DeKo DKCD20XL01 User manual

INSTRUCTION MANUAL

CORDLESS DRILL

1

Model No.: DKCD20XL01

DEKO TOOLS CO., LIMITED

www.dekotools.com Made in China

Y

2

General Power Tool Safety Warnings

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can cause you to

lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will

reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will increase the

risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase

the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use of

a cord suitable for outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating a power tool. Do

not use a power tool while you are tired or under the influence of drugs, alcohol or medication. A

moment of inattention while operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective equipment such as

a dust mask, non-skid safety shoes, hard hat or hearing protection used for appropriate conditions

will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-position before connecting to

power source and/or battery pack, picking up or carrying the tool. Carrying power tools with your

finger on the switch or energising power tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may result in personal injury.

WARNING: Read all safety warnings, instructions, illustrations and specifications pro-

vided with this power tool. Failure to follow all instructions listed below may result in electric

shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

WARNING:

3

e) Do not overreach. Keep proper footing and balance at all times. This enables better control of

the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair and clothing away from

moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection facilities, ensure

these are connected and properly used. Use of dust collection can reduce dust-related hazards.

h) Do not let familiarity gained from frequent use of tools allow you to become complacent and

ignore tool safety principles. A careless action can cause severe injury within a fraction of a second.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application. The correct power

tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or remove the battery pack, if detachable, from

the power tool before making any adjustments, changing accessories, or storing power tools.

Such preventive safety measures reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons unfamiliar with the

power tool or these instructions to operate the power tool. Power tools are dangerous in the hands

of untrained users.

e) Maintain power tools and accessories. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool’s operation. If damaged,

have the power tool repaired before use. Many accidents are caused by poorly maintained power

tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc. in accordance with these instructions, taking

into account the working conditions and the work to be performed. Use of the power tool for opera-

tions different from those intended could result in a hazardous situation.

h) Keep handles and grasping surfaces dry, clean and free from oil and grease. Slippery handles

and grasping surfaces do not allow for safe handling and control of the tool in unexpected situations.

5) Battery tool use and care.

a) Recharge only with the charger specified by the manufacturer. A charger that is suitable for one

type of battery pack may create a risk of fire when used with another battery pack.

b) Use power tools only with specifically designated battery packs. Use of any other battery packs

may create a risk of injury and fire.

c) When battery pack is not in use, keep it away from other metal objects, like paper clips, coins,

keys, nails, screws or other small metal objects, that can make a connection from one terminal to

another. Shorting the battery terminals together may cause burns or a fire.

d) Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact

accidentally occurs, flush with water. If liquid contacts eyes, additionally seek medical help.

Liquid ejected from the battery may cause irritation or burns.

e) Do not use a battery pack or tool that is damaged or modified. Damaged or modified batteries

4

may exhibit unpredictable behaviour resulting in fire, explosion or risk of injury.

f) Do not expose a battery pack or tool to fire or excessive temperature . Exposure to fire or tem-

perature above 40 °C may cause explosion.

g) Follow all charging instructions and do not charge the battery pack or tool outside the tempera-

ture range specified in the instructions. Charging improperly or at temperatures outside the speci-

fied range may damage the battery and increase the risk of fire.

6) Service

a) Have your power tool serviced by a qualified repair person using only identical replacement

parts. This will ensure that the safety of the power tool is maintained.

b) Never service damaged battery packs. Service of battery packs should only be performed by the

manufacturer or authorized service providers.

1) Wear ear protectors and goggles when impact drilling. Exposure to noise can cause hearing

loss.

2) Dusts from materials such as lead-containing coatings, some wood types, minerals and metal

can be harmful to one’s health and cause allergic reactions, lead to respiratory infections and/or

cancer. Materials containing asbestos may only be worked by specialists.

– please always keep the working place clean and well-ventilated.

– it is recommended to wear a p2 filter-class respirator.

Observe the relevant regulations in your country for the materials to be worked.

