DEK Hawkeye User manual

Part Number 195152

Issue 01 Nov 07

HawkEye - a guide to deposit verification

100 %

90

80

70

60

50

40

30

20

10

0

1700

750

Hawk Eye

1700

750

Hawk Eye

Trademark Acknowledgment

DirEKt Ball Placement , Interactiv HawkEye and PumpPrinting

are trademarks of DEK International GmbH and/or DEK Printing Machines

Limited.

Microsoft and MS-DOS are registered trademarks of Microsoft Inc. Windows,

Windows XP and Windows XP Embedded are trademarks of Microsoft Inc.

All other brand and product names are trademarks or registered trademarks

of their respective holders.

TM TM TM TM

Copyright Statement

In line with DEK Policy of continual improvement, this manual is periodically

up-issued to reflect the latest machine enhancements and is provided with an

issue state which is displayed on the front cover.

Copyright 2007 DEK International GmbH. All Rights Reserved.

, AutoFlex , FormFlex , Grid-Lok , Icon , Icon Technologies ,

ProFlow , PumpPrint , Varidot and VectorGuard are registered trademarks

of DEK International GmbH and/or DEK Printing Machines Limited.

DEK Worldwide

Contact us @ www.dek.com

1700

750

Hawk Eye

A GUIDE TO HAWKEYETM

CONTENTS

i

A GUIDE TO HAWKEYE TM

COPYRIGHT STATEMENT............................................................................................................................. Inside Front Cover

SCOPE......................................................................................................................................................................................ii

MANUAL OVERVIEW ...............................................................................................................................................................ii

OVERVIEW ..............................................................................................................................................................................1

System Description ..........................................................................................................................................................1

Practical Limitations..........................................................................................................................................................2

The HawkEye Philosophy ................................................................................................................................................3

The Print and Verification Cycle Explained ......................................................................................................................4

THE USER INTERFACE ..........................................................................................................................................................5

The Interface ....................................................................................................................................................................5

HAWKEYE SETUP ...................................................................................................................................................................13

Setup Overview ................................................................................................................................................................13

The Setup Page ................................................................................................................................................................14

HAWKEYE REPORTING ..........................................................................................................................................................22

HawkEye Alarm.................................................................................................................................................................22

OPTIMISING FOR PRODUCTION ...........................................................................................................................................24

Setting A Line - Beat Strategy ..........................................................................................................................................24

MONITORING OUTPUT............................................................................................................................................................25

SPC Data Recording.........................................................................................................................................................25

ERROR ANALYSIS...................................................................................................................................................................30

Pre-Verification Scan Offset Elimination ...........................................................................................................................30

A GUIDE TO HAWKEYETM

CONTENTS

1700

750

Hawk Eye

ii

SCOPE

This manual assumes that the reader has previously gained appropriate knowledge to be able to setup and run a board on the printing machine. The user should

be familiar with the graphical icons, parameter definitions and other advanced features available in the DEK User Interface - Instinctiv TM.

The user should be able to demonstrate knowledge of the general rules for producing good quality and consistent print. These rules include; machine, stencil

and board cleanliness, appropriate tooling placement, appropriate applicator that is in good condition for the task, optimised printer set up for cleaning cycles

and the correct print medium deposit.

The manual is aimed at personnel qualified to technician level and above who have undertaken DEK maintenance courses.

MANUAL OVERVIEW

Thismanualutilisesmanyaspectsofthe InstinctivTMstyle. ThefunctionalityembodiedwithinthisinterfaceallowstheHawkEyeTM process tobeeasilyunderstood

and remembered. The process is fully explained along with appropriate techniques to optimise performance for production.

1700

750

Hawk Eye

A GUIDE TO HAWKEYE

OVERVIEW

1

A GUIDE TO HAWKEYE

OVERVIEW

System Description

HawkEyeTM is an ultra-high speed, integrated, automatic deposit

verification system. It assesses up to 100% of printed board and

gives a rapid go/no-go indication. In production, HawkEye provides

immediate feedback on problems as they occur. The operator is

able to make simple recovery choices:

• Reprint the board

• Clean the stencil

• Add more print medium to the process

The system is programmed to verify either the complete board or

specific areas, for example, where print deposit density may be

particularly high. This allows the user to adjust the total verification

time and derive maximum value within the line beat rate.

