DECKORATORS ALX CLASSIC User manual

Your complete guide for inspiration, product offerings,

how-to-buy guides, installations and warranties.

2014 Pro Guide

RAILING • BALUSTERS • POST CAPS • LIGHTING • ACCESSORIES

2020 TECHNICAL GUIDE

DECKING •RAILING •BALUSTERS • ACCESSORIES • POST CAPS •LIGHTING • L ATTICE • PORCH

TECH GUIDE

HOW TO BUY

3 ALX Contemporary Pre-assembled

Railing

4 ALX Contemporary Cable Railing

5 ALX Pro with Face Mount

Balusters Railing

6 ALX Pro with Center Mount

Balusters Railing

7 Cable Railing

8 ALX Classic Railing

INSTALLATION GUIDES

9 Eovations

12 Deckorators Solid Decking

14 Deckorators Grooved Decking

18 Porch Flooring

20 Stair Tread

22 Fascia

23 Sleeper System

24 ALX Contemporary Railing

27 ALX Contemporary Cable Railing

38 ALX Pro Railing

42 Cable Railing

44 ALX Classic Railing

47 Secondary Handrail

49 Classic Balusters

51 Estate Balusters

53 Arc, Traditional and

Baroque Balusters

55 Scenic Glass

59 Post Caps

61 Deckorators®by Hinkley

67 Postcovers

70 Plastic Lattice

WARRANTY INFORMATION

71 Warranties

GO BEYOND ORDINARY.

Deckorators takes the enjoyment of personalizing your outdoor living

space to a whole new level. With decking and railing products that excite

and inspire, you can accessorize and enhance the world outside your four

walls with the newest, on-trend styles from the brand always leading design

innovation. Deckorators offers the quality and selection to transform decks

into a reflection of each homeowner. The first name in outdoor decorating,

we’ve staked our reputation on your satisfaction.

In fact, we’re so confident, we stand firmly behind that reputation with

some of the best, first-of-their-kind product warranties in the industry.

DECKORATORS CERTIFIED PRO PROGRAM

Our 2020 Deckorators Certified Pro program is designed to help your

business by aligning you with the leader in decking, railing, post caps,

and accessories. Certified Pros receive:

· Preferred contractor listing on Deckorators.com

· Access to the Deckorators Pro-Only site

· Sample kits

· Special promotions

· Hands-on training by a Deckorators representative

· Deckorators Rewards Program

Our new rewards program allows you to earn points for every Deckorators

purchase you make. Use points to purchase Deckorators products,

marketing materials, apparel or cash.

ON COVER:

Voyage Decking in Khaya paired with ALX

Contemporary Railing in Textured Black,

Deckorators®by Hinkley Luna Step Lights in

Black and Aluminum Secondary Handrail in

Tex tured Black

STEP 1 - CHOOSE YOUR RAILING

ALX CONTEMPORARY PREASSEMBLED RAIL - PURCHASE (1) KIT PER 6'OR 8'ON-CENTER IN-LINE RAIL SECTION. HARDWARE INCLUDED.

6' On-Center* Rectangle ALX Contemporary Preassembled Rail (36"or 42")Available colors: Textured Black, Textured White, Weathered

Brown, Textured Bronze and Brushed Titanium

8' On-Center* Rectangle ALX Contemporary Preassembled Rail (36"or 42")

*Sized for on-center lengths when installed with 2.5"posts

STEP 2 - CHOOSE YOUR POSTS

2.5"x 2.5"ALUMINUM POST KITS - PURCHASE (1) POST KIT PER RAILING, PLUS (1) TO END EACH RUN. TRIM AND POST CAP INCLUDED.

39"Aluminum Post Kit with Leveling Plate (for 36"rail) Available colors: Textured Black, Textured White, Weathered

Brown, Textured Bronze and Brushed Titanium

44"Aluminum Post Kit with Leveling Plate (for 42"rail)

STEP 3 - CHOOSE YOUR STAIR RAILING

ALX CONTEMPORARY PREASSEMBLED RAIL - PURCHASE (1) KIT PER 6'OR 8'STAIR RAIL SECTION. HARDWARE INCLUDED.

6' Rectangle ALX Contemporary Preassembled Stair Rail (36"or 42")Available colors: Textured Black, Textured White, Weathered

Brown, Textured Bronze and Brushed Titanium

8' Rectangle ALX Contemporary Preassembled Stair Rail (36"or 42")

STEP 4 - CHOOSE YOUR STAIR POSTS

2.5"x 2.5"ALUMINUM POST KITS - PURCHASE (1) POST KIT PER STAIR RAILING, PLUS (1) TO END EACH RUN. TRIM AND POST CAP INCLUDED.

49"Aluminum Post Kit with Leveling Plate (for 36"stair rail) Available colors: Textured Black, Textured White, Weathered

Brown, Textured Bronze and Brushed Titanium

54"Aluminum Post Kit with Leveling Plate (for 42"stair rail)

STEP 5 - CHOOSE YOUR POST CAPS

2.5"Luna Low voltage post caps Available colors: Matte Black, Textured White and Weathered

Brown

2.5"Solar Post Cap Available colors: Black, White, Weathered Brown

2.5"Nouveau Solar Post Cap Available colors: Black and White

HOW TO BUY:

ALX CONTEMPORARY PREASSEMBLED

2

1

NOTE: STEP 3 AND STEP 4 NOT SHOWN ON DIAGRAM

5

HOW TO BUY • ALX CONTEMPORARY PREASSEMBLED RAILING 3

HOW TO BUY • ALX CONTEMPORARY PREASSEMBLED RAILING

4 HOW TO BUY • ALX CONTEMPORARY CABLE RAILING

HOW TO BUY • ALX CONTEMPORARY CABLE RAILING

STEP 1 - CHOOSE YOUR RAILING

ALX CONTEMPORARY CABLE RAIL - PURCHASE (1) KIT PER 6'OR 8'ON-CENTER IN-LINE RAIL SECTION. HARDWARE INCLUDED.

6' On-Center* Rectangle ALX Contemporary Top Rail (36"or 42")Available colors: Textured Black, Textured White,

Weathered Brown and Textured Bronze

8' On-Center* Rectangle ALX Contemporary Top Rail (36"or 42")

*Sized for on-center lengths when installed with 2.5"posts

STEP 2 - CHOOSE YOUR POSTS

2.5"x 2.5"CABLE POST KITS - PURCHASE (1) LINE POST KIT FOR IN BETWEEN TWO RAILING SECTIONS, PLUS (1) END POST TO END EACH CABLE RUN.

TRIM AND POST CAP INCLUDED.

39"Cable Line Post Kit with Leveling Plate (for 36"rail), 10 pre-drilled holes

Available colors: Textured Black, Textured White,

Weathered Brown and Textured Bronze

39"Cable End Post Kit with Leveling Plate (for 36"rail), 10 pre-drilled holes

44"Cable Line Post Kit with Leveling Plate (for 42"rail), 12 pre-drilled holes

44"Cable End Post Kit with Leveling Plate (for 42"rail), 12 pre-drilled holes

STEP 3 - CHOOSE YOUR STAIR RAILING

ALX CONTEMPORARY CABLE RAIL - PURCHASE (1) KIT PER 6'STAIR RAIL SECTION. HARDWARE INCLUDED.

6' Rectangle ALX Contemporary Cable Stair Rail Available colors: Textured Black, Textured White,

Weathered Brown and Textured Bronze

8' Rectangle ALX Contemporary Cable Stair Rail

*46"stair spacers included for 36"and 42"stair heights. Trim to fit.

STEP 4 - CHOOSE YOUR STAIR POSTS

2.5"x 2.5"ALUMINUM POST KITS - PURCHASE (1) MIDDLE STAIR POST KIT FOR IN BETWEEN TWO STAIR RAILING SECTIONS, PLUS (1) BOTTOM STAIR

POST TO END THE CABLE RUN AT THE BOTTOM. TRIM AND POST CAP INCLUDED.

49"Cable Stair Middle Post Kit with Leveling Plate (for 36"stair rail), 10 pre-drilled slots

Available colors: Textured Black, Textured White,

Weathered Brown and Textured Bronze

49"Cable Stair Bottom Post Kit with Leveling Plate (for 36"stair rail), 10 pre-drilled holes

54"Cable Stair Middle Post Kit with Leveling Plate (for 42"stair rail), 12 pre-drilled slots

54"Cable Stair Bottom Post Kit with Leveling Plate (for 42"stair rail), 12 pre-drilled holes

STEP 5 - CHOOSE YOUR CABLE

CABLE IS AVAILABLE IN INDIVIDUAL PRE-CUT LENGTHS. PURCHASE (10) FOR EACH 36"RAILING RUN AND (12) FOR EACH 42"RAILING RUN. MULTIPLE

LENGTHS MAY BE REQUIRED BASED ON THE DECK LAYOUT. TRIM TO FIT.

1/8"SS Cable with pre-attached threaded stud and pull-lock fitting, in 5', 10', 15', 20', 25',

30', 40'and 50'lengths

Available colors: 316 Stainless

STEP 6 - CHOOSE YOUR POST CAPS

2.5"Luna Low voltage post caps Available colors: Matte Black, Textured White and

Weathered Brown

2.5"Solar Post Cap Available colors: Black, White, Weathered Brown

2.5"Nouveau Solar Post Cap Available colors: Black and White

1

2

5

6

NOTE: STEP 3 AND STEP 4 NOT SHOWN ON DIAGRAM

HOW TO BUY:

ALX CONTEMPORARY CABLE

HOW TO BUY • ALX PRO ALUMINUM RAILING WITH FACE MOUNT BALUSTERS 5

HOW TO BUY • ALX PRO ALUMINUM RAILING WITH FACE MOUNT BALUSTERS

HOW TO BUY: ALX PRO

WITH FACE MOUNT BALUSTERS

For more information visit Deckorators.com

STEP 1 - CHOOSE YOUR RAILING

ALX PRO RAIL KITS – PURCHASE (1) RAIL KIT PER 6'OR 8'SECTION.*

6' Rail kit with brackets

Available colors: Black and White

8' Rail kit with brackets

* To create stair rails, you will need to purchase (2) stair bracket kits per stair rail.

CAP RAIL KITS (OPTIONAL) – PURCHASE (1) CAP RAIL KIT PER 6'OR 8'RAIL SECTION.

6' Cap rail kit with insert rail

Available colors: Black and White

8"Cap rail kit with insert rail

STEP 2 - CHOOSE YOUR BALUSTERS (FACE MOUNT)

ARCHITECTURAL ALUMINUM BALUSTERS – PURCHASE (3) 5-PACKS PER 6'RAIL OR (4) 5-PACKS PER 8'RAIL.

