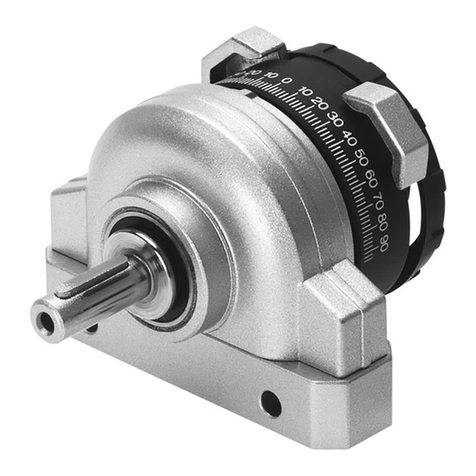

Symbol on the rating plate

DFPD-... Mode of operation Symbol

-RD-...

-LD-...

Double-acting, closes to the right / left

-RS-... Single-acting (spring return), closes to the right

-LS-... Single-acting (spring return), closes to the left

Tab. 1 Symbols for mode of operation

6 Transport and storage

WARNING!

Danger of crushing. Danger of shearing.

Body parts can be crushed or severed if the product falls.

• Use appropriate load handling equipment.

– When dispatching used products: Comply with all legal requirements for the

handling of hazardous substances and the transport of dangerous goods. For

return to Festo è 2.1 General safety instructions.

– Remove all attachments.

– Store the product in a cool, dry, UV-protected and corrosion-protected envir-

onment. Ensure that storage times are kept to a minimum.

7 Assembly and installation

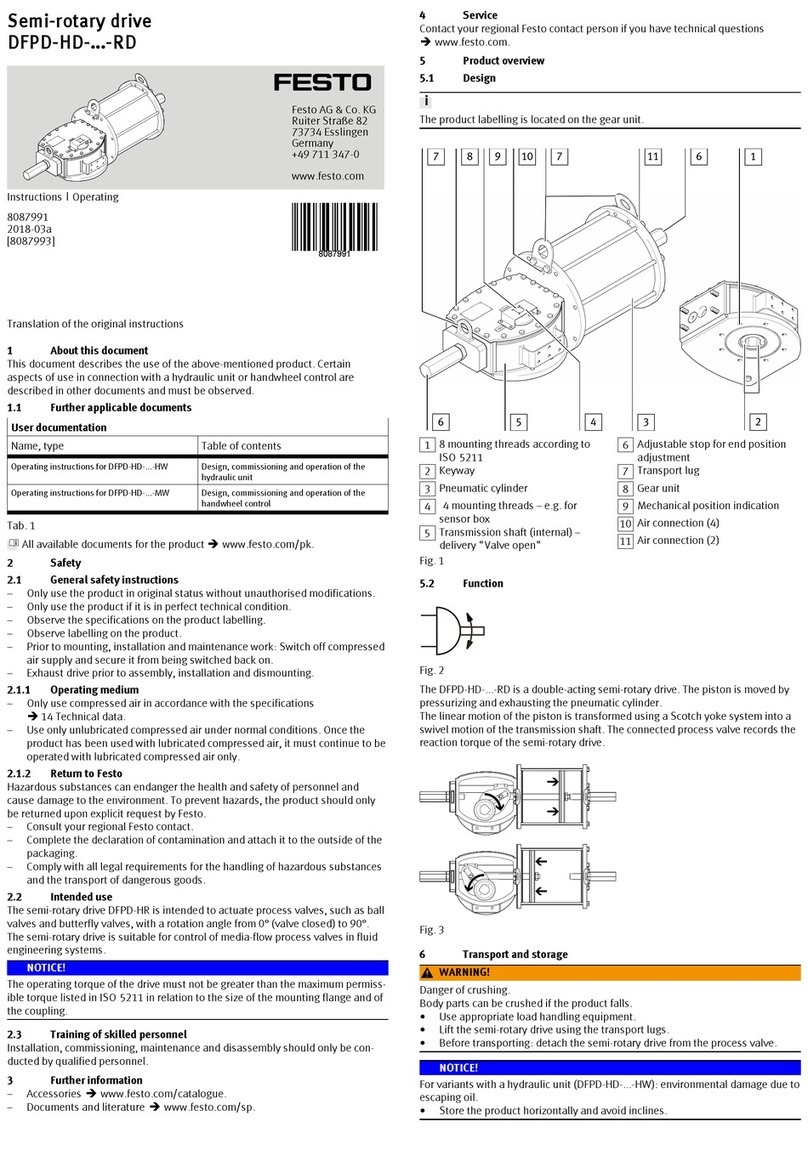

7.1 Assembly without adapter bridge

Fig. 4 Assembly without adapter bridge

1. Prepare process valve.

Adjust the control shaft of the process valve so that the desired operating

method for opening and closing is implemented.

2. Place the semi-rotary drive on the control shaft of the process valve. The con-

trol shaft must sit in the coupling of the semi-rotary drive (è Fig.1,aB)

without tilting.

3. Mount the semi-rotary drive on the connecting flange of the process valve

using 4 corrosion-resistant screws and retaining rings (material: CI).