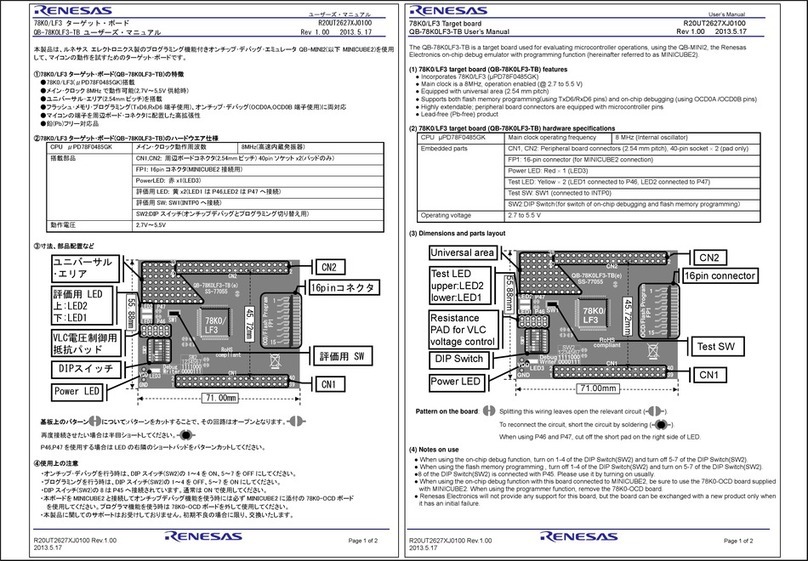

Two camera variants are available; the HawkEye 750 and the

HawkEye 1700, both run the same software package which is

capable of reporting on easily defined scan areas.

The figure shows the different scan speed ratings of the camera

types.

NOTE

Verification speed is dependant upon feature size.

HawkEye 1700 CameraHawkEye 1700 Camera

HawkEye 750 CameraHawkEye 750 Camera

1700 mm /s

2

750 mm /s

2

A GUIDE TO HAWKEYE

OVERVIEW

2

1700

750

Hawk Eye

Practical Limitations

Field of View A feature of HawkEye is that it indicates deposit levels on anything within the camera’s field of view, programmed areas smaller than this

are scanned but not exclusively reported. The camera field of view for each camera type is as follows:

• HawkEye 750 vision window = 5.4mm x 8.7mm

• HawkEye 1700 vision window = 11.3mm x 8.7mm

As can be seen in the figure, the red outer rectangle in the board view represents the total camera field of view. The area denoted by the

pinkoutlinedrectangle onthescreenviewrepresentstheprogrammedarea,the regionofinterest(ROI)(Itshould benotedthatthisrectangle

is used to highlight where the programmed ROI is for this example only and it is not used by the system). The corresponding items are

bordered with a red outline on the board view, these are the features within the programmed area. HawkEye reports on all items in the

camera field of view and if the paste level falls below the programmed level on any item (see area with light blue outlined rectangle [this

indicates a feature with the lowest paste level]) a warning or error alarm is raised regardless of the deposit levels in the area of the ROI.

Memory Size

Limit Due to memory size limitations of the HawkEye 750, the system cannot be used to scan fully populated substrates at the maximum board

size of 508mm x 508mm (Standard Machine). This need not be a limitation of the system, if the user chooses to be selective about the

areas to be scanned. See - Optimising for Production section for more details. The maximum area size that can be scanned using the

HawkEye 750 camera is 335mm2.

Print Offsets Users must determine the print offsets of the board and apply them before setting up areas, if the offsets are not applied before scanning,

the system ‘sees’ these as an error condition and reports them as errors. In extreme cases the verification system is unable to resolve any

alignment issues, ruling them out of the inspection setup altogether. See - Error Analysis section for more details.

Fiducial

Exclusion Occaisionally HawkEye highlights additional screen fiducials as unprinted board pads, if this should occur programmed areas should be

adjusted to avoid including these extra fiducials.