32-1/4" Baroque (for 36" line rail) – 5-pack (screws included)

Available colors: Black, White and Bronze

40" Baroque (for 42" line rail) – 5-pack (screws included)

32-1/4" Arc (for 36" line rail) – 5-pack (screws included) Available colors: Black and Bronze

TRADITIONAL ALUMINUM BALUSTERS – PURCHASE (1.5) 10-PACKS PER 6’ RAIL OR (2) 10-PACKS PER 8’ RAIL.

32"Traditional (for 36"line rail) – 10-pack (screws included)

Available colors: Black and Bronze

40"Traditional (for 42"line rail) – 10-pack (screws included)

GLASS BALUSTERS – PURCHASE 9 BALUSTERS PER 6'SECTION AND 12 PER 8'SECTION.

32"Clear Scenic Glass (for 36"rail) – 5-pk (screws included)

STEP 3 - SELECT YOUR POST SLEEVES AND POST BASE TRIM

4x4 POST SLEEVE AND TRIM – PURCHASE (1) POST SLEEVE PER RAILING KIT PLUS (1) TO END EACH RUN. TRIM OPTIONAL.

40-1/4"Post sleeve (for 36"rail)

Available colors: Black and White

52"Post sleeve (for 42"rail)

4x4 Post base trim

STEP 4 - CHOOSE YOUR POST CAPS

Aluminum base post caps – Purchase (1) post cap per post sleeve.

1

3

4

2

7883FaceMnt.ai

6 HOW TO BUY • ALX PRO RAILING WITH CENTER MOUNT BALUSTERS

HOW TO BUY • ALX PRO RAILING WITH CENTER MOUNT BALUSTERS

HOW TO BUY: ALX PRO

WITH CENTER MOUNT BALUSTERS

7880CntMnt.ai

1

4

5

2

3

STEP 1 - CHOOSE YOUR RAILING

ALX PRO RAIL KITS – PURCHASE (1) RAIL KIT PER 6'OR 8'SECTION.*

6' Rail kit with brackets Available colors: Black and White

8' Rail kit with brackets

* To create stair rails, you will need to purchase (2) stair bracket kits per stair rail.

CAP RAIL KITS (OPTIONAL) – PURCHASE (1) CAP RAIL KIT PER 6'OR 8'RAIL SECTION.

6' Cap rail kit with insert rail Available colors: Black and White

8' Cap rail kit with insert rail

STEP 2 - CHOOSE YOUR BALUSTERS (CENTER MOUNT)

ALUMINUM BALUSTERS – PURCHASE (1.5) 10-PACKS PER 6'RAIL OR (2) 10-PACKS PER 8'RAIL.

26"Classic (for 36"line rail) – 10-pack

Available colors: Black, Matte Black,

Bronze, White, Textured White and

Weathered Brown

32"Classic (for 42"line rail) – 10-pack

36"Classic (for 46"line rail) – 10-pack

26"Estate (for 36"line rail) – 10-pack

32"Estate (for 42"line rail) – 10-pack

GLASS BALUSTERS – PURCHASE 9 BALUSTERS PER 6'SECTION AND 12 PER 8'SECTION.

26"Clear Scenic Glass (for 36") – 5-pack

32"Clear Scenic Glass (for 42") – 5-pack (screws included)

STEP 3 - SELECT YOUR CORRESPONDING BALUSTER CONNECTORS

ALUMINUM BALUSTER CONNECTORS – PURCHASE (1) 20-PACK PER (1) BALUSTER PACK. ADD STAIR ADAPTORS AS NEEDED.

Baluster Connectors – 20-pack (use with Classic Balusters) Available colors: Black and White

Stair Connectors – 20-pack (use with Classic Balusters)

Available colors: Black, White and BronzeDesigner Baluster Connectors – 20-pack (use with Classic Balusters)

Designer Baluster Stair Adaptors – 20-pack (use with Classic Balusters)

Standard Estate Baluster Connectors – 20-pack (use with Estate Balusters) Available colors: Black and White

Standard Estate Stair Connectors – 20-pack (use with Estate Balusters)

GLASS BALUSTERS CONNECTORS – PURCHASE (1) CONNECTOR KIT PER (1) SCENIC BALUSTER.

Frontier Scenic Connectors – 2-pack Available colors: Black, Cedar, Gray and

White

Scenic Stair Connectors – 2-pack

STEP 4 - SELECT YOUR POST SLEEVES AND POST BASE TRIM

4x4 POST SLEEVE AND TRIM – PURCHASE (1) POST SLEEVE PER RAILING KIT PLUS (1) TO END EACH RUN. TRIM OPTIONAL.

40-1/4"Post sleeve (for 36"rail)

Available colors: Black and White

52"Post sleeve (for 42"rail)

4x4 Post base trim

STEP 5 - CHOOSE YOUR POST CAPS

Aluminum base post caps – Purchase (1) post cap per post sleeve.

HOW TO BUY: CABLE RAILING

1

4

7

6

2

3

5

STEP 1 - CHOOSE YOUR RAILING

(BOTTOM RAILING OPTIONAL)

Works with ALX Pro railing or wood posts/rail.

Cable can extend up to 30'and turn one corner.

Hardware packs include: 2 Eye lags, 1 fork jawand 1 turnbuckle.

STEP 2 - HARDWARE

Purchase 10 packs for a 36"rail height or 12 packs for a 42"rail height, required for each start or stop of a run/post.

STEP 3 - CABLE

Available in 100'and 500'lengths.

STEP 4 - SUPPORT

One spacer required for a 6'section, two spacers required for an 8'section.

STEP 5 - POST PROTECTORS

Post protectors are required for turning 45-degree corners – sold in packs of 10.

STEP 6 - ADD YOUR ALX PRO POST SLEEVE KITS

(if applicable)

STEP 7 - CHOOSE YOUR POST CAPS

Purchase (1) post cap per post sleeve.

