WLM2203AĆX2PAGE4 F4

PLACING INT

O SER

VICE

AIR AND LUBRICATI N REQUIREMENTS

Fi tered air wi he p extend the ife of the pump, a owing the pump to

operate more efficient y and yie d onger service ife to moving parts and

mechanisms.

•Insta an air ine fi ter to provide good qua ity c ean and dry air.

Insta it up stream from the regu ator.

•Use an air regu ator on the air supp y to contro the pump cyc e rate.

Insta the regu ator as c ose as possib e to the pump.

•In most insta ations, ubrication is not required. If the pump needs

to have ubrication, insta an air ine ubricator and supp y it with a

good grade of nonĆdetergent oi or other ubricant compatib e with

Nitri e sea s and set at a rate not to exceed one drop per minute.

INSTALLATI N

•Mount and secure the pump as required for the app ication.

•Attach a ground wire from the pump ground screw to a suitab e

ground.

•Connect a f uid hose to the pump out et. In most cases a pipe sea Ć

ant shou d be used on thread connection. Tighten a fittings. Use

caution not to damage threads.

OPERATION

STARTĆUP

1. Turn the air regu ator to 0" pressure setting.

2. Immerse the ower pump end into the materia .

3. Open the dispensing device.

4. Start the pump cyc ing s ow y by raising the pressure to 1.4 Ć 2.1 bar

(20 Ć 30 p.s.i.).

5. C ose the dispensing device. A ow the pump to sta and bui d ine

pressure. Check for any eaks and tighten fittings asneeded. Adjust

pressure as required for the app ication.

SHUTD WN

•Disconnect the air supp y from the pump if it is to be inactive for a

few hours. Open the dispensing device to re ieve ine pressure.

SERVICE

PUMP

DISASSEMBL

Y / REASSEMBL

Y

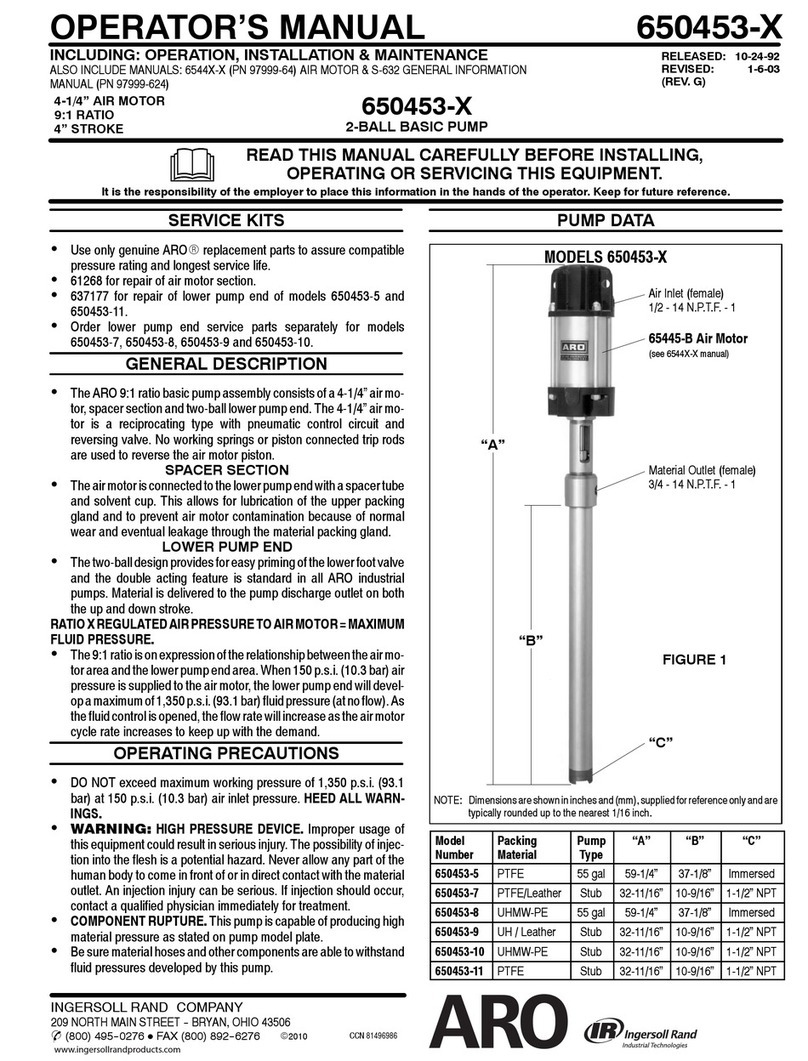

N TICE: The unique design of this pump a ows for quick basic pump

service without tota remova from the drum (refer to the views be ow).

DISASSEMBLY - All threads are right hand. Refer to figure 2.

These procedures are for the installation of repair kit parts. DisĆ

connect air supply and relieve all system pressure prior to servicĆ

ing. Carefu y remove the parts, inspect parts for damage, nicks or

excessive wear and determine if any parts wi need rep acement.

Fo ow the three disassemb y steps in the detai views be ow and p ace

the pump on a c ean bench.

1. Remove (1) bo ts. Remove (18) packing, (17) bushing and (16) O"

ring.

2. Remove (36) adapter, re easing (10) muff er.

3. Grasp the (11) cy inder and remove the (20, 14) piston assemb y.

4. Remove (15) ower cap and (3) track gasket. Remove (12) retaining

ring and (48) washer, then pu (14) piston off (20) piston rod.