Field of View Screen View

Board View

Features

within the ROI

Least Pasted

Feature

Programmed Area

(ROI)

1700

750

Hawk Eye

A GUIDE TO HAWKEYE

OVERVIEW

3

The HawkEye

Philosophy Subject to the limitations mentioned previously, the user can program HawkEye to verify specific areas or complete products.

HawkEye uses a simple verification indicator (results indicator) without the need to display large amounts of data. It shows percentage

readings to assist the setting of warning and error levels, the percentage deposit levels reported are accurate to ±5%.

High Density Inspection - 2 seconds Full Product Inspection - 20 seconds

Error

Error

Warning

Warning

100 %

90

80

70

60

50

40

30

20

10

0

A GUIDE TO HAWKEYE

OVERVIEW

4

1700

750

Hawk Eye

The Print and Verification Cycle Explained

The system requires a two-stage set up procedure. Initially it carries out a printed board verification of the programmed areas. This

information is used to determine acceptable warning and error levels which are set for the process.

The levels applied to the setup print are maintained throughout the remaining print cycle. During printing, each board is verified as

determined during the setup phase. Printing continues until the batch is completely processed or a deposit reaches an error level. In the

error state, the operator has the option to carry out a recovery action to rectify the condition.

Print Medium

Indicator (pmi)

Warning

Warning Warning

Results Indicator

Scanned Area

Initially

setup and printed.

Verify HawkEye is selected -

the system scans the

setup areas and displays

the verification page

a board is

100 %

90

80

70

60

With HawkEye levels set,

print level verification

continues

If the deposit level

does not meet

the required level,

an error is flagged.

Recovery

actions are available

Reprint

Clean Screen

Deposit Paste

The results indicator

displays the print medium level (grey bar)

and the error and warning levels

for the currently highlighted

scanned area

Recovery Actions

Selecting -

Set Level to Accept

sets the error and

warning levels

to within 5% of the

measured print level

100 %

100 %

90

90

80

80

70

70

60

60

50

50

40

40

30

30

20

20

10

10

0

0

Error

Error

1700

750

Hawk Eye

A GUIDE TO HAWKEYE

THE USER INTERFACE

5

THE USER INTERFACE

The Interface

Status Page This graphic shows the Status page. When the machine is in run mode this page can be accessed at any time by selecting the HawkEye

Status tab.

3

Adjust

HawkEye

Adjust

1

2

Hawkeye Status

Process

Status

Running

5

Large

View

4

100 %

90

80

70

60

50

40

30

20

10

0

The paste level was within the warning region of area: 2

6

Item Description Item Description

1 Adjust HawkEye Button 4 Vision Window

2 Board Representation Window 5 Board Mimic and HawkEye Active Indicator

3 Results Indicator 6 Prompt Bar

A GUIDE TO HAWKEYE

THE USER INTERFACE

6

1700

750

Hawk Eye

Adjust

HawkEye

Button

This button is used to access the adjustable functions that are available during production. If adjustment is not password

controlled,the usercanselect AdjustHawkEyetoamendselected parameterswhilstinthe runmode.When selectedduring

a scan, the printer stops after the current scan and parameters are editable at the next scan phase of the production

sequence. The editable functions are:

• Lighting

• Set Level to Accept

• Verification Start Rate

• Verification Rate

NOTE

Set Level to Accept is not selectable if Adjust HawkEye is selected before a scan has taken place.

In Adjust HawkEye mode the user can select the area representation rectangles to navigate to specific areas to set the lighting or alter the

verification start or verification rates as required. See - HawkEye Setup section of this manual for more details.

Adjust

HawkEye

1700

750

Hawk Eye

A GUIDE TO HAWKEYE

THE USER INTERFACE

7

Board

Representation

Window

The board representation window shows the synthetic representa-

tion of the full board.

There are two ways to input data, either by entering coordinates or

by loading an image file (Bitmap or Gerber).

In Setup mode - Add Area, if entering the co-ordinates, the user

measures locations on the board one-at-a-time for each area to be

scanned and then inputs thesevalues to theinterface. As areas are

added, they are shown as a series of grey bordered rectangles.

Coordinate Data

If asuitable bitmap(.bmp) orextended gerber (.gbx) file isavailable,

the image can be imported directly into the board representation

window. The user can simply add areas for scanning by using this

data as a reference and drawing the borders around the compo-

nents.