HOW TO BUY • CABLE RAILING

HOW TO BUY • CABLE RAILING 7

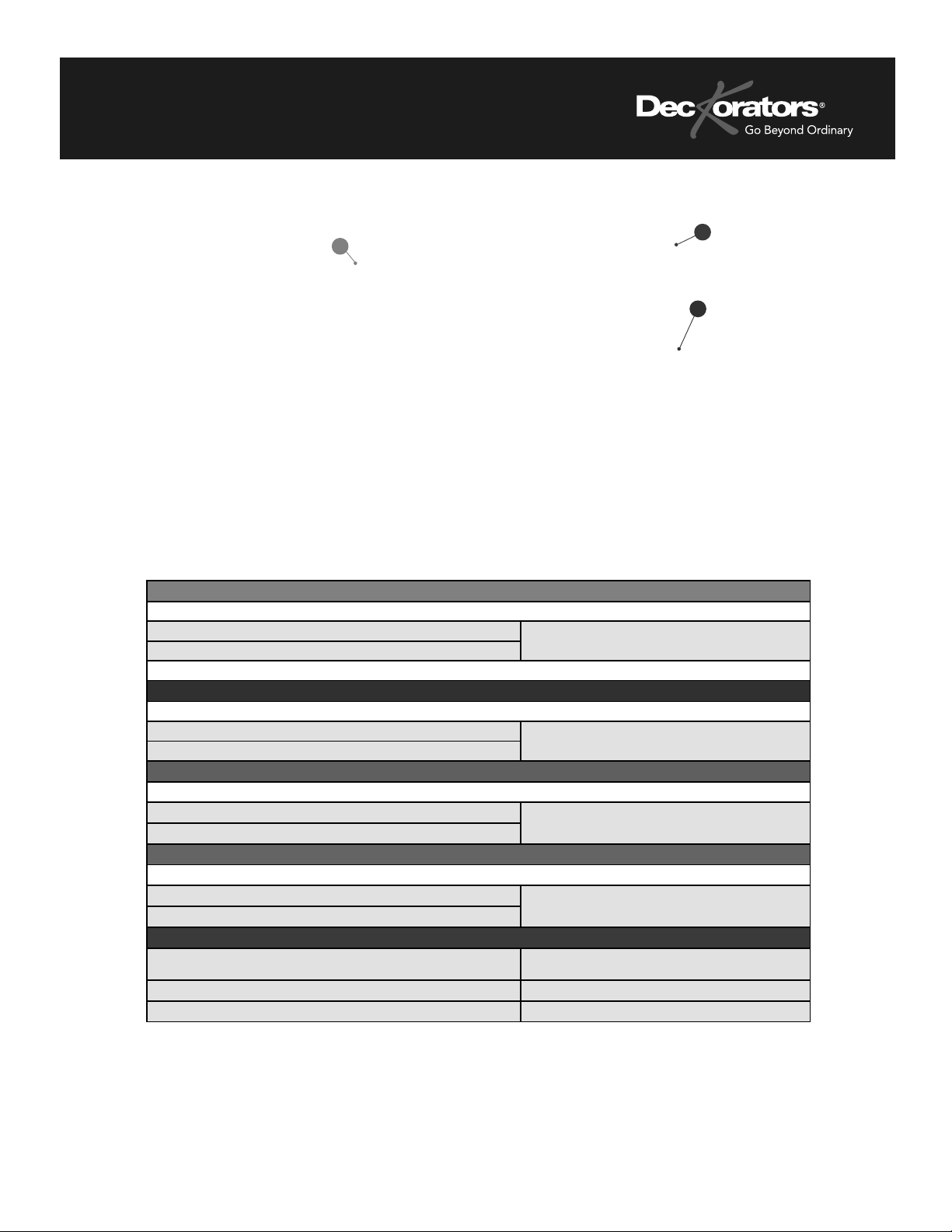

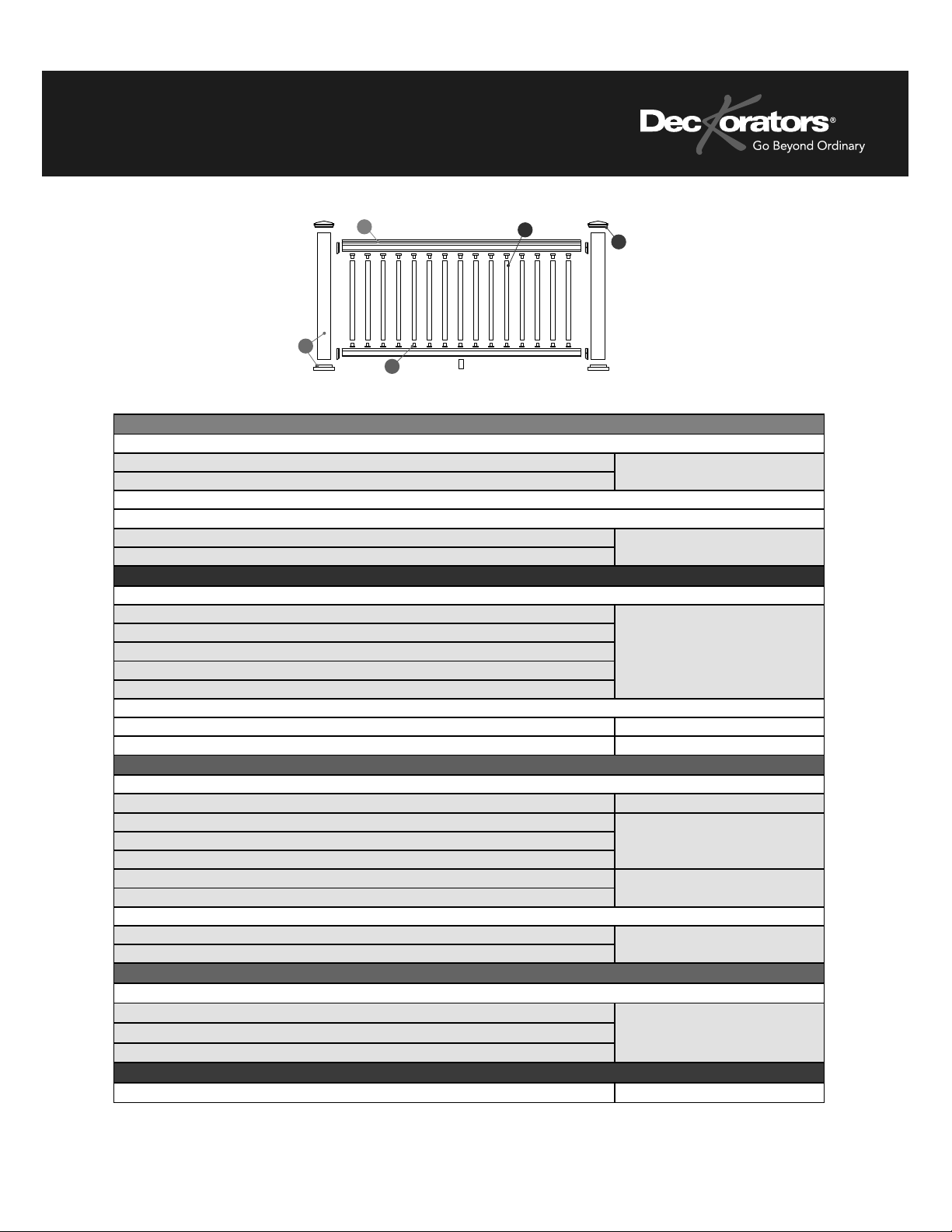

STEP 1 - CHOOSE YOUR ALX CLASSIC COMPLETE RAIL KIT

TOP & BOTTOM RAIL WITH CONNECTORS INSTALLED, BALUSTERS AND BRACKETS INCLUDED

6' On Center Rail Kit - Classic (Round) Balusters for 36"or 42"Rail Height

Available colors: Satin Black, Matte Black, Textured White,

Weathered Brown

6' On Center Rail Kit - Estate (Square) Balusters for 36"or 42"Rail Height

8' On Center Rail Kit - Classic (Round) Balusters for 36"or 42"Rail Height

8' On Center Rail Kit - Classic (Round) Balusters for 36"or 42"Rail Height

STEP 2 - CHOOSE YOUR ALUMINUM POST KITS (2.5"x 2.5"ALX CLASSIC POST KITS)

PURCHASE (1) POST KIT PER RAILING KIT PLUS (1) TO END EACH RUN. TRIM AND POST CAP INCLUDED

39"Post Kit (with leveling plate) for 36"Rail Height Available colors: Satin Black, Matte Black, Textured White,

Weathered Brown

44"Post Kit (with leveling plate) for 42"Rail Height

STEP 3 - CHOOOSE YOUR ALX CLASSIC COMPLETE STAIR RAIL KIT

EACH KIT INCLUDES (2) ALUMINUM RAILS WITH BALUSTER CONNECTORS INSTALLED, (1) STAIR HARDWARE KIT THAT INCLUDES (4) METAL STAIR

BRACKETS (8) #8 x3/4"& (8) #8 x1-3/4"SCREWS, (12) BALUSTERS FOR 6'FOR 35 DEGREE STAIR INSTALLATIONS

6' Stair Rail Kit - Classic (Round) Balusters for 36"or 42"Rail Height

Available colors: Satin Black, Matte Black, Textured White,

Weathered Brown

6' Stair Rail Kit - Estate (Square) Balusters for 36"or 42"Rail Height

8' Stair Rail Kit - Classic (Round) Balusters for 36"or 42"Rail Height

8' Stair Rail Kit - Estate (Square) Balusters for 36"or 42"Rail Height

STEP 4 - CHOOSE YOUR STAIR POST KITS

2.5"x 2.5"ALUMINUM POST KITS - PURCHASE (1) POST KIT PER STAIR RAILING, PLUS (1) TO END EACH RUN. TRIM AND POST CAP INCLUDED.

49"Aluminum Post Kit with Leveling Plate (for 36"stair rail) Available colors: Satin Black, Matte Black, Textured White,

Weathered Brown

54"Aluminum Post Kit with Leveling Plate (for 42"stair rail)

STEP 5 - CHOOSE YOUR OPTIONAL, ALTERNATIVE POST CAPS

ALUMINUM BASE POST CAPS - PURCHASE (1) OPTIONAL, ALTERNATIVE POST CAP PER POST IF DESIRED

2.5"Luna Low voltage post caps Available colors: Matte Black, Textured White and Weathered

Brown

2.5"Solar Post Cap Available colors: Satin Black, White, Weathered Brown

2.5"Nouveau Solar Post Cap Available colors: Black and White

HOW TO BUY: ALX CLASSIC

ALXClassic.ai

1

4

5

2

3

For more information visit Deckorators.com ©2020 UFP Retail, LLC. All rights reserved. Deckorators is a registered trademark

of UFP Industries, LLC 11126_3/20

HOW TO BUY • ALX CLASSIC RAILING

8 HOW TO BUY • ALX CLASSIC RAILING

INSTALLATION INSTRUCTIONS • EOVATIONS

EOVATIONS INSTALLATION INSTRUCTIONS 9

EOVATIONS INSTALLATION GUIDE

Items you will need

• Safety glasses

• Pencil or pen

• Tape measure

• Utility knife

• Jigsaw

• Carpenter square

(speed square)

• Power screw gun or drill

• Soft mallet

• Portable power saw

•Fine-tooth saw blades

(40-tooth minimum, sharp

carbide-tipped wood or

nish/trim blades)

•Large le or medium-grit

sandpaper

• Chalk line

• Spacing tools

• Fastener-specic tools

recommended by

manufacturer

Joist spacing requirements

Gapping requirements

©2019 Universal Forest Products, Inc. Deckorators is a registered trademark of Deckorators, Inc. in the U.S. All rights reserved.

5 Meadowcraft Parkway, Selma, AL 36701 800.332.5724 8529_3/19

Deckorators.com

Each Deckorators®Voyage™ and Vault board has a unique appearance

and should be arranged according to the end user’s preference. Prior to

construction, check with your local regulatory agency's code requirements.

For best results, follow all installation instructions, paying close attention to

gapping, spacing and fastener requirements.

•

•

16"

•

•

16"

•

•

12"

Eotek4.pdf

Standard Picture frame Diagonal (45°)

Residential 16" 16" 12"

Commercial 12" 12" 12"

Note: All dimensions are on-center.

Note: Joist spacing, stair stringer spacing and fastener requirements remain the

same for all Eovations deck board widths (3.5", 5.5" 7.25").

Installation style

Above 32º F

(0º C)

Below 32º F

(0º C)

Side-to-Side 1/8" 3/16"

End-to-End 1/16" 1/8"

End-to-Side 1/16" 1/8"

Abutting Solid

Objects 1/8" 1/4"

Installation temperature

Each variegated

Deckorators board

has a unique

appearance and

should be arranged

according to the

end user's

preference.

Almacenamiento

Mantenga cubierto antes de ser instalado.

Instalación

• Todas las tablas deben distribuirse de forma adecuada

para permitir la expansión y contracción. Refiérase a las

instrucciones para la instalación completa para detalles.

• Distribuya todo el material para terrazas a 1/4

(6.4 mm) de distancia de cualquier estructura

permanente o poste.

• Utilice como mínimo sujetadores para piso de terraza

de 2-1/2 pulg., resistentes a la corrosión, con rosca

inversa y con recubrimiento.

Espaciado de las vigas

• Espaciado de la viga 16 in (41 cm) en el centro para la

instalación perpendicular a la viga.

• Espaciado de la viga 12 in (31 cm) en el centro para la

instalación diagonal a la viga.

Visite Deckorators.com para instrucciones completas

de instalación, e información de la garantía y el cuidado

y limpieza.

Deckorators es una marca comercial de Universal Consumer Products, Inc. en

los EE.UU.

La garantía está disponible en www.deckorators.com.

Guarde las etiquetas UPC como comprobante de compra.

Rangement

Gardez couvert avant l'installation.

Installation

• Toutes les planches doivent être espacées

correctement pour permettre la dilatation et le retrait.

Consultez les directives d’installation complètes pour

obtenir les détails.

• Éloignez tout le matériau de terrasse de 6,4 mm (1/4

po) de toute structure permanente ou de tout poteau.

• Utiliser des attaches de terrasse en composite enduit,

à filetage inverse, résistantes à la corrosion de au

moins 2-1/2 po.

Espacement des solives

• Espacement aux solives de 41 cm (16 po) entre axes

pour l’installation perpendiculaire aux solives.

• Espacement des solives de 31 cm (12 po) entre axes

pour l’installation diagonale aux solives.

Visitez Deckorators.com pour les instructions complètes

d’installation, garantie et l’entretien.

Deckorators est une marque de commerce déposée de Universal Consumer

Products, Inc. aux États-Unis.

Le texte de la garantie est disponible à l’adresse www.deckorators.com.

Conservez l’étiquette d’extrémité à code UPC comme preuve d’achat.

Storage

Keep covered prior to installation.

Installation

• All boards must be spaced properly to allow for

expansion and contraction. Refer to complete

installation instructions for details.

• Space all decking material 1/4-in away from any

permanent structure or post.

• Use minimum 2-1/2" corrosion-resistant, reverse-thread,

coated composite decking fasteners.

Joist Spacing

• 16-in on-center for installation perpendicular to the joist.

• 12-in on-center for installation diagonal to the joist.

