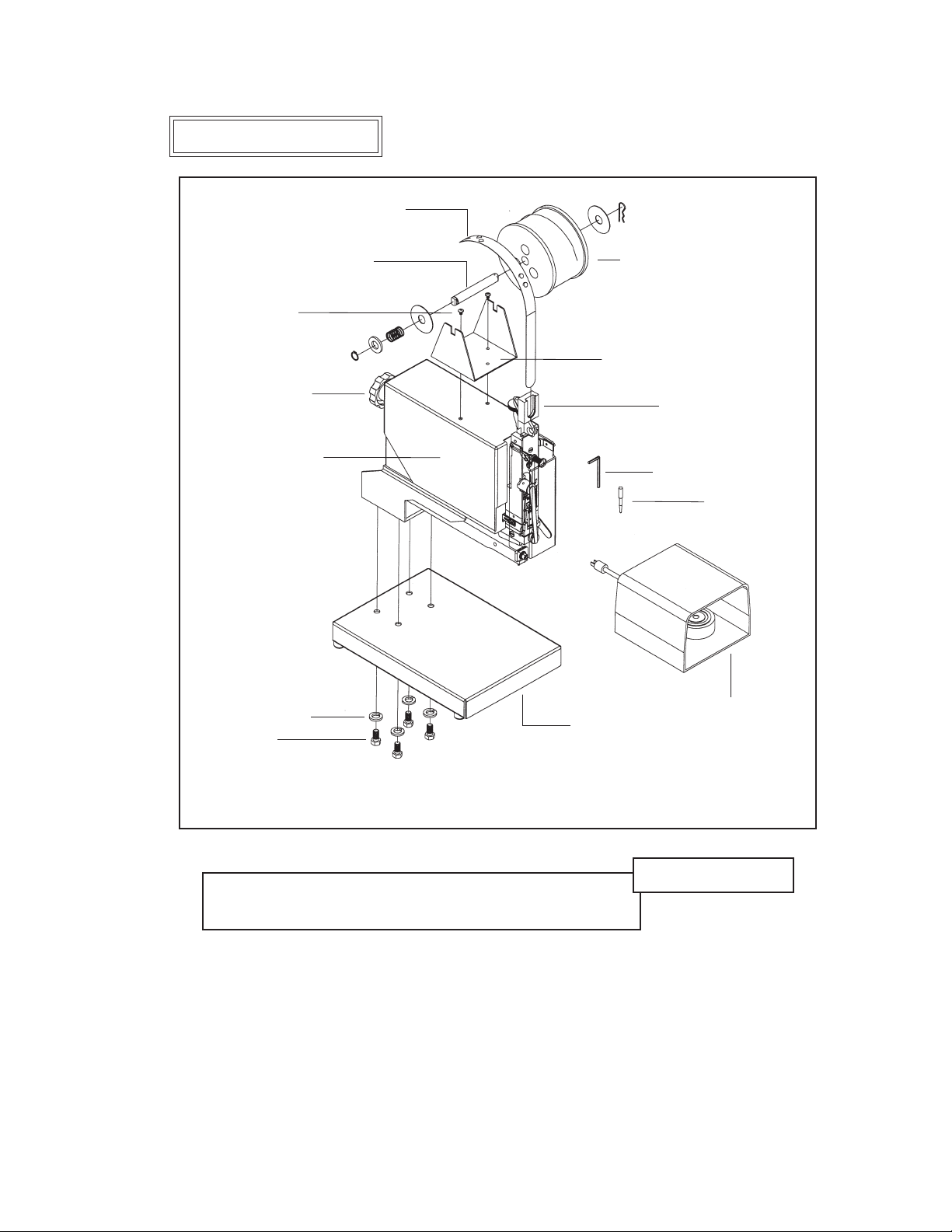

Wire Straightening (Figure 4)

Remove the Swivel Assembly (9038M or

9038A), the Swivel Operating Spring

(9046A) and the Swivel Operating Hub

(9163). The Swivel Operating Spring is

easily removed after rotating it to a position

comparable to 10:00 on the face of a clock

and pulling. Switch the Trip Mode Switch

(PG10232), found on the back of the

Machine, to continuous stitching and

activate the Foot Switch (PG10230). Watch

the feeding of the Wire through the Swivel

Holder (9043B). Notice the direction the

Wire is moving as it feeds out of the bottom

of the head. To compensate for some of the

Wire Spool’s (25G5 or 21256G5)

natural curve, the wire optimally should be

feeding slightly to the right. Use the Wire

Straightener Eccentric Nut (9067) on the

FacePlate(2132BA)toadjustthewire.

Right-to-Left Adjustment

LookthroughtheSwivelHolder(9043B)

at the Wire being fed through the Head. If

the Wire is feeding to the left or perfectly Figure 4 - Wire Straightening

Make sure the Swivel has been removed

before tripping the MiniStitcher to avoid

jams and the chipping of parts.

WARNING

8

Wire straightness is important so that the stitches are loaded, driven and closed properly. Although

straightness is set at the factory, every roll of wire has varying degrees of twist which makes it

necessary for the user to properly straighten the wire prior to production. Easy steps for straightening

the wire are listed below.

MG10001A

9070 (2)

9067 (2)

2132BA

9043B

threading process. With the Swivel still removed, power the MiniStitcher on and switch the Trip

Mode Switch (PG10232), found on the back of the Machine, to single mode stitching. Replace the

Head Guard and trip the Foot switch to allow the wire to automatically thread between the Grip and

the Grip Holder. This will also cut off any excess wire below the Cutters.

9163

9046A

!