Image File

As the user inputs areas to be scanned, the camera moves to the

coordinates and displays the location in the Vision Window. If the

area needs to be adjusted, controls are available to make fine

adjustments to position.

A GUIDE TO HAWKEYE

THE USER INTERFACE

8

1700

750

Hawk Eye

Results

Indicator The results indicator displays information about a highlighted scan area (denoted by a coloured outlined box in the board representation

window).

The print medium indicator (grey bar in the centre of the results indicator) lies between levels of the three coloured bars, this indicates the

print level for the scanned area of the least pasted feature.

The three colour bars are used to indicate:

• Good print level (green bar - print is acceptable)

• Warning level (amber bar - print may be acceptable without

rework)

• Error level (red bar - print level is unacceptable)

The print medium indicator in the centre is used to indicate:

• Percentage print medium (the grey bar bar rises and falls in the

centre of the results indicator and shows the percentage print

medium at each scanned area)

Amber Rectangle

Slight departure

from a ‘good’ print -

may require

attention before

condition becomes

‘Error’.

Grey Rectangle

Area has been set up

but has not been

scanned at this point

in time.

White Inner Rectangle

Denotes the active area

during adjustment.

Green Rectangle

Process in control

- no adjustment

necessary.

Red Rectangle

Error condition.

Operator can take

action to remedy

poor print quality.

Warning Warning

Warning

100 % 100 %

100 %

90 90

90

80 80

80

70 70

70

60 60

60

50 50

50

40 40

40

30 30

30

20 20

20

10 10

10

00

0

Error Error

Error

1700

750

Hawk Eye

A GUIDE TO HAWKEYE

THE USER INTERFACE

9

Print Medium

Indicator The print medium indicator, the grey bar in the centre of the results indicator is an active visual indicator, it represents the value of the print

at the scanned area. If the indicator reaches the green level then no error reporting is necessary as the predetermined safe level of print

has been achieved. In the board representation window, the outline of the area encapsulated is shown green and a blue rectangle within

this area is presented to show that the area has been scanned and the least pasted feature has been determined.

If the indicator falls away to the amber zone, represented by the warning threshold level, the outline rectangle for this area turns amber and

a prompt in the prompt bar states which named area falls within the warning threshold.

If the indicator falls outside the warning level into the error level an alarm is displayed.

In the board representation window, all scanned areas are shown and the display philosophy is repeated with green, amber and red

rectangles surrounding the programmed areas.

Programmed areas that have not yet been scanned during the scan phase of the machine operation are represented by grey bordered

rectangles.

The currently selected area is shown with a white bordered rectangle.

A GUIDE TO HAWKEYE

THE USER INTERFACE

10

1700

750

Hawk Eye

Vision Window During production the user has a visual indication of the status of the current print, the area in the field of view of the camera is shown in the

vision window. The user can select Large View to view enlarged detail.

Vision Window

Split Screen (HawkEye 750 option)

Vision Window Single Screen (HawkEye 1700 option)

Select Stencil View/Board View to change view mode

Large View selected.

Select Reduce View to change view mode

1700

750

Hawk Eye

A GUIDE TO HAWKEYE

THE USER INTERFACE

11

The graphic below is a drawn representation of the board and

screen. In set up mode, the camera field of view (red outlined

rectangle) is superimposed on the board view. In run mode, the

software can ‘paint’ the scanned components with colours repre-

senting threshold levels and it highlights the pad with the least print

medium deposit - shown as a light blue outlined pad.

If Toggle Paste is selected, this turns paste painting on, the varying

levelsofpastedepositcan bequicklydetectedasshowngraphically

below. Paste levels are painted green, amber and red representing

the various paste on pad levels. The pad with the least paste

deposited is surrounded by a blue outlined box. Users can easily

determine if the alarm levels that have been set are true.

With paste painting off, the user can view the print medium on the

pads without the paint overlay. This is useful for determining paste

distribution, anomalies and paste to pad mis-alignment.