Visit Deckorators.com for complete installation

instructions, warranty and care and cleaning information.

Deckorators is a trademark of Universal Consumer Products, Inc., in the U.S.

Warranty available at www.deckorators.com.

Save UPC end tags for proof of purchase.

8560 10/15

©2014-2015 Universal Forest Products, Inc. All rights reserved.

5 Meadowcraft Parkway, Selma, AL 36701 (800) 332-5724

Chaque planche de

platelage possède

une apparence

unique et devrait

donc être

disposée au goût

de l'utilisateur.

Cada tablón tiene

una apariencia

únicay debe ser

colocado de

acuerdo a la

preferencia

del usuario final.

VAULT DECKING

•

•

16"

•

•

16"

•

•

12"

Eotek4.pdf

End Tag

Product Sticker

1X6-16' GR. DKR.

• •

12"

DeckConstr.ai

• •

16"

• •

16"

• •

12"

DeckConstr.ai

• •

16"

• •

16" • •

12"

DeckConstr.ai

• •

16"

• •

16"

SIDE

VIEW

Standard Picture frame Diagonal

TOP

VIEW

•

•

16"

•

•

16"

•

•

12"

Eotek4.pdf

Note: Always follow best

workmanship practices.

Including, and not limited to,

square cutting both board ends

prior to installation.

INSTALLATION INSTRUCTIONS • EOVATIONS

10 EOVATIONS INSTALLATION INSTRUCTIONS

EOVATIONS INSTALLATION INSTRUCTIONS, CONTINUED

Cutting

Installation

©2019 Universal Forest Products, Inc. Deckorators is a registered trademark of Deckorators, Inc. in the U.S. All rights reserved.

5 Meadowcraft Parkway, Selma, AL 36701 800.332.5724 8529_3/19

Deckorators.com

• Upcut with a clean/smooth saw blade.

• Cut deck boards with the leading edge of the saw blade,

cutting into the exposed face. Use a sharp utility knife or jigsaw

to nish cuts where a circular saw cannot fully complete cut.

• Use a jigsaw to cut openings for protrusions.

• If necessary, use a large le or medium-grit sandpaper

to clean cut edges.

• Use utility knife to cut any bers or strands.

(In the rare event that a strand or fiber protrudes from

the board, do not pull it.)

•Set power driver such that screws are slightly counter sunk.

Do not overdrive.

•If using a hidden fastener system, use the manufacturer’s

recommended fastener and follow the manufacturer’s instructions.

•Two fasteners per joist minimum.

• Ends of each board must fall on a joist.

• Double joist or use blocking where two board ends meet.

• 1" maximum cantilever.

• Install entire deck at same temperature.

•Install the deck boards starting from the outside edge of the platform

and work toward anchor wall so that ripped pieces abut the wall. Start

installing from one end of the board and work toward the other end

of the board.

OR: Start installing from the center of the board and work out toward

the ends of the board. Do not install by fastening each end rst and

working toward the middle.

•Continue installing deck boards, adhering to the gapping

requirements. Ensure consistent appearance by aligning each

plank so that the cathedrals of the emboss pattern point in the

same direction.

NOTE: Cutting all ends of boards prior to installation recommended.

Fastener requirements

• 10" 40T, 80T circular blade

• 12" 40T, 72T, 80T circular blade

• Corrosion-resistant, galvanized or

stainless steel fasteners

• Reverse-thread composite screw

• Minimum of 2-1/2" long screws

• 1-1/4" minimum penetration into joist

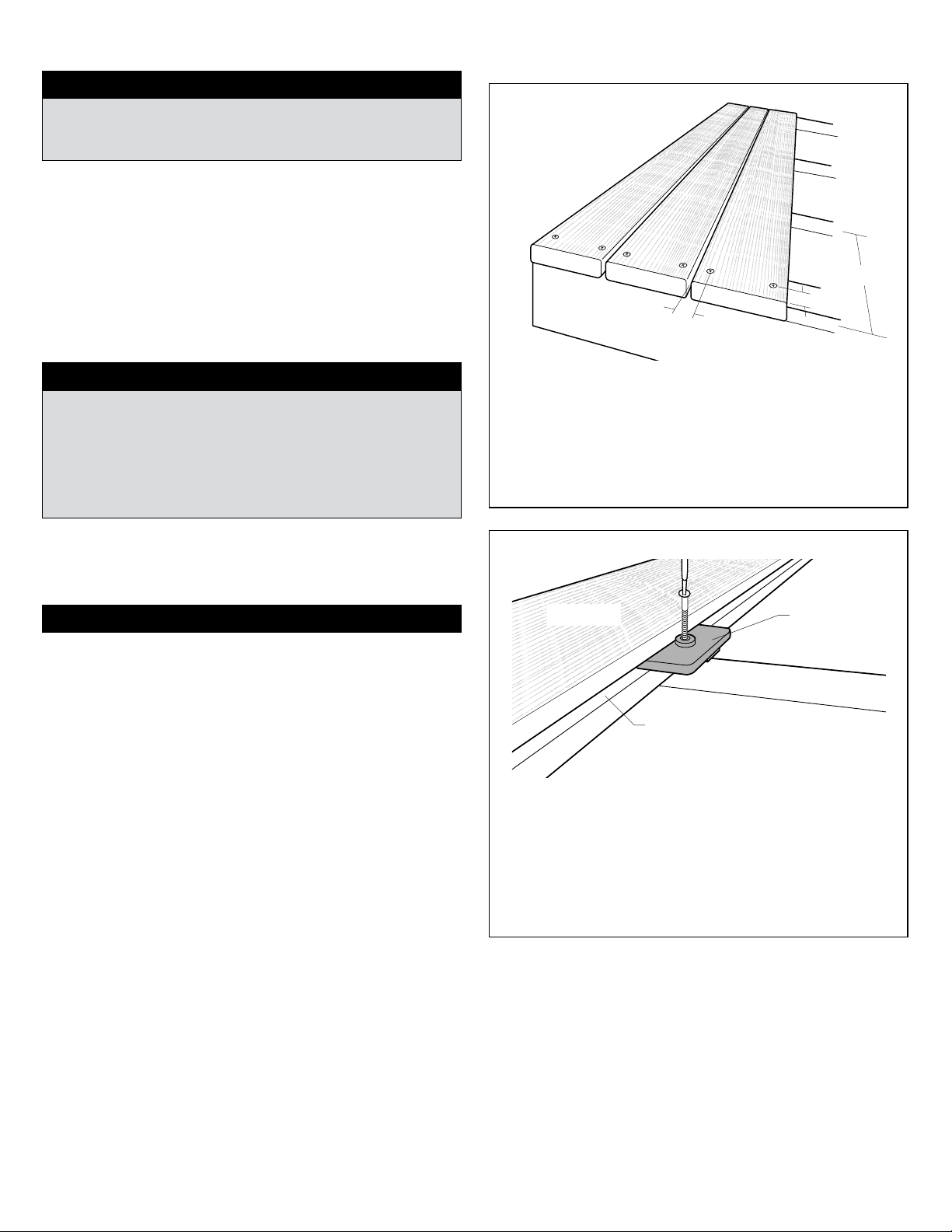

Face screw installation

Hidden fastener installation

3/8"-1"

3/8"-1"

••

Eotek 6.pdf

16" max.

•

•

•

•

Eotek 7.pdf

Hidden

fastener

Joist

Slot

•

•

Deck board

• Use reverse-threaded composite deck screws.

• Screws should be 3/8" to 1" from side of board,

3/8" to 1" from end of board.

• Use color-matched screws for best results.

• Use caution not to overdrive screw.

• Please refer to the compatible fastener information

on Deckorators.com/FastenerInfo.

• Fastener slots may be routed into the side of the

deck boards, as needed.

• Follow hidden fastener manufacturer’s instructions.

INSTALLATION INSTRUCTIONS • EOVATIONS

EOVATIONS INSTALLATION INSTRUCTIONS 11

8529

EOVATIONS INSTALLATION INSTRUCTIONS, CONTINUED

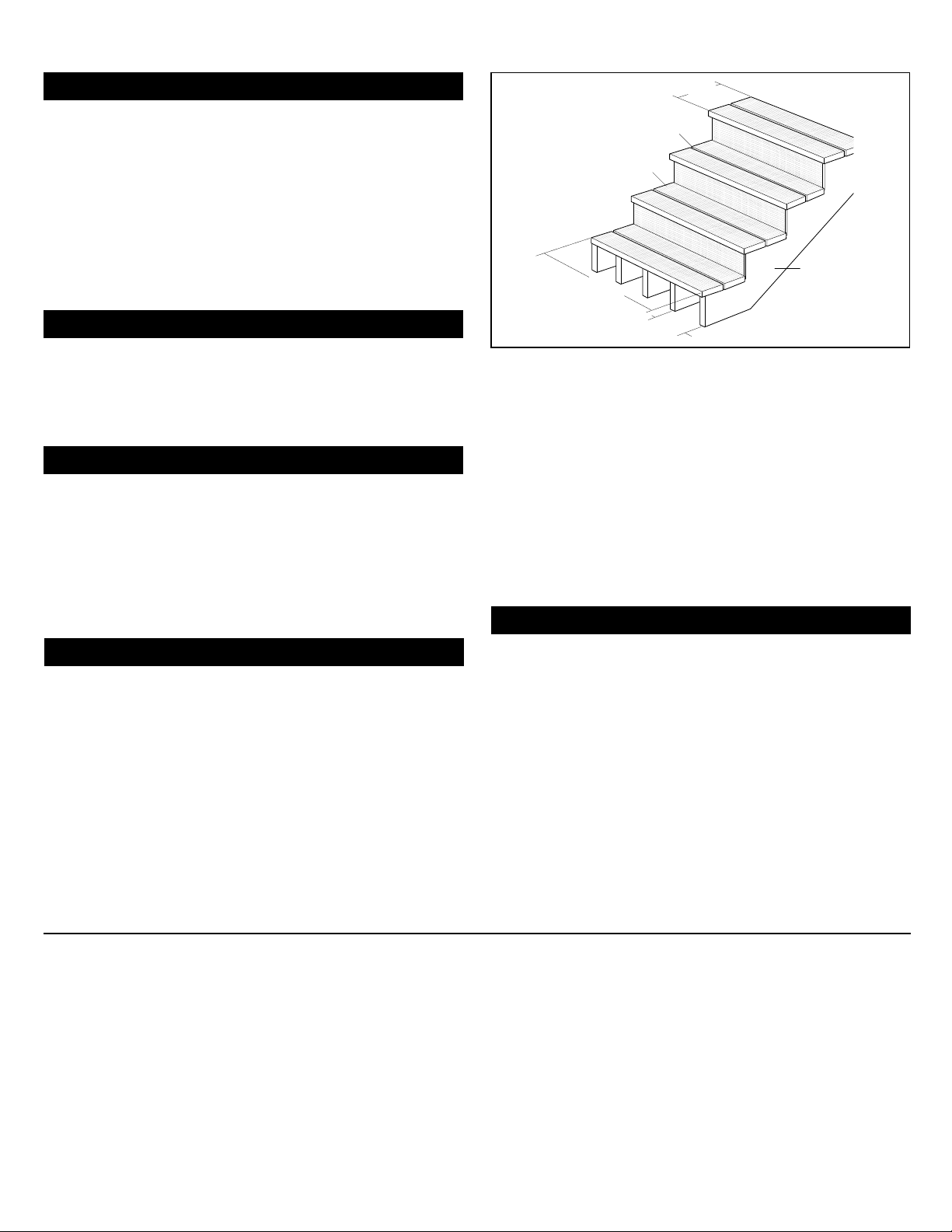

Stair installation

©2020 UFP Retail, LLC. Deckorators is a registered trademark of UFP Industries, LLC. in the U.S. All rights reserved.

