Maintenance Manual iii

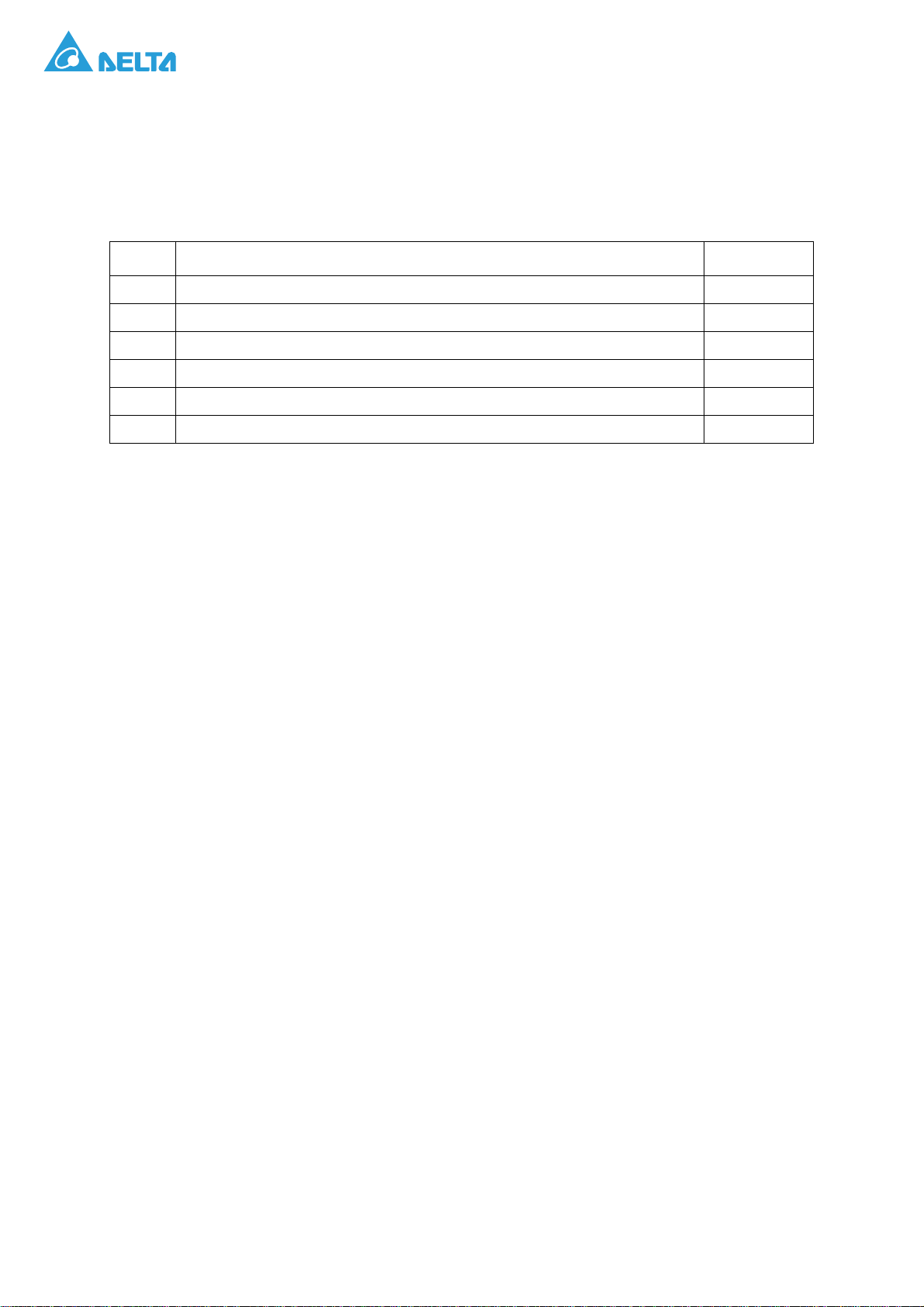

LCD Plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

LCD Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Auxiliary Heat Exchanger Power Board (G Board) . . . . . . . . . . 62

Switch Indicator for Door State (Door Sensor). . . . . . . . . . . . . . 64

DC Fuse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

AC Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Fuse for AC Surge Protection (AC SPD Fuse). . . . . . . . . . . . . . 72

AC Surge Protector (AC SPD) . . . . . . . . . . . . . . . . . . . . . . . . . . 75

DC EMI Filter Board (F Board). . . . . . . . . . . . . . . . . . . . . . . . . . 78

AC EMI Filter Board (E Board). . . . . . . . . . . . . . . . . . . . . . . . . . 80

Interface Board (J Board). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

DC Surge Protector (DC SPD). . . . . . . . . . . . . . . . . . . . . . . . . . 85

AC Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

DC Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

AC Main Contactor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

AC Softstart Contactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

DC Main Relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

DC Softstart Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

IGBT Driver Board (B Board) . . . . . . . . . . . . . . . . . . . . . . . . . . 116

IGBT Driver Adapter Board (A Board) . . . . . . . . . . . . . . . . . . . 119

DC Cap Board (D Board) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Module Control Board (M Board) . . . . . . . . . . . . . . . . . . . . . . . 128

System Control Board (S Board) . . . . . . . . . . . . . . . . . . . . . . . 132

Module Sampling Board (R Board) . . . . . . . . . . . . . . . . . . . . . 137

System Sampling Board (H Board) . . . . . . . . . . . . . . . . . . . . . 140

Ventilation Fan for Auxiliary Power . . . . . . . . . . . . . . . . . . . . . 144

Auxiliary Power Board (P Board) . . . . . . . . . . . . . . . . . . . . . . . 147

Auxiliary Transformer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152