Dekker Vmax User manual

Installation

Operation

and

Maintenance

Manual

Oil-sealed

liquid ring vacuum pump systems

SERIAL NO.:___________________________ June, 2006/13

OIL-SEALED LIQUID RING VACUUM PUMP SYSTEMS

TABLE OF CONTENTS

INTRODUCTION 3

Safety 3

STORAGE 3

INSTALLATION 3

Unpacking 3

Lifting 3

Location 3

Mounting 3

Ventilation 4

Electrical preparation 4

Vmax-VFD operational instructions 5

Vmax-VFD value chart 6

Pipe connections and sizing 7

Inlet piping 7

Discharge piping 7

Cooling water piping (water-cooled systems only) 7

THEORY OF OPERATION 8

START-UP PROCEDURES 8

SHUT-DOWN PROCEDURES 10

SEQUENCE OF OPERATION 10

SYSTEM ALARM CONDITIONS 11

MAINTENANCE 11

Bearing lubrication – Pump 11

Bearing lubrication – Motor (where required) 12

Inlet filter 13

Seal fluid 13

Devarnishing 13

Seal fluid strainer 13

Spin-on oil filter (if installed) 14

Separator element 14

Separator element oil return line 14

Mechanical shaft seals 14

MAINTENANCE SCHEDULE 14

ELECTRICAL CONTROLS 15

ACCESSORIES AND PROTECTIVE DEVICES 16

Accessories 16

Protective devices 19

TROUBLE SHOOTING 20

Trouble shooting guide 20

CUSTOMER SERVICE AND INFORMATION 22

Order information 22

WARRANTY POLICY 23

Dekker Vacuum Technologies, Inc. – Vmax/13 2

INTRODUCTION

The Vmax oil-sealed liquid ring vacuum pump system have been designed to give you safe, reliable trouble-free

service, provided some of the basic maintenance guidelines as set out in this manual are followed. Compared

with other vacuum pump systems the Vmax oil-sealed liquid ring vacuum pump system offers the advantages of

no metal-to-metal contact between the impeller and casing. Grease lubricated bearings are mounted external to

the pumping chamber, isolated by mechanical shaft seals. This means that the pump requires no internal

lubrication. However, a vacuum pump is a rotating piece of equipment and operators must exercise good

judgment and follow proper safety procedures to avoid damage to the equipment or personal injury. Please

review and follow all instructions in this manual before attempting to install, start or operate equipment.

Safety

All products offered by DEKKER have been designed and manufactured for safe operation. However, the

responsibility for safe operation rests with those who use and maintain these products. Your safety department

should establish a safety program based on OSHA, federal, state and local codes. It is important that due

consideration be given to hazards which arise from the presence of electrical power, hot liquids, toxic gases and

rotating equipment. Proper installation and care of protective devices is essential to safe system operation. These

safety procedures are to be used in conjunction with the instructions contained in this manual.

STORAGE

Keep the system in a cool dry environment and close the seal fluid isolation valve. Plug all open ports to keep

out dirt and foreign objects. Every 2 - 3 months rotate the impeller by rotating the shaft by hand.

INSTALLATION

The design of the piping system, foundation layout and plant location are the responsibility of the purchaser.

Dekker Vacuum Technologies, Inc. and its representatives may offer advice but cannot assume responsibility for

operation and installation design.

Please consult an authorized dealer or a specialist skilled in the design of plant layout, system piping design and

foundation design. The installer should carefully read this manual before installing the equipment. DEKKER or

your local dealer can provide start up assistance in most instances at reasonable cost.

Unpacking

Upon receipt of pump or system, immediately inspect for signs of damage. Carefully remove packing or

crating from around pump or system. Be sure to keep equipment in upright position. DEKKER products ship

F.O.B. factory, which means that any damage is the responsibility of the carrier and should be reported to them.

Lifting

Lift the equipment carefully and with weight evenly distributed. DEKKER is not responsible for equipment that has

been damaged through mishandling or dropping.

Location

Install the unit in a well ventilated and dust free area. The pump or system should be a minimum distance of 3

feet from surrounding walls to allow for checking fluid level, temperatures, pressures and general servicing.

Mounting

The pump or system must be installed on a level surface in a horizontal position. The foundation must be

designed to support the total unit weight, without any settlement or crushing, be rigid and substantial

enough to absorb any equipment vibration, maintain true alignment with any drive mechanism, and must

permanently support the system baseplate at all points. The vacuum system must be leveled and secured

with foundation bolts. Foundation bolts must be of adequate size to withstand the mechanical stresses

exerted on it.

Systems larger than 40 HP should also be grouted into position. The foundation should be constructed to

allow for ¾ to 1-½ inch of grout. The baseplate is set on shims and the grout is poured between the

foundation and the baseplate. To have the required body to support the baseplate, grout should be at least

¾ inch thick.

The number and location of shims will be determined by the design of the baseplate. Firm support should

be provided at points where weight will be concentrated at the anchor bolt locations. Use enough, and large

enough shims to provide rigid support. Baseplates are usually designed with openings to allow pouring

grout. When the baseplate has been shimmed and leveled and the anchor bolts have been snugly

tightened, a dam is constructed around the foundation to contain the grout. The dam level should be at

least ½ inch above the top surface of the shims. Grout should be poured inside and around the outside of

the baseplate and leveled. Allow the grout to dry for a minimum of 48 hours before tightening the anchor

bolts.

Please note that the pump/motor coupling and V-belt units will need to be realigned prior to start-

up, except with monoblock units.

Dekker Vacuum Technologies, Inc. – Vmax/13 3

Ventilation

Locate the vacuum system in an area with sufficient airflow and accessibility. To prevent excessive

ambient temperature rise it is imperative to provide adequate ventilation. Cooling is an important aspect of

reliable equipment operation and it is therefore important to install the unit in a reasonably cool area where

the temperature does not exceed 110°F (43°C). For higher ambient temperatures contact the factory.

For water-cooled vacuum systems it is necessary to check cooling water supply. A proper, consistent

water flow must be maintained for adequate cooling.

Electrical Preparation

All system wiring is performed at the factory if a control panel is supplied. Check area classification to

ensure all electrical enclosures comply to code. Required customer wiring is minimal, but should be done

by a qualified electrician in compliance with OSHA, National Electric Code and any other applicable local

electrical code concerning switches, fused disconnects, etc. DEKKER includes a wiring diagram in the

control panel for use by the installer. DEKKER recommends that a main disconnect switch be fitted

between the vacuum system and the incoming power.