3) Before any work on the machine (e.G., Maintenance, tool change, etc.) as well as during trans-

port and storage, set the rotational direction switch (forward/reverse switch ) to the center posi-

tion. Unintentional actuation of the on/off trigger can lead to injuries.

4) Hold power tool by insulated gripping surfaces, when performing an operation where the

cutting accessory or fastener may contact hidden wiring. Cutting accessory and fasteners contact-

ing a “live” wire may make exposed metal parts of the power tool “live” and could give the operator

an electric shock.

5) Hold the machine with a firm grip. High reaction torque can briefly occur while driving in and loos-

ening screws. Secure the workpiece. A workpiece clamped with clamping devices is held more

secure than by hand.

6) Never operate at higher speed than the maximum speed rating of the drill bit. At higher speeds,

the bit is likely to bend if allowed to rotate freely without contacting the workpiece, resulting in

personal injury.

7) Always start drilling at low speed and with the bit tip in contact with the workpiece. At higher

speeds, the bit is likely to bend if allowed to rotate freely without contacting the workpiece, resulting

in personal injury.

8) Apply pressure only in direct line with the bit and do not apply excessive pressure. Bits can

bend causing breakage or loss of control, resulting in personal injury.

Additional Safety Warnings for Drills and Screw Drivers

Production Specification

Save These Instructions for Future Use

Symbols Explanation in the Manual and/or on the Drill and Battery.

Denotes risk of personal injury or damage to the tool.

It is environmental friendly and could be recycled

Do not dispose of power tools and batteries/rechargeable batteries into household waste!

Dispose the products according to the regulation and requirement of local council.

Keep the battery away from the fire.

Keep the battery away from moisture or water.

5

Read instruction manual before use.

Model

Rated voltage DC 20V

0-350/0-1350/min

10mm

No load speed

Chuck size

DKCD20XL01

35mm

10mm

18+1

1.20 kg ( including battery pack)

Max. drilling dia. in steel

Torque settings

Product weight

Charge time

1 hour ~ 2 hours

Max. drilling dia. in wood

40 N.mMax. torque

Battery charger

Input: AC 100-240V, 50/60Hz, 1.0A

Output: DC 21.5V, 1.5A

DC 20V, 1.5Ah Li-ion

Battery

The center position of the control buton locks the tool in the OFF position. When changing the

position of the control button, be sure the switch is released.

Torque Adjustment Ring (18+1 Torque Settings)

Your tool has an electronic adjustable torque screwdriver system for driving and removing a

wide range of fasteners. Circling the torque adjustment ring (2) are numbers and a drill bit

symbol. These numbers are used to set the ring to deliver a torque range. The higher the

number on the ring, the higher the torque and the larger the fastener that can be driven. To

select any of the numbers, rotate until the desired number aligns with the arrow.

2-Speed Gear Switch

The 2-speed feature of your tool allows you to shift gears for greater versatility. To select speed

1 (highest torque setting), turn the tool off and permit it to stop. Slide the gear switch (1) all the

way forward to speed 2(highest speed setting).

WARNING: Do not change speed when the tool is running. Always allow the drill to come to

a complete stop before changing speeds.

Keyless Chuck

WARNING: Always lock off trigger switch and disconnect tool from power source when

changing accessories.

WARNING: Always ensure the bit is secure before starting the tool. A loose bit may eject

from tool causing possible personal injury.

Your tool features a double-sleeve keyless chuck (3). To insert a drill bit or other accessory,

follow these steps.

1. Turn tool off and disconnect tool from power source.

2. Hold the sleeve A to secure the chuck with one hand and grasp

sleeve B with the hand to change accesory. Rotate the sleeve

counterclockwise (as viewed from the front) far enough to accept

the desired accessory.

3. Insert the accessory into the chuck and tighten securely by rotating

the sleeve A clockwise.

LED Worklight

This drill features an LED worklight (7). This LED worklight (7) could automatically be turned on

when the speed control trigger is squeezed.