5 Meadowcraft Parkway, Selma, AL 36701 800.332.5724 8529_4/20

Deckorators.com

•Stairs must be constructed according to national and local building

codes. Generally, building codes require 3' minimum wide treads and

11" minimum tread depth.

• 9" maximum center-to-center spacing of stringers is required.

•Stair treads should be fastened over a minimum of 5 stringers to

meet code requirements.

• 1/2" maximum tread overhang over stringers.

•1/8" minimum gap between stair-tread boards. Local building codes

may require the gap to be increased to 1/4" - 3/8" in order to maintain

the minimum tread depth.

Like most composites, Deckorators Decking will have color variations

from piece to piece. This is due to naturally occurring variations in

polymers. Purchasing all required decking material at one time is

recommended, as manufacturing runs can produce slightly different

colors. Do not install if color variation is not acceptable.

Mold and mildew can be a nuisance on any exterior building surface,

regardless of the material. If the conditions are right, they will grow on

wood, plastic, concrete, metal and other surfaces. Mold formation is

most prevalent in consistently wet, shaded areas. Spores from the nat-

ural environment are carried by the wind and commonly land on decks

surfaces. It is important to note that the appearance of mold/

mildew is a function of nature, not necessarily a deciency with any

of the material on which it grows.

Periodic washing with soap/mild detergent and water will help remove

surface dirt. This will also help prevent the buildup of pollen, debris and

spores that can cause and accelerate mold/mildew growth.

Caution: A pressure washer should not be used to “blast” mold/mildew

or soils from a deck surface. The abrasive nature of the water stream can

potentially cause damage by driving the spores deeper into the material,

which may create a more challenging problem to remedy. A pressure

washer with a fan-tipped nozzle should be used only to lightly wet or

rinse wood or composite deck surfaces.

There are many deck wash and exterior cleaning products available at

retail. It is important to make sure you use a cleaner specically intended

for your application. After selecting a product, be certain to read,

Stringer

Stair tread

Eotek2.pdf

9" max.

36" min.

5 stringers

required

11" min.

depth

1/8" min.

gap

•

•

•

•

•

•

•

•

•

THE DIAGRAMS AND INSTRUCTIONS IN THIS BROCHURE ARE FOR ILLUSTRATION PURPOSES ONLY AND ARE NOT MEANT TO REPLACE A LICENSED PROFESSIONAL. ANY CONSTRUCTION OR

USE OF THE PRODUCT MUST BE IN ACCORDANCE WITH ALL LOCAL ZONING AND/OR BUILDING CODES. THE CONSUMER ASSUMES ALL RISKS AND LIABILITY ASSOCIATED WITH THE

CONSTRUCTION OR USE OF THIS PRODUCT. THE CONSUMER OR CONTRACTOR SHOULD TAKE ALL NECESSARY STEPS TO ENSURE THE SAFETY OF EVERYONE INVOLVED IN THE PROJECT,

INCLUDING, BUT NOT LIMITED TO, WEARING THE APPROPRIATE SAFETY EQUIPMENT. UNIVERSAL FOREST PRODUCTS, INC., MAKES NO WARRANTY, EITHER EXPRESS OR IMPLIED,

AND SHALL NOT BE LIABLE FOR ANY DAMAGES, INCLUDING CONSEQUENTIAL DAMAGES.

Color variation

Mold and mildew growth

Cleaning

Mold inhibitors

understand and follow all instructions supplied by the manufacturer.

Some cleaning products and inhibitors may be more effective than

others, depending on the environmental conditions your deck is

subjected to. Additionally, it is always a good idea to test the cleaner

in a small, inconspicuous area prior to applying it to the entire deck

(www.deckorators.com).

Tips for snow removal: Care should be taken when removing snow from

your deck to avoid damaging the deck surface. Use a plastic snow

shovel, one without a metal edge. A stiff push broom can work very well

and minimizes lifting. Light snow can be cleared using a leaf blower. Do

not attempt to break up or scrape ice from the deck surface; use ice

melt products when needed. No concerns have been reported using ice

melt products labeled “Safe for Pets”.

As with deck washes, there are several mold-inhibitor products available

from paint stores, hardware stores, online outlets and home centers to

help prevent long-term mold/mildew growth. For any product selected,

be certain to read, understand and follow all instructions provided by the

manufacturer. Depending upon the environmental factors affecting your

deck, some preventive cleaning products may be more effective than

others. It may be necessary to try more than one product. For ongoing

preventive maintenance, follow the manufacturer’s recommendation.

Note: Deckorators is not suitable for structural use. It should not be

used for primary load-bearing members such as posts, joists, beams or

stringers. The same commonsense precautions should be taken when

handling Deckorators as with wood or other building materials. Dust

masks and eye protection devices are recommended to avoid possible

irritation from sawdust and chips. Gloves will help protect hands.

Hands should be washed after construction work.

INSTALLATION INSTRUCTIONS • SOLID DECKING

12 SOLID DECKING INSTALLATION INSTRUCTIONS

Warmest annual temperature °F expected in region

°F 20 30 40 50 60 70 80 90 100 110 120

20 1/8 1/8 1/8 1/8 1/8 3/16 3/16 1/4 1/4 5/16 5/16

30 1/8 1/8 1/8 1/8 1/8 3/16 3/16 1/4 1/4 5/16

40 1/8 1/8 1/8 1/8 1/8 3/16 3/16 1/4 1/4

50 1/8 1/8 1/8 1/8 1/8 3/16 3/16 1/4

60 1/8 1/8 1/8 1/8 1/8 3/16 3/16

70 1/8 1/8 1/8 1/8 1/8 3/16

80 1/8 1/8 1/8 1/8 1/8

90 1/8 1/8 1/8 1/8

100 1/8 1/8 1/8

110 1/8 1/8

120 1/8

Temperature °F on day of installation

Board-End to Board-End Gapping Requirements

Each variegated

Deckorators board

has a unique

appearance and

should be arranged

according to the

end user's

preference.

Almacenamiento

Cubra antes de la instalación para evitar manchas

por agua.

Instalación

• Todas las tablas deben distribuirse de forma adecuada

para permitir la expansión y contracción. Permita un

espacio de 1/4 (6.4 mm) entre las orillas de las tablas.

Refiérase a las instrucciones para la instalación completa

para detalles.

• Distribuya todo el material para terrazas a 1/4

(6.4 mm) de distancia de cualquier estructura

permanente o poste.

• Use sujetadores para terrazas resistentes a la corrosión,

de compuesto recubierto para evitar el “efecto hongo”

y la posible decoloración de la terraza.

Espaciado de las vigas

• Espaciado de la viga 16 in (41 cm) en el centro para la

instalación perpendicular a la viga.

• Espaciado de la viga 12 in (31 cm) en el centro para la

instalación diagonal a la viga.

• Consulte el reporte ESR-1573 para opciones de soporte

del escalón.

Visite Deckorators.com para instrucciones completas

de instalación, e información de la garantía y el cuidado

y limpieza.

Deckorators es una marca comercial de Universal Consumer Products, Inc. en

los EE.UU.

La garantía está disponible en www.deckorators.com.

Guarde las etiquetas UPC como comprobante de compra.

Rangement

Couvrez avant l’installation pour prévenir les

taches d’eau.

Installation

• Toutes les planches doivent être espacées

correctement pour permettre la dilatation et le retrait.

Prévoyez un écart d’au moins 6,4 mm (1/4 po) entre

les bords des planches. Consultez les directives

d’installation complètes pour obtenir les détails.

• Éloignez tout le matériau de terrasse de 6,4 mm (1/4

po) de toute structure permanente ou de tout poteau.

• Utilisez des attaches pour matériaux de terrasse

composites, revêtues et résistantes à la corrosion

pour éviter la formation de cloques autour de la tête

d’attache et la décoloration possible de la terrasse.

Espacement des solives

• Espacement aux solives de 41 cm (16 po) entre axes

pour l’installation perpendiculaire aux solives.

• Espacement des solives de 31 cm (12 po) entre axes

pour l’installation diagonale aux solives.

• Veuillez consulter ESR-1573 pour les différentes

options de support de giron.

Visitez Deckorators.com pour les instructions complètes

d’installation, garantie et l’entretien.

Deckorators est une marque de commerce déposée de Universal Consumer

Products, Inc. aux États-Unis.

Le texte de la garantie est disponible à l’adresse www.deckorators.com.

Conservez l’étiquette d’extrémité à code UPC comme preuve d’achat.

Storage

Cover prior to installation to prevent water stains.

Installation

• All boards must be spaced properly to allow for

expansion and contraction. Allow a minimum 1/4-in

gap between board edges. Refer to complete installation

instructions for details.

• Space all decking material 1/4-in away from any

permanent structure or post.

• Use corrosion-resistant, coated composite decking

fasteners to minimize “mushrooming” and possible

decking discoloration.

Joist Spacing

• 16-in on-center for installation perpendicular to the joist.

• 12-in on-center for installation diagonal to the joist.

• Refer to ESR-1573 for stair tread support options.

Visit Deckorators.com for complete installation

instructions, warranty and care and cleaning information.

Deckorators is a trademark of Universal Consumer Products, Inc., in the U.S.

Warranty available at www.deckorators.com.

Save UPC end tags for proof of purchase.

7928 11/14

©2014-2015 Universal Forest Products, Inc. All rights reserved.

1801 E. Lessard, Prairie du Chien, WI 53821, (877) 463-8379

Chaque planche de

platelage possède

une apparence

unique et devrait

donc être

disposée au goût

de l'utilisateur.

