DeguDent SOLARIS User manual

DeguDent SOLARIS

Name:

Version:

Date:

Page:

Service Manual

1.8

21 Jan 2005

1of 43

DeguDent SOLARIS Service Manual

DeguDent SOLARIS

SERVICE MANUAL

DeguDent SOLARIS

Name:

Version:

Date:

Page:

Service Manual

1.8

21 Jan 2005

2of 43

DeguDent SOLARIS Service Manual

Contents

1INTRODUCTION ...................................................................................................................0

2TECHNICAL SPECIFICATIONS .............................................................................................0

3WARNINGS...........................................................................................................................0

4ASSEMBLY...........................................................................................................................0

4.1 BASIC STRUCTURE ...............................................................................................................0

4.2 VERTICAL DRIVE..................................................................................................................0

4.3 VERTICAL UNIT ....................................................................................................................0

4.4 HORIZONTAL UNIT................................................................................................................0

4.5 STIRRING DRIVE...................................................................................................................0

4.6 HEAD.................................................................................................................................0

5GENERAL WIRING DIAGRAM ...............................................................................................0

6COMPONENT MOUNTING DIAGRAM....................................................................................0

7DATA ADMINISTRATION.......................................................................................................0

7.1 EEPROM DATA...................................................................................................................0

7.2 DETAILS .............................................................................................................................0

8LOCAL OPERATION; GALVANIZATION PROCESS................................................................0

8.1 LOCAL OPERATION ...............................................................................................................0

8.2 GALVANIZING PROCESS.........................................................................................................0

9THE COMMAND INTERFACE................................................................................................0

9.1 OUTPUT AND LOGGING..........................................................................................................0

9.2 COMMANDS.........................................................................................................................0

10 PROGRAMMING INSTRUCTIONS FOR SOFTWARE DOWNLOADS ......................................0

11 TROUBLESHOOTING ...........................................................................................................0

11.1 POWER-UP SELF-TEST......................................................................................................0

11.2 MOTOR PROBLEMS ...........................................................................................................0

11.3 DISPLAY ERRORS .............................................................................................................0

11.4 CONTROL KNOB ERRORS ...................................................................................................0

11.5 HEATER PROBLEMS ..........................................................................................................0

11.6 PROCESS ERRORS ...........................................................................................................0

11.7 ERROR OPERATING DEVICE VIA THE COMMAND INTERFACE......................................................0

11.8 GENERAL ERRORS ...........................................................................................................0

12 PARTS LIST..........................................................................................................................0

13 APPENDIX............................................................................................................................0

13.1 CURRENT ASSIGNMENT RULES IN NORMAL MODE...................................................................0

13.2 CURRENT ASSIGNMENT RULES IN POWER MODE ....................................................................0

13.3 PREPARING FOR CALIBRATION............................................................................................0

13.4 CALIBRATION PROCEDURE FOR CURRENT CORRECTION VALUES...............................................0

13.5 CALIBRATION PROCEDURE FOR VOLTAGE CORRECTION VALUES ...............................................0

13.6 CALIBRATION PROCEDURE FOR CLOSED-CIRCUIT CURRENTS...................................................0

13.7 CALIBRATION PROCEDURE FOR POWER MODE.......................................................................0

13.8 DUAL-LOADING MATRIX .....................................................................................................0

13.9 SERVICE REPORTS ...........................................................................................................0

13.10 DOCUMENTS ...................................................................................................................0

DeguDent SOLARIS

Name:

Version:

Date:

Page:

Service Manual

1.8

21 Jan 2005

3of 43

DeguDent SOLARIS Service Manual

1Introduction

This document describes service-relevant details o the DeguDent Solaris unit and supports the

technician’s troubleshooting efforts. This manual is to be used in connection with the Instructions for

Use, which it will refer to from time to time.

The target group for this document consists of authorized service technicians.

2Technical specifications

Dimensions (W × D × H) Approx. 480 × 270 × 475 mm

Weight Approx. 12.5 kg

Storage and transport

Ambient temperature +10°C to +60°C

Relative humidity 20% to 60% at 35°C

Atmospheric pressure 800 to 1060 hPa

Operation

Ambient temperature +10°C to +45°C

Relative humidity 20% to 85% at 35°C

Height above sea level max. 2000 m

Atmospheric pressure 800 to 1060 hPa

Degree of contamination 2

Operating data

Operation In closed rooms

Protection class I

Protection type, housing IP20

Electrical safety Pursuant to DIN EN 61010 (IEC 61010-1)

including CSA and UL guidelines

Overvoltage category II

Interference suppression Pursuant to EN 55011, limit curve B

Immunity to electrical noise (sound level) Pursuant to EN 50082-2

Mains voltage 100/230 V ±10%

Internal voltage selection

Mains frequency 50/60 Hz

Power requirements Max. 250 VA

Fuses according to IEC 60127 2 × T 2.5 A/H, 5×20 mm

DeguDent SOLARIS

Name:

Version:

Date:

Page:

Service Manual

1.8

21 Jan 2005

4of 43

DeguDent SOLARIS Service Manual

3Warnings

DeguDent Solaris is intended for dental use only.

DeguDent Solaris must be operated using original replacement parts only. This is the only way

to ensure the stated performance and operating safety.

Do not open the unit. Dangerous voltages are present inside.

All maintenance, service and repair work must be performed only by service technicians

authorized by DeguDent.

Protect the unit from moisture to avoid shortcuts and other damage. Do not expose the device

to steam.

Disconnect the device from mains if it is not used for a certain period of time.