Item Description

1 Screen view in setup mode

2 Set up alignment crosshair - used to program area

3 Pad above warning threshold (coloured green)

4 Pad below warning threshold (coloured amber)

5 Pad below error threshold (coloured red)

6 Camera field of view (red outline)

7 Pad with least print medium deposit (outlined blue)

Screen View

Board View

43

7

65

12

A GUIDE TO HAWKEYE

THE USER INTERFACE

12

1700

750

Hawk Eye

Board Mimic

and Active

HawkEye

Indicator

The figure shows the board mimic and HawkEye indicators. The sequence starts with a board entering the machine, this is depicted by the

yellow boardindicator at the left (or right) inroad conveyor. The board enters the printstation, the system carries outa fiducial search routine

and the board is printed (represented by the squeegee travelling over the board in the direction indicated by the white arrow.) The camera

carries out a scan of all the pre-programmed areas, the HawkEye indicator above the board mimic, turns on for the duration of the board

scan. Finally, the board is passed downline. The sequence repeats for the next board.

Prompt Bar The prompt bar indicates the state of various events that are occurring during the differnt stages of production.

The paste level was within the warning region of area: 2

1700

750

Hawk Eye

A GUIDE TO HAWKEYE

HAWKEYE SETUP

13

HAWKEYE SETUP

Setup Overview

Clean Board - Ready

Clean Stencil - Loaded

Machine - Ready to print

Select

Setup Product

Select Load Board -

load the board

Select

Maintenance

Select

Machine Setup

Select Print

and print the

batch

Setup

acceptance

levels for

each area

Load the correct

product file or Create

a New product by

modifying an existing one

Setup fiducials and

confirm alignment

HawkEye

Enable HawkEye

Select Load Image

to load Gerber

or Bitmap Images

(if avaliable)

ENABLED

Select Hawkeye

Select

Add Area

Select

Print Board

Select

Verify Hawkeye

Place the cursor on

the board image

Select Confirm First Corner

Place the cursor on

the board image

Select Confirm Second Corner

Continue adding

areas as required

Warning

100 %

90

80

70

60

50

40

30

20

10

0

Error

Monitor Hawkeye Status

Hawkeye Status

NOTE

Throughout this sequence

some steps have been

omitted e.g. Back buttons.

A GUIDE TO HAWKEYE

HAWKEYE SETUP

14

1700

750

Hawk Eye

The Setup Page

Adding Areas HawkEye provides an instinctive interface for setting up areas to be scanned.

1700

750

Hawk Eye

A GUIDE TO HAWKEYE

HAWKEYE SETUP

15

Setup Using

Coordinates In the setup page select Add Area .

Using the board, measure the location of the first area to be scanned.

NOTE

With the board facing the feed direction (in the example below) the left edge is the datum point for X and the front edge is the datum for Y.

Select Corner X Corner Y. Input the X and Y coordinates to plot the position of the first corner in the top left position of the area.

Select Accept. Using the vision monitor check the crosshairs do not cut component pads but align closely to them. Use the nudge arrows

to adjust position as required. Select Confirm First Corner.

Repeat the above in the bottom right hand corner of the area to create the second corner.

Select Confirm Second Corner.

Repeat this procedure to add other areas into the product file.

Input Coordinates Corner 1

Corner 2

Enter the coordinates of the first corner in

the appropriate parameter panel for X and Y.

Repeat for the second corner to fully

describe the area. Use the vision window

to confirm position.

Corner X

Corner Y

Corner X

Corner Y

30 mm

112 mm

Product Feed DirectionProduct Feed Direction

First

Corner

Second

Corner

X

0

0

Y

A GUIDE TO HAWKEYE

HAWKEYE SETUP

16

1700

750

Hawk Eye

Setup Using

Image Files Selecting the Load Image button opens the file directory page where users can select an image file to load into the board representation

window. Two file types can be loaded, Gerber (.gbx) or Bitmap (.bmp).

A graphical representation of the board is loaded into the board representation window.

Select Add Area.

Place the cursorat the position on the graphic close to the first corner of the area to be scanned. See Image Controls information for details.

Select and confirm the first corner of the area to scan. Repeat the process for the opposite corner, the resultant rectangle is the first area

to be positioned.

Repeat this procedure to add other areas.

Table of contents