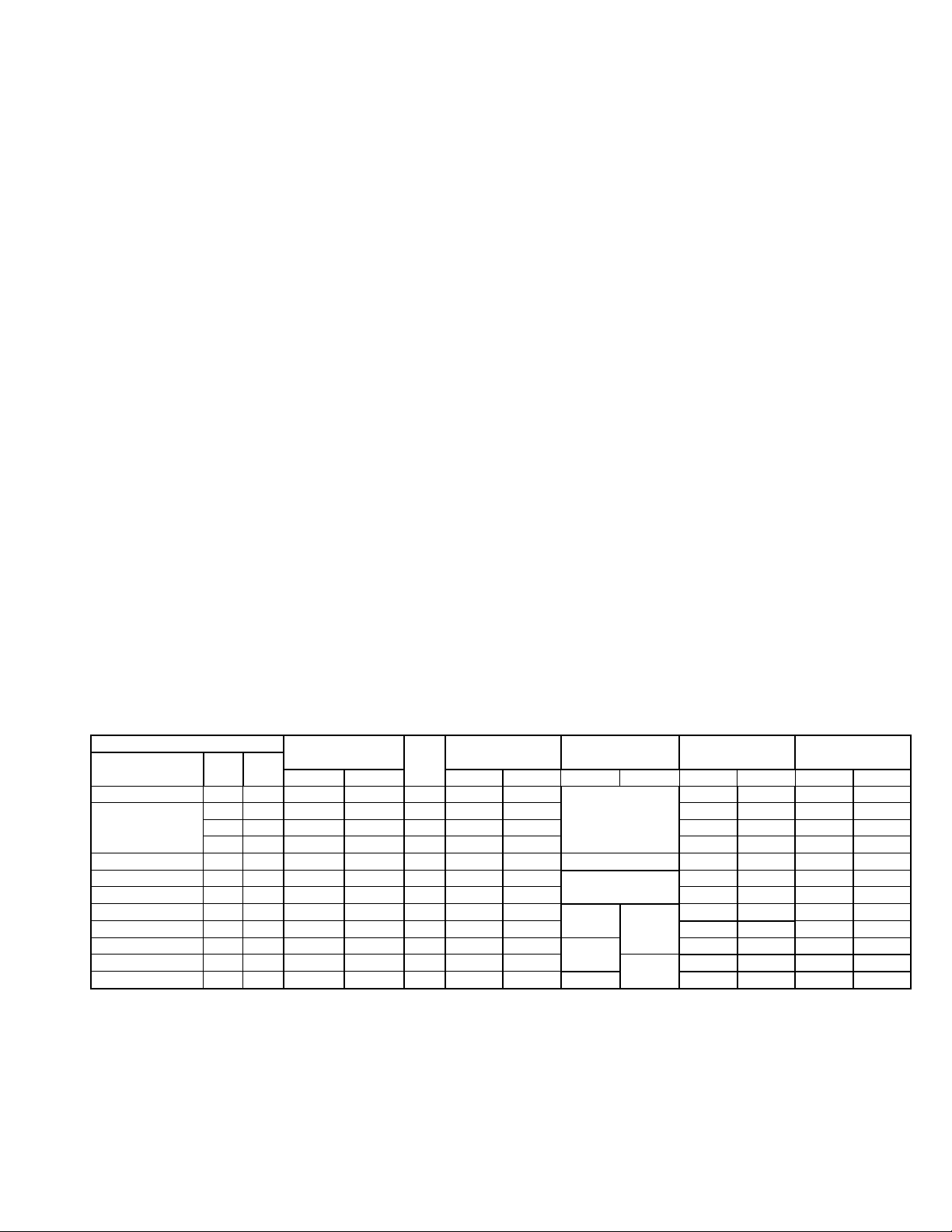

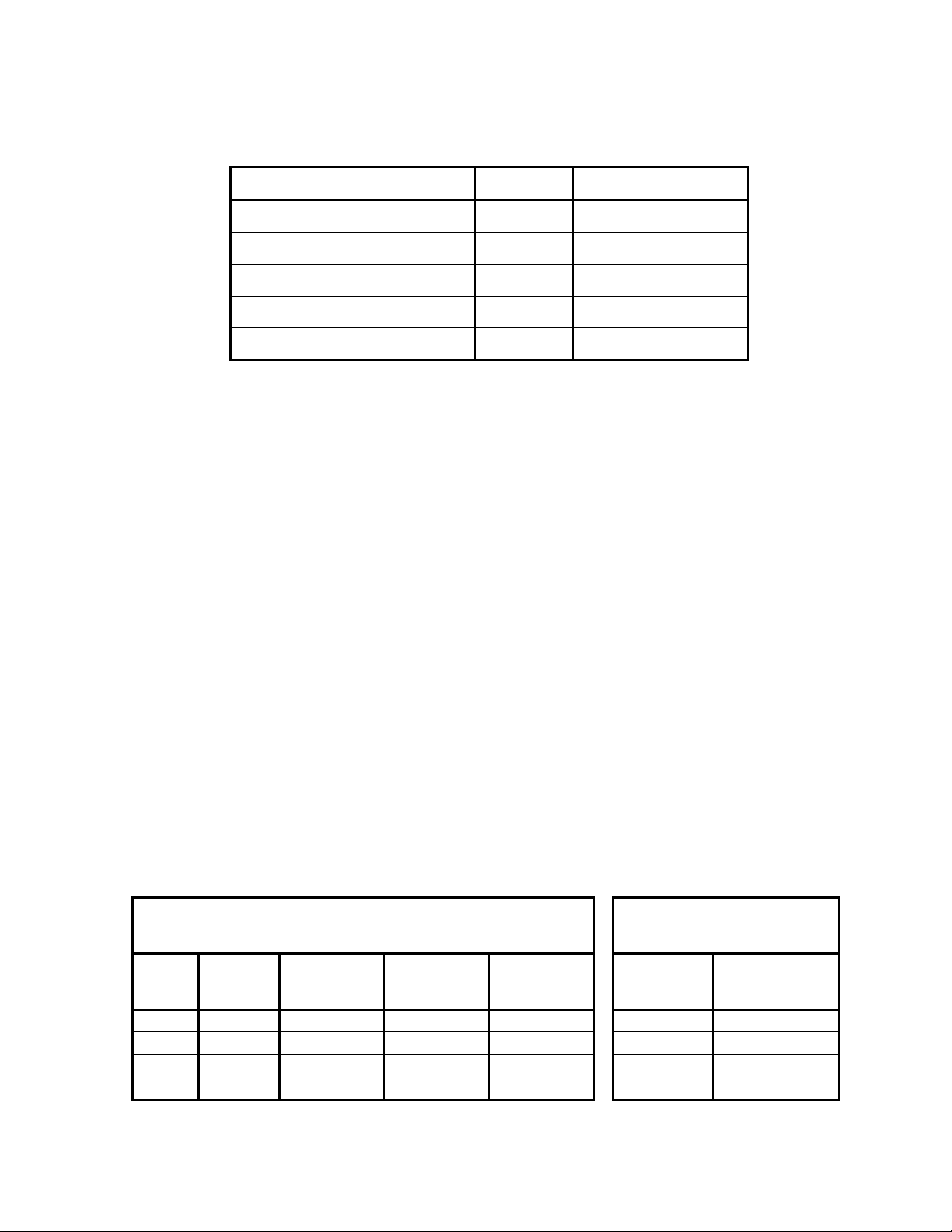

Wire Size Chart

(

AWG

)

b

y

Vmax Horse

p

ower

Recommended Wire Size and Disconnect Size for Vmax S

y

stems

Vmax

System

Serv Full Load Amperage at Volt. Copper AWG (kcmil) Recommended Conduit

Size in Inches Recommended

Disconnect (Amps) Recommended Class

J Fuse

Model No. HP Fact 200V 230V 460V Tol. 200V 230V 460V 200V 230V 460V 200V 230V 460V 200V 230V 460V

VMX0023MA1 1.5 1.15 4.0 2.0 ±13%

VMX0023KA1 1.5 1.15 3.8 1.9 ±10% 15 15 9 5

VMX0036MA1 3 1 7.8 3.9 ±13%

VMX0036KA1 3 1.15 7.2 3.6 ±10%

14

25 15 17.5 8

VMX0063MA1 5 1.15 14.4 7.2 ±13%

VMX0063KA1 5 1.4 13.8 12.0 6.0 ±10%

VMX0083MA1 5 1.15 14.4 7.2 ±13% 40 20 25 15

VMX0083KA1 5 1.4 13.8 12.0 6.0 ±10%

10

40 40 20 30 25 15

VMX0103MA1 7.5 1 18.8 9.4 ±13% 8 60 35 40 20

VMX0103KA1 7.5 1.3 22.0 19.0 9.5 ±10% 10 60 60 35 40 35 20

VMX0153MA1 10 1 24.8 12.4 ±13% 8 60 35 45 25

VMX0153KA1 10 1.28 27.6 24.0 12.0 ±10% 10

1/2"

70 60 35 50 45 25

VMX0203KA1 15 1.3 45.0 39.0 19.5 ±10% 6 3/4" 100 100 60 80 70 35

VMX0303KA1 20 1.25 58.4 50.8 25.4 ±10% 125 110 60 100 90 45

VMX0303KA1-20 20XP 1.15 50.8 25.4 ±10% 4 1”

VMX0453KA1 25 1.3 74.6 62.0 31.0 ±10%

VMX0453KA1-20 25XP 1.15 83.0 72.2 36.1 ±10% 2 1-1/4”

150 150 70 125 110 60

VMX0553KA1 40 1.3 114.0 99.0 49.5 ±10% 00 4 1-1/4” 1” 200 200 100 200 175 90

VMX0553KA1-20 40XP 1.15 142.3 123.4 61.9 ±10%

VMX0753KA1 50 1.28 142.3 123.8 61.9 ±10% 4 1” 250 225 150 250 200 100

VMX1003KA1 60 1.15 169.7 146.8 73.4 ±10%

000 00

2

2” 1-1/4”

300 250 150 300 250 125

VMX1103KA1 75 1.15 200.0 174.0 87.0 ±10% 250 0000 2 350 300 150 350 300 150

VMX1203KA1 100 1.15 266.8 232.0 116.0 ±10% 400 350 0

2-1/2”

1-

1/2

” 450 400 200 450 400 200

NOTES: 1. Based on no more than three single insulated conductors rated 0-2000 volts.

2. Conduit sizes shown does include ground conductor if required (over 60 amperes).

3. Wire sizes are based on THHN 75 deg. C rated conductors.

4. Approved trade size conduit or metal tubing.

5. Motors with voltage tolerance of +/-13% have a voltage range of 200-260V, and 400-520V. Use the disconnect and fuse corresponding to the 230V or 460V range

6. Above information is general information. Please confirm actual motor full load amperage before proceeding.

After the electrical wiring connections are completed, check the incoming voltage to make sure that the incoming

voltage is the same as the vacuum system voltage. Line voltage should be within the voltage tolerance as

specified on the motor. Check the system for proper motor rotation. The direction of rotation is always clockwise

when looking at the shaft of the pump and is marked by an arrow on the motor or pump housing. Jog the motor

by pressing the START button, and then the STOP button. If the rotation is incorrect switch any two of the three

main power leads on the contactor inside the control panel. Failure to do so could result in serious equipment

damage.

WARNING: Install, ground, and maintain equipment in accordance with the National Electrical Code

and all applicable federal, state and local codes.

WARNING: For NFPA 99 hospital and generator applications: please shut down the vacuum pumps

prior to generator testing. The rapid stop and restart may cause damage to the pump and/or motor.

Dekker Vacuum Technologies, Inc. – Vmax/13 4

Vmax-VFD Operational Instructions

Some systems are equipped with a Variable Frequency Drive (VFD) with an Operator Interface Module

(OIM) remote keypad.

Following are brief general instructions and charts. Please refer to Vmax-VFD system-specific

operation instructions included with each Vmax-VFD system.

On systems with a VFD, remember to open the seal fluid valve located under the separator tank before

startup. Upon power up of the system, the VFD will go thru an initial self-check, and the remote OIM will

display the main menu.

There are two custom windows that will display on the OIM (Operator Interface Module) screen by pressing

the ESC/PROG button on the keypad. The first screen shows three items, the first item is total run hours

that the motor has run, second is Torr set point (vacuum level set point) and finally Torr feed back (vacuum

level pump is at) (Torr (mmHg) = 760 – (“HgV x 25.4). When you press F3 again, the second screen shows

HP (horse power), AMPS, and Hz (Hertz). Pressing F3 again will bring you back to the first display screen.

The High Temperature light will be on. You must push the Alarm Condition Reset button before you can

place the system in the required mode of operation.

In Manual Mode, the system will run at a constant RPM. In Auto Mode, the system will monitor a set point

that the operator sets. The vacuum set point for the system is achieved by using the Operator Interface

Module (OIM) on the front door of the control panel (some models may have the OIM inside the front door

of the panel). Using the up and down arrows on the keypad, a window will pop up displaying the (% OIM

Ref). By pressing the up or down arrow key, the % value will increase or decrease to the required

percentage of the transducer output signal (preset to 26.33% = 22” HgV).

The VFD chart on the next page gives you the % VFD value that is associated with the transducer voltage

which then correlates to a vacuum level. The VFD will maintain the vacuum level at the set point by

increasing or decreasing the RPM of the motor. To verify whether the VFD is in Auto or Manual mode, look

in the upper right-hand corner of the screen. If it is in Manual mode it will display Man, and if it is in Auto

mode it will display Auto. To change the desired mode, press the F1 button in the main menu screen.

All system wiring is performed at the factory. Check area classification to ensure all electrical enclosures

comply to code. Required customer wiring is minimal, but should be done by a qualified electrician in

compliance with OSHA, National Electric Code and any other applicable local electrical code concerning

switches, fused disconnects, etc. DEKKER includes a wiring diagram in the control panel for use by the

installer. DEKKER recommends that a main disconnect switch be fitted between the vacuum system and

the incoming power.

Wire Size Chart

(

AWG

)

b

y

Vmax-

V

FD Horse

p

ower

Recommended Wire Size and Disconnect Size for Vmax-

V

FD S

y

stems

Vmax-VFD

System Serv.

