Deldent JETPOLISHER 2000 User manual

INSTRUCTIONS FOR CLEARING JETPOLISHER 2000 CLOGGING

BACKGROUND

Your Jetpolisher 2000 unit incorporates Deldent’s patented H.S.T.®

polishing system. This advanced system premixes the air / powder stream

with the water stream just before exit from the single orifice nozzle.

This is in contrast to other airpolishing units, that deliver the water stream

and air / powder stream from distinctly separate concentric or adjacent

nozzles. The H.S.T. (Homogenous stream technology) design, virtually

eliminates nozzle clogging by significantly reducing the risk of build-up of

Anhydrous Sodium Bicarbonate, a hard, white crystalline deposit that

builds up, so frequently, in the lumen of the nozzle orifice, in other

systems. The unique H.S.T. system has been shown to give prolonged

clog-free nozzle function as compared to competitive units.

However, there are other reasons why your Jetpolisher 2000 unit may

become clogged. Careful attention to these points will avoid unnecessary

clogging.

•Damp air supply – always ensure that a quality air drying system is fitted

to the main air supply system of the operatory. The compressor should be

drained of water build-up every day according to its manufacturer’s

instructions.

•Loose connection between the dental unit tubing connector and the

connector on the front of the Jetpolisher 2000 - This can result in water

mixing with the dry air supply before entering the Jetpolisher 2000 unit.

Ensure that the connector is firmly screwed to ensure adequate pressure

against the Jetpolisher 2000’s connector gasket.

•Occluding the nozzle orifice against soft tissue or otherwise, may

result in a back-flow of water along the air / powder supply tubing in

the Jetpolisher 2000 handpiece, which in extreme conditions may

reach the powder reservoir.- ensure that the sprayhead nozzle is held

approx 3-5 mm from the work surface being treated.

•Never use inferior quality prophy powder in your Jetpolisher 2000.

Deldent’s specially formulated and carefully graded JETSTREAM™

powder, is the airpolishing powder of choice for your unit, to give you

trouble free function. It is available from most leading dealers.

•Never use aluminum oxide or other powder in your Jetpolisher 2000.

In the event that your Jetpolisher 2000 system becomes clogged, our

professional staff is always available to offer you advice and help.

However, in most instances, clearing the blockage is a simple procedure,

that, if performed by yourself or your staff, will quickly have your unit back

in function, save you the need to reschedule your patients, and save

unnecessary service costs.

CLEARING A CLOGGED UNIT.

The following are simple to follow steps to help you get your unit back in

function quickly.

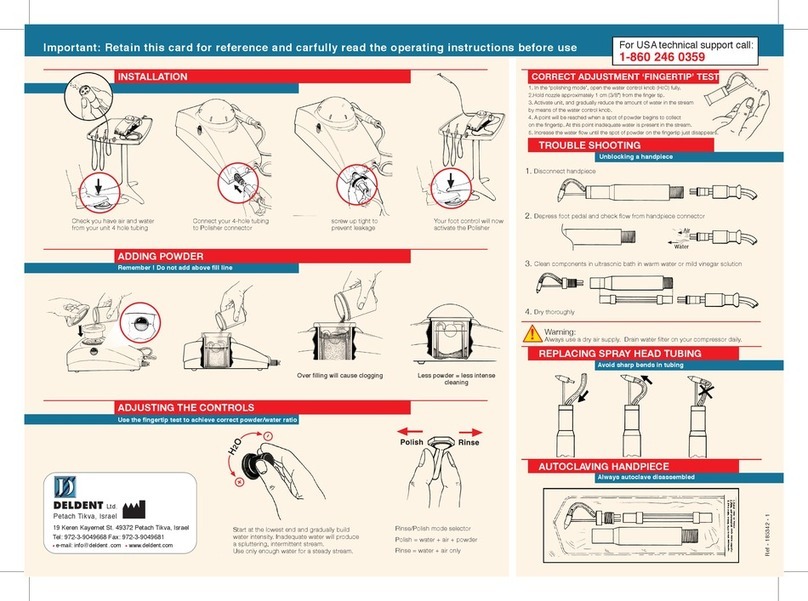

1. Disconnect the unit from the dental supply tubing.

2. Remove the powder reservoir lid.

3. Check the powder reservoir. – If the powder is lumpy or does not

flow freely when agitated, discard all remaining powder in the

reservoir. Flush the reservoir with a little warm water to dissolve any

remaining traces of powder, and dry thoroughly by means of tissues

or a dry air supply, if available.

4. Reconnect the unit to the dental supply tubing.

•Firmly close down the water control valve fully.

•Ensure that the intensity valve has been fully opened.

•Activate the unit with the mode selector switch in the ‘POLISH’

mode position.