Keep Solaris Galvano liquid away from the eyes.

Avoid all contact of Solaris Galvano liquid with skin, eyes, and soft tissue.

Do not swallow Solaris Galvano liquid.

Immediately wash your hands on contact with Solaris Galvano liquid.

Disclaimer

The manufacturer will not assume liability for any damage caused by unauthorized changes or

abuse or other uses contrary to the Instructions of Use.

DeguDent SOLARIS

Name:

Version:

Date:

Page:

Service Manual

1.8

21 Jan 2005

5of 43

DeguDent SOLARIS Service Manual

4Assembly

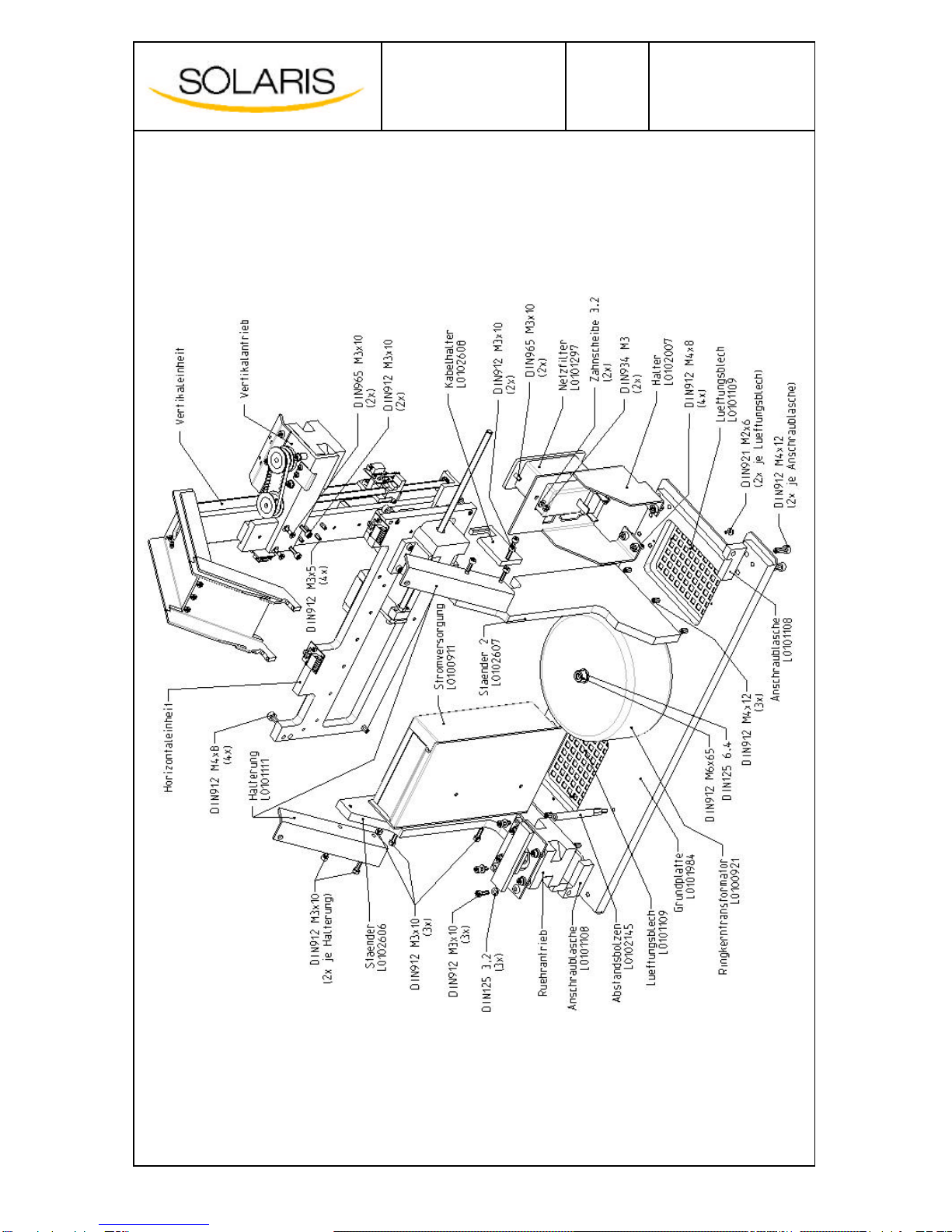

4.1 Basic structure

DeguDent SOLARIS

Name:

Version:

Date:

Page:

Service Manual

1.8

21 Jan 2005

6of 43

DeguDent SOLARIS Service Manual

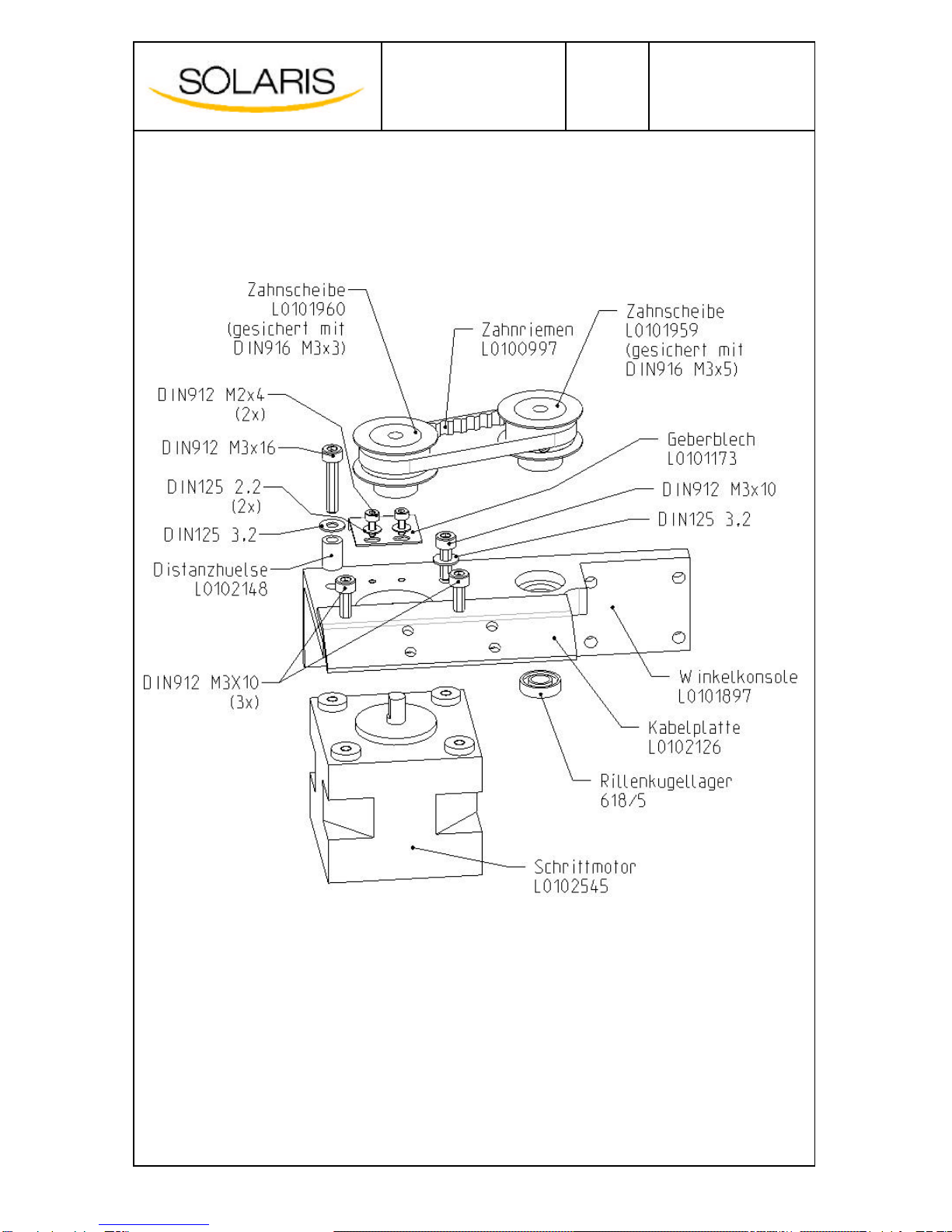

4.2 Vertical drive

DeguDent SOLARIS

Name:

Version:

Date:

Page:

Service Manual

1.8

21 Jan 2005

7of 43

DeguDent SOLARIS Service Manual

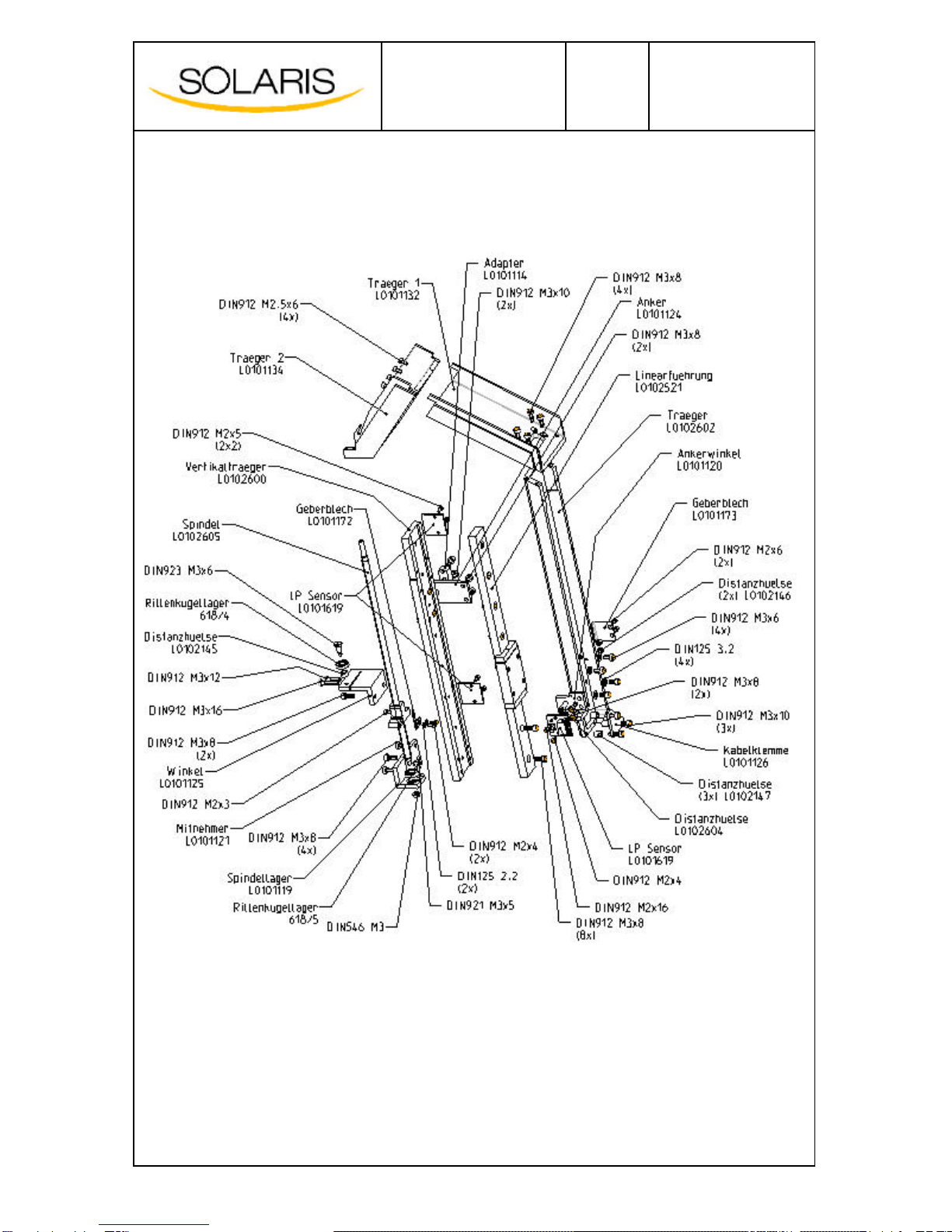

4.3 Vertical unit

DeguDent SOLARIS

Name:

Version:

Date:

Page:

Service Manual

1.8

21 Jan 2005

8of 43

DeguDent SOLARIS Service Manual

4.4 Horizontal unit

4.5 Stirring drive

DeguDent SOLARIS

Name:

Version:

Date:

Page:

Service Manual

1.8

21 Jan 2005

9of 43

DeguDent SOLARIS Service Manual

4.6 Head

DeguDent SOLARIS

Name:

Version:

Date:

Page:

Service Manual

1.8

21 Jan 2005

10 of 43

DeguDent SOLARIS Service Manual

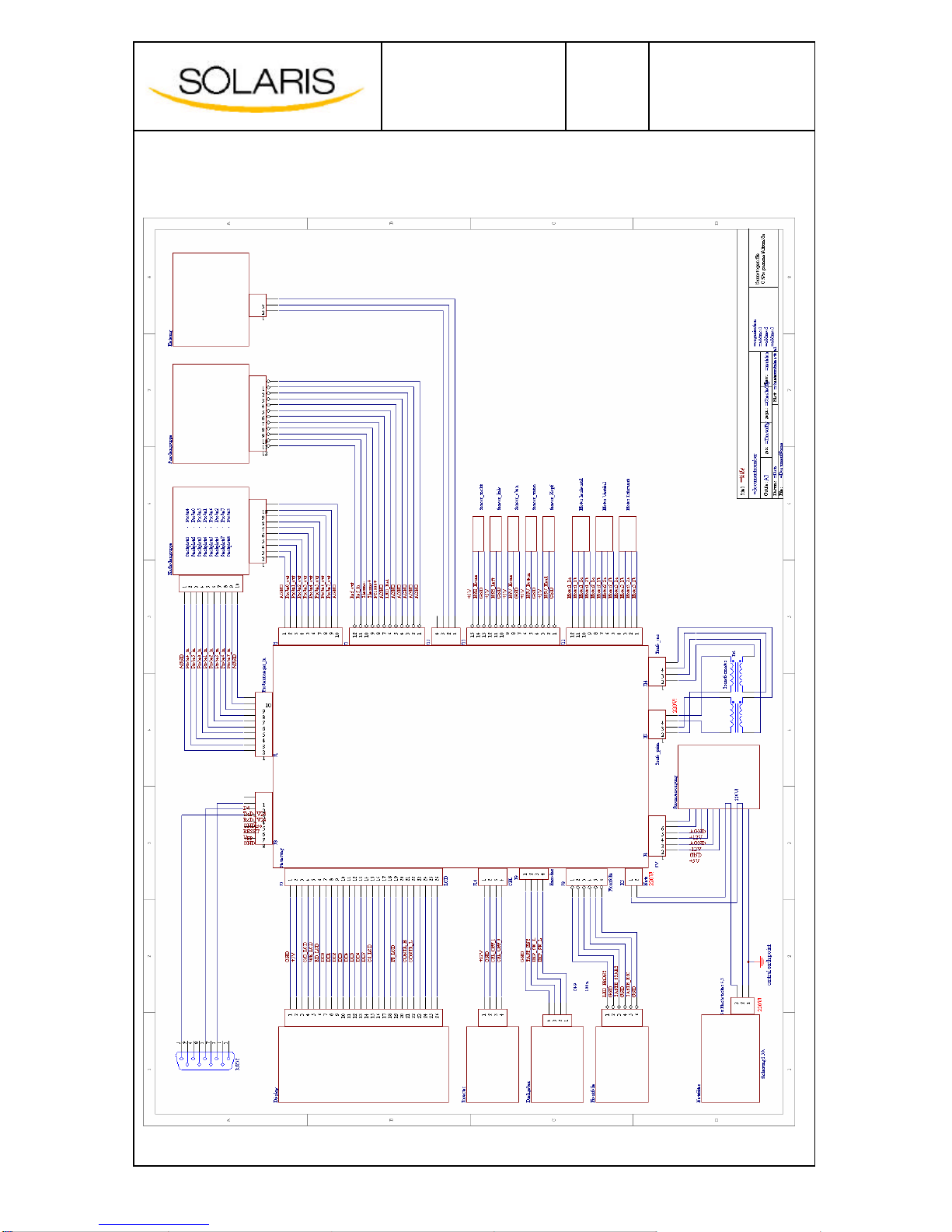

5General wiring diagram

DeguDent SOLARIS

Name:

Version:

Date:

Page:

Service Manual

1.8

21 Jan 2005

11 of 43

DeguDent SOLARIS Service Manual

6Component mounting diagram

DeguDent SOLARIS

Name:

Version:

Date:

Page:

Service Manual

1.8

21 Jan 2005

12 of 43

DeguDent SOLARIS Service Manual

7Data administration

The unit uses non-volatile EEPROM to store important device and process data and to ensure that

data are available across power-on cycles.