WARNING: The light of this power tool is intended to illuminate the power tool’s direct area

of working operation and is not suitable for household room illumination.

Installing and Removing the Battery Pack

NOTE: For best results, make sure your battery pack is fully charged. To install the battery

pack (8) into the tool handle, align the battery pack with the rails inside the tool’s handle and

slide it into the handle until the battery pack is firmly seated in the tool and ensure that it does

not disengage. To remove the battery pack from the tool, press the release button (9) and firmly

Parts Description

1.2-speed gear switch

2.Torque adjustment ring

3. 10mm(3/8”) keyless chuck

4. Forward/reverse switch

5. Speed on/off control trigger

6. Handle

7. LED worklight

8.Battery pack

9.Battery pack release button

10.Battery indicator

11.Charing input port.

12.Adapter/Charger

13. Indicator light

Red light--- in charge

Green light- fully charged

10

13

12

11

6

Intended Use

The machine is intended for driving in and loosening screws as well as for drilling in wood,

metal, ceramics and plastic.

DO NOT use under wet conditions or in presence of flammable liquids or gases.

DO NOT let children come into contact with the tool. Supervision is required when inexperi-

enced operators use this tool.

Variable Speed Control Trigger

To turn the tool on, squeeze the

speed on/off control trigger

(5). To turn the tool off, release

the trigger. The chuck will stop as soon as the trigger (5) is fully released.

NOTE: Continuous use in variable speed range is not recommended. It may damage the switch

and should be avoided.

Forward/Reverse Switch

A forward/reverse switch (4) determines the direction of the tool and also serves as a lock-off

button.

To select forward rotation, release the switch and depress the forward/reverse control button

on the right side of the tool.

To select reverse, release the switch and depress the forward/reverse control button on the left

side of the tool.

1

2

5

4

6

3

7

8

9

The center position of the control buton locks the tool in the OFF position. When changing the

position of the control button, be sure the switch is released.

Torque Adjustment Ring (18+1 Torque Settings)

Your tool has an electronic adjustable torque screwdriver system for driving and removing a

wide range of fasteners. Circling the torque adjustment ring (2) are numbers and a drill bit

symbol. These numbers are used to set the ring to deliver a torque range. The higher the

number on the ring, the higher the torque and the larger the fastener that can be driven. To

select any of the numbers, rotate until the desired number aligns with the arrow.

2-Speed Gear Switch

The 2-speed feature of your tool allows you to shift gears for greater versatility. To select speed

1 (highest torque setting), turn the tool off and permit it to stop. Slide the gear switch (1) all the

way forward to speed 2(highest speed setting).

WARNING: Do not change speed when the tool is running. Always allow the drill to come to

a complete stop before changing speeds.

Keyless Chuck

WARNING: Always lock off trigger switch and disconnect tool from power source when

changing accessories.

WARNING: Always ensure the bit is secure before starting the tool. A loose bit may eject

from tool causing possible personal injury.