Full Load Amperage at Volt. Copper AWG (kcmil) Recommended

Conduit Size in Inches Recommended

Disconnect (Amps) Recommended Class

J Fuse (Amps)

Model No. HP Fact. 230V 460V Tol. 230V 460V 230V 460V 230V 460V 230V 460V

VMX-VFD0063KA1 5 1.0 12.0 6.0 ±10% 12 16 20 15 15 10

VMX-VFD0083KA1 5 1.0 12.0 6.0 ±10% 12 16 20 15 15 10

VMX-VFD0103KA1 7.5 1.0 19.0 9.5 ±10% 10 14 30 20 25 15

VMX-VFD0153KA1 10 1.0 24.0 12.0 ±10% 10 12

½”

35 25 30 20

VMX-VFD0203KA1 15 1.0 39.0 19.5 ±10% 8 10 ¾” 60 30 50 25

VMX-VFD0303KA1 20 1.0 50.8 25.4 ±10% 6 10 60 35 60 30

VMX-VFD0453KA1 25 1.0 62.0 31.0 ±10% 4 8 1” 80 40 70 35

VMX-VFD0553KA1 40 1.0 99.0 49.5 ±10% 1 6 125 70 125 60

VMX-VFD0753KA1 50 1.0 123.0 61.9 ±10% 1/0 4 1-1/4” 150 80 150 70

VMX-VFD1003KA1 60 1.0 146.8 73.4 ±10% 2/0 4

1” 200 100 175 90

VMX-VFD1103KA1 75 1.0 174.0 87.0 ±10% 3/0 2 2” 200 100 200 100

VMX-VFD1203KA1 100 1.0 232.0 116.0 ±10% 250 1 2-1/2” 1-1/4” 250 150 250 125

NOTES: 1. Based on no more than three single insulated conductors rated 0-2000 volts.

2. Conduit sizes shown does include ground conductor if required (over 60 amperes).

3. Wire sizes are based on THHN 75 deg. C rated conductors.

4. Approved trade size conduit or metal tubing.

5. Use the disconnect and fuse corresponding to the 230V or 460V range

6. Above information is general information. Please confirm actual motor full load amperage before proceeding.

Dekker Vacuum Technologies, Inc. – Vmax/13 5

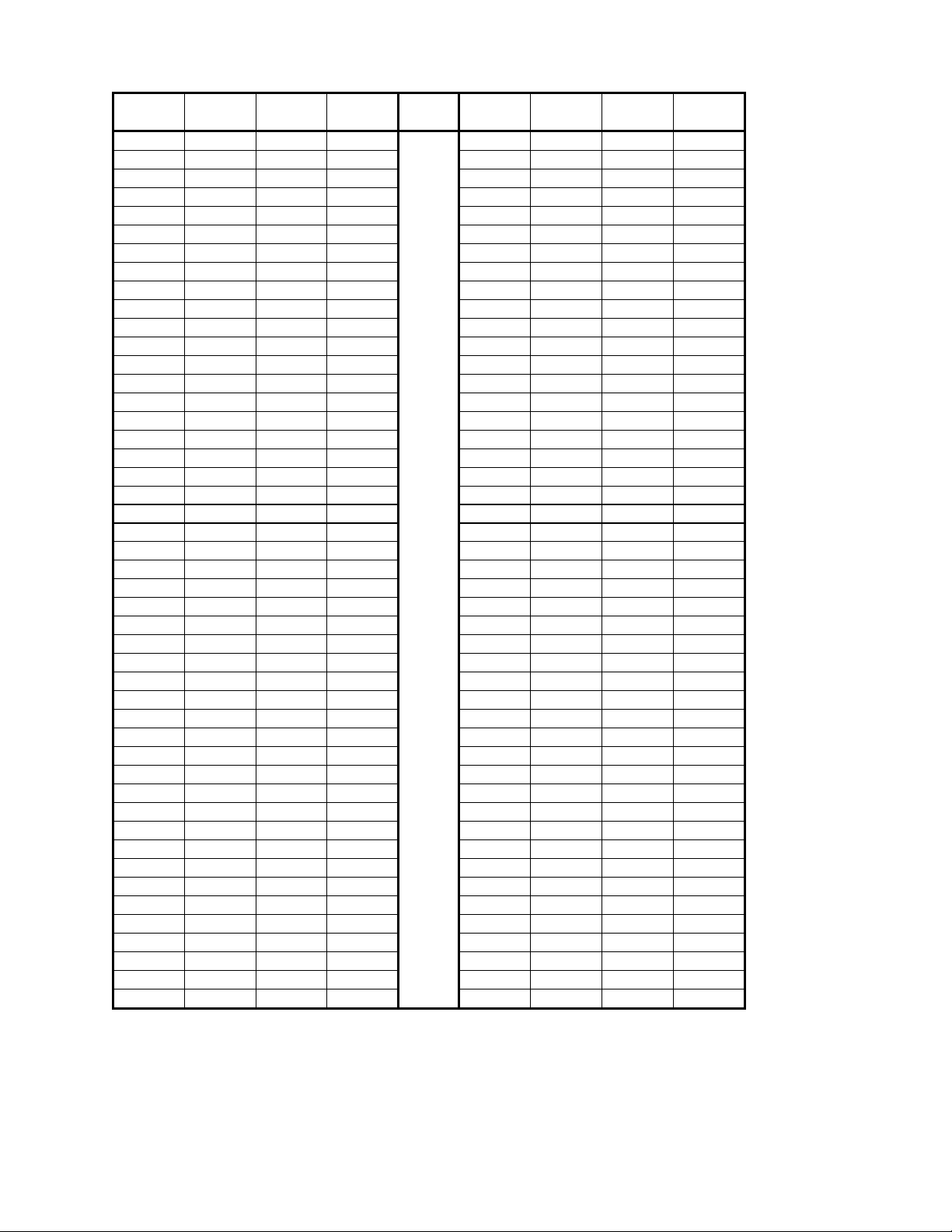

V

FD value , transducer voltage and vacuum level chart

VFD

Value %

Transd.

Voltage Vac.lvl.

Torr Vac.lvl.

"HgV VFD

Value % Transd.

Voltage Vac.lvl.

Torr Vac.lvl.

"HgV

10.00 1.00 0.00 29.92 56.00 5.60 349.60 16.16

11.00 1.10 7.60 29.62 57.00 5.70 357.20 15.86

12.00 1.20 15.20 29.32 58.00 5.80 364.80 15.56

13.00 1.30 22.80 29.02 59.00 5.90 372.40 15.26

14.00 1.40 30.40 28.72 60.00 6.00 380.00 14.96

15.00 1.50 38.00 28.42 61.00 6.10 387.60 14.66

16.00 1.60 45.60 28.12 62.00 6.20 395.20 14.36

17.00 1.70 53.20 27.83 63.00 6.30 402.80 14.06

18.00 1.80 60.80 27.53 64.00 6.40 410.40 13.76

19.00 1.90 68.40 27.23 65.00 6.50 418.00 13.46

20.00 2.00 76.00 26.93 66.00 6.60 425.60 13.16

21.00 2.10 83.60 26.63 67.00 6.70 433.20 12.87

22.00 2.20 91.20 26.33 68.00 6.80 440.80 12.57

23.00 2.30 98.80 26.03 69.00 6.90 448.40 12.27

24.00 2.40 106.40 25.73 70.00 7.00 456.00 11.97

25.00 2.50 114.00 25.43 71.00 7.10 463.60 11.67

26.00 2.60 121.60 25.13 72.00 7.20 471.20 11.37

27.00 2.70 129.20 24.83 73.00 7.30 478.80 11.07

28.00 2.80 136.80 24.53 74.00 7.40 486.40 10.77

29.00 2.90 144.40 24.24 75.00 7.50 494.00 10.47

30.00 3.00 152.00 23.94 76.00 7.60 501.60 10.17

31.00 3.10 159.60 23.64 77.00 7.70 509.20 9.87

32.00 3.20 167.20 23.34 78.00 7.80 516.80 9.57

33.00 3.30 174.80 23.04 79.00 7.90 524.40 9.28

34.00 3.40 182.40 22.74 80.00 8.00 532.00 8.98

35.00 3.50 190.00 22.44 81.00 8.10 539.60 8.68

36.00 3.60 197.60 22.14 82.00 8.20 547.20 8.38

37.00 3.70 205.20 21.84 83.00 8.30 554.80 8.08

38.00 3.80 212.80 21.54 84.00 8.40 562.40 7.78

39.00 3.90 220.40 21.24 85.00 8.50 570.00 7.48

40.00 4.00 228.00 20.94 86.00 8.60 577.60 7.18

41.00 4.10 235.60 20.64 87.00 8.70 585.20 6.88

42.00 4.20 243.20 20.35 88.00 8.80 592.80 6.58

43.00 4.30 250.80 20.05 89.00 8.90 600.40 6.28

44.00 4.40 258.40 19.75 90.00 9.00 608.00 5.98

45.00 4.50 266.00 19.45 91.00 9.10 615.60 5.68

46.00 4.60 273.60 19.15 92.00 9.20 623.20 5.39

47.00 4.70 281.20 18.85 93.00 9.30 630.80 5.09

48.00 4.80 288.80 18.55 94.00 9.40 638.40 4.79

49.00 4.90 296.40 18.25 95.00 9.50 646.00 4.49

50.00 5.00 304.00 17.95 96.00 9.60 653.60 4.19

51.00 5.10 311.60 17.65 97.00 9.70 661.20 3.89

52.00 5.20 319.20 17.35 98.00 9.80 668.80 3.59

53.00 5.30 326.80 17.05 99.00 9.90 676.40 3.29

54.00 5.40 334.40 16.76 100.00 10.00 684.00 2.99

55.00 5.50 342.00 16.46

Dekker Vacuum Technologies, Inc. – Vmax/13 6

Pipe Connections and Sizing

Before installation, remove all protective inserts on the pump suction and discharge. Piping connected to

the system must be installed without imposing any strain on the system components. Improperly installed

piping can result in misalignment, general operating problems and pump failure. Use flexible connectors

where necessary. Piping must be cleaned of debris before installation.

Inlet Piping

Note: Install a temporary screen at the pump inlet flange at first start-up to protect the unit against

carry over of pipe debris and welding slag. The screen must be removed after the initial run in

period.