7.1 EEPROM data

EEPROM entry Unit Valid range Default

Device-specific values

Unit No. -ASCII, 8 characters Serial number

Current offset, samples (8 x) bit 54 … 250 54

Current offset, ref. electrode bit 109 … 350 225

Current factor, samples (8 x) -0.975 … 1.025 1.0

Current factor, ref. electrode -0.987 … 1.013 1.0

Current offset, Power mode (2/5) bit 0 … 10054

Current factor, Power mode (2/5) -0.90 … 1.00 0.96

Voltage offset, samples (8×) bit 484 … 540 512

Closed-circuit current,

samples (8×) bit 0 … 10 5

Closed-circuit current,

reference bit 0 … 30 15

X-position, rinsing cup increments > 00

X-position, galvanization beaker increments > 040000

Y-position, beaker increments > 0112000

Encoder type (control knob) -0=optical, 1=mechanical 1

DA converter type (control PCB) -0 –new (AD5328)

0xFF –old (MAX5306) 0xFF

Hour counters

Complete unit seconds > 0-

Anode (not used)

Reference electrode (not used)

Heater seconds > 0-

Stirring motor (Motor 3) seconds > 0-

Motor X (Motor 1) seconds > 0-

Motor Y (Motor 2) seconds > 0-

Custom settings

Language -0 –German

1 –English

2 –French

3 –Italian

4 -Spanish

German: 0

Contrast -1…30 10

Units -0 –Standard

1 –U.S. Default: 0

Temperature control

Temperature offset bit Fixed value 72

Temperature factor 1/1000 Fixed value 9660

Electroplating temperature 1/10 °CFixed value 650

Heating rate 1/1000 °C/min Fixed value 1500

Process data

DeguDent SOLARIS

Name:

Version:

Date:

Page:

Service Manual

1.8

21 Jan 2005

13 of 43

DeguDent SOLARIS Service Manual

Recipe data for the last three galvanization cycles

Error history

Last ten error codes with date and time; error counter

When the device is powered up, all the relevant data are read from EEPROM and are available for

program-internal use. If parameters are changed from the menu, the new values are in turn stored.

Recipe data are updated dynamically during preparation and during the galvanization process. The

error history is updated as errors occur.

To ensure the integrity of the data, the EEPROM is secured by a checksum mechanism. Integrity of

the data is checked each time the device is powered up. Any errors are reported to the used and

cannot be cleared except by servicing (see Section 11.1).

7.2 Details

7.2.1 Device-specific values

The device number is the serial number of the device. It is invariably 8 characters long and must agree

exactly with the number on the ID label at the back of the device.

Current-specific correction parameters, Current offset/Current factor, samples, Current offset/Current

factor, reference electrodeand Current offset/Current factor, power mode (channels 2/5)serve to

compensate for the device-specific deviations when converting electric current values (for individual

samples or for the reference electrode) in bit values.

The voltage correction parameter, Voltages offset, Samples serve to compensate for the device-

specific deviations when converting bit values to voltage differences (between the samples and the

reference electrode).

All correction parameters are specific correction factors.

They are determined at a special test station for and stored in EEPROM.

The device is shipped adjusted (delivery setting), ensuring that the device perform within the tolerance

range.

The X-position, rinsing cup and X-position, galvanization beaker position settings define the absolute

horizontal position (increments) of the slide head for lowering into the respective beaker. The criterion

for determining whether the target position is reached when lowering the head is the motor stop as the

head meets an obstacle. This ensures that the beaker is sealed by the slide during processing. The Y-

position, beaker is therefore not to be seen as an absolute position, but as a threshold. If the slide

meets an obstacle before the value is reached, the rim of the beaker is considered to have been

touched. In all other cases, the collision signal is considered to signal motor failure (see 11.2).

The encoder type defines the type of the built-in control knob (mechanical or optical). The fact that the

two are distinguished in the software ensures that they work analogously.

At delivery, this setting will correspond to the hardware installed (delivery setting). If a different

encoder is installed at a later time, a service technician may have to adjust the type setting.

The DAC type defines the type of the DA converter integrated on the control PCB. In order to be able

to react flexibly to the market situation for electronic components, two different types of this

component are supported. Since these differ in the way they are driven, the software looks for

information about the installed type at this EEPROM address. If a different PCB is installed later, a

service technician may have to adjust the type setting.

7.2.2 Hour counters

These counters represent the uptime of the entire device or of individual components. These are

regularly updated while the device is operative. Their value at delivery should not differ significantly

from 0.

DeguDent SOLARIS

Name:

Version:

Date:

Page:

Service Manual

1.8

21 Jan 2005

14 of 43

DeguDent SOLARIS Service Manual

7.2.3 Custom settings

The device has a multilingual user interface. The menu language is determined by the Language

parameter.

Supported languages are English, French, German, Italian and Spanish.

The Contrast setting defines the LCD display contrast.

The Units setting defines the units for displaying temperatures and dimensions:

Default U.S.

