODEL TYPE (MECHANICAL)

04: MODEL MOTION (NUMBER OF STOPS)

ND1: MODEL GEAR-MOTOR (NORD GEAR-MOTOR 1)

A: GEAR-MOTOR RATIO OPTION (RATIO-A)

B: GEAR-MOTOR BRAKE OPTION (BRAKE-B)

1: GEAR-MOTOR MOUNT SIDE (SIDE-1)

E: MODEL SENSOR OPTION (SENSOR-E)

14

Intended

use

manufacturer/supplier assumes no liability for injury or damage resulting from such use.

This risk must be borne solely by the owner.

The intended use also includes observance of the operating

manual and compliance with the inspection and maintenance

conditions.

4.3 Foreseeable Improper Use

Foreseeable

improper use

Any use, setting, application or alteration of the unit beyond the stated terms in

section 4.5 is defined as improper and prohibited.

15

4.4 Design and Components of the Machine

Front and Top View

A

16

Section and Side View

17

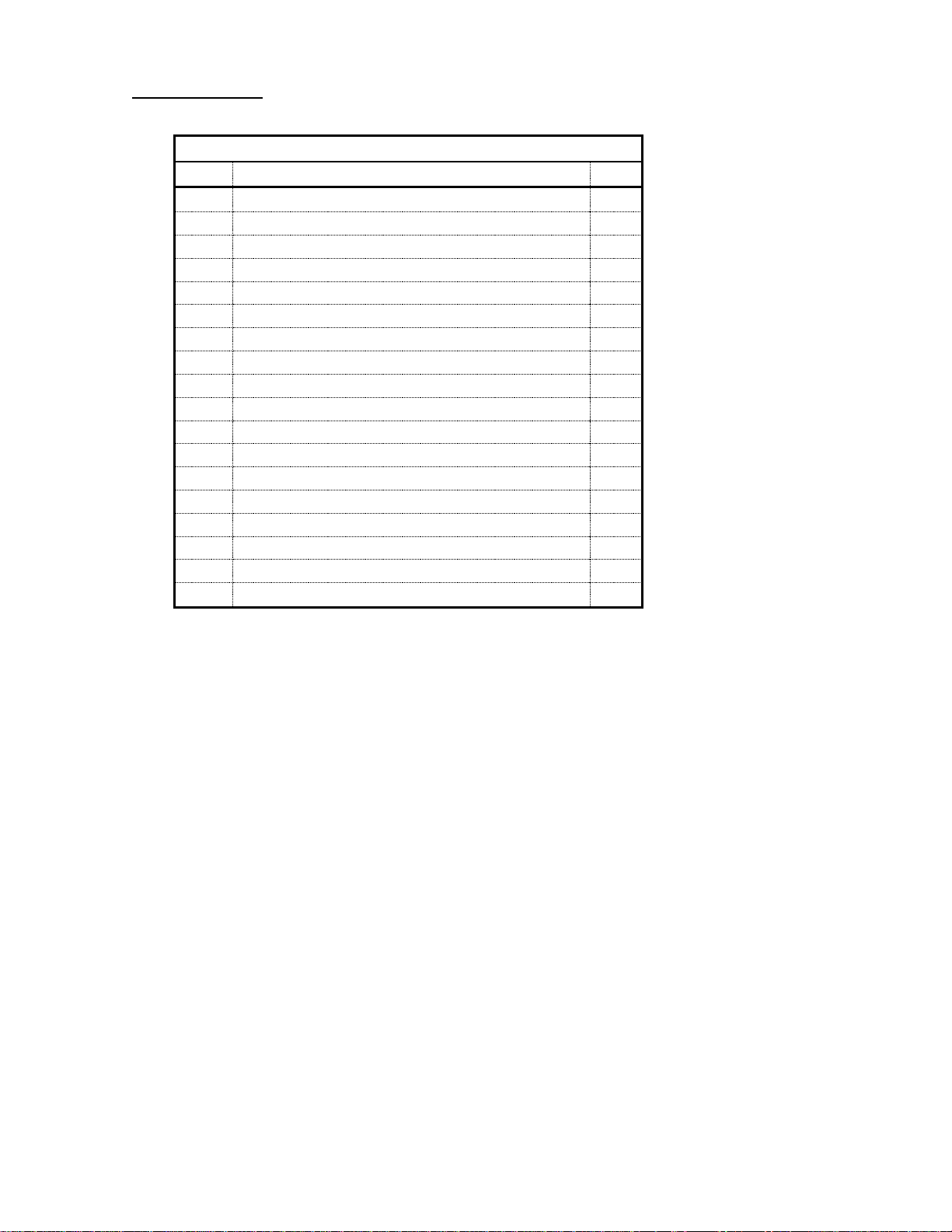

Bill Of Materials

MDE Bill Of Materials

ITEM

DESCRIPTION

QTY

1

HOUSING

1

2

HOUSING COVER

1

4

BREATHER

1

5

DRAIN PLUG

1

6

SIGHT GLASS

1

7

CAM SHAFT

1

8

CAM-MDE

1

9

INPUT CARTRIDGE

2

12

OIL SEAL INPUT

2

28

LUBE NIPPLE

2

29

FOLLOWER WHEEL

1

30

CAM FOLLOWER

v

32

FOLLOWER CARTRIDGE

v

33

ROUND CLAMP

v

35

V-SEAL

1

36

DIAL PLATE MOUNT

1

39

PROXIMITY/SENSOR SWITCH BRACKET

v

41

PROXIMITY/SENSOR SWITCH

v

4.5 Description of Function

The Mechanical MDE Series Indexer is a pre-loaded-right-angle indexing table

designed to precisely move heavy loads at a predetermined number of stations with

zero-backlash. This machine is exactly defined as incompleted machinery that has

no specific function / output until incorporated into a complete machine.

Description of

function

4.6 Places of Work of the Operating Personnel

The Mechanical MDE Series Indexer is designed for integration into complete

machines. Safe operation and control are the responsibility of the machine builder

and the machine operator.

Places of

work of the

operating

personnel

18

4.7 Hazard Zones

Hazard zones

Hazardous zones of the machine may only be entered by designated and authorised

persons!

If several persons are working on the machine, good cooperation and close

coordination of the activities is necessary.

Electrical energy

a) Use only original fuses with the prescribed amperage! In the event of faults in

the electric power supply, switch off the machine immediately!

b) Work on electrical installations or equipment may only be carried out by an

electrician or by trained persons under the instruction and supervision of an

electrician.

c) Parts of machines and installations on which inspection, maintenance and

repair work is being carried out on the electrical equipment must –if prescribed

