DeKo DKCSP03 User manual

INSTRUCTION MANUAL

THERMOPLASTIC UTILITY PUMP

Model NO.:DKCSP03/DKCSP03BL, CSP9026/CSP9028

DKCSP04/DKCSP04BL,CSP9025/CSP9027

⚠IMPORTANT: Read this instruction manual before operating this product. Keep

the instruction manual for future reference.

DEKO TOOLS CO., LIMITED

www.dekotools.com Made in China

100V-V2304

1

General Tool Safety Warnings

Read all safety warnings and all instructions. Failure to follow all warnings and

instructions may result in electric shock, fire and/or serious injury. Save all warnings and

instructions for future reference. For safety reasons, people who are not familiar with

these operating instructions should not use this Submersible Pump.

Before Start-up, Note The Following!

Mains Supply

Your new submersible pump is equipped with a shock-proof plug according to

regulations.the pump is designed to be connected to a 100-120V~50/60Hz(for final and

correcct voltage /frequency info, please refer to the rating label on the product) safety

socket. Make sure that the socket is sufficiently secured and is in excellent condition.

Introduce the plug into the socket and the pump is ready to go.

⚠WARNING: If the mains cable or plug suffers any damage from external action,

repairs to the cable should be serviced by a qualified specialist using only standard

spare parts. This will ensure that it meets the required safety standards.

Always check the pump (above all power cable and plug) before each operation. A

damaged pump must not be used. It is absolutely necessary to have the pump

checked by your electrician.

Take care that the electrical connections are made within a dry area, protected

from flooding.

Protect plug and power cable from heat, oil and sharp edges.

Check line voltage. Data indicated on the type plate must match technical data of

the main supply.

Children under the age are not allowed to operate the pump. Keep them away from

the connected unit.

Before use, first clear the outlet.

Circulation of aggressive fluids,as well as the circulation of abrasive Materials must

be avoided at all costs.

The submersible motor-driven pump must be protected from frost.

The pump has no self-stop function. In order to prevent the pump from running dry

or other faults, it is necessary to ensure that the pump is kept in observation during

operation.