Inlet piping should be at least the size of the pump inlet. Install the system as close as possible to the

process to minimize losses due to the length of the suction line. If the system has to be installed further

away from the process, be sure that the inlet piping is oversized accordingly to minimize the overall line

pressure drop. For more information consult your dealer or call the factory.

Pump systems operating in parallel on a common manifold must each have a manual or automatic shut-off

valve and a suitable check valve installed in the suction line close to the pump suction flange. This allows

each individual system to be isolated when it is not in operation. The line size of the manifold should be a

minimum equal to the sum of the individual system pipe areas.

Vmax systems are supplied with an inlet check valve as standard. This valve provides a minimum of

resistance close to the pump suction flange to prevent back flow of process gas and seal fluid when the

pump is stopped.

If the inlet gas pumped contains dust or foreign particles, a suitable 10 micron (or finer) inlet filter should be

installed at the inlet port

If the possibility exists that the pump inlet can become closed during operation it will be essential to install

some type of vacuum relief valve (anti-cavitation valve) so that air can enter the pump inlet. Never run a

pump with a closed suction, which causes cavitation and will damage the pump.

Discharge Piping

Discharge piping should be at least the size of the separator discharge. Do not discharge the exhaust

gases from the pump system into the area where the system is installed. Vapors pulled over from the

process could be hazardous. Install an exhaust line of at least the same diameter as the discharge

connection on top of the separator reservoir leading outside. Install a dripleg with tee on the discharge line

to prevent condensables from draining back into the separator reservoir. See the “Discharge piping

diagram” on the next page.

For pump systems operating in parallel on a common discharge, we recommend the installation of a

suitable check valve close to the separator discharge flange of each unit. When discharging more than one

pump in a common discharge line and/or over a long distance, oversize pipe accordingly.

Discharge piping diagrams

Cooling water piping (water cooled systems only)

Water-cooled systems require an adequate supply of cooling water at a maximum of 85°F and a minimum

supply pressure of 20 psig. If the cooling water temperature is higher or available pressure lower, consult

your dealer or call the factory.

The cooling water outlet connection of the heat exchanger may be fitted with an optional automatic

temperature control valve, which regulates the cooling water flow rate depending on pump operating

temperature. The valve is preset at the factory. To raise the system operating temperature, turn the valve-

adjusting screw counter-clockwise. To lower operating temperature, turn clockwise. Normal system

operating temperature is between 140° - 185° F. The valve will only open when the system operating

temperature is reached.

Dekker Vacuum Technologies, Inc. – Vmax/13 7

THEORY OF OPERATION

The DEKKER Vmax oil-sealed liquid ring vacuum pump system includes our high efficiency liquid ring

vacuum pump. The liquid ring vacuum pump is known for its simplicity in design and low maintenance

requirements, due to the absence of wearing parts such as pistons, sliding vanes and internal bearings.

The impeller assembly is the only moving part, which rotates freely in the casing without metal-to-metal

contact. This means that no internal lubrication is required. The function of the sealing liquid is to create a

liquid piston action used to produce vacuum and to remove the heat of compression. The seal fluid in the

system circulates in a closed loop passing through an air- or water-cooled heat exchanger that removes the

heat of compression. The discharge separator/reservoir holds the seal fluid and incorporates the DEKKER

patented high-efficiency separator arrangement to separate the seal fluid from the air or gases discharged

by the pump. See “Piping and Instrument Diagram” of the Vmax oil-sealed liquid ring vacuum pump system

below.

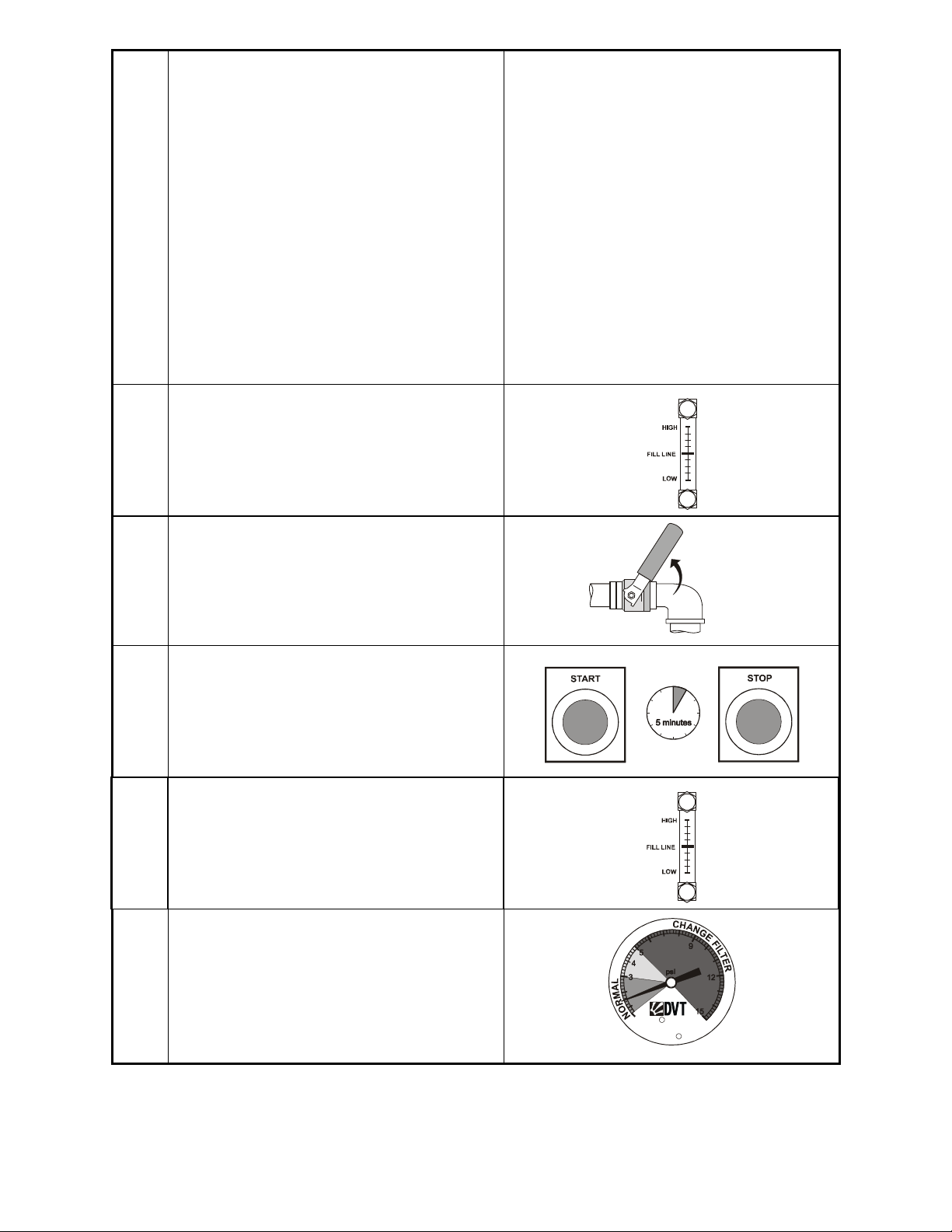

START UP PROCEDURES

1 Ensure seal fluid isolation valve is open. This

valve is located below the separator and/or

before the strainer.

2 Jog the motor briefly and check direction of

rotation. The correct direction of rotation is

marked by an arrow on the motor or pump

housing. If direction is incorrect switch any

two of the three leads at the power

connection. The correct direction of rotation is

clockwise facing the pump from the drive end

and counter-clockwise if viewed from the non-

drive end.

3A Check drive coupling alignment. Angular

alignment should be within .035” - .175”.

Parallel alignment should be within .010” -

.025”. Consult the factory for specific system

size alignment. Mono-block units do not

require any field adjustment (motors are C-

face mounted).

Dekker Vacuum Technologies, Inc. – Vmax/13 8

3B For units utilizing V-belt drives, make sure the

sheaves are properly installed and aligned

before attempting to tension the drive. The V-

belts should be placed over the sheaves and

in the grooves without forcing them over the

sides of the grooves. The tensioning steps 1,

2, 3 and 4 can be used for all types of V-

belts, all cross sections and number of belts

and all types of construction.

Avoid excessive heat (140oF and higher);

belt life will be shortened. Never switch or

mix belts from one groove to another on the

sheaves. Do not use belt dressing. Sheaves

should remain free of oil and grease. When

replacing belts install an identical set.

For more specific V-belt tensioning guidelines

consult factory.

1. With all belts in their grooves, adjust

centers to take up the slack until they are

fairly taut. Use standard V-belt tensioning

guidelines.

2. Start the drive and continue to adjust until

the belts have only a slight bow on the

slack side while operating with load

conditions.

3. After several days of operation, the belts

will seat themselves in the sheave

grooves. Further tensioning may be

necessary to the point that the drive

shows a slight bow in the slack side.

Insufficient tension is often evidenced by

slipping (squealing) at start-up.

4. If the unit is idle for an extended period of

time, the tension on the belts should be

removed.

4 Check fluid level in separator reservoir. The

fluid level should be at the FILL LINE on the

sight gauge. Add oil if necessary.

5 If your system contains an inlet valve, set it to

approximately 3/4 closed, and start pump. If

valve is not supplied, one should be installed.

6 Run the pump for a few minutes, then turn it

off.

7 With the pump shut off, check fluid level

again. The fluid level should be at the FILL

LINE on the sight gauge. Add fluid if

necessary.

Warning: never remove the oil fill plug

while the pump is running.

8 Start pump again and check that discharge

pressure on the separator pressure gauge

does not exceed 2 psig when operating under

vacuum conditions. A pressure higher than 2

psig is a sign of high back-pressure in the

discharge pipe system. Pressure gauge might

show a higher pressure at start-up at low

vacuum (0-10" Hg).