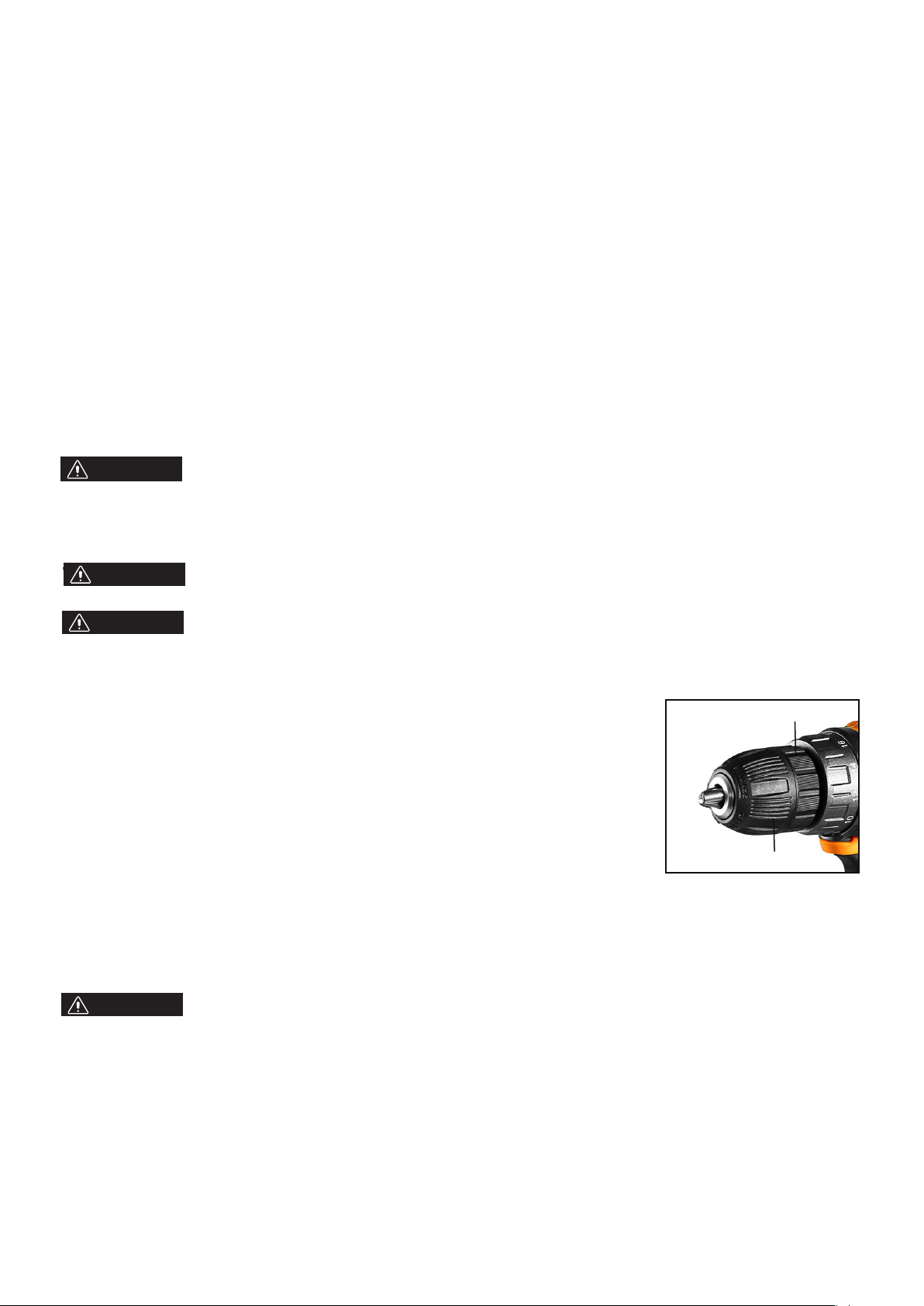

Your tool features a double-sleeve keyless chuck (3). To insert a drill bit or other accessory,

follow these steps.

1. Turn tool off and disconnect tool from power source.

2. Hold the sleeve A to secure the chuck with one hand and grasp

sleeve B with the hand to change accesory. Rotate the sleeve

counterclockwise (as viewed from the front) far enough to accept

the desired accessory.

3. Insert the accessory into the chuck and tighten securely by rotating

the sleeve A clockwise.

LED Worklight

This drill features an LED worklight (7). This LED worklight (7) could automatically be turned on

when the speed control trigger is squeezed.

WARNING: The light of this power tool is intended to illuminate the power tool’s direct area

of working operation and is not suitable for household room illumination.

Installing and Removing the Battery Pack

NOTE: For best results, make sure your battery pack is fully charged. To install the battery

pack (8) into the tool handle, align the battery pack with the rails inside the tool’s handle and

slide it into the handle until the battery pack is firmly seated in the tool and ensure that it does

not disengage. To remove the battery pack from the tool, press the release button (9) and firmly

7

The machine is intended for driving in and loosening screws as well as for drilling in wood,

metal, ceramics and plastic.