2

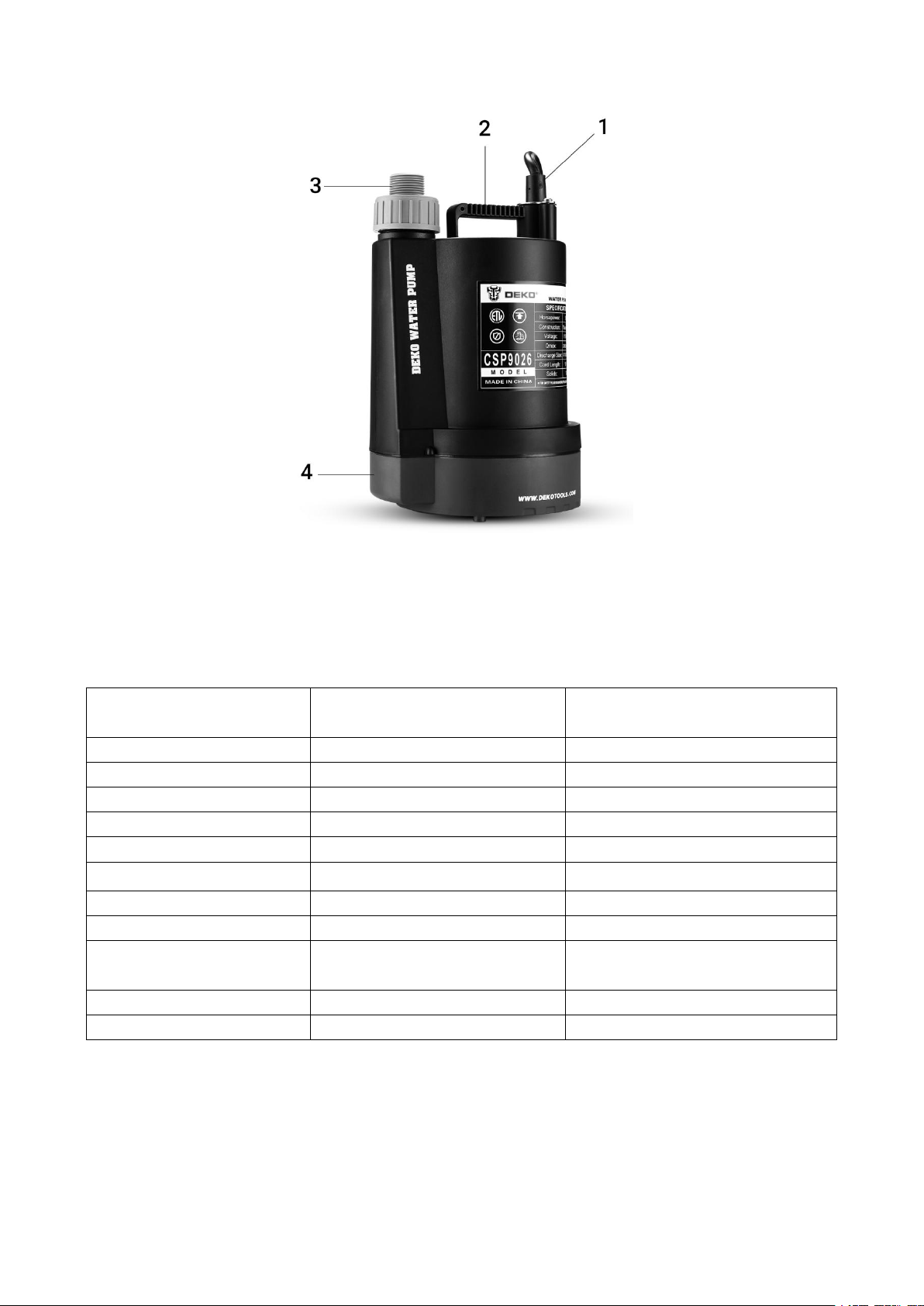

Parts Description

1. Power cable

2. Handle

3. Output hose fitting ( GHT 3/4", NPT 1-1/4" From up to down)

4. Pump base

Specifications

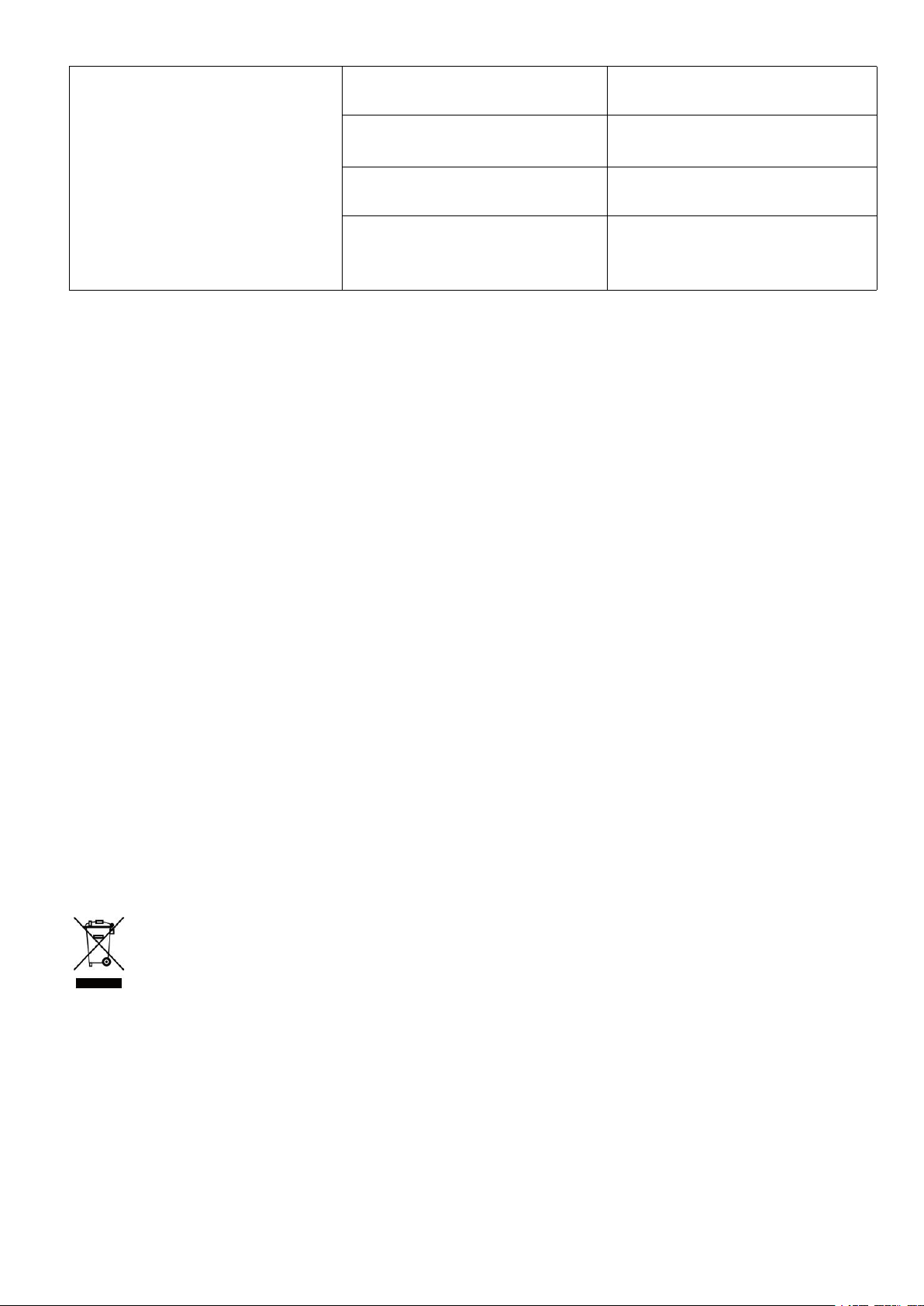

Model

DKCSP03/DKCSP03BL

CSP9026/CSP9028

DKCSP04/DKCSP04BL

CSP9025/CSP9027

Rated Voltage

100-120V~50/60Hz

100-120V~50/60Hz

Power

1/3HP

1/4HP

Amps

3.5 Amp

3 Amp

Q.max (Max. Flow Rate)

2450GPH

1850 GPH

H.Max (Max. Lift Height)

28ft (8.5m)

27 ft (8m)

Max. Submersion Depth

23.0ft (7m)

23.0ft (7m)

Max. Grain Size

1/8” (3.2mm)

1/8” (3.2mm)

Power Cord Length

10 ft (3m)

10 ft (3m)

Diameter of Pipe

GHT 3/4", NPT 1-1/4"(From

Up to Down)

GHT 3/4", NPT 1-1/4"(From Up

to Down)

Max. Water Temperature

95°F (35°C)

95°F (35°C)

Waterproof Class

IPX8

IPX8

Remark: for final and correct voltage / frequency info, please refer to the rating label on the

product.

Intended Use

This non-automatic submersible utility pump is designed to remove water from, flooded

basements, window wells and stock tanks, etc.

3

Assembly

Hose Connection

The output hose fitting and adapter allows

connection of GHT 3/4", NPT 1-1/4" hose

(From Up to Down), depending on your

individual requirement or applications.

Remark: the comming fitting/adapter may

vary according to different countries or

markets. Please refer to the package, sales

details or your dealer.