Dekker Vacuum Technologies, Inc. – Vmax/13 9

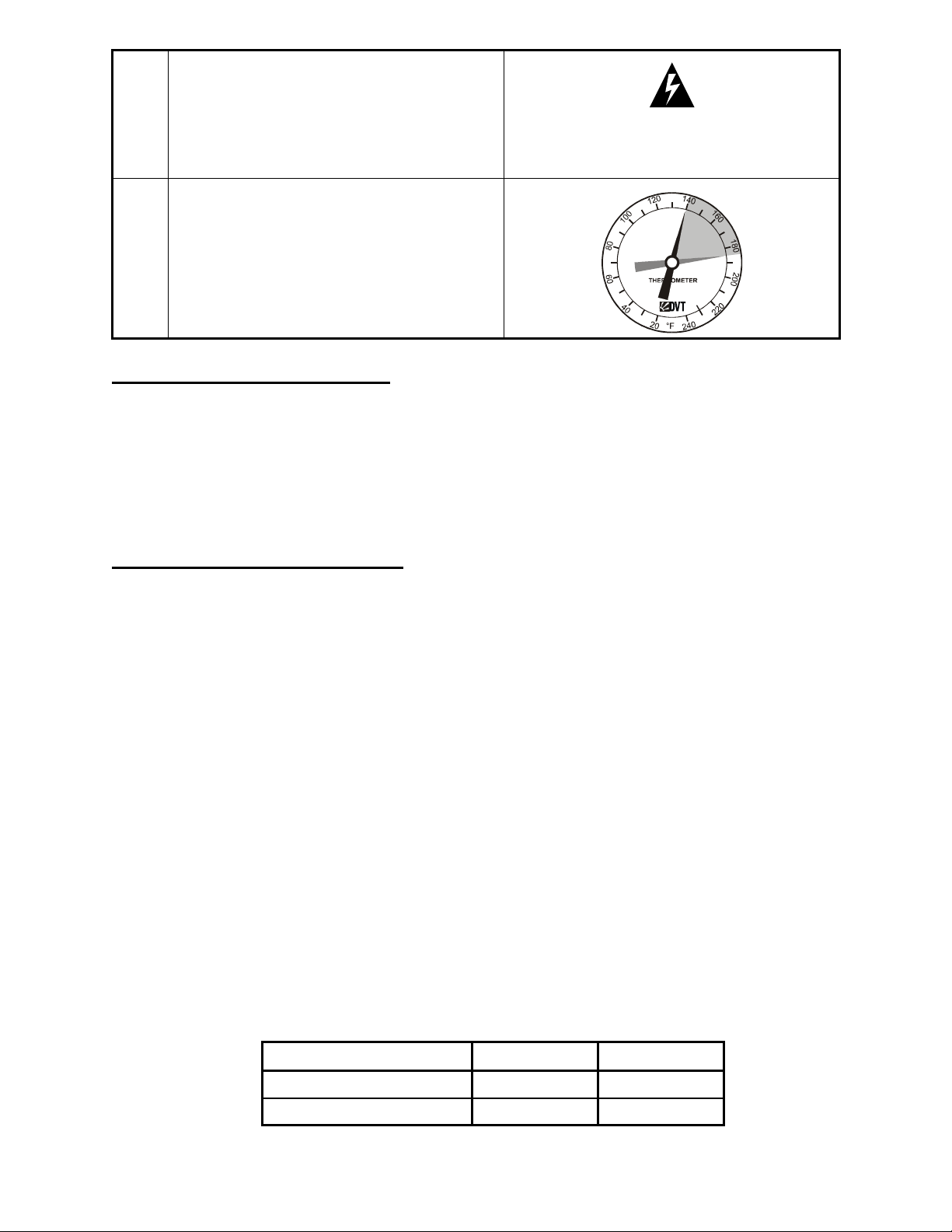

9 Check the voltage and motor current, they

should be within the specifications for the

motor. Standard motors have a 1.15 S.F.

(Service Factor).

Note: This test should also be performed

under normal system operating conditions.

DANGER: HIGH VOLTAGE!

Lethal shock hazard present.

USE EXTREME CAUTION!

10 After 15-30 minutes of operation, check pump

operating temperature, which should be in the

140° to 185° F range. Some smaller units may

run cooler.

SHUT DOWN PROCEDURE

To stop the pump system follow the procedure as lined out below.

Push the STOP button, or turn switch to the OFF position. The inlet check valve will prevent fluid from the

system being sucked back into the inlet manifold.

Note: If inlet piping could be under vacuum for an extended period of time without the pump

running, inlet piping should be vented to atmosphere.

Note: Close the seal fluid isolation valve and the pump inlet isolation valve during extended periods

of storage or when transporting. Open valves before starting system.

SEQUENCE OF OPERATION

The following sequence of operation is a description of how the Vmax oil-sealed vacuum pump system

should operate. The description is general to cover simplex to multiplex (more than one pump) systems. It

is assumed that all start-up procedures have been followed. Ensure that pump reservoirs are filled with oil

(See “Start-up Procedures”, page 5). Make sure that the seal fluid isolation valve is in the open position. If

unsure about the function of one of the electrical controls mentioned below, see the "Electrical Controls"

section (page 10) for a description of the component. If any of the below do not occur, see the "Trouble-

shooting " section (page 12).

Once the power connection to the system has been made, the following should occur:

♦If disconnects or circuit breakers are installed on the control panel, and are turned to the ON position,

the system will be energized. If POWER ON indicating lights are installed on the panel, the lights will be

illuminated.

♦If any other lights are illuminated, see the "Trouble-shooting" section (page 12).

♦If HAND-OFF-AUTO selector switches are installed and are turned to the HAND mode, the pump(s) will

immediately start. If PUMP ON light(s) are installed on the panel, they should light up to indicate pump

operation. We suggest that each pump be tested ("bump started") in the HAND mode initially to check

rotation of the pump. When facing the drive end of the pump, the correct rotation is clockwise. When in

HAND mode, the pumps will run continuously unless an alarm condition is triggered. If such a condition

occurs, see the "Trouble-shooting " section.

♦When the HAND-OFF-AUTO selector switch is placed in the AUTO mode, the pumps will operate from

vacuum switches (if installed). In multiplex pump systems, each vacuum switch is set with a differential

as well as an offset relative to the next switch. The switches should not be set identically. The

differential is usually between 3 to 6” Hg. For details on setting the vacuum switches, see the

“Accessories and Protective Devices” section on page 11. Below is an example for a duplex system.

The differential for each switch is 4"Hg, the offset between the two switches is 2"Hg.

PUMP PUMP ON PUMP OFF

Pump 1 (lead pump) @ 21"Hg @ 25"Hg

Pump 2 (lag pump) @ 19"Hg @ 23"Hg

Dekker Vacuum Technologies, Inc. – Vmax/13 10

♦The switches are set in this manner so that if pump 1 (lead pump) cannot satisfy demand and the

vacuum level drops below 21"Hg, the lag pump (2) will start-up when the vacuum level reaches 19"Hg

and stops at 23” Hg.

♦All multiplex systems are supplied with "Automatic alternation" and "Frequent stop/start protection"

unless otherwise specified.

♦"Automatic alternation" allows the pumps to operate equally (even run time) by alternating each pump

whenever the pump(s) shut down. When alternation occurs, the "lead" pump becomes the "lag" pump

and the "lag" pump becomes the "lead" pump.

♦"Frequent stop/start protection" is used to allow the pump(s) to operate a minimum amount of time.

The time period is factory-set at 10 minutes. This allows the pump(s) to warm up and eliminate frequent

starting of the pump(s) which can cause premature coupling failure and breakdown of electrical

components. The pump(s) will continue to operate after the vacuum level has been satisfied. If the

possibility exists that the pump could work with a closed suction, a relief valve must be installed to

prevent cavitation.

♦If the pump(s) are not alternating and/or are frequent starting, one of the electrical components may be

defective. Contact the factory for more information.

SYSTEM ALARM CONDITIONS

The following is a description of how alarm conditions will affect the operation of the system.

♦If a "Lag pump in operation" alarm is installed in the panel, observe the following. Such an alarm is

usually only supplied with medical packages. The alarm consists of a warning light and an audible

alarm. The alarm will trigger when the "lag" pump starts up. The alarm will not affect the operation of

the system. The light will illuminate and the alarm will sound. The audible alarm can only be silenced by

physically (or remotely) pushing the ALARM SILENCE button. This will not stop the LAG PUMP ON

light from illuminating. The light can be reset by physically (or remotely) pressing the ALARM RESET

button.

Note: If the lag pump is still operating when the ALARM SILENCE or ALARM RESET buttons are

pressed, the alarm will continue to sound. The alarm will only reset if the lag pump is not running.

♦"Transformer failure" light (optional). Only installed if more than one control voltage transformer is

supplied. If the TRANSFORMER FAILURE light is illuminated, one of the transformers has

malfunctioned and the second one has picked up. As long as a back-up transformer is available, the

above alarm will not affect the operation of the system. If both transformers fail, the system will shut

down.

♦"High temperature" light. If the HIGH TEMPERATURE light illuminates, the affected pump will shut

down unless otherwise specified at time of purchase of the equipment. The back-up pump(s) will

continue to operate unless a high temperature (or other) alarm occurs in those pump(s).

♦"Low level" light (optional). If the LOW OIL LEVEL light is illuminated, the affected pump will shut

down. The back-up pump(s) will continue to operate unless a similar condition occurs in those pump(s).

MAINTENANCE

As you proceed in reading this section, it will become clear that the “Maintenance Schedule” for DVT Vmax

oil-sealed liquid ring vacuum pump systems is quite minimal. The use of the service gauges will alert you

when service is required.

WARNING: Before attempting any maintenance such as changing the fluid, disconnect all power

from the system by switching off the main breaker or disconnect switch. This will prevent the

system from automatically starting from a vacuum switch.

Bearing Lubrication - Pump

The .25 – 20 HP Titan-series single-stage liquid ring vacuum pumps are installed with sealed bearings that

require no field lubrication.

The 25 – 40 HP Titan-series single-stage liquid ring vacuum pumps which are belt-driven, the 50 – 100 HP

Titan-series single-stage pumps and the 2 – 60 HP two-stage Titan-series pumps require lubricating every

3000 hours. Extreme operating conditions may require more frequent lubricating. Grease fittings are

located on the top of each bearing housing.

For Titan-series two-stage pumps 100 HP and up, please consult Factory.

Dekker Vacuum Technologies, Inc. – Vmax/13 11

The Maxima-K series of large capacity single-stage liquid ring vacuum pumps require lubricating every

1500 hours of operation. Grease fittings are located on the top of each bearing housing.

Use a good quality high temperature lithium based grease of #2 consistency. Typical products are Texaco

Premium RB and Chevron SR1 #2.

