Model No.

Description

PRODUCT

CONCEPT AND MAIN APPLICATIONS

P 1/16

Specification

Standard equipment

6842, 6843, 6844

Auto Feed Screwdriver

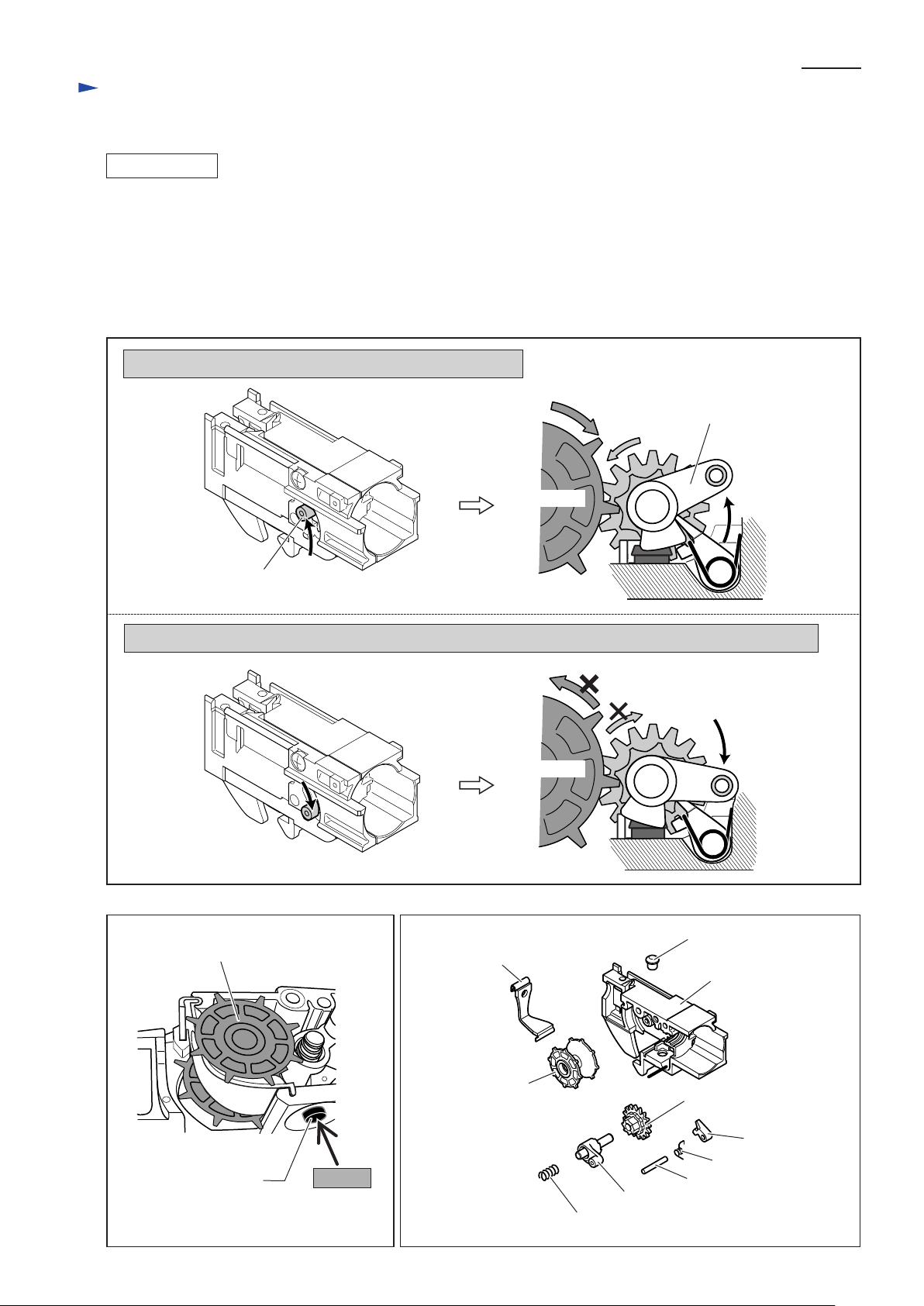

Models 6842, 6843 and 6844 have been developed

as the successor models of 6833 series models.

These models feature more reliable casing attachment

with the following benefits:

Rigid aluminum casing

Stopper base with anti-tilt device for preventing screws from swaying

Rubber cap securely fixed to stopper base

Dust-proof construction for smooth sliding action

6842 series also includes Auto feed screwdriver with coil magazine

available as Model 6845.

Dimensions: mm (")

Width (W)

Height (H)

Length (L) 400 (15-3/4) 440 (17-1/4)

6842/ 6843 6844

75 (2-15/16)

243 (9-9/16)

L

H

Optional accessories

W

Specification

Net weight: kg (lbs) 2.0 (4.4) 2.1 (4.6)

Model 6843 6844

Power supply cord: m (ft) Europe: 4.0 (13.1), Other countries: 2.5 (8.2)

6842

6842/ 6843/ 6844

6842/ 6843

Continuous Rating (W)

Voltage (V) Cycle (Hz) Input Output Max. Output (W)

110

120

220

230

240

4.5

4.3

2.3

2.2

2.1

50/60

50/60

50/60

50/60

50/60

470

---

470

470

470

190

190

190

190

190

400

400

400

400

400

Current (A)

Note: The standard equipment for the tool shown above may differ by country.

Phillips bit 2-162 or 2-157 (for 6842/ 6843)

Square bit 2-162 or 2-157 (for 6842/ 6843)

Phillips bit 2-182 or 2-177 (for 6844)

Square bit 2-182 or 2-177 (for 6844)

Extension handle

Casing attachment

Plastic carrying case

Phillips bit 2-162 or 2-157 ....................... 3

Belt clip ................................................... 1

Thumb screw (for fixing Belt clip) .......... 1

Plastic carrying case ................................ 1

6844

Phillips bit 2-182 or 2-177 ....................... 3

Belt clip ................................................... 1

Thumb screw (for fixing Belt clip) .......... 1

Plastic carrying case ................................ 1

4 (5/32)

25 to 55

(1 to 2-3/16)

45 to 75

(1-3/4 to 2-15/16)

Diameter

Overall length

6,000 3,0004,700No load speed: min.-1 = rpm

Driver bit: mm (")

Capacities: mm (")

[collated drywall screw]

Reverse switch

Protection against electric shock

6.35 (1/4) Hex

162 (6-3/8) or 157 (6-3/16) 182 (7-1/8) or 177 (7)

Shank

Overall length*

Yes

Double insulation

*Overall length of driver bit may differ by country.

6842/ 6843

6844

TECHNICAL INFORMATION