Delta-T SOL2-UM-2 User manual

SOLAR POWER SUPPLY

for Delta-T logging systems

Type SOL2

USER MANUAL

SOL2-UM-2

SOL2

SOL2-UM-2 Oct 2001

Page 2

CONTENTS

INTRODUCTION AND DESCRIPTION 3

UNPACKING AND INSTALLATION 4

WIRING AND COMMISSIONING 5

MAINTENANCE 5

REPAIRS, SERVICE & SPARES 6

ADDITIONAL INFORMATION at end

Copyright

Copyright ©2001 Delta-T Devices Ltd., 128 Low Road, Burwell, Cambridge,

CB5 OEJ, England. All rights reserved. Under the copyright laws this book

may not be copied, in whole or in part, without the written consent of Delta-T

Devices Ltd. Under the law, copying includes translation into another language.

Delta-T Devices Ltd

128 Low Road, Burwell,

Cambridge CB5 OEJ, England

Telephone : (01638) 742922

Fax : (01638) 743155

Web site : www.delta-t.co.uk

SOL2

INTRODUCTION AND DESCRIPTION

This Manual describes the general specification, installation and maintenance of the SOL2 Solar

Power Supply. Detailed information on the system components can be found at the end of this

Manual.

The system may be used with either DL2e or DL3000 data loggers. This Manual should be read

in conjunction with the User Manual for the data logger used in the system, or with the

Application Manual, if supplied with the system.

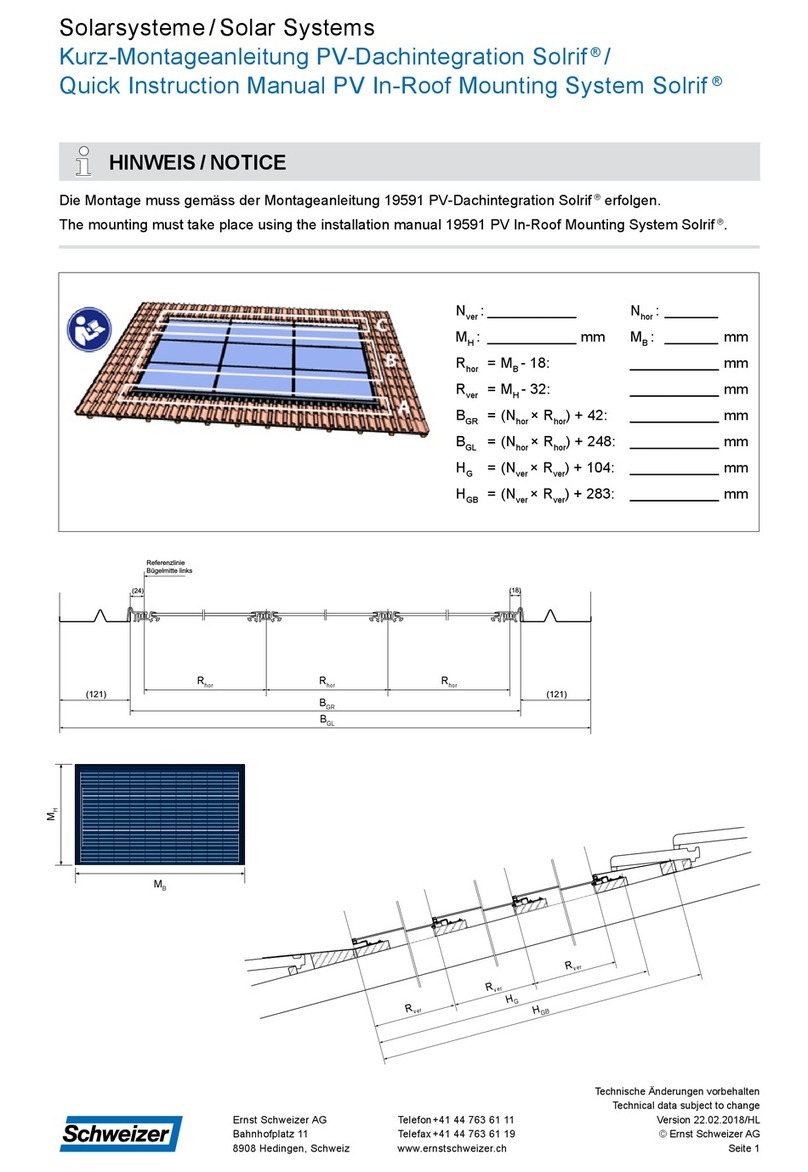

The Solar Power Supply type SOL2 comprises two main components:

A. Photovoltaic cell, Siemens type SM10. This will provide approximately 0.5A at 12-

15VDC when exposed to solar radiation levels of 1000 W/m2.

B. System Regulator, Solsum type 6.6x. This monitors the photovoltaic cell and battery

voltage and controls the battery charging rate. (Inside weatherproof enclosure and

desiccant bag).

Additionally a battery type LBAT2 will be supplied to match the solar system:

C. High capacity, 38Ah, 12v, deep discharge battery. (Can be stored inside a lockable,

weatherproof box type BTBOX2)

Additionally a 2M length of white, 1.5mm² twin core cable is to be connected to the battery and

a 1M length of black 0.75mm² twin core cable is to be connected to the data logger.