Pump bearing lubricating schedule

Pump type Pump HP Greasing schedule

Titan-series single-stage .25 - 20 none required

Titan-series single-stage 25 – 100 every 3000 hours

Titan-series two-stage 2 – 60 every 3000 hours

Titan-series two-stage 100 - up consult factory

Maxima-K-series large capacity 50 - up every 1500 hours

Bearing Lubrication – Motor (where required)

The motors are shipped from the factory with the bearings properly packed with grease. During extended

storage of 6 months or greater, the ball-bearings should be re-lubricated prior to starting with a good quality

high temperature lithium based grease of #2 consistency. Typical products are Texaco Premium RB and

Chevron SR1 #2. Roller-bearings (V-belt drive systems) use the Texaco Premium RB or Chevron Black

Pearl EP #2.

The bearings may be lubricated with the motor running or stationary. Stationary with the motor warm is

preferred. Locate the grease inlets – there is one on each end of the motor.

Note: This is generally the case with domestic motors. European motors use sealed bearings and

do not require lubrication. Consult Factory with any questions.

Clean the area and replace the pipe plug with a grease fitting as generally they are not equipped with a

grease fitting. Remove the grease drain plug, located at the lower portion of each motor face (typically a

plastic plug), and loosen any hardened grease that may block the drain. Add the recommended volume of

the previously described grease using a hand operated grease gun. Run the motor for two hours. Replace

the pipe plug in grease drain.

Mixing of lubricants is not recommended due to possible incompatibility. Signs of incompatibility are

extreme soupiness from the grease relief drain or from the shaft opening. If changing a lubricant, grease

and then re-grease after 100 hours of service.

Frequency/volume of greasing is based on service conditions, speed and frame size. See table below.

Standard conditions: 8 hour day operation, normal or light loading, clean environment at a 100 ºF

maximum ambient temperature.

Severe conditions: 24 hour operation or shock loading, vibration, dirty or dusty environment, running at a

100 ºF to 120 ºF ambient temperature.

Extreme conditions: heavy shock, vibration, or dust.

See table below for lubricating details.

Motor bearing lubricating schedule

Lubrication Frequency – Ball Bearings

Roller bearings – divide time by 2

Lubrication

Volume

NEMA VolumeSpeed

(RPM)

NEMA

Frame

Standard

Conditions

Severe

Conditions

Extreme

Conditions Frame (Cubic inches)

1800 182-215 3 years 1 year 6 months 182-215 0.5

1800 254-365 2 years 6-12 months 3 months 254-286 1.0

1800 404-449 1 year 6 months 1-3 months 324-365 1.5

3600 ALL 6 months 3 months 1 month 404-449 2.5

Dekker Vacuum Technologies, Inc. – Vmax/13 12

Inlet Filter (if installed)

Check after first 8 hours of operation. Clean or replace inlet filter element every 1000 to 3000 hours

depending on application or if excessive pressure drop is noticed. In some applications it may be

necessary to clean inlet filter more often.

CAUTION: Be careful not to allow accumulated foreign material to fall in the pump suction opening

when removing the filter cartridge. Horizontal filter installation is recommended to prevent this.

Filters must be disposed of properly as they might contain toxic substances carried over from the

process.

Seal Fluid

The system(s) are shipped with our especially formulated Vmaxol seal fluid. These fluids are specifically

designed for use in our Vmax systems, providing low viscosity, excellent water separating qualities, anti-

foaming and low oxidation. We recommend that our Vmaxol sealing fluids be used for obtaining ultimate

performance from your Vmax vacuum pump system and to guarantee the extended 3-year warranty period.

Container

Size

Standard

Vmaxol

(10,000 hours of operation)

Synthetic/Food grade

Long-life Vmaxol

(15,000 hours of operation)

5 Gallon Container 5220-0050-000 5220-0050-001

55 Gallon Drum 5220-0550-000 5220-0550-001

Material Safety Data Sheets available upon request

When using Standard Vmaxol it is recommended that the seal fluid be changed every 10,000 hours of

operation or once a year, whichever comes first. When using Synthetic/Food grade Long-life Vmaxol,

seal fluid may be changed every 15,000 hours of operation or once a year, whichever comes first. Extreme

operating conditions may require more frequent changes.

To change the fluid, first make sure there is no power to the system and the pump is off. Drain the fluid

reservoir, vacuum pump and heat exchanger using the drain valves. We recommend that the fluid be

changed when the system is at operating temperature.

When charging the system with new fluid, make sure that the pump is filled with oil to the shaft centerline

level. Do not fill the pump above the shaft centerline. Starting the pump with oil level above the shaft

centerline may result in shaft or impeller damage or failure. You can add oil by removing the suction or

discharge flange and pouring oil through pump suction or discharge port.

Fill the reservoir to the FILL LINE on the sight gauge. Open the air bleed valve on the heat exchanger to

remove all air from the system. Run the pump for a few minutes, stop and check fluid level again. If

required, add additional fluid to the reservoir. Be sure not to overfill.

Check seal fluid level in the reservoir. A high fluid level could mean a build-up of water in the reservoir,

which should be drained. Check every 500 hours.

Devarnishing

The operating life of the unit is greatly enhanced based on the quality of the seal fluid. Oxidized or

darkened seal fluid is a sign of trouble. Plugged filters reduce performance and may damage pump.

Periodic maintenance will offer the best protection for your equipment.

DEKKER offers a specially formulated devarnishing compound Proclean 39V for oil-sealed liquidring

pumps and systems. Procedure for using Proclean 39V and MSDS sheet are included with the product.

The compound is available in the following quantities:

Proclean 39V (part no.: 5230-0010-000) – 1 gallon

Proclean 39V (part no.: 5230-0050-000) – 5 gallon

Proclean 39V (part no.: 5230-0055-000) – 55 gallon

NOTE: Varnished pumps are not covered under warranty.

Seal Fluid Strainer

After the first 50 hours of operation, clean the strainer in the seal fluid line. This is done to remove any

debris carried over into the system from the process. Clean and inspect the strainer every 1000-3000

hours depending on application or if excessive oil discharge temperature (above 185°F) is indicated. An

increase in pump discharge oil temperature is an indication of low oil flow and normally is an indication of

Dekker Vacuum Technologies, Inc. – Vmax/13 13

strainer blockage. If cleaning of strainer does not decrease temperature check the seal fluid line for

blockage.

Spin-on Oil Filter (if installed)

If you notice that the operating temperature of your system steadily increases, change the spin-on filter.

Separator Element

The separator elements are located in the separator reservoir. Its purpose is to remove the oil from the

discharge air. Replace the element every 10,000 hours or once a year. Earlier replacement may be

necessary when the back-pressure is higher than 4 psig. High back-pressure is a result of dirt build-up on

the separator element due to oil varnish, or contaminated inlet gas stream. Replacement may vary

depending on application.

NOTE: Thread-in style filters are installed hand-tight as an oil filter. Do not over-tighten with a

wrench.

Separator Element Oil Return Line

The separator element oil return lines are 1/4” to 3/8” transparent tubing. The purpose of these lines is to

remove excessive oil build-up from inside the separator and separator element. If excessive smoking or oil

mist is present, check the oil return lines for blockage and replace if necessary. Also check that the steel

section of oil return line located on top of the separator reservoir is cut at a 45° angle and is touching the

bottom of the separator element.

Mechanical Shaft Seals

All DEKKER oil-sealed liquid ring vacuum pumps are fitted with mechanical shaft seals. Mechanical seals

do not require maintenance unless there is more than a small amount of leakage. To define this we

differentiate between the following:

Weepage: Mechanical seals work by having two flat surfaces pushed together by axial force from the

closing mechanism and by product pressure in the seal chamber. When the seal is in operation, the seal

fluid lubricates the tow faces. This thin film of lubrication protects the faces of the seal from heat and

excessive wear, but it can also allow for a small amount of leakage across the seal face. This small

leakage is called a “weep”. While a weep has rather arbitrary limits, it is commonly considered to be a

leakage rate of less than one drop of liquid every minute. Seal weeps are not covered under warranty.

Leakage: a leakage rate of more than one drop per minute is considered to be a “leak”. Seal leakage is

normally a result of a build-up of abrasive particles carried over in the pump suction. These particles cause

excessive wear on the seal faces. Leakage caused by wear and tear is not covered under warranty.

Seal replacement is addressed in the assembly and disassembly instruction for the specific pump model

used. Consult factory for assistance.

MAINTENANCE SCHEDULE

To help ensure trouble free system operation, a basic maintenance schedule consisting of the following

system checks is recommended.

First 8 hours operation

Check oil level and inlet filter element if installed. Clean strainers and remove temporary inlet screen.

Check for water in sight gauge and drain if necessary. Check piping for signs of oil leakage and tighten if

necessary.

500 hours operation

Under normal operating conditions repeat 8 hour check procedure as described above

1000 hours operation

Check back-pressure on separator element; it should not exceed 4 psig. Change separator element if back-

pressure exceeds 4 psig. Also check discharge pipe system for blockage.

Clean or replace inlet filter element every 1000 to 3000 hours depending on application or if excessive

pressure drop is noticed.

Remove debris from pump housing, motor fan guard and heat exchanger.

1,000-3,000 hours of operation

Applicable to pumps equipped with grease fittings located on each bearing housing. Grease bearings with

a #2 quality lithium grease. Do not over-grease, 3 to 4 pumps with a grease gun is sufficient under normal

conditions.

Dekker Vacuum Technologies, Inc. – Vmax/13 14

10,000 hours of operation

Or once per year, change seal fluid. Use DEKKER Vmaxol seal fluid. Life of Standard Vmaxol is 10,000

hours of operation. Synthetic/Food grade Long-life Vmaxol may be changed every 15,000 hours of

operation or once a year, whichever comes first.

Change separator element if back- pressure exceeds 4 psig.

Check coupling element for wear. Replace if worn.

Clean strainer in seal fluid line.

30,000 hours of operation

Or every 5 years, it is recommended that you replace the vacuum pump’s mechanical seals and bearings

as preventative maintenance. This should be done by a DEKKER authorized distributor or properly trained

service technician.

ELECTRICAL CONTROLS (if included)

♦Disconnect Handles: must be turned on to energize the system. The handles must be turned off to

open control panel.

♦CAUTION: High voltage, main disconnect must be off when servicing panel.