5. Remove (2) cap and (3) track gasket. Push on the arge o.d. end of

the (7) spoo to remove the (4) s eeve. Grab the nose of (7) spoo

and pu out. Repeat for other s eeve and spoo .

REASSEMBLY - Thoroughly clean and lubricate all seals and

bores with Shell Darina EP" 2 upon assembly. Replace all soft

parts with new ones included in the repair kit.

Note: Refer to the i ustration (figure 2) for U" cup ip sea direction.

1. Rep ace the sea s on both the (7) spoo s and (4) s eeves.

2. Locate the va ve chamber on the (11) cy inder where the 3/8'' dia.

ho e is ocated and insta one of the (4) s eeves. Insert the (7) spoo

from the opposite end. Next, insta the remaining s eeve and spoo .

3. Rep ace the (3) track gasket and insta (2) cap.

4. Rep ace the (13) piston U" cups (refer to figure 2 for proper orientaĆ

tion). Rep ace the (19) O" ring and assemb e (14) piston to (20) pisĆ

ton rod and retain with (48) washer and (12) retaining ring.

5. Insta the (20, 14) piston assemb y using great care to co apse the

outer ip of the second U" cup, a owing it to s ip into the cy inder.

6. Rep ace the (3) track gasket and insta the (15) cap. Insta the (16)

O" ring onto the piston rod, rep ace (17) bushing and (18) packing.

7. Rep ace the (25) O" ring and reĆattach the (24) inner check.

8. S ide the pump assemb y back into the (26) base / ower pump secĆ

tion. Press the sections together and a ign the air in et and pump

out et as required and rep ace the four (1) bo ts and (27) nuts (tightĆ

en to 9 Nm (79.7 in. bs).

TROUBLE SHOOTING

If the pump will not cycle or will not deliver material.

•Be certain to check for nonĆpump prob ems inc uding kinked, reĆ

strictive or p ugged in et / out et hose or dispensing device. DepresĆ

surize the pump system and c ean out any obstructions in the in et /

out et materia ines.

•Check a sea s, inc uding track gaskets.

•Check direction of U" cup ips.

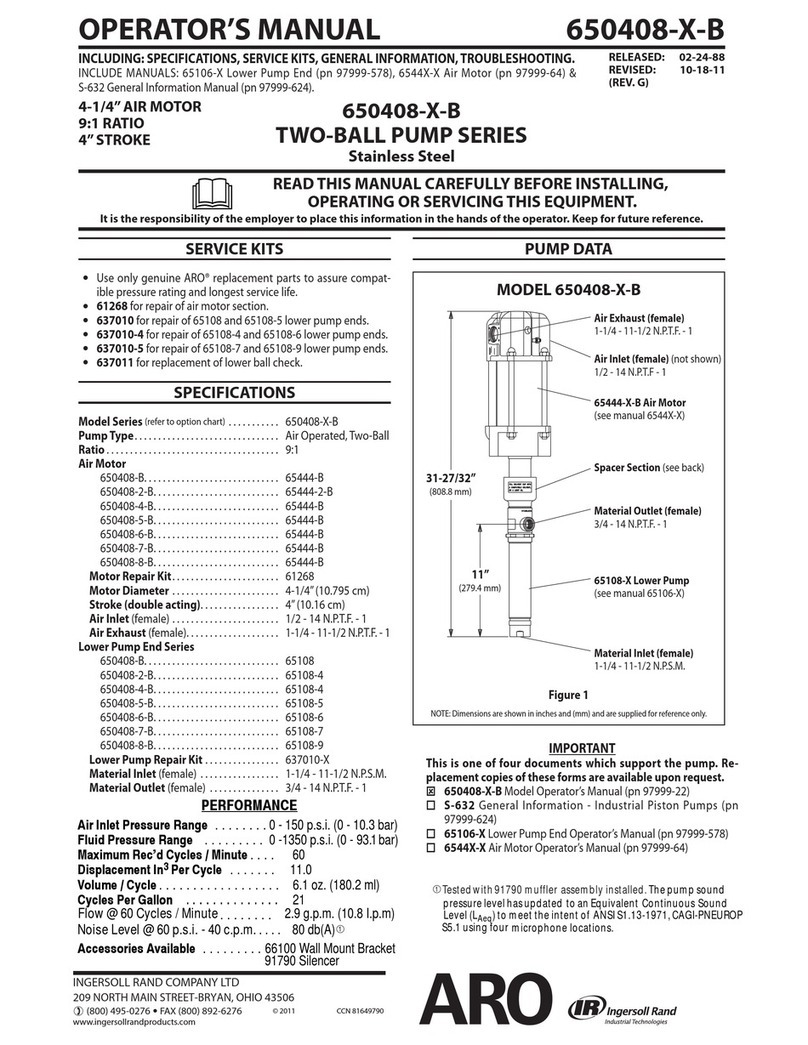

C) Un ock the (24) inner

check from the piston rod.

FIGURE 5

FIGURE 4

B) Grasp the ower motor

cap and pu out the motor

and upper section of the

ower section.

PUMP DISASSEMBLY DETAIL

FIGURE 3

A) Remove the four

nuts from the base of

the Air Motor.

PN 97999Ć865