Cada tablón tiene

una apariencia

únicay debe ser

colocado de

acuerdo a la

preferencia

del usuario final.

16" on-center for residential perpendicular applications. Residential parquet

patterns and diagonal or herringbone designs all require joist spacing

12" on-center. Contact Deckorators product support at 800-332-5724

for commercial applications. Use 1/4" for side gapping.

(A) End Tag

(B) Product Sticker

fig. 1

DECKORATORS SOLID DECKING

INSTALLATION INSTRUCTIONS

Tools and Items Needed

• Drill/power screwdriver

• 1/8" drill bit

• Circular saw with

carbide-tip blade

• 2½" composite wood

deck screws

• Tape measure

• Carpenter’s pencil

• Safety glasses/goggles

Notice to installers

• DO NOT use cordless

impact drivers

Joist Span

Each Deckorators®Vista™, Heritage™, Vault™and Voyage™board has a unique

appearance and should be arranged according to the end user’s preference.

Prior to construction, check with your local regulatory agency for special code

requirements in your area. For best results, follow these simple installation

instructions, paying close attention to gapping, spacing and fastener requirements.

1X6-16' GR. DKR.

Allow a minimum of 1/16"gap between board ends for every

20°F of difference between installation temperature and

the hottest temperature expected (fig. 1). Additional blocking

may be needed for support (fig. 2). Allow 1/4" distance

between all decking material and any permanent structure

or post. After all decking has been attached, snap a chalk

line (white or yellow chalk recommended) flush with or up to

1-1/2"out from the deck framing and trim with a circular saw.

Deckorators decking, like all wood and composite decking

products, requires proper ventilation and drainage in order to

ensure its longevity. When using a minimum 2x6 joist standing

on edge, with the suggested 1/4"side gap, there should be a 2"

clear space between the bottom edge of the joists and grade to

allow for proper ventilation. Adequate drainage is also needed

to prevent water from pooling under the deck.

NOTE: ONLY Deckorators Voyage, Vault and Frontier deck

material, manufactured with Eovations™technology, may be

installed in contact with the ground or incidental submersion in

water when a project design requires those conditions.

End-to-End Spacing

• Set drill speed to

1500-1750 RPM

• Max torque not to

exceed 23 inch pounds

• Pre-drill knots

or dense hardwood

Fasteners

For a list of recommended and compatible fasteners please visit

www.Deckorators.com/FastenerInfo. Recommended fasteners are those

which are recommended by the manufacturer of Deckorators Decking.

Compatible fasteners are those which have been tested and recommended

for use with Deckorators Decking by the fastener manufacturer. The use of a

non-recommended fastener will not void the Deckorators Decking Warranty;

however if a decking failure is caused by the use of a non-recommended

fastener, any corresponding warranty claim will be denied.

For ease of installation, we recommend using 2-1/2"corrosion-resistant,

composite wood deck screws. These screws help minimize the common

“mushroom” effect that sometimes occurs when using standard fasteners.

They can also reduce the amount of pre-drilling and countersinking. If using

ordinary coarse thread deck screws, always pre-drill a pilot hole and countersink

prior to driving screws.

Pre-drill and countersink all deck screws, regardless of type,

that are within 1-1/2"of the end of the deck board.

fig. 2

Note: Cutting all ends of boards prior to installation

recommended.

Note: Always follow best workmanship

practices. Including, and not limited to,

square cutting both board ends prior to

installation.

SOLID DECKING INSTALLATION INSTRUCTIONS 13

INSTALLATION INSTRUCTIONS • SOLID DECKING

7903

THE DIAGRAMS AND INSTRUCTIONS IN THIS BROCHURE ARE FOR ILLUSTRATION PURPOSES ONLY AND ARE NOT MEANT TO REPLACE A LICENSED PROFESSIONAL. ANY CONSTRUCTION OR USE

OF THE PRODUCT MUST BE IN ACCORDANCE WITH ALL LOCAL ZONING AND/OR BUILDING CODES. THE CONSUMER ASSUMES ALL RISKS AND LIABILITY ASSOCIATED WITH THE CONSTRUCTION

OR USE OF THIS PRODUCT. THE CONSUMER OR CONTRACTOR SHOULD TAKE ALL NECESSARY STEPS TO ENSURE THE SAFETY OF EVERYONE INVOLVED IN THE PROJECT, INCLUDING, BUT NOT

LIMITED TO, WEARING THE APPROPRIATE SAFETY EQUIPMENT. EXCEPT AS CONTAINED IN THE WRITTEN LIMITED WARRANTY, THE WARRANTOR DOES NOT PROVIDE ANY OTHER WARRANTY,

EITHER EXPRESS OR IMPLIED, AND SHALL NOT BE LIABLE FOR ANY DAMAGES, INCLUDING CONSEQUENTIAL DAMAGES.

©2020 UFP Retail, LLC. All rights reserved. Deckorators is a registered trademark of UFP Industries, LLC.

7903 1/20

Deckorators.com

Mold Inhibitors

Preventing Mold and Mildew Growth

Color Variation

Cleaning

Like most composites, Deckorators Decking will have color variations from piece to piece. This is due to naturally occurring variations in

wood fibers and polymers. Purchasing all required decking material at one time is recommended, as manufacturing runs can

produce slightly different colors. Do not install if color variation is not acceptable.

Mold and mildew can be a nuisance on any exterior building surface, regardless of the material. If the conditions are right, they will

grow on wood, plastic, concrete, metal and other surfaces. Mold formation is most prevalent in consistently wet, shaded areas.

Spores from the natural environment are carried by the wind and commonly land on decks surfaces. It is important to note that the

appearance of mold/mildew is a function of nature, not necessarily a deficiency with any of the material on which it grows.

Periodic washing with soap/mild detergent and water will help remove surface dirt. This will also help prevent the buildup of pollen,

debris and spores that can cause and accelerate mold/mildew growth. Caution: A pressure washer should not be used to “blast” mold/

mildew or soils from a deck surface. The abrasive nature of the water stream can potentially cause damage by driving the spores

deeper into the material, which may create a more challenging problem to remedy. A pressure washer with a fan-tipped nozzle should be

used only to lightly wet or rinse wood or composite deck surfaces.

There are many deck wash and exterior cleaning products available at retail. It is important to make sure you use a cleaner specifically

intended for your application. After selecting a product, be certain to read, understand and follow all instructions supplied by the

manufacturer. Some cleaning products and inhibitors may be more effective than others, depending on the environmental conditions

your deck is subjected to. Additionally, it is always a good idea to test the cleaner in a small, inconspicuous area prior to applying it to

the entire deck (www.deckorators.com).

Tips for snow removal: Care should be taken when removing snow from your deck to avoid damaging the deck surface. Use a plastic

snow shovel, one without a metal edge. A stiff push broom can work very well and minimizes lifting. Light snow can be cleared using

a leaf blower. Do not attempt to break up or scrape ice from the deck surface; use ice melt products when needed. No concerns have

been reported using ice melt products labeled “Safe for Pets”.

As with deck washes, there are several mold-inhibitor products available from paint stores, hardware stores, online outlets and

home centers to help prevent long-term mold/mildew growth. For any product selected, be certain to read, understand and follow all

instructions provided by the manufacturer. Depending upon the environmental factors affecting your deck, some preventive cleaning

products may be more effective than others. It may be necessary to try more than one product. For ongoing preventive maintenance,

follow the manufacturer’s recommendation.

Note: Deckorators is not suitable for structural use. It should not be used for primary load-bearing members such as posts, joists,

beams or stringers. The same common-sense precautions should be taken when handling Deckorators as with wood or other

building materials. Dust masks and eye protection devices are recommended to avoid possible irritation from sawdust and chips.

Gloves will help protect hands. Hands should be washed after construction work.

Screws should be driven flush with the Deckorators decking surface. Do not over-tighten. Use two fasteners per deck board at each

joist. For any decking where two boards meet end-to-end over a joist, add additional blocking (fig. 2). Always pre-drill a pilot hole

and countersink at board ends when using either composite or wood screws. Be careful not

to over-tighten screws near board ends.

Please refer to PFS-TECO RR-0100 for stringer spacing when deck boards are used as stair treads.

14 STOWAWAY INSTALLATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS • STOWAWAY HIDDEN FASTENER

Follow the gapping requirements listed in fig. 1.

For any decking where two boards meet end-to-

end over a joist, add additional blocking (fig. 2 on

the following page). Allow 1/4" distance between

all decking material and any permanent structure

or post. After all of the decking has been attached,

snap a chalk line (white or yellow chalk

recommended) flush with or up to 1-1/2" out from

the deck framing and trim with a circular saw.

All wood and composite decking products

require proper ventilation and drainage to ensure

their longevity. When using a minimum 2x6 joist

standing on edge and the suggested 1/4" side

gap, there should be a 2" clear space between

the bottom edge of the joists and grade in order to

allow for proper ventilation. Adequate drainage is

also needed to prevent water from pooling under

the deck.

Note: ONLY Deckorators Voyage, Vault and

Frontier decking material, manufactured with

Eovations technology, may be installed with the

ground or incidental submersion in water when a

project design requires those conditions.

GROOVED DECKING INSTALLATION INSTRUCTIONS

USING STOWAWAYTM HIDDEN FASTENERS

Each Deckorators Vista, Heritage, Vault and Voyage

board has a unique appearance and should be

arranged according to the end user’s preference.

Prior to construction, check with your local

regulatory agency for special code requirements in your

area. For best results, follow these simple installation

instructions, paying close attention to gapping,

spacing and fastener requirements.