Temperature °C °C (°F)

Measurements µm mm

7.2.4 Temperature control

The Temperature offset and Temperature factor correction parameters are used for converting the bit

values at the temperature sensor to a temperature value in°C.

The galvanization temperature is the required process temperature of the galvanization bath

expressed in 1/10°C.

The heating rate defines the maximum temperature increase in the galvanization bath over time during

the heating period in order to protect it from overheating and deposits.

7.2.5 Error history

The error history is a list with the last ten error codes with date and time including the error counter.It

is used for error tracing and problem-driven troubleshooting.

Possible error codes are listed in Section 11.The corresponding time stamp (date/time) is stored in

encode form. The data can be retrieved with a service command via the RS-232 port. The

corresponding error text is output automatically. By way of additional information, the absolute error

counter of the special error code 42 is also logged. Analysis can only be performed by authorized

service technicians.

Examples:

(1) Error History:

15-03-04 12:32:16: error code=41 (Invalid galvanization parameter. Start

current out of range.)

07-03-04 19:04:05: error code=32 (Error reaching clean position. Possibly no

glass on clean position.)

29-02-04 06:21:11: error code=20 (Incomplete recipe found in EEPROM. Previous

galvanisation terminated.)

16-02-04 17:48:55: error code=31 (Error reaching start position. Possibly no

glass on start position.)

13-02-04 08:37:49: error code=36 (Connection failure to all objects.

Galvanisation terminated.)

01-02-04 09:12:36: error code=52 (Error while writing data to EEPROM.)

11-01-04 14:07:00: error code=39 (Invalid galvanization parameter. Object

surface out of range.)

error counter (error code=42)=5

(2) Error History:

(empty)

error counter (error code=42)=0

DeguDent SOLARIS

Name:

Version:

Date:

Page:

Service Manual

1.8

21 Jan 2005

15 of 43

DeguDent SOLARIS Service Manual

7.2.6 Process data

The process data of the last three recipes are stored in EEPROM. A recipe counter that is also

present in EEPROM defines the number of the last recipe applied, facilitating analysis of the relevant

data for errors and process failures due to power outages. The following process data are stored for

each object:

Name Meaning Comment

EnblFlg Indicates whether object is in

use TRUE (1) -Object in use

FALSE (0) -Object not in use

RunFlg Indicates whether process is

active TRUE (1) -Process started (active)

FALSE (0) -Process terminated

(inactive)

ErrVal Type of failure Error during galvanization, see Section 11

SplType Object type (sample type) Subdivision into types 1…8, user selection 1

CurStart Start current [mA]

CurEnd End current [mA] Characteristics of the current curve during

galvanization

Surface Surface [mm²] Object surface including contact surface1

LayerThick Layer thickness [µm] Object-specific, user selection

GoldMass Gold mass [mg] Calculated total mass, object-specific

Location Slot Logical slot number 2

Zone Internal or external slide ring 0 –Internal ring

1 -External ring

CurrentCurrent [mA] Last current value used

GalProcTime Total process time Object-specific

GalProcRstTime

Remaining process time Object-specific

TimeStamp Time of last updated Date/time, can be traced back one month

The sequence of object data corresponds to the physical channel numbers. Data are not accessible

via the local menu but only via the serial command interface. Analysis of the process data can only be

performed by authorized service technicians.

