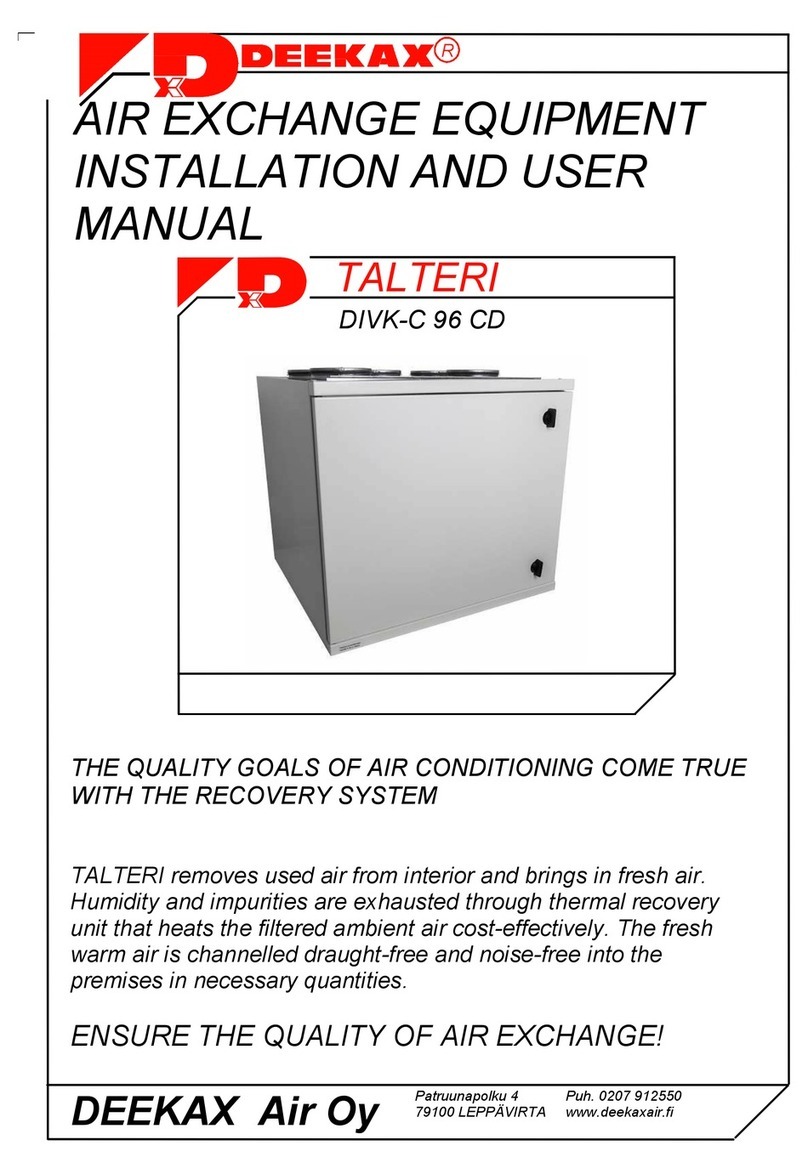

Deekax TALTERI DIVK-C 99 CD User manual

TALTERI

DEEKAX Air Oy

Patruunapolku 4 Tel. 0207 912550

79100 LEPPÄVIRTA www.deekaxair.fi

R

AIR EXCHANGE EQUIPMENT

INSTALLATION AND USER

MANUAL

THE QUALITY GOALS OF AIR CONDITIONING COME TRUE

WITH THE RECOVERY SYSTEM

TALTERI removes used air from interior and brings in fresh air.

Humidity and impurities are exhausted through thermal recovery

unit that heats the filtered ambient air cost-effectively. The fresh

warm air is channelled draught-free and noise-free into the

premises in necessary quantities.

ENSURE THE QUALITY OF AIR EXCHANGE!

DIVK-C 99 CD

QUALITY TESTED

21

EQUIPMENT DETAILS AND TECHNICAL DATA

1 Exhaust air out.............. . 125 or 160 mm

2 Outdoor air for the system ..... 125 or 160 mm

3 Extract air for the system...... 125 or 160 mm

4 Supply air indoors................. 125 or 160 mm

5 Kitchen exhaust .................... 125 mm

6 Door switch

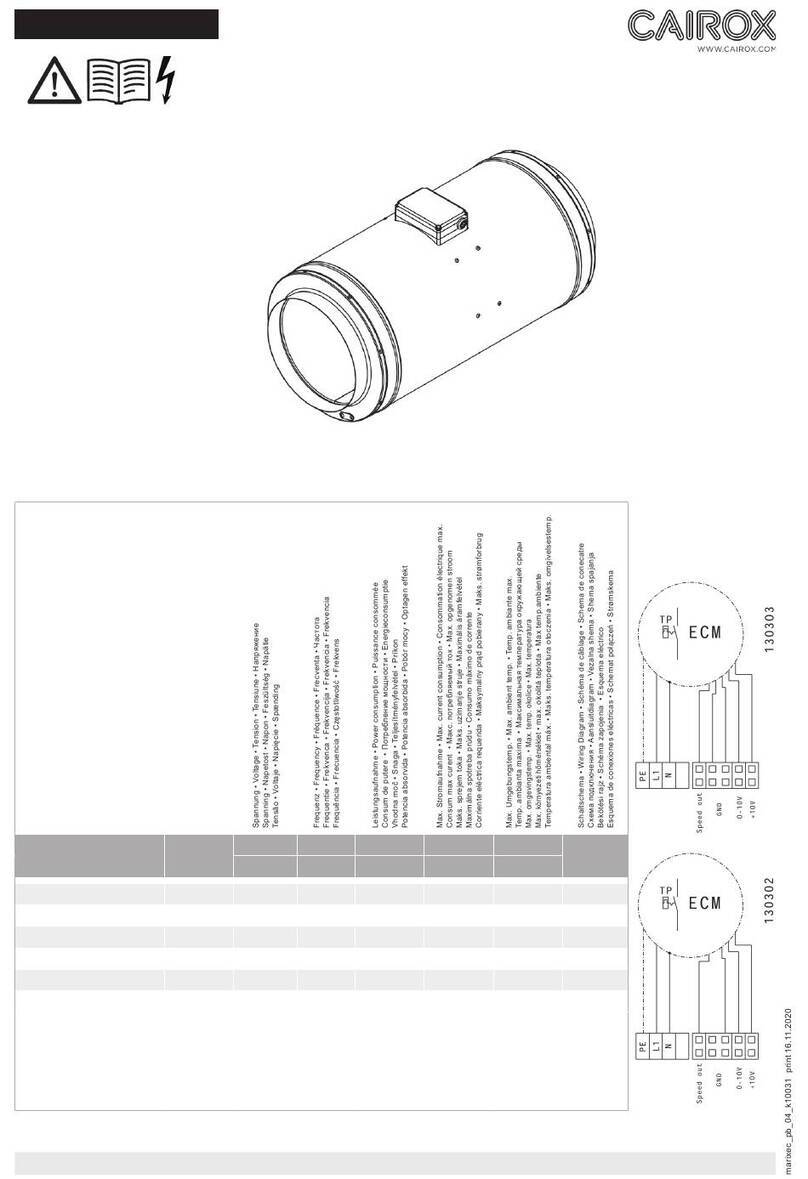

7 Supply fan, adjustable...........EC 166 W

8 Extract fan, adjustable..........EC 166 W

9 Heat exchanger

10 Postheater, adjustable........ 500 W

11 Preheater, adjustable .........1000 W

12 Extract air filter (G4) ISO Coarse>75%

13 Supply air filter (F7) ISO ePM1

14 Supply air filter (G4) Coarse>75%

16 Preaheater manual overheat protection

17 Postheater manual overheat protection

18 Summer bypass appliance

19 Exhaust of condensing water

20 Humidity transmitter(optional)

21

T

ouch screen

control panel

for setting up

or contro

l

ing

the

HRV

unit

(optional)