Joist Span

End-to-End Spacing

16" on-center for residential perpendicular appli-

cations. Residential parquet patterns and diago-

nal or herringbone designs require joist spacing

of 12" on-center. Contact Deckorators product

support at 800-332-5724 for commercial appli-

cations. Use 1/4"for side gapping.

fig. 1

Warmest annual temperature °F expected in region

°F 20 30 40 50 60 70 80 90 100 110 120

20 1/8 1/8 1/8 1/8 1/8 3/16 3/16 1/4 1/4 5/16 5/16

30 1/8 1/8 1/8 1/8 1/8 3/16 3/16 1/4 1/4 5/16

40 1/8 1/8 1/8 1/8 1/8 3/16 3/16 1/4 1/4

50 1/8 1/8 1/8 1/8 1/8 3/16 3/16 1/4

60 1/8 1/8 1/8 1/8 1/8 3/16 3/16

70 1/8 1/8 1/8 1/8 1/8 3/16

80 1/8 1/8 1/8 1/8 1/8

90 1/8 1/8 1/8 1/8

100 1/8 1/8 1/8

110 1/8 1/8

120 1/8

Temperature °F on day of installation

Board-End to Board-End Gapping Requirements

Tools and Items Needed

• Drill/power screwdriver

• 1/8" drill bit

• Circular saw with

carbide-tip blade

• Assorted fasteners

(see instructions)

• Tape measure

• Carpenter’s pencil

• Safety glasses/goggles

Notice to installers:

• Use 305 stainless steel,

black head screws

• DO NOT use cordless

impact drivers

• Set drill speed at

1500-1750 RPM

• Max torque not to

exceed 23 inch pounds

• Pre-drill knots

or dense hardwood

JOIST SPACING

DECK SIZE 12” on-center 16” on-center

100 sq. ft. 210 fasteners 175 fasteners

200 sq. ft. 441 fasteners 336 fasteners

300 sq. ft. 672 fasteners 512 fasteners

400 sq. ft. 882 fasteners 672 fasteners

500 sq. ft. 1,113 fasteners 848 fasteners

STOWAWAY™

HIDDEN FASTENERS

Page 1

Note: Always follow best workmanship practices. Including, and not limited to, square

cutting both board ends prior to installation. Cutting all ends of boards prior to installation

recommended.

Fasten the outside edge of the first board to the rim joist with screws. Pre-drill and countersink all deck

screws, regardless of type, that are within 1-1/2" of the end of the deck board. On the other side of

the board, place a Stowaway hidden fastener into the slot and center on the joist.

fig. 2

STOWAWAY INSTALLATION INSTRUCTIONS 15

INSTALLATION INSTRUCTIONS • STOWAWAY HIDDEN FASTENER

Fasteners

For ease of installation, our Stowaway fastener

fits into the groove on each side of the deck board

to eliminate pre-drilling and provide a fastener-free

deck surface. The deck boards require traditional

fasteners on the outside and inside edges of

the deck.

Step 1

Begin by fastening the outside edge of

the first board to the rim joist every 16". For this,

we recommend using 2-1/2" corrosion-resistant,

composite wood deck screws. These screws

help minimize the common “mushroom” effect

that sometimes occurs when using standard

fasteners. They can also reduce the amount of

pre-drilling and countersinking.

N

ote: If using ordinary coarse-thread deck

screws, always pre-drill a pilot hole and countersink

prior to driving screws. Screws should be driven

flush with the surface. Do not over-tighten. Use

one fastener per board every 16".

Step 2

For any decking where two boards meet

end-to-end over a joist, add additional blocking.

Always predrill a pilot hole when fastening within

1-1/2" of board ends, whether using composite

or wood screws. Do not over-tighten screws at

board ends.

Step 3

On the other side of the board, place a

Stowaway hidden fastener into the groove and cen

-

ter on the joist (fig. 3). Install the preset screw at

a 90° angle through the Stowaway fastener and

drive flush. Do not over-tighten. The fastener wings

must remain level with the joist for the next board

to fit correctly (fig. 4).

Step 4

Install one Stowaway fastener at each

joist location. Slide the next board into place so

the wings on the previous fasteners fit into the

groove on the side of the board. Make sure the

side gap between the boards is 1/4".

Step 5

To keep the interior boards from moving

over time, we recommend pinning the boards at

the center of their length using a #8, 2" stainless

steel screw. This holds the deck board in place at

the center of each board and allows the decking

to expand/contract at the ends. Pre-drill in the

groove of the deck board with an 1/8" drill bit (fig.

5a). Drive screw into the groove so it’s flush with

the bottom of the groove (fig. 5b). This will allow

you to properly fit a Stowaway hidden fastener into

the groove.

Step 6

Install a Stowaway hidden fastener clip over

the screw and centered over the joist. Fasten using

preset screw at a 90° angle through the Stowaway

hidden fastener and drive flush with the clip (fig. 6).

The fastener wings must remain level with the joist

for the next board to fit correctly (fig. 4).

Warning.eps

Deck boards

If desired, the board profile

may be concealed with fascia

Fig.2.eps

Fig.1.eps

Joist

fig. 3 fig. 4

fig. 5a fig. 5b

Page 2

fig. 6

16 STOWAWAY INSTALLATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS • STOWAWAY HIDDEN FASTENER

Mold and mildew can be a nuisance on any

exterior building surface, regardless of the material.

If the conditions are right, they will spawn on wood,

plastic, concrete, metal and other surfaces. Mold

formation is most prevalent in consistently wet,

shaded areas. Spores from the natural environment

are carried by the wind and commonly land on

deck surfaces. It is important to note that the

appearance of mold/mildew is a function of

nature, not necessarily a deficiency with any

of the material on which it grows.

Preventing Mold and Mildew Growth

Cleaning

Periodic washing with soap/detergent and water

will help remove surface

dirt. This will also help

prevent the buildup of pollen, debris and spores

that can cause and accelerate mold/mildew

growth.

CAUTION

: A pressure washer should not be used

to “blast” mold/mildew or soils from a deck surface.

The abrasive nature of the water stream can

potentially damage the material by driving the

spores into the material, which may create

a more

challenging problem to remediate. A pressure

washer with a fan-tipped nozzle should be used

only to lightly wet or rinse wood or composite

deck surfaces

.

There are many deck wash and exterior cleaning

products available at

retail stores. It is important

to make sure you use a cleaner specifically

Note: To predrill a groove on one side of deck

board, we recommend using a 5/32" T-slot cutter.

Step 7

Install one Stowaway fastener at each

joist location along the length of the board. For

installations where deck boards are butted

end-to-end at the joist, we recommend add

-

ing an 8” block and using a Stowaway hidden

fastener clip at the end of each board (fig. 7 and

fig. 8). Be sure to gap the boards as previously

described.

Step 8

Repeat the process for each board until

the outside edge of the final board is fastened

with screws. Use fascia to conceal the board

profile and inhibit board movement over time.

Please refer to the fascia installation instructions

for the approved fastening methods for fascia

boards.

Step 9

If no fascia is being used, the entire

perimeter of the deck should be fastened to the

rim joist with screws. Use two screws per joist on

the perimeter board. These screws will be incon

-

spicuous once the railing is installed. Decking

should be fastened with screws when being used

as stair treads.

fig. 7

fig. 8

Page 3

STOWAWAY INSTALLATION INSTRUCTIONS 17

INSTALLATION INSTRUCTIONS • STOWAWAY HIDDEN FASTENER

7904

THE DIAGRAMS AND INSTRUCTIONS IN THIS BROCHURE ARE FOR ILLUSTRATION PURPOSES ONLY AND ARE NOT MEANT TO REPLACE A LICENSED PROFESSIONAL. ANY CONSTRUCTION OR USE

OF THE PRODUCT MUST BE IN ACCORDANCE WITH ALL LOCAL ZONING AND/OR BUILDING CODES. THE CONSUMER ASSUMES ALL RISKS AND LIABILITY ASSOCIATED WITH THE CONSTRUCTION

OR USE OF THIS PRODUCT. THE CONSUMER OR CONTRACTOR SHOULD TAKE ALL NECESSARY STEPS TO ENSURE THE SAFETY OF EVERYONE INVOLVED IN THE PROJECT, INCLUDING, BUT NOT

LIMITED TO, WEARING THE APPROPRIATE SAFETY EQUIPMENT. EXCEPT AS CONTAINED IN THE WRITTEN LIMITED WARRANTY, THE WARRANTOR DOES NOT PROVIDE ANY OTHER WARRANTY,

EITHER EXPRESS OR IMPLIED, AND SHALL NOT BE LIABLE FOR ANY DAMAGES, INCLUDING CONSEQUENTIAL DAMAGES.

©2019 Universal Forest Products. Deckorators is a registered trademark of Deckorators, Inc. in the U.S. All rights reserved.

1801 E. Lessard St. Prairie du Chein, WI 53821

7904 9/19

Deckorators.com

intended for

your application. After selecting

a product, be certain to read, understand

and follow all instructions supplied by the

manufacturer. Some cleaning products and

inhibitors may be more effective than others,

depending on the environmental conditions

your deck is subjected to. Additionally,

it is

always a good idea to test the cleaner in a small,

inconspicuous area

prior to applying it to the

entire deck.

Tips for snow removal: Care should be taken

when removing snow from your deck to avoid

damaging the deck surface. Use a plastic snow

shovel, one without a metal edge. A stiff push

broom can work very well and minimizes lifting.

Light snow can be cleared using a leaf blower.

Do not attempt to break up or scrape ice from

the deck surface; use ice melt products when

needed. No concerns have been reported using

ice melt products labeled “Safe for Pets”.

Mold Inhibitors

As with deck washes, there are several mold-

inhibitor products available from paint stores,

hardware stores, online outlets and home

centers to help prevent long-term mold/mildew

growth. For any product selected,

be certain

to read, understand and follow all instructions

provided by the

manufacturer. Depending upon

the environmental factors affecting your deck,

some preventive cleaning products may be

more effective than others. It may be necessary

to try more than one. For ongoing preventive

maintenance, follow the manufacturer’s

recommendation.

Note:

Deckorators is not suitable for structural

use. It should not be used for primary load-bearing

members such as posts, joists, beams or stringers.

The same common-sense precautions should

be taken when handling Deckorators as with

wood or other building materials. Dust masks

and eye protection devices are recommended

to avoid possible irritation from sawdust and

chips. Gloves will help

protect hands. Hands

should be washed after construction work.

Page 4

18 PORCH FLOORING INSTALLATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS • PORCH FLOORING

PORCH FLOORING INSTALLATION INSTRUCTIONS

MADE WITH EOVATIONS™TECHNOLOGY

Tools and Items Needed

• Safety glasses

• Pencil or pen

• Tape measure

• Utility knife

• Jigsaw

• Carpenter’s square

(speed square)

• Power screw gun or drill

• Flooring nailer

• Soft mallet

• Portable power saw

• Fine-tooth saw blades (40-

tooth minimum, sharp car-

bide-tipped wood or finish/

trim blades

Joist Spacing Requirements

• Large file or medium-grit

sandpaper

• Chalk line

• Spacing tools

• Fastener-specific tools

recommended by

manufacturer

Deckorators®porch flooring has a unique appearance and should be arranged according to the end user’s preference. Prior to

construction, check with your local regulatory agency’s code requirements. For best results, follow all installation instructions, paying

close attention to gapping, spacing and fastener requirements.

Deckorators porch flooring is a one-sided product and must be installed with the embossed surface up. Deckorators porch flooring

must be installed over a code-compliant substructure and is not intended to support structural columns or porch posts. Structural

support for columns and porch posts must be incorporated into the substructure design. Deckorators porch flooring is not intended to

be used in applications that require a watertight surface. Caulk and adhesives should not be used in the tongue and groove. Painting is

not recommended.

