10

feeding downward, turn the Eccentric clockwise.

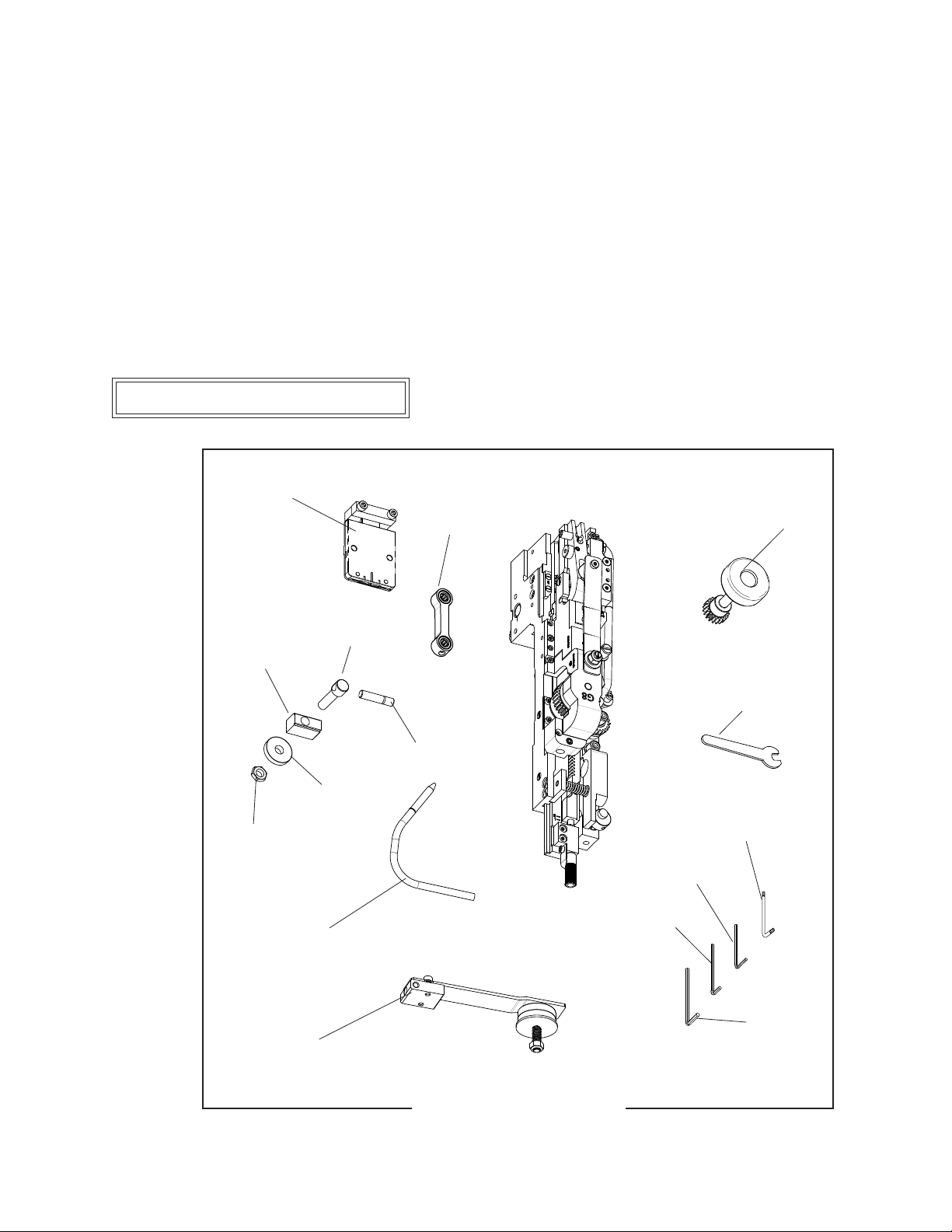

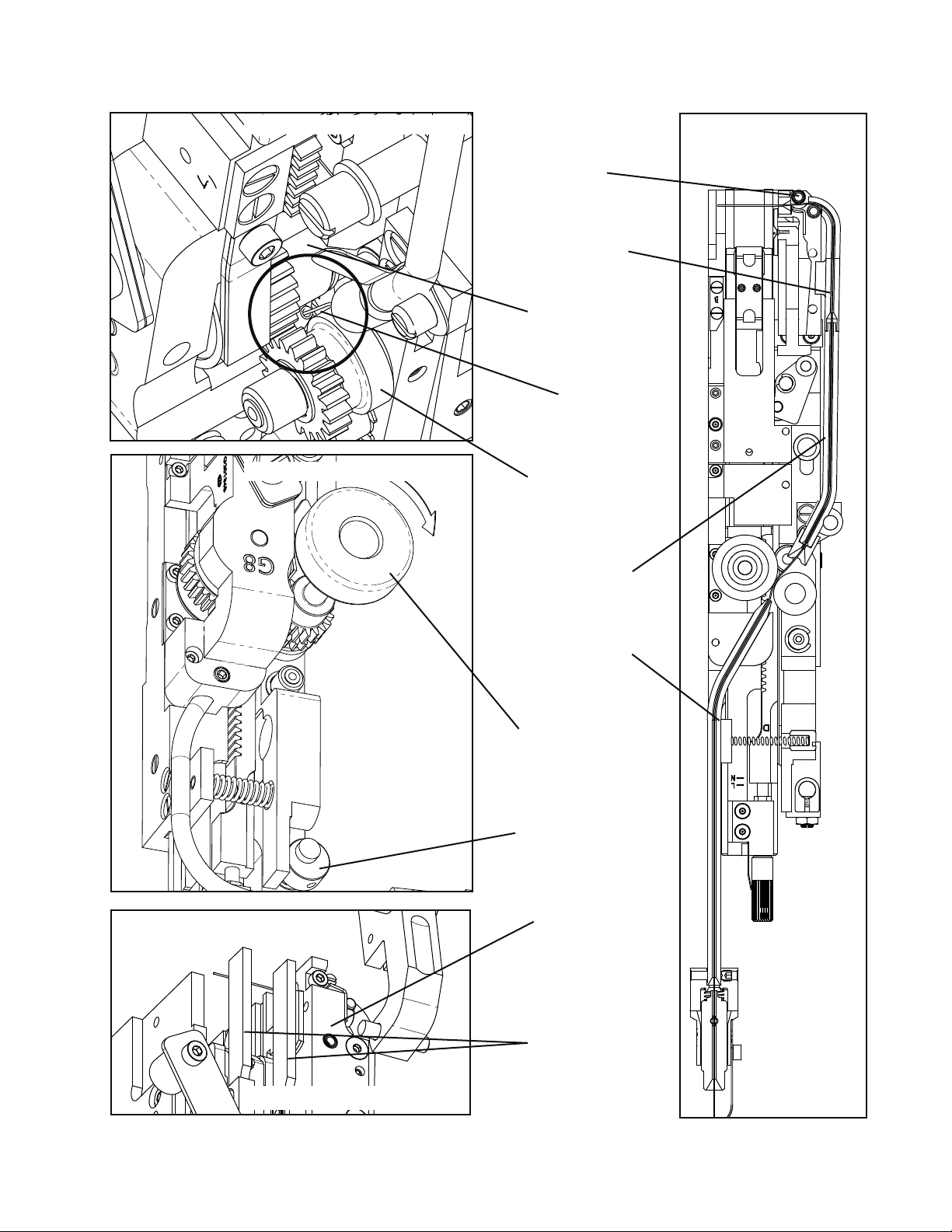

Front-to-Back Adjustment (APPLY ONLY UP TO LOT13)

If the Wire Guide Bars are not properly positioned, the wire

will rub against them as it exits the Cutter Block. Look at the

G8 Head from the side past both the Right and Left Wire Guide

Bars(Figure12).Makesurethereisaclearviewoftheopening

in the Fixed Wire Cutter from the side of the G8 Head. If there

isnot,loosentheFlatHeadMachineScrewssecuringtheWire

Guide Bars to the Pivot Block and move them out of the path of

the wire. Tighten the Screws after making sure the Wire Guide

Bars are even with each other. Replace the Wire Holder and re-

engage the Wire Holder Retaining Spring.