14

13

16

8

19

9

6

7

10 17

12

20

18

11

2

50

100

150

200

250

300

350

20 40 60 80 100 120 140

30%

100%

Airflow

l/s

Pa

80%

60%

40%

400

450

Extract air

Supply air

C99-160

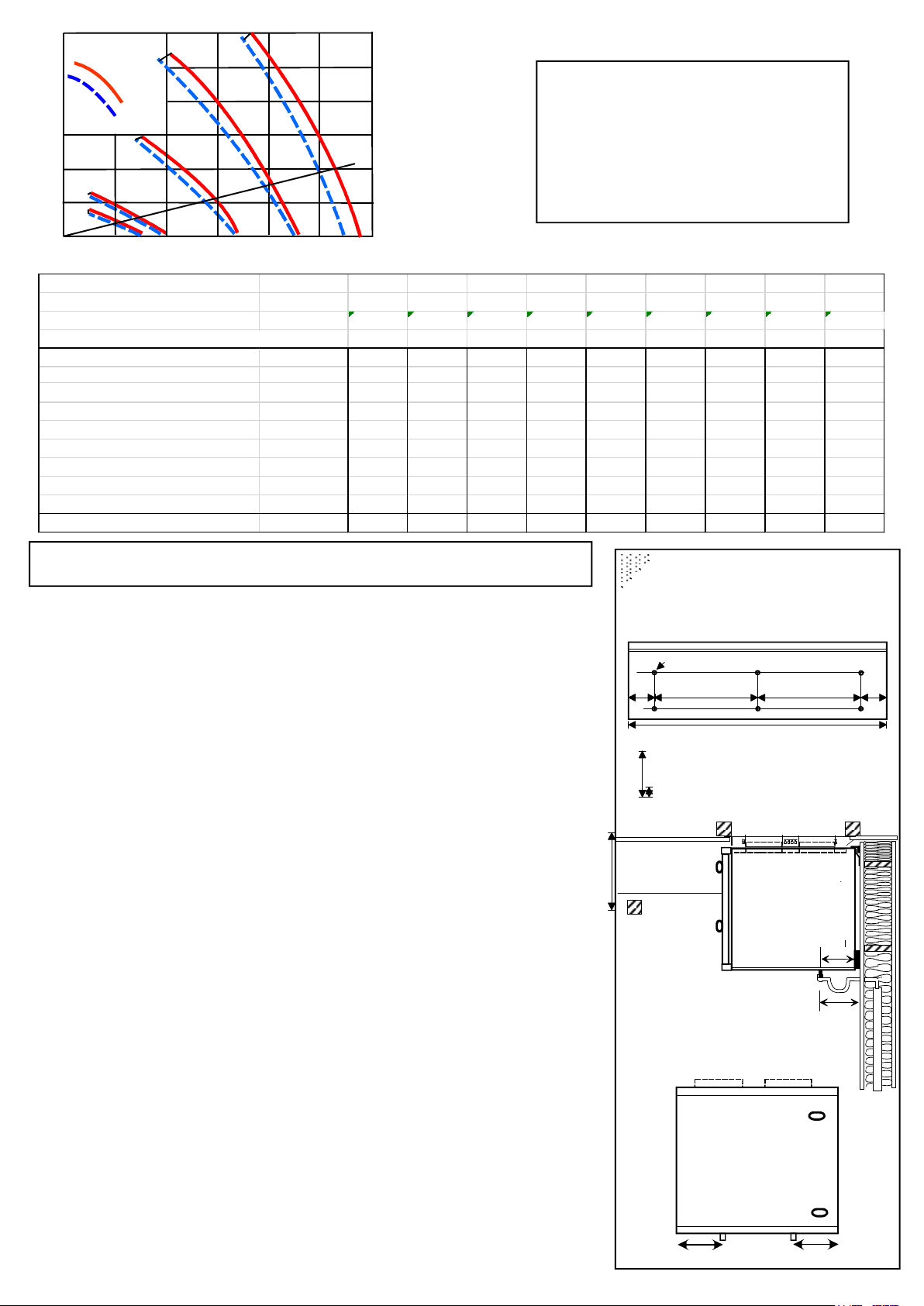

EXTERNAL PRESSURE OF THE DUCTWORK

Fan speed 20 30 40 50 60 70 80 90 100

Fan input power W 12 18 26 41 69 105 158 223 283

Sound pressure level (LpA) l/s 16/15 25/22 38/33 52/44 68/60 83/72 98/86 112/101 122/112

to the room (sound adsorbtion 10m2) dB(A) 15 19 21 26 30 35 37 40 42

Sound power level in

Hz

E S

E S

E S

E S

E S

E S

E S

E S

E S

the extract(E)and the supply(S)

63

29 41

36 53

42 56

47 62

51 66

53 70

56 72

58 74

58 75

duct by octave bands, Lw(dB)

125

23 38

32 48

39 53

44 59

50 63

54 66

56 69

59 71

58 72

250 25 33 33 41 40 47 45 53 50 57 54 61 57 64 59 67 60 68

500 16 35 25 44 31 50 36 55 41 59 45 62 47 66 50 69 50 70

1000 15 29 27 42 33 48 37 53 40 57 43 60 45 62 47 64 48 65

2000 * 22 14 37 22 46 28 53 33 58 36 62 39 65 41 68 41 69

4000 * 8 4 28 14 39 21 46 26 52 31 57 34 60 37 63 37 65

8000 * * * 16 4 30 12 40 19 47 23 52 27 56 30 59 30 61

Total sound power level L

wa

19 33

29 45

35 52

40 58

44 63

48 66

51 69

53 72

53 74

Input

power

C99-160

1 EXHAUST AIR

2 OUTDOOR AIR

3 EXTRACT AIR

4 SUPPLY AIR

5 KITCHEN EXHAUST

DUCT OUTLETS

HANDEDNESS RIGHT(R)

4 EXHAUST AIR

3 OUTDOOR AIR

2 EXTRACT AIR

1 SUPPLY AIR

5 KITCHEN EXHAUST

DUCT OUTLETS

HANDEDNESS LEFT(L)

DOOR

In the picture is shown a right handed (R) unit

3

TALTERI DIVK-C 99 INSTALLATION

WALL ATTACHMENT

The wall mounting kit includes a ceiling mounting plate, a wall-mounting plate

and 15 mm thick insulation pieces. A wall-mounting plate is installed about 25 mm

below the roof surface.The wall attachment plate will be fixed to the wall and then

the unit is lifted up to the attachment plate, checked into perfectly horizontal position

and then drill holes for the metal screw through the mounting plate in to the bottom of

the machine.Roof moldings can be put around the machine.