•Confirm that there air is flowing from the air inlet tube ( U –

shape) of the powder resevoir.

This confirms that there is no blockage in the system prior to the

powder reservoir.

5. Replace the powder reservoir lid firmly. Do not add powder at this

stage.

6. Disconnect the polishing handpiece from the handpiece tubing by

unscrewing the handpiece connector.

7. Activate the unit and confirm that air is flowing from the wider

diameter tube of the handpiece connector.

This will confirm that the blockage is in the handpiece, and not in the

handpiece tubing. Proceed to the section on handpiece blockage

below, if the blockage appears to be in the handpiece

8. If no air is flowing from the handpiece connector, remove the powder

reservoir lid and, using a stream of compressed air if available or,

blow air, backwards from the handpiece connector along the wider

bore tube towards the powder reservoir. This will normally clear the

blocked handpiece tubing. Warning: To prevent particulate material

getting into the eyes, avoid looking into the powder reservoir, during

this procedure. Replace the powder lid and repeat step 7.

9. If this does not clear the blockage, gentle tapping along the length of

the handpiece tubing will often break-up clumps of powder that may

have accumulated in the tubing especially if the unit has not been

operational for some time.

10. The handpiece tubing can easily be removed from the unit by

disconnecting its wide-bore air tube from the connector at the

powder reservoir outlet, and its narrow-bore water tube that is

connected to the water control valve outlet. Activate the unit and

confirm that air is flowing from the outlet connector of the powder

reservoir. The absence of airflow indicates a blockage in the L-

shaped outlet tube of the powder reservoir.

11.Blockage in the L-shaped outlet tube of the powder reservoir can be

cleared either by blowing air through this tube in either direction, or

filling the empty powder reservoir with warm water and a little

vinegar to cover the L-shaped outlet tube, and leaving for a few

hours. Soaking a blocked handpiece tubing in warm water and a

little vinegar will dissolve any build-up of sodium bicarbonate inside

the tubing. Some mild effervescence may be generated during this

procedure, so it is better performed with the unit or handpiece tubing

placed in a suitable receptacle.

12.Replace the powder lid and repeat step 7.

13.Repeat step 11 if the blockage persists, followed by step 7.

14.If the handpiece tubing has been disconnected from the unit,

reconnect at this time and repeat step 7.

15.The unit should be fully dried at this stage by dry tissues and / or a

constant stream of dry air, until no sign of condensation or water

mist is observed on a mirror surface placed close to the air outlet

tube of the handpiece connector. Operating the unit without powder

in the powder reservoir can achieve this.

BLOCKED HANDPIECE:

1. Disconnect the handpiece from the handpiece connector if this has

not already been done.

2. disassemble the handpiece into its 3 components, as for the

handpiece autoclaving procedure.

3. Carefully remove the transparent spray head tubing it may be

necessary to cut this if it will not pull off gently or with aq little

rotation movement. Warning: Excessive force may result in bending

of the spray head water tube or even failure of its solder joint.

4. Soak the handpiece components in warm water and a little vinegar,

to dissolve any accumulated sodium bicarbonate. Dry the

components thoroughly, and confirm by holding the components up

to the light, that all of the channels are clear. Repeat step 4 as

necessary.

5. Before reassembling the Handpiece, repeat step 7 of the ‘Clearing a

clogged unit’ section above.

6. Place some Jetstream Powder in the powder reservoir and firmly

replace the powder reservoir lid. Repeat step 7 of the ‘Clearing a

clogged unit’ section above and confirm that powder is flowing freely

from the wide-bore tubing of the handpiece connector.

7. MOVE THE MODE SELECTOR SWITCH INTO THE ‘RINSE’ MODE

POSITION and repeat this step, to clear the tubing of residual

powder.

8. Reassemble the handpiece components, and connect the handpiece

to the handpiece connector. With the mode selector still in the

‘RINSE’ mode position, open the water control valve fully. And

activate the unit. Confirm that there is a steady stream of atomized

water flowing from the spray nozzle.

9. Move the mode selector switch into the ‘POLISH’ mode position, and

activate the unit. Adjust the water flow rate as necessary to create a

steady flowing homogenous atomized stream of air water and

powder.

RECOMMENDATIONS.

•Between treatment sessions, always flush the system for a few

moments by activating the unit in the ‘RINSE’ mode position.

This will flush residual powder from the system.

•Regularly disassemble the handpiece into its components for

autoclaving or cleaning.

•Always change the transparent spray head tubing after each

patient.

•Use only reputable prophy powder such as Deldent’s

Jetstream™ powder in your Jetpolisher 2000.

Table of contents

Other Deldent Dental Equipment manuals