Standard Picture Frame Diagonal (45˚)

16" 16" 12"

Gapping Requirements

Above 32˚F (0˚C) Below 32˚F (0˚C)

End-to-End 1/8" 3/16"

End-to-Side 1/8" 3/16"

Abutting Solid Objects 1/8" 1/4"

Cutting

• 10" 40T, 80T circular blade.

• 12" 40T, 72T, 80T circular blade.

• Upcut with a clean/smooth jigsaw blade.

• Cut porch flooring with the leading edge of the saw blade, cutting into the

exposed face. Use a sharp utility knife or jigsaw to finish cuts where a circular

saw cannot fully complete cut.

Fastener Requirements

• For best results, use a 2" SS "L" or "T" shape cleat nails.

• Where face fasteners are used, use corrosion-resistant, galvanized or stainless steel fasteners.

• #8x2" SS trim head screws.

• Reverse thread composite screws.

• Set power driver such that screws are slightly counter sunk. Do not overdrive.

PorchFloor1

PorchFloor2

45°

Face Screw

•

•

•

PorchFloor3

• Use a jigsaw to cut openings to protrusions.

• If necessary, use a large file or medium-grit sandpaper to clean cut edges.

• Use a utility knife to cut any fibers or strands. (In the rare even that a strand or fiber protrudes from the board, do not pull it.)

Note: Always follow best workmanship practices. Including, and not

limited to, square cutting both board ends prior to installation.

PORCH FLOORING INSTALLATION INSTRUCTIONS 19

INSTALLATION INSTRUCTIONS • PORCH FLOORING

©2018 Universal Forest Products. Deckorators is a registered trademark of Universal Consumer Products, Inc. in the U.S. All rights reserved.

1801 E. Lessard St. Prairie du Chein, WI 53821

9716_2/18

Deckorators.com

THE DIAGRAMS AND INSTRUCTIONS IN THIS BROCHURE ARE FOR ILLUSTRATION PURPOSES ONLY AND ARE NOT MEANT TO REPLACE A LICENSED PROFESSIONAL. ANY CONSTRUCTION OR USE

OF THE PRODUCT MUST BE IN ACCORDANCE WITH ALL LOCAL ZONING AND/OR BUILDING CODES. THE CONSUMER ASSUMES ALL RISKS AND LIABILITY ASSOCIATED WITH THE CONSTRUCTION OR

USE OF THIS PRODUCT. THE CONSUMER OR CONTRACTOR SHOULD TAKE ALL NECESSARY STEPS TO ENSURE THE SAFETY OF EVERYONE INVOLVED IN THE PROJECT, INCLUDING, BUT NOT LIMITED

TO, WEARING THE APPROPRIATE SAFETY EQUIPMENT. EXCEPT AS CONTAINED IN THE WRITTEN LIMITED WARRANTY, [UNIVERSAL CONSUMER PRODUCTS, INC.] DOES NOT PROVIDE ANY OTHER

WARRANTY, EITHER EXPRESS OR IMPLIED, AND SHALL NOT BE LIABLE FOR ANY DAMAGES, INCLUDING CONSEQUENTIAL DAMAGES.

• If using a hidden fastener system, use the manufacturer's recommended fastener and follow the manufacturer's instructions.

• One fastener per joist minimum.

• Ends of each board must fall on a joist.

• Double joist or use blocking where two board ends meet.

• 1" maximum cantilever.

• Install entire porch at same temperature.

• Square the first board to the house, paying attention to gapping requirements, and secure in place using face screws on the groove

side.

• The tongue side is fastened using cleat nails with a flooring nailer, or screws. If using screws, insert the screw just above the tongue

at a 45˚angle and counter sink the screw 1/6" into the material to allow for the next board. If using a flooring nailer, ensure the nailer

is properly seated on the tongue side of board and drive cleat into the board, following the proper nailer instructions. If the nailer is not

properly seated it could cause difficulty installing the next board and in some instances, even cause blemishes on the surface of

the porch flooring.

• Install the porch flooring starting from the outside edge of the platform and work toward anchor wall so that ripped pieces abut the

wall.

• Start installing from one end of the board and work toward the other end of the board. OR: Start installing from the center of the board

and work out toward the ends of the board. Do not install by fastening each end first and working toward the middle.

• Continue installing porch flooring, adhering to the gapping requirements. Note: ONLY Deckorators Frontier and Vault decking material

and porch flooring, manufactured with Eovations™technology, may be installed in contact with the ground or incidental submersion in

water when a project design requires those conditions.

Like most composites, Deckorators porch flooring will have color variations from piece to piece. This is due to naturally occuring

variations in polymers. Purchasing all required porch flooring material at one time is recommended, as manufacturing runs can produce

slightly different colors. Do not install if color variation is not acceptable.

Mold and mildew can be a nuisance on any exterior building surface, regardless of the material. If the conditions are right, they will grow

on wood, plastic, concrete, metal and other surfaces. Mold formation is most prevalent in consistently wet, shaded areas. Spores from

the natural enviornment are carried by the wind and commonly land on porch surfaces. It is important to note that the apperance of

mold/mildew is a function of nature, not necessarily a deficiency with any of the material on which it grows.

Periodic washing with soap/mild detergent and water will help remove surface dirt. This will also help prevent the buildup of pollen, debris

and spores that can cause and accelerate mold/mildew growth. Caution: A pressure washer should not be used to "blast" mold/mildew

or soils from a porch surface. The abrasive nature of the water stream can potentially cause damage by driving the spores deeper into

the material, which may create a more challenging problem to remedy. The water stream can also cut into the surface of the board if it is

too intense. A pressure washer with a fan-tipped nozzle should be used only to lightly wet or rinse wood or composite porch surfaces.

There are many deck/porch wash and exterior cleaning products available at retail. It is important to make sure you use a cleaner

specifically intended for your application. After selecting a product, be certain to read, understand and follow all instructions supplied by

the manufacturer. Some cleaning products and inhibitors may be more effective than others, depending on the enviornmental conditions

your porch is subjected to. Additionally, it is always a good idea to test the cleaner in a small, inconspicuous area prior to applying it to

the entire porch (www.deckorators.com).

As with deck/porch washes, there are several mold-inhibitor products available from paint stores, hardware stores, online outlets and

home centers to help prevent long-term mold/mildew growth. For any product selected, be certain to read, understand and follow all

instructions provided by the manufacturer. Depending upon the enviornmental factors affecting your porch, some preventive cleaning

products may be more effective than others. It may be necessary to try more than one product. For ongoing preventive maintenance,

follow the manufacturer's recommendation.

Note: Deckorators is not suitable to structural use. It should not be used for primary load-bearing members such as posts, joists, beams

or stringers. The same commonsense precautions should be taken when handling Deckortaors as with wood or other building materials.

Dust masks and eye protection devices are recommended to avoid possible irritation from sawdust and chips. Gloves will help protect

hands. Hands should be washed after construction work.

9716

20 STAIR TREAD INSTALLATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS • STAIR TREAD

STAIR TREAD INSTALLATION INSTRUCTIONS

Tools and Items Needed

• Drill/power screwdriver

• 1/8" drill bit

• Circular saw with carbide-tip blade

• 2 1/2" composite wood deck screws

• Tape measure

• Carpenter’s pencil

• Safety glasses/goggles

Notice to installers:

• DO NOT use cordless impact drivers

• Set drill speed to 1500-1750 RPM

• Max torque not to exceed 23 inch pounds

• Pre-drill knots or dense hardwood

Prior to construction, check with your local regulatory agency for special code

requirements in your area. For best results, follow these simple installation

instructions, paying close attention to gapping, spacing and fastener requirements.

Allow a minimum of 1/8" between board ends. Allow 1/4" distance between all stair tread material and any permanent structure or post.

Spacing

Fasteners

For a list of recommended and compatible fasteners please visit http://deckorators.com/plan-install/literature.aspx. Recommended

fasteners are those which are recommended by the manufacturer of Deckorators Stair Tread. Compatible fasteners are those which

have been tested and recommended for use with Deckorators Stair Tread by the fastener manufacturer. The use of a non-recommend-

ed fastener will not void the Deckorators Decking Warranty; however if a stair tread failure is caused by the use of a non-recommended

fastener, any corresponding warranty claim will be denied.

For ease of installation, we recommend using 3" corrosion-resistant, composite wood deck screws. These screws help minimize the

common “mushroom” effect that sometimes occurs when using standard fasteners. They can also reduce the amount of pre-drilling

and countersinking. If using ordinary coarse thread deck screws, always pre-drill a pilot hole and countersink prior to driving screws.

Screws should be driven flush with the Deckorators stair tread surface. Do not over-tighten.

Use two fasteners per stair tread at each stringer. For any stair tread where two boards meet end-to-end, an additional stringer is

required so each end is supported (Figure 2). Always pre-drill a pilot hole and countersink at board ends when using other composite or

wood screws. Be careful not to over-tighten screws near board ends.

Stringers spacing is a maximum of 9” on-center. Minimum of 5 stringers with 4 spans. For commercial applications, maximum of 8”

on-center.

Stringer Spacing

Color Variation

Like most composites, Deckorators stair tread will have color variations from piece to piece. This is due to naturally occuring variations

in wood fibers and polymers. Purchasing all required stair tread material at one time is recommended, as manufacturing runs can pro-

duce slightly different colors. Do not install if color variation is not acceptable.

Preventing Mold and Mildew Growth

Mold and mildew can be a nuisance on any exterior building surface, regardless of the material. If the conditions are right, they will grow

on wood, plastic, concrete, metal and other surfaces. Mold formation is the most prevalent in consistently wet, shaded areas. Spores

from the natural enviornment are carried by the wind and commonly land on deck surfaces. It is important to note that the appearance

of mold/mildew is a function of nature, not necessarily a deficiency with any of the material on which it grows.

Cleaning

Periodic washing with soap/mild detergent and water will help remove surface dirt. This will also help prevent the buildup of pollen,

debris and spores that can cause and accelerate mold/mildew growth. Caution: A pressure washer should not be used to “blast” mold/

mildew or soils from a deck surface. The abrasive nature of water stream can potentially cause damage by driving spores deeper into the

Stringer

Stair tread

Eotek2.pdf

9" max.

36" min.

5 stringers

required

11" min.

depth

1/8" min.

gap

•

•

•

•

•

•

•

•

•

Note: Always follow best workmanship practices. Including, and

not limited to, square cutting both board ends prior to installation.

Other manuals for ALX CLASSIC

2

This manual suits for next models

4

Table of contents