KITCHEN EXHAUST DUCT

The channel output (5) in intended for exhaust channel of the cooker hood.

If the exhaust channel of the cooker hood is not in use, it must close.

If the cooker hood is connected to the kitchen exhaust duct ( heat recovery bypassed)

all the basic ventilation holes of the cooker hood's damper must be closed

and in the kitchen it is needed a separate extract air valve which is connected to

the extract air duct.

The air exchange unit is meant for warm inner facilities. Suitable installation spots are,

among others, office, dressing or household facilities and technical or warm storages. In case

the temperature of the installation location is lower than room temperature, the factory settings

of the appliance must be changed to obtain faultless functioning. The unit can not be installed

into cold outer premises or garages.

UPPER BASE DUCT

The channelling is usually mounted to the upper base thermal insulation.

The steam barrier puncture must be carefully sealed. While installing the unit to

channels, steel steam barrier plate, supplied as extra, will come handy. The steam

barrier plate is attached securely between the roof trusses, 10 mm smaller hole

must be cut into the gasket mat and channels are installed through the plate.

The steam barrier must be hermetically taped.

The unit can be attached right to the steam barrier plate with four M8 thread bars

at desired height. Note the measurements of the steam barrier plate during the

installation process.

The bolts and thread bars are purchased separately.

CONDENSATE

Condensate drain is connected to the machine condensate connector (3/8 "external thread).

Condensate can be made at a least 10 mm in the bore copper pipe or Relatively stiff hose.

The water pipe Making about 10 cm in the water trap and the tube is connected to a floor drain.

The water line shouldnt be connected directly to the sewer.

TALTERI

KONEEN OVI

177

177

Kondenssivesiliitäntä

oikea (R)

Kondenssivesiliitäntä

vasen (L)

157

43

200 200 43

20

90

130

485

Seinäkiinnityslevy

6kpl D=6,5mm

172

EXTERNAL PRESSURE OF THE DUCTWORK

Airflow

extract air

supply air

Fan speed % 20 30 40 50 60 70 80 90 100

Fan input power W 12 16 23 35 51 113 156 221 290

Sound pressure level (LpA) l/s 17/16 22/20 33/30 46/42 59/55 72/68 82/78 95/90 106/98

to the room (sound adsorbtion 10m2) dB(A) 15 18 22 27 30 35 38 39 42

Sound power level in

Hz

E S

E S

E S

E S

E S

E S

E S

E S

E S

the extract(E)and the supply(S)

63

* 37

23 49

33 54

38 58

42 61

44 65

47 68

50 71

52 72

duct by octave bands, Lw(dB)

125

23 36

31 46

41 53

46 57

50 60

53 64

56 66

58 69

59 70

250 22 30 29 39 35 44 40 49 46 54 49 57 52 61 54 64 56 66

500 11 29 19 40 25 45 29 50 34 54 37 57 40 61 43 63 45 65

1000 11 24 21 38 27 45 32 50 35 54 38 57 41 59 42 62 44 63

2000 * 18 9 34 18 44 24 51 28 56 32 59 34 62 37 64 38 66

4000 * 4 * 25 11 37 18 45 24 50 28 54 31 58 34 61 36 64

8000 * * * 11 * 27 6 36 13 44 18 48 21 52 24 56 26 58

Total sound power level Lwa 15 28 23 41 30 49 35 55 39 60 43 63 45 66 48 69 49 71