Installation

1. Install the pump on a hard level surface in the water. If necessary, place bricks

operation blocks under the pump to raise it off the bottom. Do not place the pump

directly in mud, sand or silt or on rocky surfaces as these materials can clog or cause

damage to the pump.

2. Connect a hose to the pump discharge. Use either the supplied garden hose adapter

or other hose fitting (sold separately). Choose the best size hose or pipe for your

application.

NOTE: To keep friction loss as low as possible, do not use a hose that is smaller than

3/4".

Operation

⚠WARNING: After having read these instructions carefully, you can set your pump to

work, reconsidering the following item:

Check if the pump rests on the ground.

Check if pressure cord has been attached properly.

Check if the voltage/frequency of the receptable corresponds to that of te pump.

Make sure that water and humidity can never come to the mains supply.

Avoid pump running dry.

1. Connect the plug into a 100-120 volt AC grounded outlet. The use of a GFCl is

strongly recommended.

2. After the power is connected, the water pump starts to run. After the power is

disconnected, the water pump stops running.

3. Do not let the pump run dry. The pump depends on water for cooling and lubrication.

Operating the pump without water may cause the motor to overheat or cause damage to

internal parts. It may shorten the life of your pump. Pumping fluids above 95°F (35°C)

also shortens the life of the pump.