♦HOA (Hand-Off-Auto) Selector Switches: are supplied only if vacuum switches are supplied. Pump

units will start in HAND mode (unless units are in a shutdown alarm condition). The pumps will bypass

vacuum switches. AUTO mode, allows units to start upon contact closure of the vacuum switch.

♦Stop/Start Push Buttons: are included if HOA selector switch is not installed.

♦Reset Button: is used to reset the starter overloads.

♦Power On Light: indicates that power is on in panel.

♦Pump Running Light: indicates a pump is operating.

♦High Temperature Overload Light: indicates a pump has overheated and shuts the pump down.

The ALARM RESET button needs to be pressed to reset the alarm condition. If high temperature

condition has not been fixed, the alarm will not reset.

♦High Back-pressure Light: indicates the exhaust filter element in the vacuum pump needs to be

replaced. Alarm does not shut down the pump. Replace element as soon as possible.

♦Transformer Failure Light: indicates transformer failure. If alternate transformers are included in the

panel, the alternate transformer will pick up. The pump will shut down if only one transformer is

present and fails.

♦Lag Pump In Operation Light: When the light illuminates, the lag pump is in operation.

♦Audible Alarm: signals that the lag pump is in operation. The alarm can be silenced by pressing the

ALARM SILENCE button. The audible alarm may also be used to signal other alarm conditions, such

as high temperature, low oil level or high back pressure.

♦Alarm Silence Button: is used to silence the audible alarm, but the light will remain on unless alarm

condition has been corrected.

♦Alarm Reset Button: is used to reset an alarm condition when the condition has been rectified. The

ALARM RESET button will stop the light and alarm if alarm condition has been corrected.

♦Hour Meter: is a running clock that indicates how many hours each pump has been operating. It

should be used to determine when the oil in the pump and the discharge filter element needs to be

replaced. See Maintenance Schedule (page 9) for oil life.

ACCESSORIES AND PROTECTIVE DEVICES (if included)

Accessories

The following accessories are available for Vmax oil-sealed liquid ring vacuum pump systems.

♦Flexible Connectors (optional): are used in piping systems to eliminate vibration transmission from

machinery throughout the piping network. If ordered, DEKKER uses braided flexible connectors on the

Vmax oil-sealed vacuum pump systems.

Dekker Vacuum Technologies, Inc. – Vmax/13 15

♦Vibration Isolators (optional): are used to eliminate vibrations, noise and shock transmission from

machinery to the floor. Floor-mount type vibration isolators are used for Vmax vacuum pump systems.

The vibration isolators have a steel top plate, threaded insert and steel base, both totally imbedded in

an oil-resistant neoprene. The isolators bolt onto a tank or base-frame with one bolt and have two

mounting bolts to mount to the foundation or floor.

♦System Isolation Valve (optional): may be installed on the vacuum receiver tank or vacuum pump

manifold. Usually the valve is used to isolate the vacuum system from the piping network.

♦Inlet Filter (optional): An inlet filter may be installed on the Vmax oil-sealed vacuum pump systems

to prevent carry-over of particles into the pump.

♦Vacuum Relief Valve (optional): This valve may be installed on the pump suction manifold or on the

receiver. The vacuum relief valve is used to protect the vacuum pump from closed suction which can

damage the pump.

♦Vacuum Switch (optional): is used to automatically switch the vacuum pump ON and OFF, based on

demand. This switch is standard on all multiplex systems.

Switches are factory preset for your application and it is NOT RECOMMENDED to adjust the

vacuum switch. Each switch is labeled as LEAD or LAG and is marked with the corresponding PUMP

ON and PUMP OFF points.

If the vacuum switch must be adjusted, please follow these instructions:

1. To increase the point at which the vacuum pump turns

ON, turn the RANGE ADJUSTMENT SCREW (R) counter-

clockwise. See the range scale on switch for

approximation. Use vacuum gauge to observe actual

PUMP ON and PUMP OFF point.

2. To increase the differential, which is the difference between

the PUMP ON and PUMP OFF point, turn the

DIFFERENTIAL ADJUSTMENT SCREW (D) counter-

clockwise. To obtain the correct PUMP OFF point observe

the physical opening of the contact switch as compared to

the vacuum gauge reading. The vacuum pump will not stop

running, because all systems are equipped with “10 minute

mimum run” timers.

3. Remember you will need to vary the vacuum level in the

receiver or manifold to see a change in the vacuum level,

and to adjust the switches.

♦Microprocessing Controller (optional): system may be equipped with this very reliable and compact

Controller module for controlling and monitoring basic machinery functions. The following instructions

should help guide the end user to perform simple changes to the Controllers’ pre-programmed

settings. The specific preset areas that may be modified are outlined below.

Set the Internal Clock:

Upon powering the system control panel, the installation technician must ensure that the internal clock

in the Controller has been set to the current military time setting. The Controller is equipped with an

internal capacitor that will hold the time for approximately 80 hrs. If your system has not been installed

within the allotted time frame, the alternation of the automatic mode will not occur and only one of the

pumps will function until the time parameter has been updated. Refer to the following instructions for

access to and changing of the parameters.

Sequence of Operation Automatic Mode:

The switch on the front of the system control panel must be placed in the automatic mode before the

Controller program will initiate. Upon starting the system, all pumps should come on line and run for a

minimum of 10 minutes each. As the demand for the vacuum pumps change, the individual units will

turn off and on as required, each time running for a minimum of 10 minutes after initial start. If all the

individual pumps are not placed in automatic mode simultaneously, there may be a pump that does

not ramp up to speed with the lead pump. This does not mean that there is a problem with your

vacuum system. The reason for this can be the switch settings for lead and lag pumps. When the

system is started and individual units are placed in automatic mode at different times, the demand for

lag pump may not be present due to the time lapse between placing the various pumps in automatic

mode.

Dekker Vacuum Technologies, Inc. – Vmax/13 16

After 24 hours of operation (1 calendar day), the lead pump will become the lag pump and the

remaining pumps will shift one spot forward, keeping the same on and off switch settings as before.

The alternation of the vacuum pumps will allow equal usage of the equipment and will increase the life

expectancy of the system. If the demand for the remaining pumps needs to change, you must enter

the necessary value in the Controller for the level of vacuum you wish to maintain as a

minimum/maximum for each on/off switch point. If there is not a demand for the lag pump(s) they will

never run with the lead pump. Every day the lead pump will change.

When the lead pump cannot handle the demand of the system, the remaining pump(s) will turn on. For

medical packages: when the last pump in the system is required to operate, the alarm condition will

trigger the audio or visual signal that the lag pump is operating, and the system is near full capacity.

The alarm reset button should be pressed and the light or audible sound will stop.

Manual Modes:

Any pump can be independently started manually by placing the system in manual mode. All high

temperature and low/high level switches will still be monitoring the equipment, thus ensuring the safe

operation of your Vacuum system. The Controller program will not initiate and the automatic

alternation will not function. The cost of operating the system will be considerably higher than in

automatic mode.

Switching to parameterization mode:

In order to change any of the preset values in the Controller, the initial procedure is the same:

1. Turn on power to the Controller.

2. Place pump(s) in manual (Hand) mode. This is done so vacuum will be maintained, otherwise

when saving changes, the pump(s) will shut down.

3. Press ESC, then scroll down to “Set Param”, then push OK.

The Controller switches to parameterization mode and displays the parameterization menu. The operator

can now access the various menus by using the up or down arrows to toggle to desired menu.

Selecting a parameter:

The following can be parameters:

•The delay times of a time relay.

•The switching times of an alternation time switch.

•The threshold value of a counter.

•The monitoring time of an operating hours counter (internal clock).

•The switching thresholds of a vacuum switch.

To select a parameter, proceed as follows:

1. Select the “Set Param” option from the parameterization menu. (UP or DOWN arrows)

2. Once you have the cursor (>) on the desired parameter, press OK.

The Controller displays the first parameter. If parameters cannot be set or modified, you can use ESC

to return to the parameterization menu. The ESC key can be used at any time to leave the

parameterization mode and return to the running mode.

3. Select the desired parameter by using the UP or DOWN arrows to toggle through until the

desired parameter is displayed in the window.

4. To change a parameter, you must select it and press OK.

Changing a parameter:

To change a parameter, you first must select it as shown above. Once you have selected the desired

parameter, you can change the value by moving the cursor to the desired location with the <or >

arrows. The actual value is changed by using the UP or DOWN arrow. The steps are as follows:

1. Move the cursor to the point at which you want to make the change. (<or >arrows)

2. Change the value. (UP or DOWN arrows)

3. Accept the value. (OK)

Once all parameters are modified, you’ll need to exit the “Set Param” mode by followings these steps:

1. Press ESC until you reach the screen that has STOP.

2. Arrow up to STOP and press OK.

3. When prompted Stop Prg, use arrow UP or DOWN to Yes and press OK.

4. Arrow down to Start and press OK. (This will save the changes)

5. Turn pump(s) to Automatic mode.

Vacuum pump ON/OFF settings for Microprocessing Controller (Vacuum in “Hg):

When setting the ON and OFF switch points in your Controller, use the following table for reference:

Dekker Vacuum Technologies, Inc. – Vmax/13 17

Inches of HgV PLC Setting

29 234

28 488

27 742

26 996

25 1250

24 1504

23 1758

22 2012

21 2266

20 2520

19 2775

18 3028

17 3282

16 3536

15 3790

14 4044

13 4298

12 4552

11 4806

10 5060

This table will apply to all single and multiplex systems equipped with a Controller after 5/15/02 (all units

supplied with a Controller prior to this date must contact the Service or Engineering department with

serial number of supplied equipment for assistance). These values are entered directly into the

Controller in the appropriate block number for lead and lag pumps. Refer to the specific instruction set

provided with the IOM for block number identification.

- The correct value can also be determined by the following formula:

7600 – (Inches of HgV x 254) = Controller setting

Example: SW↑= 3282 – switch pump on at 17”HgV (7600 – (17 x 254) = 3282)

SW↓= 2520 – switch pump off at 20”HgV (7600 – (20 x 254) = 2520)

- To determine the vacuum point displayed on the LED of the Controller unit use the following

formula:

“HgV = 29.92 – (Displayed Value/254)

Please note that the values you are working with are Torr values multiplied by 10.