DO NOT use under wet conditions or in presence of flammable liquids or gases.

DO NOT let children come into contact with the tool. Supervision is required when inexperi-

enced operators use this tool.

Variable Speed Control Trigger

To turn the tool on, squeeze the

speed on/off control trigger

(5). To turn the tool off, release

the trigger. The chuck will stop as soon as the trigger (5) is fully released.

NOTE: Continuous use in variable speed range is not recommended. It may damage the switch

and should be avoided.

Forward/Reverse Switch

A forward/reverse switch (4) determines the direction of the tool and also serves as a lock-off

button.

To select forward rotation, release the switch and depress the forward/reverse control button

on the right side of the tool.

To select reverse, release the switch and depress the forward/reverse control button on the left

side of the tool.

WARNING:

WARNING:

WARNING:

WARNING:

sleeve A

sleeve B

The center position of the control buton locks the tool in the OFF position. When changing the

position of the control button, be sure the switch is released.

Torque Adjustment Ring (18+1 Torque Settings)

Your tool has an electronic adjustable torque screwdriver system for driving and removing a

wide range of fasteners. Circling the torque adjustment ring (2) are numbers and a drill bit

symbol. These numbers are used to set the ring to deliver a torque range. The higher the

number on the ring, the higher the torque and the larger the fastener that can be driven. To

select any of the numbers, rotate until the desired number aligns with the arrow.

2-Speed Gear Switch

The 2-speed feature of your tool allows you to shift gears for greater versatility. To select speed

1 (highest torque setting), turn the tool off and permit it to stop. Slide the gear switch (1) all the

way forward to speed 2(highest speed setting).

WARNING: Do not change speed when the tool is running. Always allow the drill to come to

a complete stop before changing speeds.

Keyless Chuck

WARNING: Always lock off trigger switch and disconnect tool from power source when

changing accessories.

WARNING: Always ensure the bit is secure before starting the tool. A loose bit may eject

from tool causing possible personal injury.

Your tool features a double-sleeve keyless chuck (3). To insert a drill bit or other accessory,

follow these steps.

1. Turn tool off and disconnect tool from power source.

2. Hold the sleeve A to secure the chuck with one hand and grasp

sleeve B with the hand to change accesory. Rotate the sleeve

counterclockwise (as viewed from the front) far enough to accept

the desired accessory.

3. Insert the accessory into the chuck and tighten securely by rotating

the sleeve A clockwise.

LED Worklight

This drill features an LED worklight (7). This LED worklight (7) could automatically be turned on

when the speed control trigger is squeezed.

WARNING: The light of this power tool is intended to illuminate the power tool’s direct area

of working operation and is not suitable for household room illumination.

Installing and Removing the Battery Pack

NOTE: For best results, make sure your battery pack is fully charged. To install the battery

pack (8) into the tool handle, align the battery pack with the rails inside the tool’s handle and

slide it into the handle until the battery pack is firmly seated in the tool and ensure that it does

not disengage. To remove the battery pack from the tool, press the release button (9) and firmly

pull the battery pack out of the tool handle.

Battery charging

Note: The battery is supplied partially charged to prevent possible problems. Therefore, you should

charge it prior to use. Batteries will not reach full charge the first time they are charged. Allow

several charging/discharging cycles for them to fully charge.

WARNING Do not continue to press the On/Off switch after the machine has been automati-

cally switched off. The battery can be damaged. The battery is equipped with an NTC temperature

control which allows charging only within a temperature range of between 10°C-40°C(50°F-104°F).

A long battery service life is achieved in this manner. Observe the notes for disposal.

Use only original DEKO battery in conjunction with your DEKO power tool. This measure alone

protects the battery against dangerous overload. When using other batteries, e.g.imitations, recon-

ditioned batteries or other brands, there is danger of injury as well as property damage through

exploding batteries.