4. Tighten the screws crosswise è Tab. 8 Tightening torque for flange.

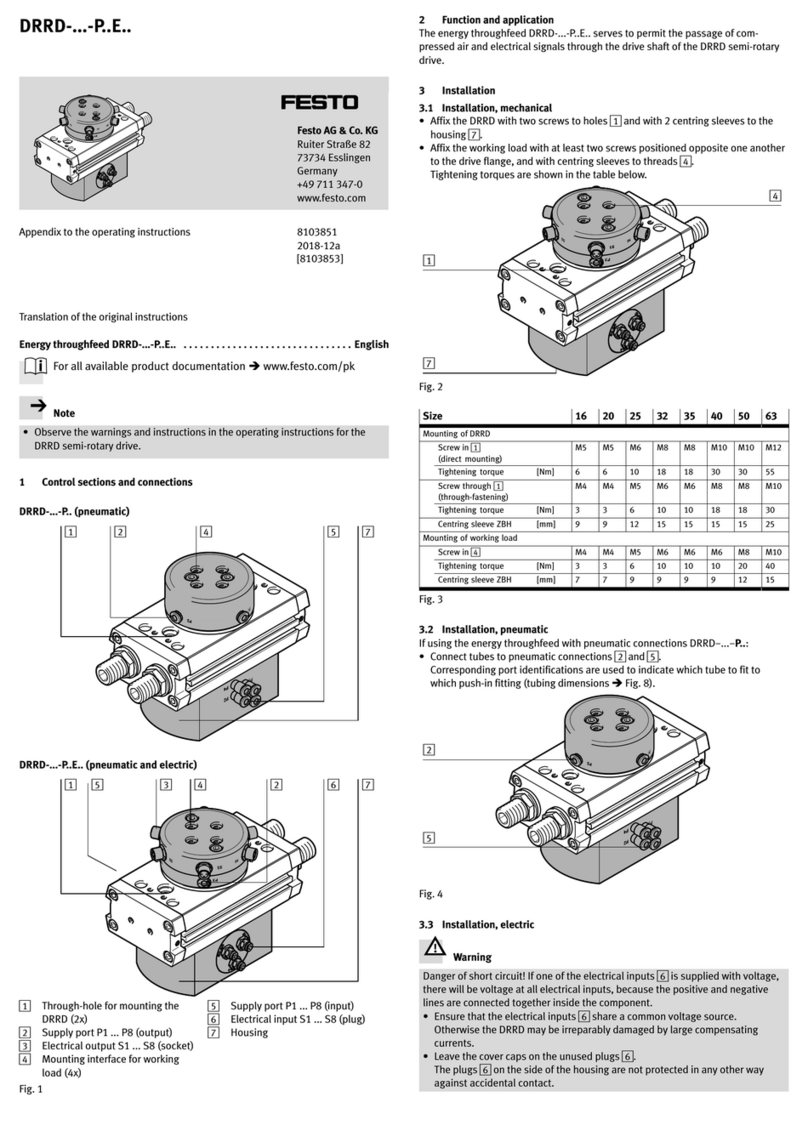

7.2 Assembly with adapter bridge

1Adapter bridge

2Coupling

Fig. 5 Assembly with adapter bridge

1. Have adapter bridge and coupling ready.

– Accessories è 3 Additional information

2. Mount the adapter bridge 1 on the semi-rotary drive.

– Align studs of the adapter bridge lengthwise to the drive.

– Align open side of the adapter bridge with the process valve.

– Do not jam the centring ring in the drilled hole for the adapter bridge.

– Tighten screws, but not yet fully tight.

3. Prepare process valve.

Adjust the control shaft of the process valve so that the desired operating

method for opening and closing is implemented.

4. Insert the coupling 2. The square of the coupling must sit in the coupling of

the semi-rotary drive without tilting (è Fig.1,aB).

5. Place the semi-rotary drive with adapter bridge and coupling on the control

shaft of the process valve. The square of the process valve must sit in the

coupling without tilting.

6. Mount the adapter bridge on the connecting flange of the process valve using

4 corrosion-resistant screws and retaining rings (material: CI).

7. Tighten the screws at both the drive and process valve crosswise

è Tab. 8 Tightening torque for flange.

7.3 Pneumatic connection

Single-acting semi-rotary drive

1. Prevent corrosive atmosphere in the spring space. If there is a corrosive atmo-

sphere, use a rebreather block.

2. Mount a filter element on the exhaust port 4 (A) to prevent ingress of dirt.

DFPD-... Supply port Effect

2 Air supply; always connected-RS-...

-LS-... 4 Pressurisation of spring space

Tab. 2 Supply port for single-acting semi-rotary drive

Double-acting semi-rotary drive

DFPD-... Supply port Effect1)

2 Air supply direction of rotation anti-clockwise-RD-...

4 Air supply direction of rotation clockwise

2 Air supply direction of rotation clockwise-LD-...

4 Air supply direction of rotation anti-clockwise

1) Viewed from the connection point of the accessory

Tab. 3 Supply port for double-acting semi-rotary drive

8 Commissioning

Requirements

– The drive is fully mounted and connected.

Commissioning the drive

1. Pressurise drive slowly.

2. Check correct function at low travel speed.

– Direction of rotation of drive

– Position of process valve

9 Maintenance

When used as intended, the product is maintenance-free.

10 Malfunctions

NOTICE!

Repairs to the product are not permissible. In the event of malfunctions or failure:

Replace the product and let Festo know about the failure. Return defective

products to Festo.