A perfect vacuum is approaching a setting of 0 and at atmospheric pressure at sea-level the setting is

at 7600 (760 Torr x 10).

Settings for Simplex Systems:

- Unless otherwise noted, the standard switch points for a Simplex System will be set at:

Lead pump ON at 17”HgV – OFF at 20”HgV

- Specific block numbers for Simplex Controller Program:

Lead pump =B15

Setting for Duplex Systems:

- Unless otherwise noted, the standard switch points for a Duplex System will be set at:

Lead pump ON at 17”HgV – OFF at 20”HgV

Lag pump ON at 16”HgV – OFF at 19”HgV

- Specific block numbers for Duplex Controller Program:

Lead pump =B15

Lag pump =B16

Alarm visual/audible =B13 (Typically set to come on and off with lag pump settings)

Setting for Triplex Systems:

- Unless otherwise noted, the standard switch points for a Triplex System will be set at:

Lead pump ON at 17”HgV – OFF at 20”HgV

Mid pump ON at 16”HgV – OFF at 19”HgV

Lag pump ON at 15”HgV – OFF at 18”HgV

- Specific Block number for Triplex Controller Program:

Lead Pump =B15

Mid pump =B16

Lag pump =B23

Alarm visual/audible =B13 (Typically set to come on and off with lag pump settings)

Dekker Vacuum Technologies, Inc. – Vmax/13 18

Protective Devices

The following protective devices are available to protect the unit from being damaged and to help with

maintenance.

♦High Temperature Switch (standard except on VmaxLT): will signal when the temperature of the oil

is exceeding the shut-down level. The switch will shut the unit down. The unit will not restart until the

alarm condition is acknowledged and is reset. The switch is a “snap disc” type of switch that is

normally closed. When the temperature reaches the maximum setpoint, the switch will open. Once

the switch has opened, there is a 10-20oF differential that the temperature will need to drop to, in order

for the switch to close.

♦High Back-pressure Switch (optional): is installed on the discharge of the separator. When the

back-pressure reaches a pre-determined level (4 psi), the switch will signal the control panel. A high

back-pressure light may be installed on the control panel, which, when illuminated, signals that the

exhaust element in the vacuum pump needs to be replaced. Note that the high back-pressure switch

will not shut the unit down, but the exhaust element must be replaced as soon as possible.

♦Lag Pump On Alarm (optional): An NFPA 99 requirement on medical systems. This is an

audio/visual alarm that signals lag pump operation. Once the alarm triggers, the alarm must be

acknowledged and reset. The alarm will not reset if the lag pump is still in operation. This alarm

indicates vacuum is greater than the supply of the lead pump only.

♦Transformer Failure Light (optional): All standard medical NFPA 99 oil-sealed liquidring vacuum

pump systems are supplied with two (2) control voltage transformers (one primary and one for

backup). If indication is desired in the event that the primary transformer fails and the backup

transformer picks up, a TRANSFORMER FAILURE light will be necessary. The defective transformer

should be replaced as soon as possible. When the primary transformer fails, the operation of the

system will not be interrupted. If the backup transformer also fails, the system will shut down.

♦Low Oil Level Switch (optional): This switch is installed in the separator/reservoir of the liquidring

vacuum pump. It is a float type of switch. If the level switch is triggered, the affected pump will shut

down. The LOW OIL LEVEL light on the control panel will be illuminated. The low level switch will be

wired into the main alarm of the panel. The alarm will have to be reset to restart the pump. When

filling the system with oil, make sure that the power to the pump is off because if the alarm

reset button has been reset and the level switches contacts close while filling the pump, the

pump will start-up automatically.

♦Frequent Stop/Start Protection (standard on multiplex systems): Allows each pump to run a

minimum amount of time. Frequent stopping/starting can reduce coupling life and is also less efficient

from a power consumption standpoint.

♦Automatic Alternation (standard on multiplex systems unless otherwise specified): Allows the

pumps to alternate. The primary feature of automatic alternation is to equalize the running time on all

the pumps.

Dekker Vacuum Technologies, Inc. – Vmax/13 19

TROUBLE-SHOOTING

Following is a basic trouble-shooting guide. We recommended that you consult your local dealer for

service. Each Vmax system is tested and checked at the factory. Always indicate system model and serial

number when calling.

WARNING: Before attempting any repairs, disconnect all power from the system by switching off

the main breaker or disconnect switch. This will prevent the system from automatically starting

from a vacuum switch.

TROUBLE SHOOTING FAQS (Frequently Asked Questions)

VMAX OIL-SEALED LIQUID RING VACUUM PUMP SYSTEMS

START-STOP PROBLEMS:

System will not start in HAND or AUTO position: (Vmax)

1. Check if the disconnect or circuit breaker is switched on.

2. Check the overload setting on the starter and fuses.

3. Check alarm reset, light should be off.

4. Ensure that the proper voltage is supplied and that the wire size is correct.

5. Check electrical control panel (if installed). Make sure that all wires are tight. Wires may vibrate loose during shipment or

operation.

6. Check low oil level switch (if installed). Add oil to reservoir if needed.

7. Check if the pump has seized by rotating the coupling by hand (disconnect power first). If a rubbing noise or

binding is observed, contact authorized dealer.

8. Check the high temperature switch, which should be set for 225oF.

9. Check if pump operates against high back-pressure (> 4 psig), if so replace oil separator element.

10. Check vacuum switch (if installed).

System shuts down while running: (Vmax)

1. Check oil temperature gauge for operating temperature.

2. Check the overload setting on the starter and fuses.

3. Ensure that the proper voltage is supplied and that the wire size is correct.

4. Check for loose electrical connections.

5. Check the vacuum switch setting (if installed).

6. Check low oil level switch (if installed), add oil to reservoir if needed.

7. Check if the pump has seized by rotating the coupling by hand (disconnect power first). If a rubbing noise or

binding is observed, contact authorized dealer.

8. Check high temperature switch, which should be set for 225oF.

9. Clean oil strainer.

10. Check if pump operates against high back-pressure (> 4 psig), if so replace oil separator element.

11. Check the overload setting on the starter and fuses.

VACUUM PROBLEMS:

System operates, but does not achieve desired vacuum level: (Vmax)

1. Stop system and disconnect power.

2. Check if the inlet valve is open and inlet filter is clean.

3. Ensure that no lines are open to the atmosphere, causing loss of vacuum.

4. Check for leaks in piping systems, using conventional leak detection methods.

5. Ensure that the oil level is correct and that the pump is primed and filled with oil to the shaft centerline only.

6. Check if the oil isolation valve is open.

7. Check if the oil solenoid valve (if installed) is working.

8. Check the vacuum switch setting (if installed).

9. Check setting of vacuum relief valve (if installed) and adjust as needed.

10. Check if the motor rotation is correct. Rotation should be clockwise (facing pump from motor side) and marked by

an arrow on the motor or pump housing. If incorrect, switch any two of the three main power leads on the

contactor inside the control panel.

Dekker Vacuum Technologies, Inc. – Vmax/13 20

This manual suits for next models

2

Table of contents

Other Dekker Water Pump manuals

Popular Water Pump manuals by other brands

Aquascape Pro

Aquascape Pro AquaSurge PRO 2000-4000 Instructions & maintenance

Haskel

Haskel AAD-5 Operating and maintenance instructions

Pfeiffer Vacuum

Pfeiffer Vacuum MVP 040-2 operating instructions

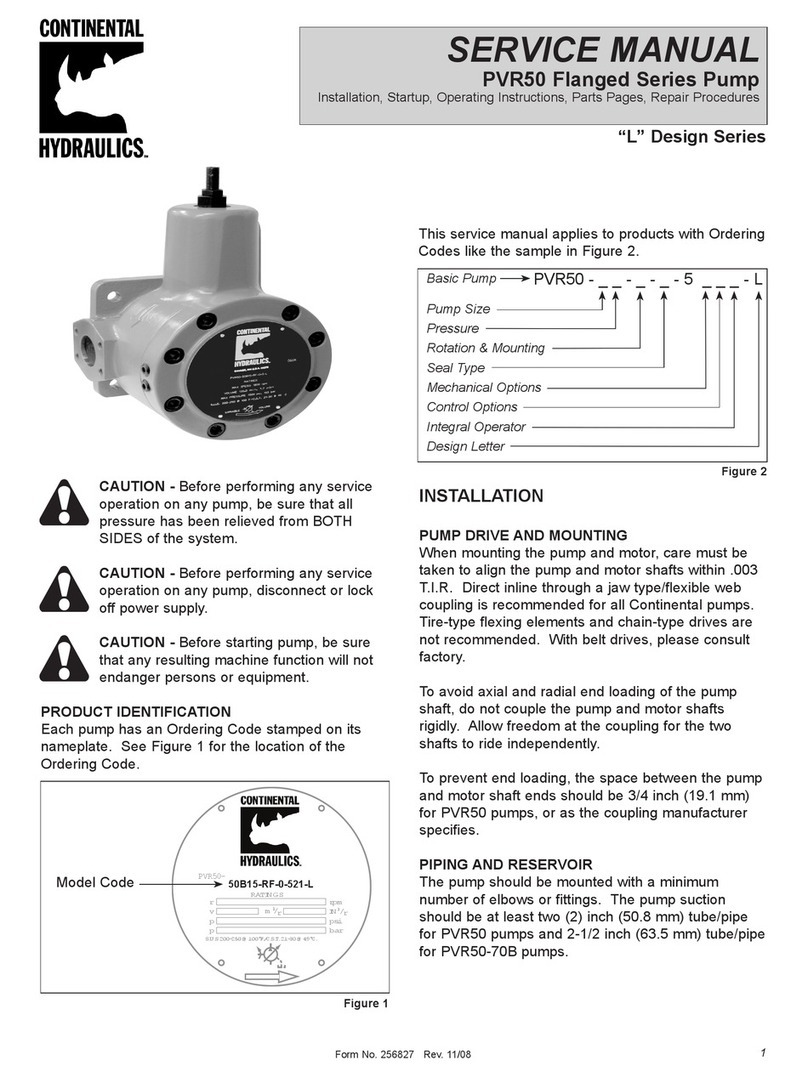

Continental Hydraulics

Continental Hydraulics PVR50 Flanged Series Service manual

Delta Membranes

Delta Membranes Delta Foul V3 installation instructions

Peerless Pump

Peerless Pump AEF Installation, operation and maintenance manual