C99-125

Input

power

Control

voltage

Airflow

% 40 60 80 100

23 33 42 50

KITCHEN EXHAUST AIRFLOW

l/s

Total sound

power level of

the kitchen

exhaust duct

45 55 61 64

Lwa

C99-125

50

100

150

200

250

300

20 40 60 80 100 120

30%

100%

l/s

Pa 80%

60%

40%

4

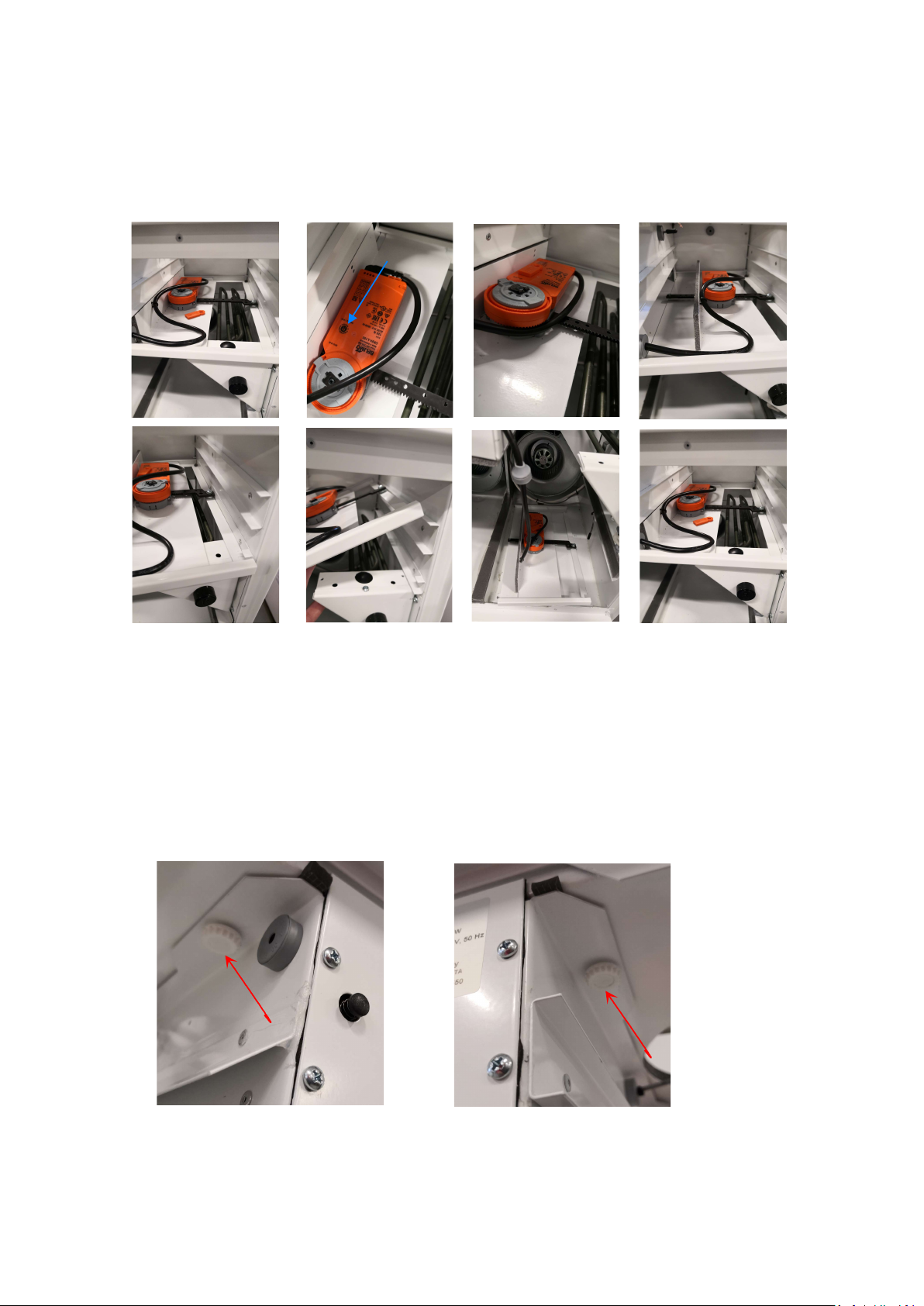

REMOVAL OF THE SUMMER BYPASS PLATE

In order to facilitate the installation of the ceiling mounting plate bolts, the summer bypass plate

can be removed during installation. The heat exchanger and the filters are removed from the machine.

If the the plate is in the winter position (Figure. 1), the motor is released with the magnet.

The magnet is placed to the position shown in the figures 2 and 3. The summer bypass plate is pulled

open by hand (Figure 4). Pull the plate outwards (Figure 5) and lift the outer edge above the filter brackets (Figure 6).

The summer bypass plate can be placed on the bottom of the machine (Figure 7). Reassemble in the reverse order,

remove the magnet from the motor, install the grommet and the motor cable as shown in the figure 8.

1. 2. 3. 4.

5. 6. 7. 8.

REMOVAL OF THE ELECTRICAL CONNECTION BOX

The electrical connection box can be removed, for example for maintenance or modbus termination, by

removing the summer bypass plate and then loosening the thumbscrews, as shown in the figures below.

DIVK

-

C

99

INSTALLATION TO A SUSPENDED CEILING

The ceiling-mounting plate is attached

to the roof with M8, thread bars (not included in the

delivery).

RUBBER SILENCER

WASHER

NUT

5

5mm

40-50

mm

The head of the threaded bar can not

reach below the bottom of the plate.

The unit will be pushed to the mounting plate and

tightened with four M8 bolts against the mounting plate

so that the cover seal of the unit is evenly sealed against

the m

ounti

ng plate

, not tighter.

MOUNTING PLATE BINDING

UPPER SURFACE IS

INSTALLED 5 mm

BELOW THE ROOF SURFACE

LEAVE A 40-50MM GAP

BETWEEN THE CEILING AND

THE FRONT EDGE OF THE

MOUNTING PLATE

SERVICE HATCH

M8 THREADED BAR

BACKUP NUT

THE UNIT IS PULLED

INTO THE MOUNTING

PLATE “RAILS”

WASHER

BOLT M8X40

THE UNIT IS ATTACHED

TO THE MOUNTING

PLATE FROM THE INSIDE

BY FOUR M8 BOLTS

MEASURES OF THE MOUNTING PLATE

SERVICE HATCH SERVICE HATCH

DOOR

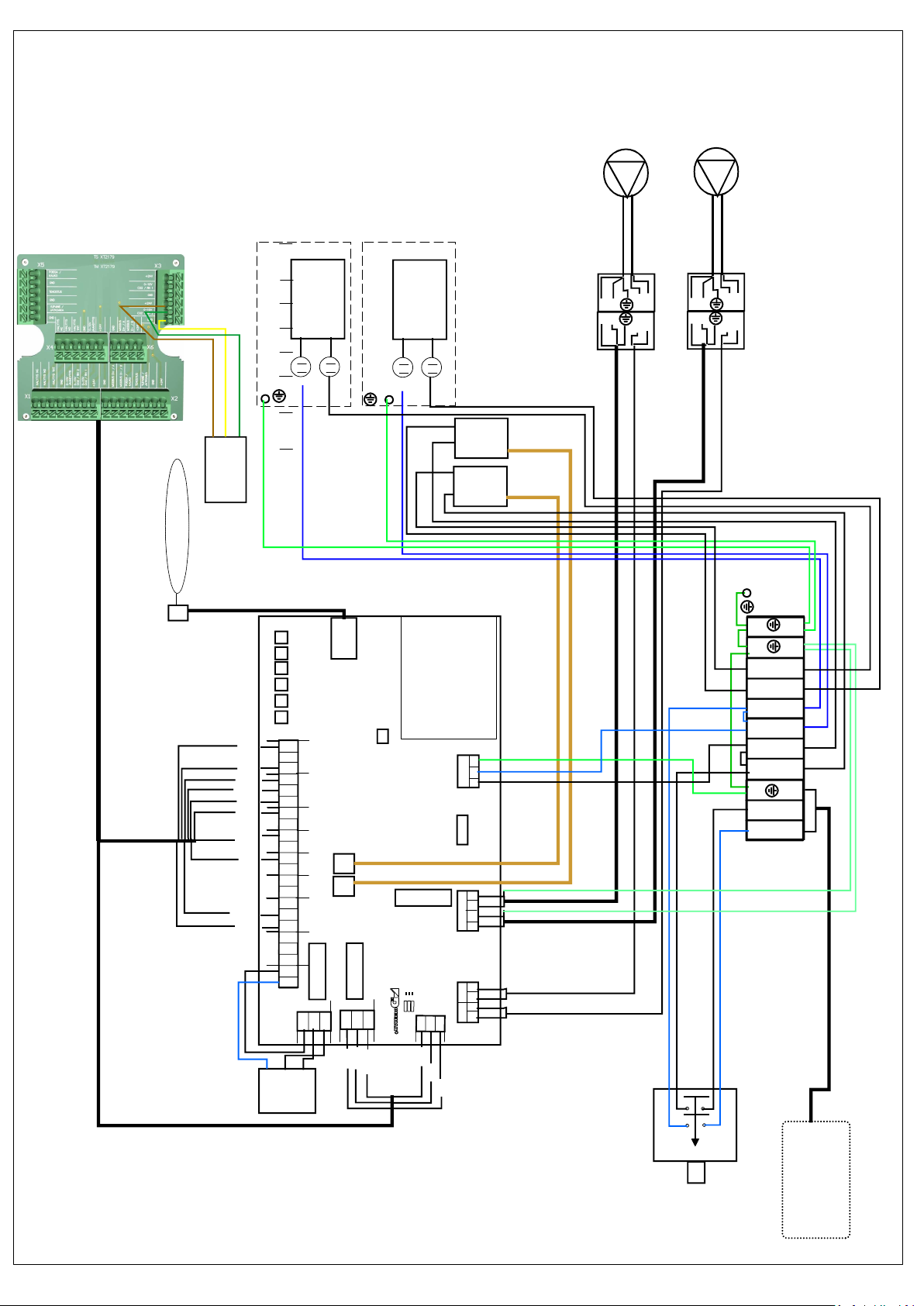

ELECTRICAL CONNECTIONS

Electrical connections must be done following the installation manual

and wiring diagram.