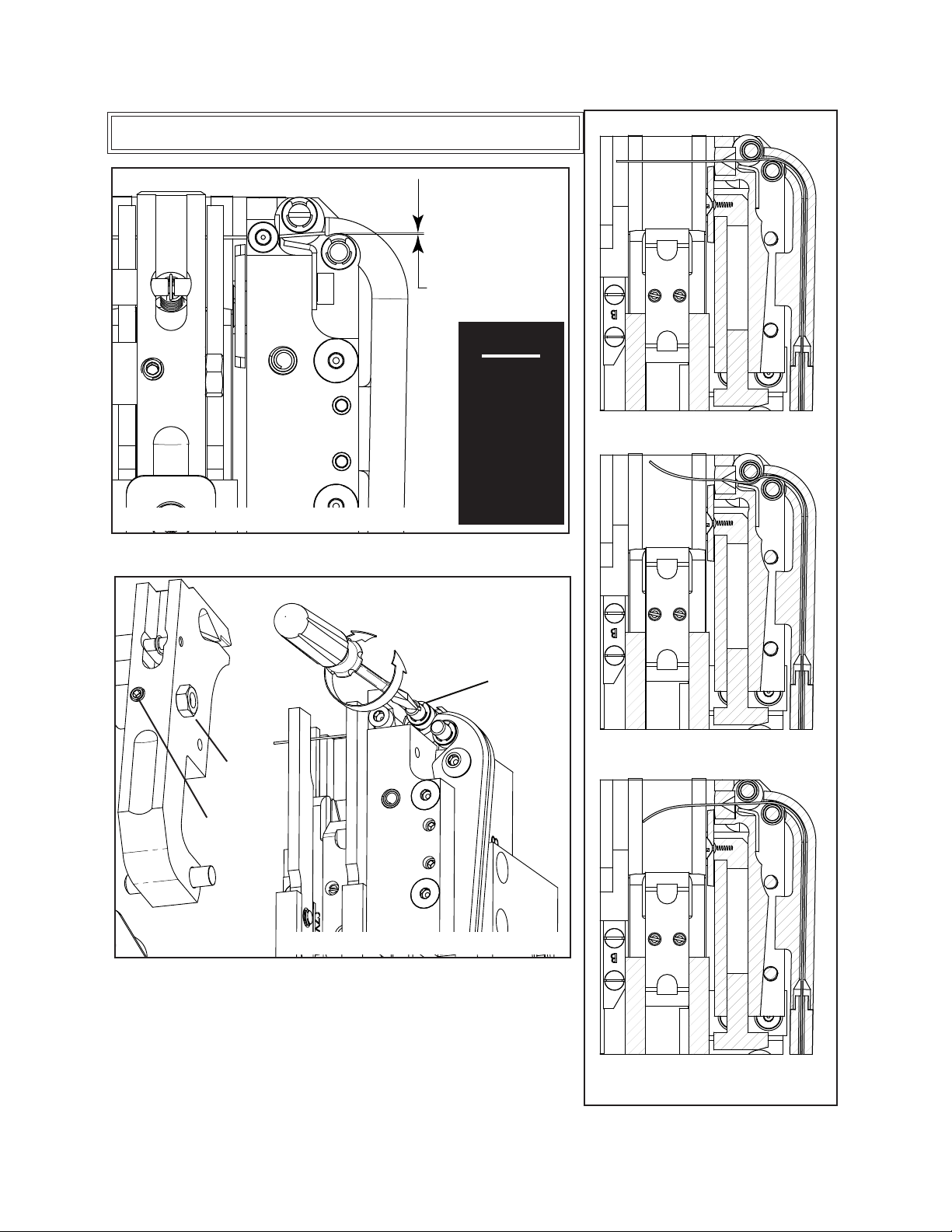

In order to form a quality stitch, the

Wire Holder has to be in alignment with

the Bender Bar. Specifically, the cut piece

of wire held in the Wire Holder has to line

up with the grooves in the Bender Bar.

Pooradjustmentmaycausebrokencrowns

or other poor stitching.

Aligning the Wire Holder (Figure 13a & b)

Figure 12 - Wire Guide Alignment

Fixed Wire

Cutter

Screw

(1 per side)

WIRE IN

WIRE

HOLDER

ALIGN TO

BENDER

BAR

GROOVE

Wire Holder

Adjustment Screw

Figure 13a - Wire Holder Alignment

WIRE

BETWEEN

BENDER

INSERT

GROOVES

Figure 13b - Wire Holder Alignment