Decotech DT-767 Series User manual

Operating Manual

DT-767 SERIES

Table of Contents

Safety Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Applications and Features . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Touch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Print Head. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Screen Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Safety

1. Eye protection

a. Whenever main machine cover is open( during set up) and UV lamp is on, the

operator should always wear 100% UV protective glasses to avoid damage to the

eyes from ultraviolet rays.

b. When main machine cover is open, the machine operator and people near the

machine should never lookd irectlya t the UV lamp. Doing so will cause damage

to the eyesf rom ultraviolet rays.

2. Skin protection

The operator should wear UV p rotective clothing when working with the UV

light source during set up. The UV lamp will cause skint o be burned when it’s

exposed to UV light directly.

3. Protection from poisonous gas

a. Keep working area well-ventilated.

b. Do not store or use chlorinated solvents in the working area. Many of them will

produce poisonous gas when they are radiated by ultraviolet rays.

4. Protection from electricals hock

a. Check the power cable from machine to power supply regularly. If the cable is

damaged, turn main power source off and lock out machine until repaired. Only a

qualified electrician should make this repair. Severe injury or deathm ay occur if

damaged lines aret ouched because of electrical shock.

b. The main power should be turned off and locked out before changing electrical

parts, componentso r UV lamp(s).

page - 1

Applications and Features

1. Application

The DT-767 is specially designed for screen printing on cylindrical. It’s available for

printing both single color and multicolor containers. It is widely used on many types

of containers such as cosmetics, pharmaceutical, food, detergent, ornamentation, etc.

2. Features

a. The DT-767 integrates automatic feeding,p rinting, UVc uring and

other functions synchronously. I t is m echanically and pneumatically driven. All of

these greatly improve printing efficiency.

b. TheD T-767c an p re-check t he p ositiono ft he c ontainera t the in-feed b efore

printing and re-orientate the container ensuring t he c ontainer is i n the correct

orientation for printing.

c. Due to specialized sensors, it can monitor functionss uch as “No part, no print” and

an automatic alarm whent he air pressure is too low.

d. Machine operation is easy with simple to read touch panel.

e. All electrical components and control systems are of the highest quality.

page - 2

page - 3

Specifications

Max. Printing Diameter (Cylindrical) ø: 100 mm

Min. Printing Diameter (Cylindrical) ø: 20 mm

Max. Printing Diameter (Elliptical) R: 250 mm

Min. Printing Diameter (Elliptical)R : 25 mm

Max. Printing Width (Elliptical)1 20 mm

Min. Printing Width (Elliptical)4 0 mm

Max. Length of bottle 300 mm

Min. Length of bottle 50 mm

Max. Printing Length 250 mm

Max. Printing Speed 3600 Pcs/hr (Cylindrical)

Air Pressure 6-7 Bar

Power Supply(Single Color) 480v 50/60Hz

Weight1 500Kg

Standard Dimensions 2700(L)x2000(W)x1600(H)mm

page - 4

1.

2. 3. 4.

5. 6.

4

Main Screen

page - 5

onitor

1.

2.

3.

4.

5.

6.

7.

8.

9.

5

page - 6

6

Save/Load Screen

page - 7

Parameter Screen

..

2.

page - 8

1.

sing this button will go the the Monitor scree .

3. Pressing this button will go to Parameter screen.

1.

2. 3.

page - 9

1. 2. 3.

4. 5. 6.

7. 8.

1. Pressing turns Bowl Feeder OFF/ON.

2. Pressing jogs Bowl Feeder incrementally.

3. Indicator lamp-Bowl Feeder OFF/ON.

4.P ressing turns Prefeeder OFF/ON.

5. Pressing manually moves feeder ramp UP/DOWN.

6. Indicator lamp-Prefeeder OFF/ON.

7. Pressing will go to Monitor screen.

8. Pressing will go to Parameter screen.

page - 10

Print Parameter Screen

1. 7.

2.

3.

4.

5. 6.

.

.

.

.

.

.

Indicates if sensors are activated.

Adjusts angle of when Air turns OFF an d ON.

Adjusts angle of when Flood turns OFF and ON .

Adjusts angle of when Print turns OFF an d ON.

Pressing this button will take you back to the Monitor Screen.

Pressing this button will take you back to the Parameter Screen.

Pressing this button will activate No Part/No Print feature .

page - 11

.P ressing turns the UV Lamp ON.

.P ressing puts the UV L o

.P ressing will go to Monitor screen.

4. Indicator Lamp-UV is ON/OFF.

5. Indicator Lamp-UV bulb is is ON/OFF in Standby mode .

6.Pressing will go to Parameter screen.

7. Indicator showing start up and shutdown of UV unit.

8. Pressing turns the UV Lamp OFF.

1.

2.

3.

4.

5.

6.

7.

8.

page - 12

9

.

.

.

8

8.

page - 13

Alarm Records Screen

This screens will show various alarms; the time they happened and what

part of the machine was affected.

page - 14

nputs and Outputs

page - 15

page - 16

Control Panel

1.

2.

3.

4.

5.

6.

7.

8.

9.

Pressing and holding this button will run the machine continuously until the

button is released. This button is used for set up.

Pressing this button will put the machine is continuous run mode.

3. This button will stop the machine .

4. This switch will turn on the vacuum blower .

5. This button has no function on this machine .

6. Pressing this button will shut down all f unction of the machine in case of emergency.

7. Power ON Indicator Lamp.

8. This knob controls the speed of the machine (parts per minute) .

9. Power OFF Indicator Lamp.

page - 17

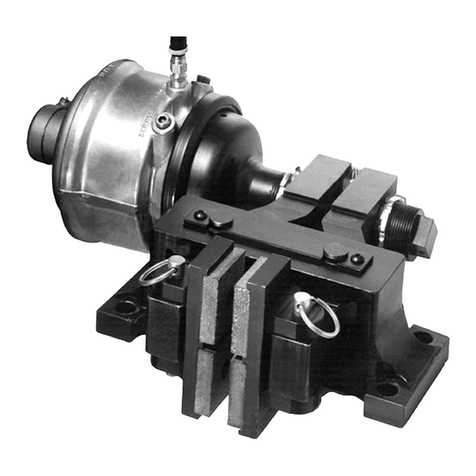

Print Head and Components

. Print head locking knobs (front to back).

4. Squeegee stroke adjustment.

13. Print head height adjustment

14. Print head locking knob (front to back).

15. Squeegee locking thumb screw (same on other side for floodbar.

16. Squeegee holder.

page - 18

Screen Frame Holder

Screen frame height adjustment.

2. Locking bolts for screen frame height adjustment.

3. Screen frame locking knobs.

4. Swivel locking knob.

5. Screen angle adjustment knobs.

6. Locking knob for XYR adjustment.

7. Screen frame holder.

8. XYR adjusting knob.

Note: This is the right side of the frame holder,

the left side is exactly the same.

Table of contents