ELECTRICAL CONNECTIONS CAN BE DONE ONLY BY

AN ENTREPRENEUR WITH RESPECTIVE INSTALLATION RIGHTS.

6

VAK

Alarm and operation

indication

max 24 V

as contact tip information

from the unit

0-10V

GND

24V

CO2

trans-

mitter

VAK

0

0-10V

KITCHEN HOOD

0-10v control

0

0-10V

PC EC

PG EC

DS EC

DSA EC

Input

-power cord

230V,

50 Hz

10 A

NO

NC

0-10V

GND

24V

RH

trans-

mitter

-

+

MODBUS

GND

D+/ A

D- / B

Out-of-home

switch

Pulse

switch

switch

Under pressure

compensation

set value 0 as

contact tip infor-

mation

Fireplace

Over pressure

KITCHEN HOOD

boosting with

contact tip information

NO

COM

NC

open

closed

Pulse

switch

Boost

switch

switch

set value 0

as contact tip

information

Boost

switch

Extended time

Cooling

radiator

actuator

DC 24 V

0-10v

set value 0

as contact tip

information

Internal connection of the HRV unit

Input,

-power cord

230V,

50 Hz

10 A

RJ12 2,5 m AHU

To control panel

Input

230V,

50 Hz

10 A

-power

cord

(plug)

(

Pulse

switch

Input

-power

cord 1 m

(plug)

connection box

cable 1 m

External connections of the HRV unit are connected to the connection

box located on the top the unit.

The unit is equipped with a power plug.

The unit is set up and the setvalue changes are made via a separate AHU

control panel. The control panel is connected to the cable above the unit

with the RJ12 connector.

The following can be connected as

accessories:

- Carbon dioxide transmitter;

- Humidity transmitter;

- Separate Over pressure or Extended

time switch (pulse switch);

- Separate Boost switch (pulse switch);

or setting off as pre-data (for instance,

sauna oven, stove hood);

- Remote control or out-of-home switches

(pre-data);

- Differential pressure switches for filters;

- External speed control 0-10V.

- Modbus.

The functions can be operated through

maintenance and setup menus of the

operating panel.

7

Br-gr

Ye-br

Wh-ye

Red

Blue

Pink

KS KS

T1 T2 T3 T4 T5 T6

OUT SUP-

PLY

EX-

TRACT

EX-

HAUST

WATER

PRE

HEATER

POST

HEATER

CONTROLL PANEL

230VAC

L N PE

FUSE

TEMPERATURE SENSORS

+24 0 0-10

CO2/%RH1

+24 00-10

CO2/%RH2

OVER-

PRESSURE/

EXTENDED

TIME

BOOS-

TING

0-10

OUT-OF-

HOUSE/

REMOTE

+24 0 0-10

COOLING

+24 0

WATER

RADIATOR

FILTER

+24 0

HEAT RECOVERY

BYPASS

WIN-

TER

YHT

SUM-

MER

ALARM

NC

YHT

NO

Circuit board

ECU

R

EXTRACT SUPPLY

0-10 0-10

0 0

SUPPLY /EXTRACT

N NU U

TRIAC

PREH.

TRIAC

POSTH.

SUPPLY

FAN

EXTRACT

FAN

N3 2 1

K

S

N3 2 1

KS

N3 2 1

K

S

N3 2 1

K

S

1

-

2

+

3

+

Belimo CH 24

Summer

bypass

POST

HEATER

50c 90c

PRE

HEATER

50c 90c

1000W

500W

MODBUS

A/D+

B/D-

0

O O O

O O O

O O O

ON OFF BIAS B

ON OFF Term

ON OFF BIAS A

RJ12 3 m AHU CONTROL PANEL

DOORSWITCH

N

4

L

1

L

2

N

3

L

N

E

J

Input

230V,

50 Hz

10 A

-power

cord

(plug)

( IU )

Black

Violet

Gr-Pi

R-bl

Wh-gr

Grey

Yellow

Green

Brown

White

C99 CD

Humidity trans-

mitter

Optional

0-10

0

+24

8

INTRODUCTION OF THE AIR EXCHANGE SYSTEM

BEFORE OPERATING YOUR AIR EXCHANGE SYSTEM,

MAKE SURE THAT:

- There are no loose objects within the unit or the air impeller;

- The coverings of construction-time are removed from

the outlet- and exhaust air holes;

- All isolations and steam barriers are in order;

- The heat transfer and fans are in their places;

- The condensing water outlet is installed and the water

is drained out;

- The air impellers and their adjusters are in working order;

- Afterheating is regulated and working.

USAGE DURING INSTALLING

The air exchange unit should be started as soon as

installation permits.

Efficient air exchange promotes drying of the constructions

and prevents damage.

In case channelling has not been completed, fans and adjustments

are missing,filter paper must be used in place of fans to keep

the channels clean andprovide sufficient counterpressure for

preventing overload. The unit must be used with full power and

check the drainage of the condensing water.

The appliance, filters and heat exchangers must be cleaned

and the systemadjusted after the construction works are

completed.

BASIC ADJUSTMENT OF AIRFLOW

The unit alone can not produce good interior ear in case

the channels and fans are installed carelessly and main

adjustments are not made.

Regulate the inlet and outlet fans to the planned positions

and start the unit

at design power speed. Measure the airflow in outside- and

exhaust air channels.

The outlet must be 5-10% higher than inlet. Check the

pressure level of thechannels by checking from the fans and

adjust it accordingly to obtain the pressure level

for vents; adjust and lock the pattern.Draw measuring- and

adjustment records!

USAGE AND CORRECT LEVEL OF AIR EXCHANGE

The air exchange level is regulated by changing the

working speed of the air impeller from the operating panel.

Airflow of different adjustable positions can be seen

from table 2.

Adjustable position 1 is for basic air exchange for an empty house.

Adjustable position 2 and 3 are normal working positions.

Adjustable position 4 and 5 are efficiency positions (i.e. for saunas).

The correct usage positions will be found by experience;

observing the purity of the air or sultriness when coming in

from outside, observing moisture on the windows or drying

of the sauna.

AFTERHEATING AND SUMMER BYPASS OF INLET AIR

The unit is equipped with 500 W electrical battery operated

by the means of triac-adjuster operated by the operating device

for afterheating the heat recovered inlet air.

The temperature of inlet air is usually regulated to +17C.

The temperature may be adjusted to higher during winter so there

would be no draught like feeling. In case of severe frost and

efficiency mode the heating power might turn out insufficient –

in such circumstances, the air exchange should be reduced.

The overheating protection launched during malfunctioning

must be annulled manually.