Logger Cable,

enclosure and

terminal block

Battery Cable with

battery lugs

System regulator,

Solsum type 6.6x

(lid removed)

Photovoltaic cell,

Siemans type

SM10

SOL2-UM-2 Oct 2001

Page 3

SOL2

UNPACKING AND INSTALLATION

Unpacking

The system has been tested and checked at the factory and is ready for installation.

Immediately on receipt of the consignment, check it for possible damage in transit. Unpack the

consignment carefully and check all the items in the packing list. Do not dispose of any packing

material until any suspected shortage has been established beyond all possible doubt.

Please contact your agent or Delta-T Devices if damage has occurred, or if any parts on the

packing list are missing.

Installation

A crossarm and clamp type SOL2B are normally provided for attachment to the vertical pole of

the standard weather station mast.

The panel assembly should be positioned as shown in the picture. The battery should placed

beneath the solar panel as shown to give natural protection from solar radiation. This may have

been supplied with a lockable battery box type BTBOX2 to enable easier protection and greater

security.

The orientation of the solar panel is determined by the geographical location of the system.

Basically the panel should face directly towards the position of the mid-day sun, with as little

amount of shade as possible. It is normally good practice to mount the panel as close to the

ground as possible in order to reduce the effects of strong wind loads.

SOL2-UM-2 Oct 2001

Page 4

SOL2

SOL2-UM-2 Oct 2001

Page 5

WIRING AND COMMISSIONING

The photovoltaic cell is pre-wired to the system regulator before shipment to prevent reverse

polarity interconnection

Two, twin core cables are pre-attached to the system regulator.

A. Battery cable. Identified by its white sheath and battery lugs attached to each core.

Brown core must be connected to the POSITIVE battery terminal.

Blue core must be connected to the NEGATIVE battery terminal.

B. Load cable.

BROWN core should be connected the positive side of the load distribution block for your

application. This is the place where all your loads are brought to a central point. For most

applications this will be the digital connection block of the logger. For exact connection refer to

your logger or application manual

BLUE core should be connected the negative side of the load distribution block for your

application. This is the place where all your loads are brought to a central point. For most

applications this will be the digital connection block of the logger. For exact connection refer to

your logger or application manual.

NOTE THAT CARE MUST BE TAKEN TO ENSURE THAT BOTH THE BATTERY

CABLE AND LOAD CABLE ARE CORRECTLY CONNECTED. INCORRECT

CONNECTION MAY DAMAGE THE EQUIPMENT.

Before connecting either the battery or load, cover the solar panel to minimise the voltage

generated.

First connect the Battery cable to your battery. Then connect the Power Cable to the load

distribution block ONLY after thoroughly checking that your load wiring is correct

Specifications and general notes for the Photovoltaic cell System Regulator are attached, but all

the necessary modifications for your application have already been made. A 6.3A fuse is

installed on the System Regulator terminal board, to protect against excessive load currents.

MAINTENANCE

The solar panel and regulator are sealed against the environment. Maintenance is limited to

regular washing of the solar panel surface with fresh water.

The battery supplied with this system is of the sealed, lead acid type and requires no topping up

of electrolyte. The battery terminals should be greased and kept free from dust and moisture.

Some protection is achieved by placing the battery beneath the solar panel. Th battery can be

placed in a vented box if further protection is required.

SOL2

SOL2-UM-2 Oct 2001

Page 6

GUARANTEE, REPAIRS AND SPARES

Our Conditions of Sale ref: COND/91/11 set out Delta-T's legal obligations on these matters. For

your information the following paragraphs summarise Delta-T's position but reference should

always be made to our Conditions of Sale which prevail over the following explanation.

Instruments supplied by Delta-T are guaranteed for one year against defects in manufacture or

materials used. The guarantee does not cover damage through misuse or inexpert servicing, or

other circumstances beyond our control.

For the UK this means that no charges are made for labour, materials or return carriage for

guarantee repairs.

For other countries, the guarantee covers free exchange of faulty parts during the guarantee

period.

Alternatively, if the equipment is returned to us for guarantee repair, we make no charge for

labour or materials but we do charge for carriage and UK. customs clearance.

We strongly prefer to have such repairs discussed with us first, and if we agree that the

equipment does need to be returned, we may at our discretion waive these charges.

SERVICE AND SPARES

We recognise that some users of our instruments may not have easy access to technically

specialised backup.

Spare parts for our own repairable instruments can be supplied from our works. These can

normally be despatched within 1 working day of receiving an order.

Spare parts and accessories for sensors not manufactured by Delta T, but supplied by us

individually or as part of the weather station or other system, may be obtained from the original

manufacturer. We will endeavour to obtain parts if requested, but a certain amount of additional

delay is inevitable.

Should it prove necessary, instruments may be returned to our works for servicing. We normally

expect to complete repairs of our own instruments within 2 days of receiving the equipment.

Other manufacturers' sensors supplied by us and returned for servicing will take longer. They

will have to be returned to the original manufacture for servicing, and may be subject to

additional delays of two to four weeks.

Users in countries that have a Delta-T Agent or Technical Representative should contact them in

the first instance.

Table of contents