4

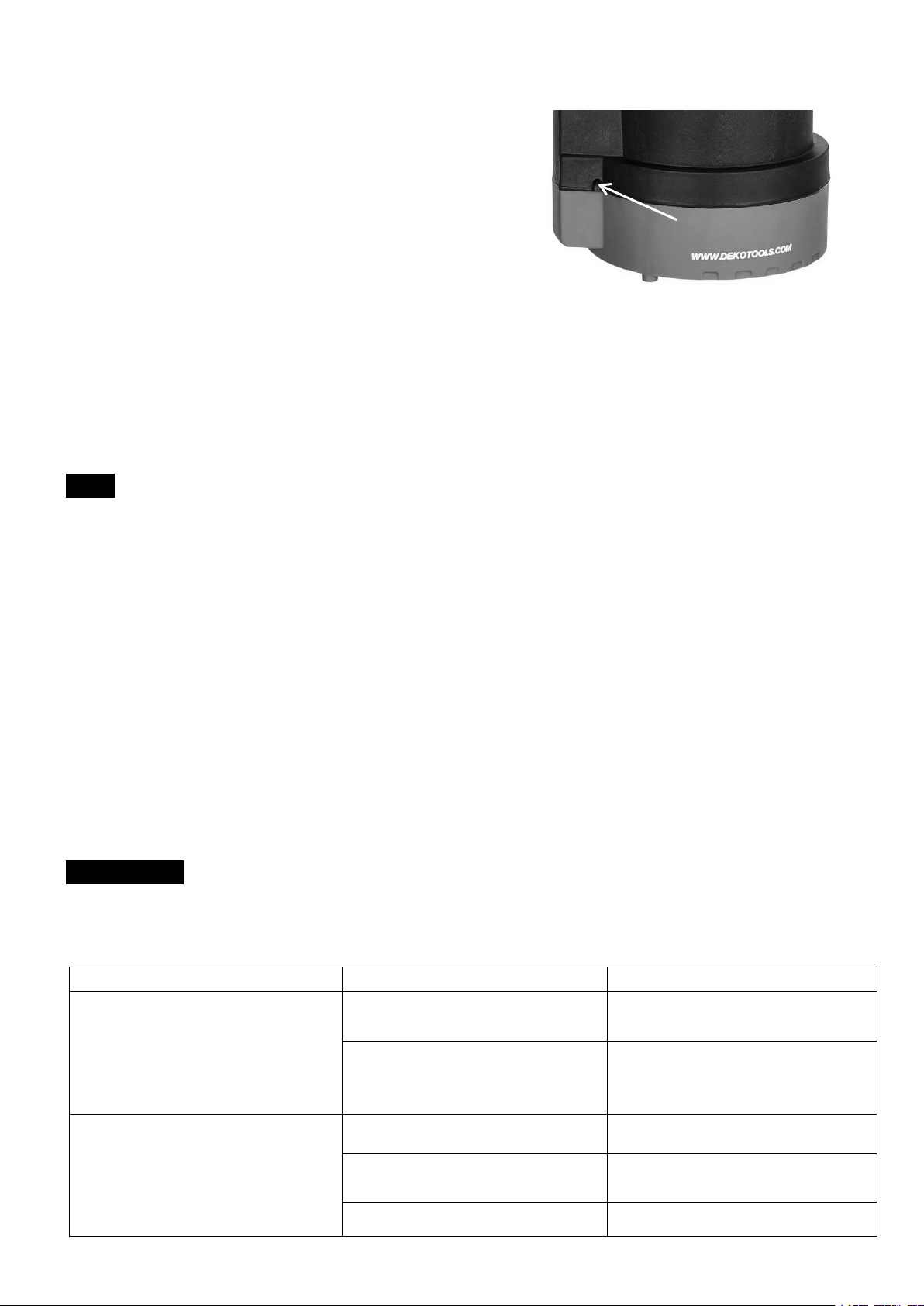

Air Lock

When a pump airlocks, it runs but does not move

any water. An airlock will cause the pump to

overheat and fail. This pump has an air discharge

hole to prevent airlock. If you suspect an airlock,

unplug the pump, clean out the anti-air lock hole

with a paper clip or piece of wire, and restart the

pump.

Maintenance

Maintenance Guidelines

This submersible pump is an approved, maintenance-free high quality product, which is

subject to severe final controls.

We recommend, regular inspection and maintenance to ensure long equipment life and

uninterrupted operation.

Note:

Remove the mains plug before all maintenance work.

In the event that the pump is often transported in the course of operation, it should

be cleaned out with clear water after every use.

In case of stationary installation,the function of the locating switch should be

checked every 3 months.

All fibrous particles which may have built-up inside the pump housing should be

removed with a water jet.

Every 3 months the shaft ground and as should be cleaned from mud.

Remove deposits on the floater with clear water.

Cleaning The Impeller

If excessive deposits collect in the pump case you must dismantle the bottom part of

the pump as follows:

1 Remove the intake cage from the pump case.

2 Clean the impeller with clear water.

⚠WARNING: Do not put down or rest the pump on the impeller!

3 Assemble is reverse order

Trouble Shooting

Incidents

Causes

Remedies

If the pump does not start

run

-Pump is not plugged in,

switch or breaker is off

-Plug pump in or turn on

switch /breaker

-Check for blown fuses or

tripped circuit breakers or

tripped outlets

-Replace fuse, reset breaker,

reset outlet

If the pump runs but moves

little or no water

Clogged intake screen

Clean or replace screen

Clogged discharge

hose/pipe

Remove clog

Impeller obstructed

Remove obstruction/debris

Air discharge hole

5

Guarantee Note

Not covered by guarantee:

Destruction to rotating mechanical seal by dry running or impurities in water.

Blockage of running wheel through foreign bodies

Transport damage

Damage caused by unauthorized persons

Service Information

This tool is warranted to the original purchaser to be free from defect in materials and

workmanship for a period of 2 years from the original purchase date.

If the tool should fail some day in spite of our quality controls and materials, only have it

repaired by an authorized electrician or contact your local distributor or service agent.

Or you can contact us by emails:

services@dekotools.com, support@dekotools.com

The warranty will not apply to the following cases:

(i) where this product has been subjected to misuse, abuse, accident or want of care;

(ii) where this product has been used for a purpose for which it was not designed or is

not suited;

(iii) where the service of this product has been undertaken by a non-authorised person or

company or if non-approved parts have been used.

(iv) components that are subject to natural wear and tear caused by use in accordance

with operating instructions.