During summertime, the HR-exchanger element on the bypass plate

will be closed so the exhaust air will not warm up the inlet air.

CONDENSING WATER AND FREEZING PREVENTION

As the extract air cools in the heat exchanger, the moisture

condenses into water, which flows into the condensate tank and

from there along the hose through the water trap to the open drain.

In cold weather, freezing of the water in the heat exchanger is

prevented by a double-function anti-freeze function, which first

switches the preheater on and switches it off when the temperature

rises above the set value.

If the preheater power is not sufficient and the exhaust air

temperature falls below the "exhaust air cold" limit value, the input

fan power is reduced step by step until the limit value is reached.

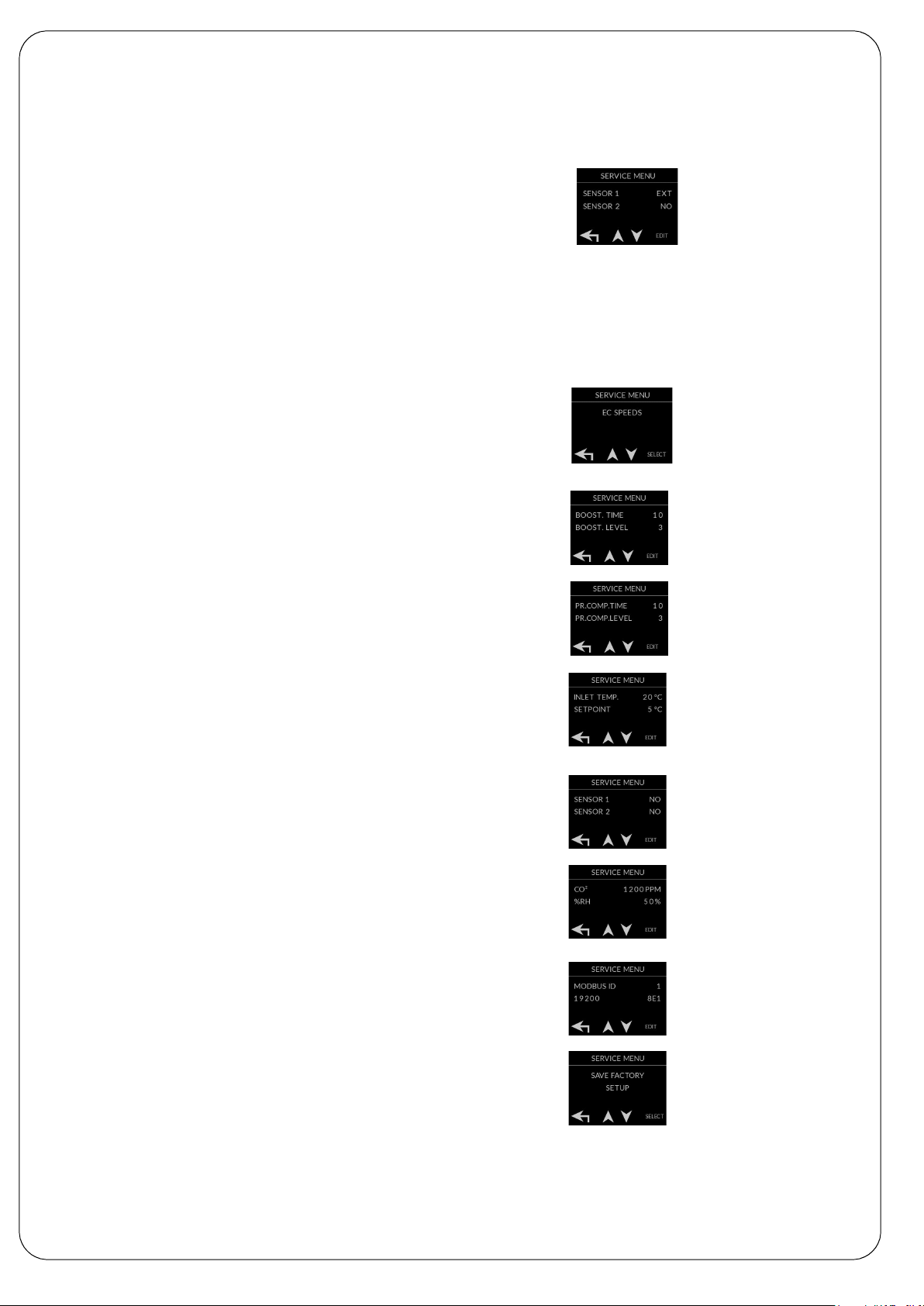

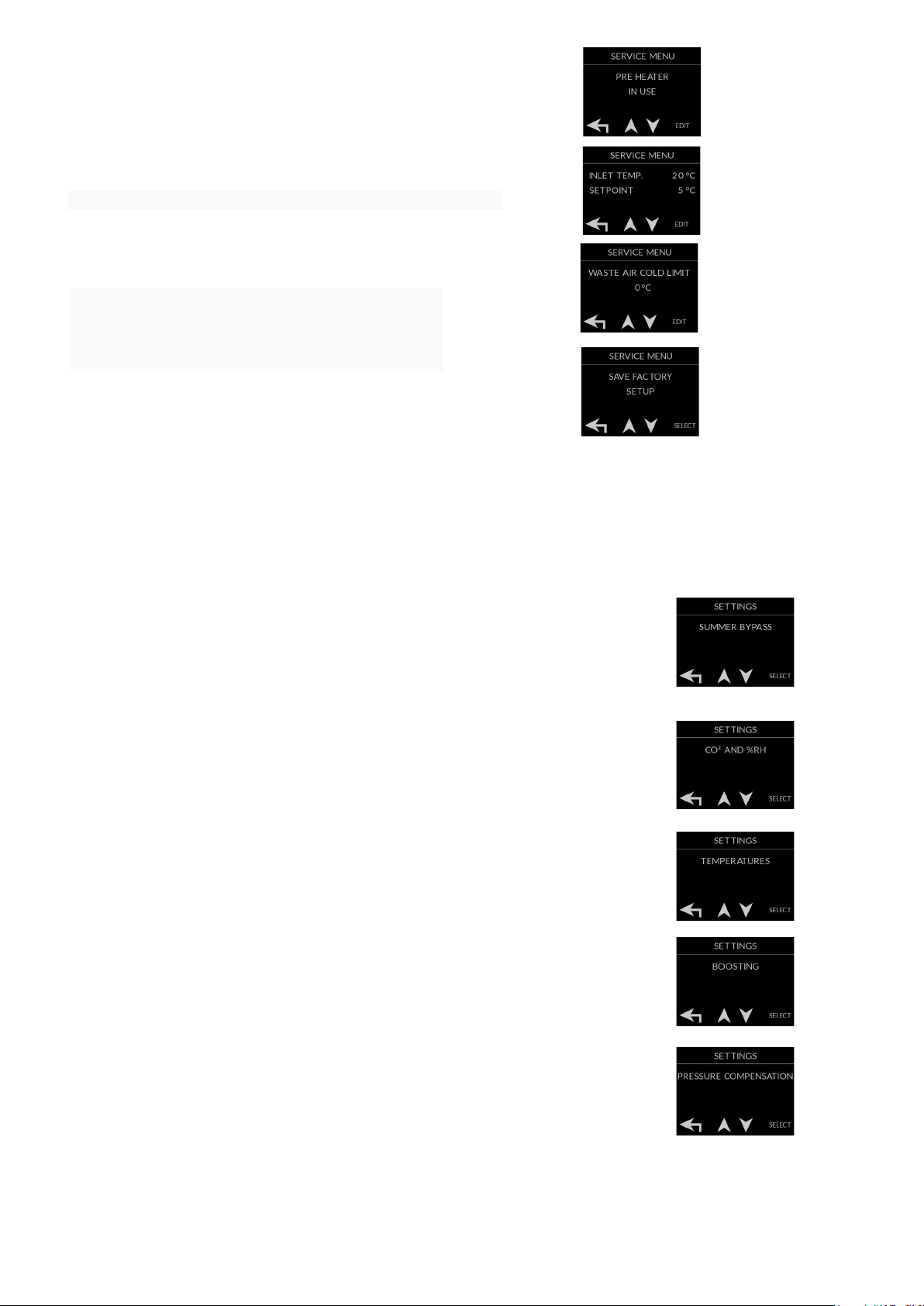

SERVICE MENU

INTRODUCTION OF THE AHU CONTROL PANEL

Settings are applied via the service menu

SETTINGS

NOTE! SWIPE RIGHT AT THE TOP OF THE SCREEN

Touch screen buttons:

Boosting

Fireplace switch

(pressure compensation)

Out-of-house mode

Fan speed adjustment 1....5

The button can be used to browse

the menu upwards and change settings.

The button can be used to browse

the menu downwards and change setting value.

Return to the previous or main menu.

THE SUMMER BYPASS OF THE HEAT RECOVERY UNIT MUST BE IN THE WINTER POSITION WHILE THE

AIRFLOWS ARE BEING ADJUSTED.

9

THE CHANGES OF THE SERVICE MENU SETTINGS ALWAYS HAVE TO BE SAVED

.

Factory setting

10 min

3

Factory setting

17

o

C

MODBUS MENU

Check the separate Modbus manual

SEPARATE FIREPLACE SWITCH OR PRESSURE COMPENSATION

Factory setting

10 min

1

INTRODUCTION OF THE AHU CONTROL PANEL

0-10V external control (0-10V hood,remote monitoring) select the deployment

SENSOR 1 "EXT" or SENSOR 2 "EXT"

External control controls the basic speed , replaces the fan speed set in the menu.

Out-of-home, overpressure and boost are in use normally.