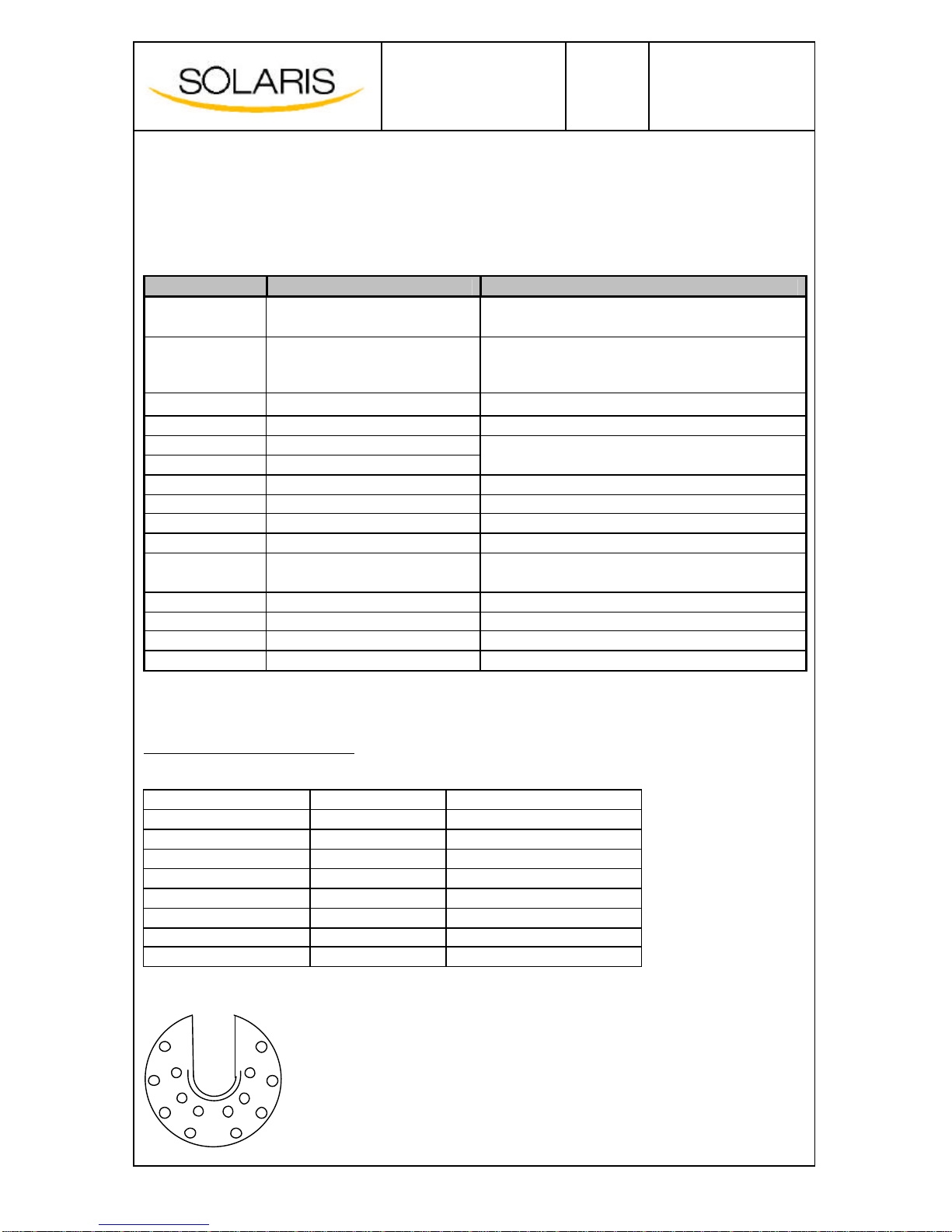

1Object type

Type Surface (mm²) Contact surface (mm²)

150,0

10

265,0

10

387,5

10

4115,0

10

5150,0

10

6200,0

10

7265,0

10

2Logical slot numbers (seen from below):

1

2

3

4

8

7

5

6

DeguDent SOLARIS

Name:

Version:

Date:

Page:

Service Manual

1.8

21 Jan 2005

16 of 43

DeguDent SOLARIS Service Manual

8Local operation; galvanization process

8.1 Local operation

Local operation is described in detail in the Instructions for Use and the Operating Instructions.

8.2 Galvanizing process

8.2.1 Process steps

Parameter menu #1

-For determining the number of electrodes/superstructures

-For turning the automatic divesting process at the end of the

galvanizing cycle on or off

Galvanizing

Go to rinsing position

(automatic divesting if selected)

Parameter menu #2

for defining

-Individual sample layer thickness

-Sample type and surface (manually from table)

àLiquid amount and beaker size display.

Loading

menu

for getting an overview over

-Parameters selected

-Settings for loading, liquid amount and beaker size

Galvanizing menu

with

-Display of remaining time, temperature and status

-

START key.

Go to start position

Galvanizing bath heating

Internal pa

rameter calculation

Connection test

DeguDent SOLARIS

Name:

Version:

Date:

Page:

Service Manual

1.8

21 Jan 2005

17 of 43

DeguDent SOLARIS Service Manual

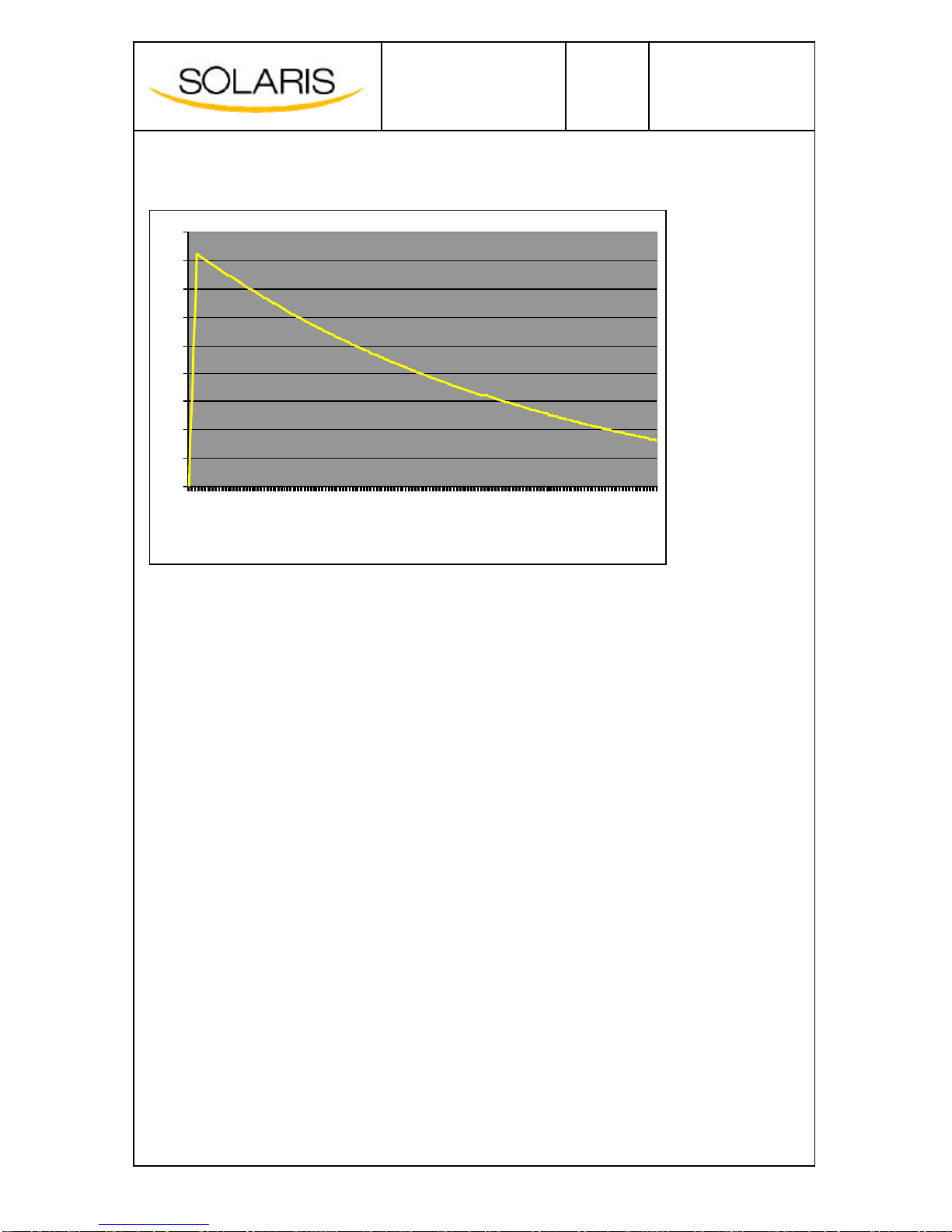

8.2.2 Current curve

For objects not exceeding the surface limits for object type 8, all electric currents during the process

are generated in normal mode. If this is not possible because of the operator’s surface selection,

Power mode is automatically selected, which allows a current output that is approximately four times

higher. The mode can be toggled using the sip service command. Current assignment rules for either

mode are found in the Appendix (see Sections 13.1and 13.2)

0

5

10

15

20

25

30

35

40

45

00:00:00

00:15:38

00:31:38

00:47:38

01:03:38

01:19:38

01:35:38

01:51:38

02:07:38

02:23:38

02:39:38

02:55:38

03:11:38

03:27:38

03:43:38

03:59:38

04:15:38

04:31:38

04:47:38

DeguDent SOLARIS

Name:

Version:

Date:

Page:

Service Manual

1.8

21 Jan 2005

18 of 43

DeguDent SOLARIS Service Manual

9The command interface

An alternative to local operation is operation using a serial command interface. The serial interface

parameters are as follows:

Baud rate: 19,200

Data bits: 8

Parity: None

Stop bits: 1

Flow control: None

There are two types of commands: standard commands and service commands. Servicecommand

are password-protected and require operator authorization.

There are commands

-for parameter and user settings and requests

-for device status requests

-for evaluating recipe data

-for requesting the error history

-…

A detailed command description exist for each command.

The serial port can be accessed using a standard terminal program (e.g. Hyperterminal).

9.1 Output and logging

Depending on the command issued and on the currently running processes, text output may be

available at the serial port. They represent command responses, error messages, information

messages …

9.1.1 Output modes

There are four output modes that determine the amount and type of output received.

Output mode Description

0No output

1Output of galvanization parameters during process

2Comprehensive troubleshooting output

4Minimal output, for internal use only

DeguDent SOLARIS

Name:

Version:

Date:

Page:

Service Manual

1.8

21 Jan 2005

19 of 43

DeguDent SOLARIS Service Manual

9.1.2 Data logging

Events may be logged by activating the logging function of the terminal program (e.g. Hyperterminal).

Data generated by Mode 1 can easily be imported into Microsoft Excel to create diagrams for

visualizing process data.

Data logs are helpful in providing detailed information to service technicians in case of problems.

Creating a data log in Hyperterminal:

-Start data logging, selecting the log file and path

-End of logging; log file is closed

DeguDent SOLARIS

Name:

Version:

Date:

Page:

Service Manual

1.8

21 Jan 2005

20 of 43

DeguDent SOLARIS Service Manual

9.2 Commands

Remotely controlling the device using the command interface is restricted to trained

service technicians, since maladjustment of internal parameters can result in

malfunction of the device including adverse effects on the galvanization process.

Service commands can only be issued after the password-protected service mode has

been activated.

9.2.1 Syntax

Commands are issued as plain text. Parameters are separated by commas.

Command names must be entered in lowercase letters.

Decimals are not supported when entering command parameters.

Command parameters must be whole numbers.

CAUTION:

The parameters of all service commands are based on physical channel numbers. These are different

from the logical slot/sample numbers in the local operating menu.

Either type of numbers can be readily converted to the other type:

Channel

(physical number) Slot

(logical number)

02

14

26

38

41

53

65

77

This list will be output after issuing the rc command.

9.2.2 Standard commands

Command: LS - Service authorization

Command Parameters Explanation and examples

i,<password> Activate service mode (log in)

Example: lsi,<password> -> activates service mode

ls

oLeave service mode (log out)

Example: lso -> leaves service mode

Command: H – Online help

Command Parameters Explanation and examples

hl -Online help: Command overview (standard and service commands)

Command: M – Output modes

Command Parameters Explanation and examples

0Mode 0: No output.

1Mode 1: Output of galvanization parameters during process

2Mode 2: Comprehensive troubleshooting output

m

4Mode 4: Minimal output, for internal use only

!

Other manuals for SOLARIS

1

Table of contents

Popular Medical Equipment manuals by other brands

Barco

Barco Nio Color 5MP user guide

O-Two

O-Two 01MN1000 Operator's manual

Datex-Ohmeda

Datex-Ohmeda S/5 Compact Anesthesia Monitor Technical reference manual

Fresenius Medical Care

Fresenius Medical Care 2008K2 troubleshooting guide

Rosie Connectivity Solutions

Rosie Connectivity Solutions Scan Assembly guide

Albrecht

Albrecht CDS KNEE BRACE FLEXION User instructions