Do not open the battery. Danger of short-circuiting may occur. Protect the battery against heat, e.g.,

against continuous intense sunlight, fire, water, and moisture. Danger of explosion may occur.

Screw Driving

1. Select the desired speed/torque range using the gear switch (1) to match the speed and torque

to the planned operation.

2. Turn the torque adjustment ring (2) to the desired position.

NOTE: Use the lowest torque setting required to seat the fastener at the desired depth. The lower

the number, the lower the torque output.

3. Insert the desired fastener accessory into the chuck.

4. Make some practice runs in scrap or on unseen areas of the workpiece to determine the proper

position of the torque adjustment ring.

5. Always start with lower torque settings, then advance to higher torque settings to avoid damage

to the workpiece or fastener.

Drilling

NOTE: If drilling thin material, use a wood “back-up” block to prevent damage to the material.

1. Select the desired speed/torque range using the gear switch (1) to match the speed and torque

to the planned operation. Turn the torque adjustment ring (2) to the drill symbol.

2. Always choose appropriate drill bits for different materials.

3. Always apply pressure in a straight line with the bit. Use enough pressure to keep drill biting, but

do not push hard enough to stall the motor or deflect the bit.

4. Hold tool firmly with both hands to control the twisting action of the drill.

WARNING: Drill may stall if overloaded, causing a sudden twist.

Always expect the stall. Grip the drill firmly to control the twisting action and avoid injury.

5. IF DRILL STALLS, it is usually because it is being overloaded or improperly used. RELEASE TRIG-

GER IMMEDIATELY, remove drill bit from work, and determine cause of stalling. DO NOT DEPRESS

TRIGGER ON AND OFF IN AN ATTEMPT TO START A STALLED DRILL — THIS CAN DAMAGE THE

The machine is intended for driving in and loosening screws as well as for drilling in wood,

metal, ceramics and plastic.

DO NOT use under wet conditions or in presence of flammable liquids or gases.

DO NOT let children come into contact with the tool. Supervision is required when inexperi-

enced operators use this tool.

Variable Speed Control Trigger

To turn the tool on, squeeze the

speed on/off control trigger

(5). To turn the tool off, release

the trigger. The chuck will stop as soon as the trigger (5) is fully released.

NOTE: Continuous use in variable speed range is not recommended. It may damage the switch

and should be avoided.

Forward/Reverse Switch

A forward/reverse switch (4) determines the direction of the tool and also serves as a lock-off

button.

To select forward rotation, release the switch and depress the forward/reverse control button

on the right side of the tool.

To select reverse, release the switch and depress the forward/reverse control button on the left

side of the tool.

WARNING:

WARNING:

8

The center position of the control buton locks the tool in the OFF position. When changing the

position of the control button, be sure the switch is released.

Torque Adjustment Ring (18+1 Torque Settings)

Your tool has an electronic adjustable torque screwdriver system for driving and removing a

wide range of fasteners. Circling the torque adjustment ring (2) are numbers and a drill bit

symbol. These numbers are used to set the ring to deliver a torque range. The higher the

number on the ring, the higher the torque and the larger the fastener that can be driven. To

select any of the numbers, rotate until the desired number aligns with the arrow.

2-Speed Gear Switch

The 2-speed feature of your tool allows you to shift gears for greater versatility. To select speed

1 (highest torque setting), turn the tool off and permit it to stop. Slide the gear switch (1) all the

way forward to speed 2(highest speed setting).

WARNING: Do not change speed when the tool is running. Always allow the drill to come to

a complete stop before changing speeds.

Keyless Chuck

WARNING: Always lock off trigger switch and disconnect tool from power source when

changing accessories.

WARNING: Always ensure the bit is secure before starting the tool. A loose bit may eject

from tool causing possible personal injury.

Your tool features a double-sleeve keyless chuck (3). To insert a drill bit or other accessory,

follow these steps.