The main screen shows the fan speed at REMOTE CONTROL and

below of it is the speed of the supply fan.

External control fan speeds

0-2V fan 0

2-5V fan 2

5-7V fan 3

7-9V fan 4

9-10V fan 5

DEFAULT SETTINGS

1. 30 %

2. 40 %

3. 60 %

4. 80 %

5. 100 %

FAN SPEED PRIORITY

Fan speed preselection is performed from the control panel service menu.

Inlet and outlet fans can be individually adjusted for five different speeds with fan speeds of 20-100%

BOOSTING FROM THE COOKER HOOD WITH CONTACT TIP INFORMATION.

Boosting time settings 0 and 5...120 min. In 0 position with different pre-data.

Boosting level settings 1...4 (the air impellers higher than basic speed), can be

adjused also from the settings menu.

Overpressure duration specification 0 and 5...20 min. In 0 position with different

pre-data.

Overpressure limit regulation 1...4 (inlet air impeller higher than outlet air impeller)

REGULATION of the INLET AIR TEMPERATURE

Inlet air temperature range 5...30 oC,

can be adjusted via SETTINGS menu

CO2 AND/or RH SENSORS ACTIVATION

CO2 AND HUMIDY PERCENTAGE SETTING

Note: set the sensor on in the settings menu

SPEED CONTROL WITH A COOKER HOOD (0-10V)

Factory setting

IN USE

Factory setting

5

o

C

Factory setting

0

o

C

THRESHOLDS FOR FREEZING PROTECTION

The preheater is switched onfrom the service menu.

The limit value of the preheater can be changed from

the service menu if necessary. The adjustment range is 0 - +10

o

C.

The limit value of the preheater must be

approx. 5

o

C higher than

the WASTE AIR COLD limit.

Temperature measurements of the preheater and

WASTE AIR COLD are measured from the waste air temperature

It is recommended to use value a minimum of 5

o

C for the

WASTER AIR COLD limit, if the preheater is not in use. When

the preheater is in use, the set value is about 5

o

C lower than the

limit value of the preheater. The adjustment range is -10 ... + 10

o

C

The preheater and freezing protection are enabled,

changes are only if needed.