–be isolated and secured to prevent restarting. First check that the isolated

parts are no longer live, then earth and short-circuit and isolate adjacent live

parts

d) The electrical equipment of the machine must be inspected and checked at

regular intervals. Faults such as loose connections or scorched cables must be

remedied immediately.

e) If work is necessary on live parts, have a second person standing by who can

turn off the master switch or emergency stop switch in the event of an

emergency. Cordon off the working area with a red/white safety chain and a

warning sign. Use only insulated tools and equipment!

f) When working on high-voltage assemblies, switch off the power supply, connect

the supply cable to earth and short-circuit the components, e.g. capacitors, with

a ground rod.

19

Hazard zones

Hydraulic/pneumatics

a) Work on this equipment may only be carried out by persons with specialist

know-how and experience!

b) Inspect all lines, hoses and screw fittings at regular intervals for leaks and

obvious signs of damage! Repair damage immediately! Escaping oil can lead to

injuries and fires.

c) Depressurise system sections and pressure lines to be opened in accordance

with the descriptions of the assemblies before starting the repair work!

d) Lay and install hydraulic and compressed air lines correctly! Do not confuse

connections. Fittings, lengths and qualities of the hoses must comply with the

requirements.

Noise

a) Soundproofing installations on the machine must be functional during operation.

b) Wear the prescribed personal protective equipment (ear protectors)!

Oils, greases and other chemical substances

a) Process media must be used and disposed of in accordance with the instruction

of the manufacturers of these substances.

b) Pay particular attention with hot process media (risk of burns and scalding)!

This manual suits for next models

3

Table of contents

Popular DC Drive manuals by other brands

Vacon

Vacon 100 INDUSTRIAL user manual

Allen-Bradley

Allen-Bradley PowerFlex 6000 installation instructions

TIME LED

TIME LED 781234 Installation and operating instructions

INVT

INVT 0R7G-4 Operation manual

Siemens

Siemens SINAMICS PERFECT HARMONY GH180 Function manual

ABB

ABB ACQ580-01 Series Quick installation and start-up guide

HAUTAU

HAUTAU SVA 18 v Mounting instructions

TRENDnet

TRENDnet TE100-PCBUSR - DATA SHEETS Quick installation guide

Aquagem

Aquagem iSAVER Power+1100 Installation & user guide

Hytronik

Hytronik HED1050L instruction manual

Iomega

Iomega Zip 750MB Quick install

motortronics

motortronics VMX-Synergy Plus ANSI quick start guide