1. Turn tool off and disconnect tool from power source.

2. Hold the sleeve A to secure the chuck with one hand and grasp

sleeve B with the hand to change accesory. Rotate the sleeve

counterclockwise (as viewed from the front) far enough to accept

the desired accessory.

3. Insert the accessory into the chuck and tighten securely by rotating

the sleeve A clockwise.

LED Worklight

This drill features an LED worklight (7). This LED worklight (7) could automatically be turned on

when the speed control trigger is squeezed.

WARNING: The light of this power tool is intended to illuminate the power tool’s direct area

of working operation and is not suitable for household room illumination.

Installing and Removing the Battery Pack

NOTE: For best results, make sure your battery pack is fully charged. To install the battery

pack (8) into the tool handle, align the battery pack with the rails inside the tool’s handle and

slide it into the handle until the battery pack is firmly seated in the tool and ensure that it does

not disengage. To remove the battery pack from the tool, press the release button (9) and firmly

DRILL.

6. To minimize stalling or breaking through the material, reduce pressure on drill and ease the bit

through the last fractional part of the hole.

7. Keep the motor running when pulling the bit back out of a drilled hole. This will help prevent jam-

ming.

Residual risks

Even when the tool is used as prescribed it is not possible to eliminate all residual risk factors.

The following hazards may arise in connection with the tool’s construction and design:

1, Damage to lungs if an effective dust mask is not worn.

2, Damage to hearing if effective hearing protection is not worn.

3, Health defects resulting from vibration emission if the power tool is being used over longer

period of time or not adequately managed and properly maintained.

Maintenance and Cleaning

Before any work on the machine (e.g., maintenance, tool change, etc.) as well as during transport

and storage, set the rotational direction switch to the center position.Unintentional actuation of the

On/Off switch can lead to injuries.

For safe and proper working, always keep the machine and ventilation slots clean.

To ensure product SAFETY and RELIABILITY, repairs and any other maintenance or adjustment

should be performed by a qualified repair person, always using DEKO replacement parts.

Service Information

We provide 1-year quality warranty from purchasing date and friendly customer service. Our

after-sales service responds to your questions concerning maintenance and repair of our product

as well as spare parts. Please contact your local distributor or send emails to services@deko-

tools.com

Transport

The contained lithium-ion batteries are subject to the Dangerous Goods Legislation requirements.

The user can transport the batteries by road without further requirements. Dispatch batteries only

when the housing is undamaged. When being transported by third parties (e.g.: air transport or

forwarding agency), special requirements on packaging and la belling must be observed. For

preparation of the item being shipped, please observe possibly more detailed national regulations

and consult an expert for hazardous material.

The machine, rechargeable batteries, accessories, and packaging should be sorted for envi-

ronmental-friendly recycling. Do not dispose of power tools and batteries/rechargeable

batteries into household waste! Please recycle them at collection points provided for the

purpose. Ask your local authority for information about recycling.

Disposal

The machine is intended for driving in and loosening screws as well as for drilling in wood,

metal, ceramics and plastic.

DO NOT use under wet conditions or in presence of flammable liquids or gases.

DO NOT let children come into contact with the tool. Supervision is required when inexperi-

enced operators use this tool.

Variable Speed Control Trigger

To turn the tool on, squeeze the

speed on/off control trigger

(5). To turn the tool off, release

the trigger. The chuck will stop as soon as the trigger (5) is fully released.

NOTE: Continuous use in variable speed range is not recommended. It may damage the switch

and should be avoided.

Forward/Reverse Switch

A forward/reverse switch (4) determines the direction of the tool and also serves as a lock-off

button.

To select forward rotation, release the switch and depress the forward/reverse control button

on the right side of the tool.

To select reverse, release the switch and depress the forward/reverse control button on the left

side of the tool.

9

DEKO TOOLS CO., LIMITED

www.dekotools.com

Made in China

Table of contents

Other DeKo Power Screwdriver manuals