CHANGES OF THE SERVICE MENU SETTINGS ALWAYS HAVE TO BE SAVED

10

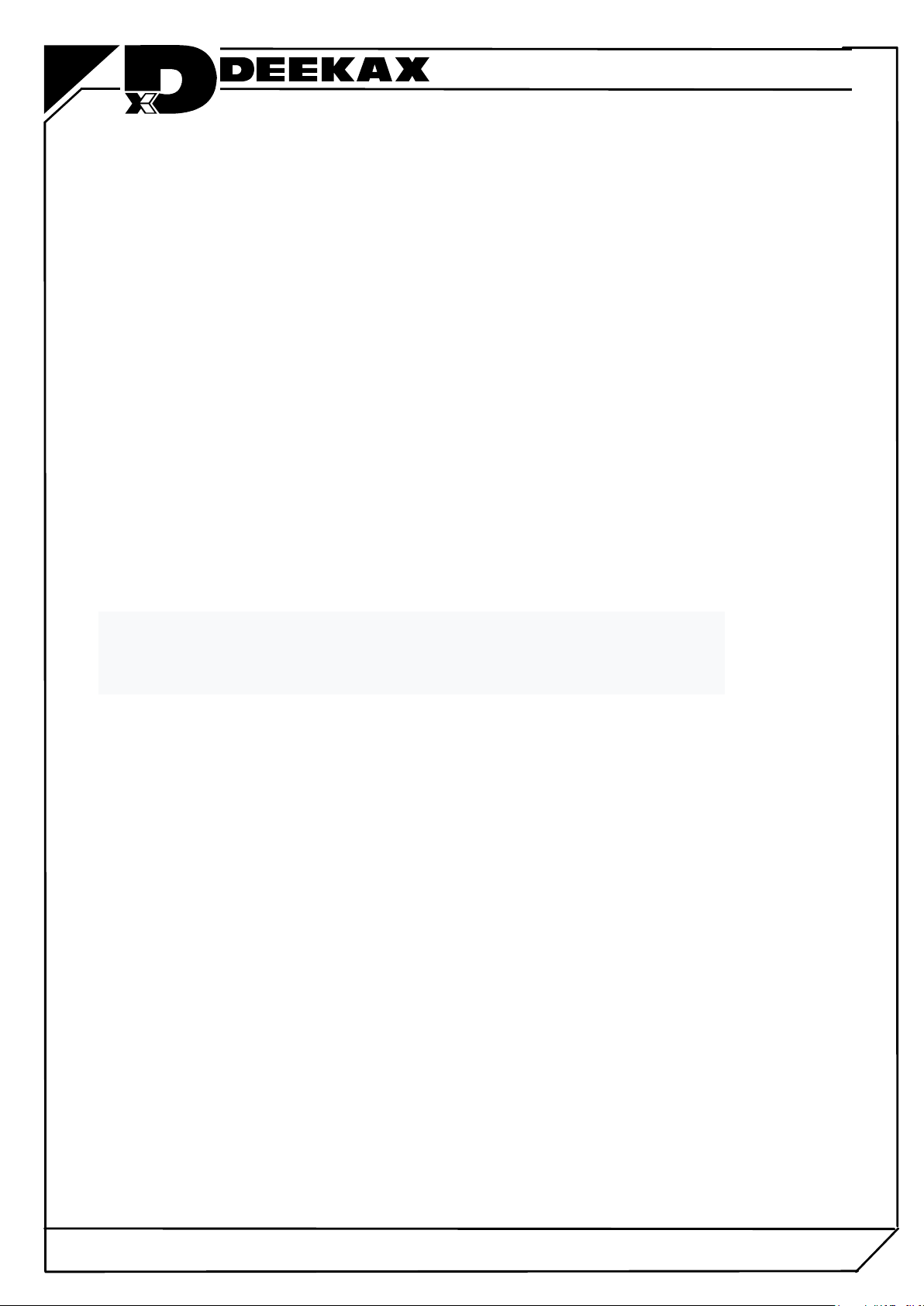

The summer bypass plate control. The user of the unit can set the bypass

plate manually to SUMMER/WINTER or AUTOMATIC mode.

In summer mode the bypass plate is activated

In the automatic mode, the plate works according to outside temperature.

Set value 15...20 oC

The automatic mode has adjustment amplitude of approx 2 hours

Set value of boosting duration 0 and 5…120 min.

In 0 position with different pre

-

data.

Set value of overpressure duration time (fireplace switch) 0 and 5…30

min. In 0 position with different pre-data.

CO

2

transmitter ON/OFF switching. Setting of CO

2

upper limit.

Set value 250...1500ppm, 50ppm steps

%RH transmitter ON/OFF switching.

Setting of RH upper limit. Set value 30...80%, 5% steps

Regulating amplitude 5...20min

Regulation of inlet air afterheating set value 5...30 oC

SETTINGS ARE APPLIED VIA THE SETTINGS MENU OF THE CONTROL PANEL

INTEGRATED HUMIDY TRANSMITTER

(optional)

The humidity transmitter is active when SENSOR 2 RH

is selected in the service menu

The humidity percentage is displayed on the main menu

screen.

If the unit is eqipped with a factory-fitted extract air humidity trasmitter.

The fan speed is automatically enchanced when the humidity

exceeds the limit value.

The limit value, the adjustment interval and ON/OFF can be

selected in the SETTINGS menu under CO2 and %RH

DOOR REVERSAL EXHANGE

REMOVING THE FAN

The fans can be removed for cleaning or replacement.

Before removing the fans, remove the HR cell and filters.

When removing supply fan, remove side support (1) of the HR cell

and the heater element case (2) from the side wall and the

cover plate (3) in the front of fan.

When removing the extract fan remove side support of

the heat recovery cell (4) and the heating element case(5)

from the side wall of the HRV and the cover plate (6) in the front of fan.

Unplug the fan plug connector. The fan is pulled out of the machine.

11

1

2

3

4

5

6

Door reversal can be changed by pushing the hinge pin

e.g with narrow tip screwdriver from the machine below

or from above

.Note! if the hand of the door is turned so that hinged side is

on the supply air filter side note that the door has room

to turn 180 degrees.

The humidity transmitter also has an on / off switch

DEEKAX Air Oy

Patruunapolku 4 Puh. 0207 912550

79100 LEPPÄVIRTA www.deekaxair.fi

PURE JOY FROM INDOOR AIR !

MAINTENANCE OF TALTERI

For producing good indoor climate continuously, the air exchange systems require regular maintenance.

The metallic grease filter of stove hood must always be kept clean for fire safety reasons. Cleansing with hot

water

or dishwasher once a month is necessary. Substances suitable for machine washing may darken the

aluminium parts of the filter.

The inlet and outlet filters of Talteri must be cleansed at least twice a year.

In summertime the summer cassette plate will be set to summer mode when the external air should come in

fresh and clean.

The heat recovery cell will be pulled out of the unit and washed thoroughly in autumn just before the heating

season begins –the heat recovery will then be at its best. Check the condition of sealing and push the heat

recovery cell back to its place.

The inner painted walls of the unit are easy to clean. Check the condition of sealing, clean the outlet hose of

condensing water and make sure the water flows freely and without any obstructions.

The impellers, air exchange adjusters and thermostats are components that do not require regular

maintenance. Electrical works can be carried out only by a qualified electrician.

During the frosty period the heat recovery cell is defrozen by using the preheater. The power of the

preheater is mainly adequate to keep the heat recovery cell defrozen. In extreme conditions, if the power of

the preheater is inadequate, the supply fan power will be reduced or stopped by the freezing protection

thermostat when the exhaust air temperature drops below the set value (0

o

C). The supply fan starts when

the exhaust air temperature rises above the set value.

Under extreme conditions (humidity /harsh cold) the heat recovery element may freeze over and the anti-

freeze protection defreezing cycles are not able to defrost it. If such a case occurs, the machine has to be

stopped, opened and the cold flow stopped and the ice

given the necessary time to melt. Check the drainage

of condensing water! In case the water-lock dries out and makes pulping noise, you can pour a drop or two

of cooking oil.

In really cold weather, the head recovery unit heats the preheated inlet air with afterheating. The functionality

can be proved by comparing the temperature of inlet air to the set value of the inlet air afterheating.

The overheat protection has been activated in case the temperature has risen +90

o

C (for instance, in case

of power failure). Reset the overheat temperature by pressing the switch under the threaded contact

protection.

The channels must be checked if the impeller works but the air exchange is inadequate or the temperature

changes in the channels between the interior and the machine. Temperature changes and humidity

concentration in channels must be prevented by improving the isolation.

Table of contents

Other Deekax Fan manuals

Popular Fan manuals by other brands

Lasko

Lasko T32200 Important instructions & operating manual

Nortek

Nortek REZNOR DS-4 Series installation manual

Harbor Breeze

Harbor Breeze E-WCK44ABZ5LKS manual

Cosa

Cosa M1-5B/56 instruction manual

Modern Forms

Modern Forms Skylark Flush installation instructions

Montigo

Montigo LDVPV58 Installation operation & maintenance