Disposal

The machine and packaging should be sorted for environmental-friendly

recycling. Do not dispose of power tools into household waste! Please recycle

them at collection points provided for the purpose. Ask your local authority for

information about recycling.

Frozen discharge

hose/pipe

Allow hose/pipe to thaw

Pump is air locked

Clean out airlock hole with a

paper clip or pipe cleaner

Low line voltage

Check wire size and

increase if necessary

Worn, damaged or clogged

pump parts

Inspect for wear, damage or

clog and clean or replace if

necessary

DEKO TOOLS CO., LIMITED

www.dekotools.com

Made in China

This manual suits for next models

7

Table of contents

Popular Water Pump manuals by other brands

Liquiflo

Liquiflo FTS300 Series SAFETY, INSTALLATION, OPERATION AND MAINTENANCE INSTRUCTIONS

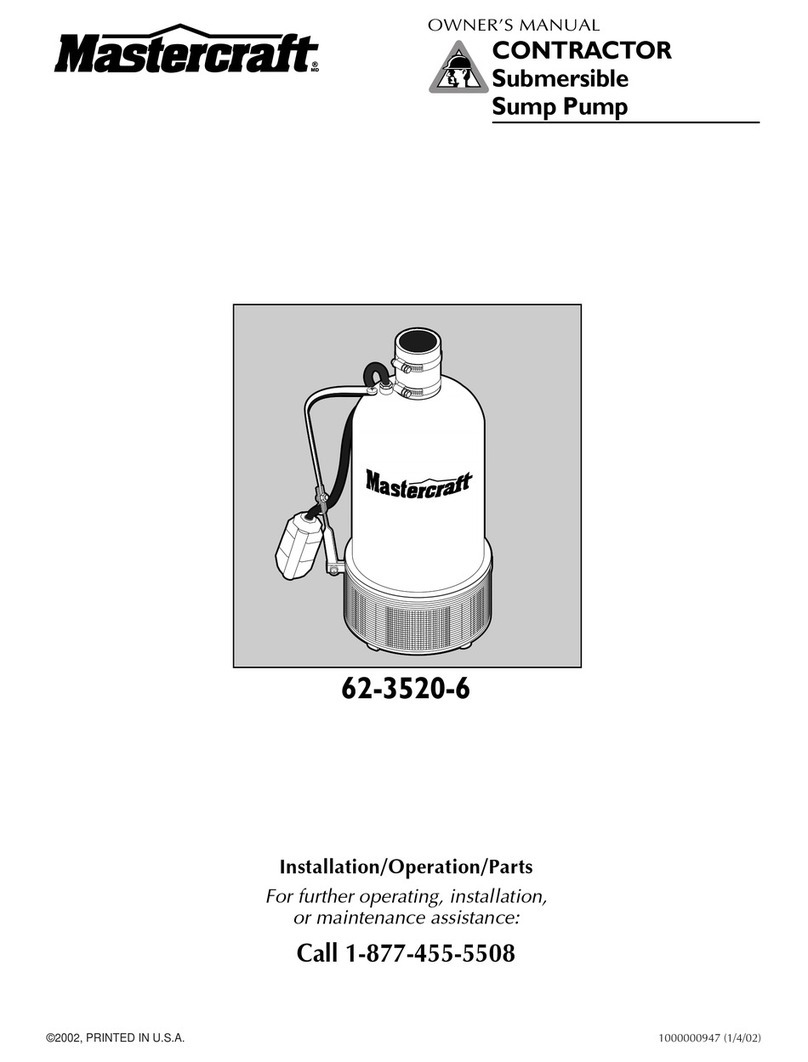

MasterCraft

MasterCraft 62-3520-6 owner's manual

Gardena

Gardena inox automatic 5900/4 Operator's manual

Kracht

Kracht BT Series operating instructions

Standard Pump

Standard Pump SP3A15NPT Service & operating manual

HPP

HPP GL 135/235 Assembly and special maintenance instructions