DEMA MixRite TF-25 User manual

MixRite TF-25

2

MixRite TF 25 Proportional Dosing Injectors

We congratulate you on your purchase of one of MixRite's excellent products.

It is important to devote a few minutes to carefully reading the explanations and recommendations

in this user's manual in order to get the most from the proportioning dosing injector.

Operation of the injector

The proportioning dosing injector is fitted on the water line. The flow of water passing through the

injector activates it and causes the pumping of liquid additive and inserts it in a relative quantity

into the water line.

The MixRite TF 25 proportioning dosing injector will operate in the following

conditions:

The flow rate of the water passing through the MixRite TF 25 is between 2 and 25 m3/hour (530-

6600 gal/hour).

The water pressure is between 1 and 8 bar (14-120 PSI).

Head loss for MixRite TF 25: Minimum flow 0.1 Bar – Maximum flow 1.5 Bar

The water & air temperature are not less than 4ºC (40ºF) and not more than 40ºC (104ºF)

The flow rate of the additive can be adjusted relative to the flow rate of the water in the range of

0.1% to 1% for Model 001 and of 0.3% to 2.5% for Model 002 and in the range of 1% to 5.5% for

Model 005.

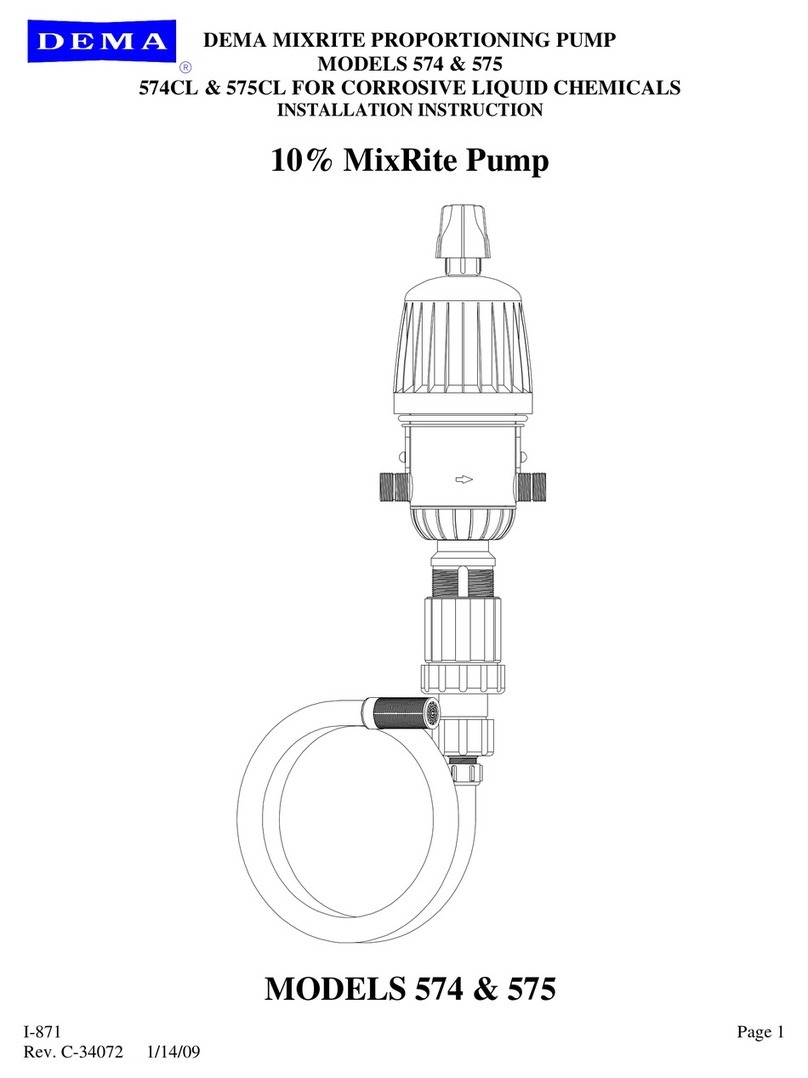

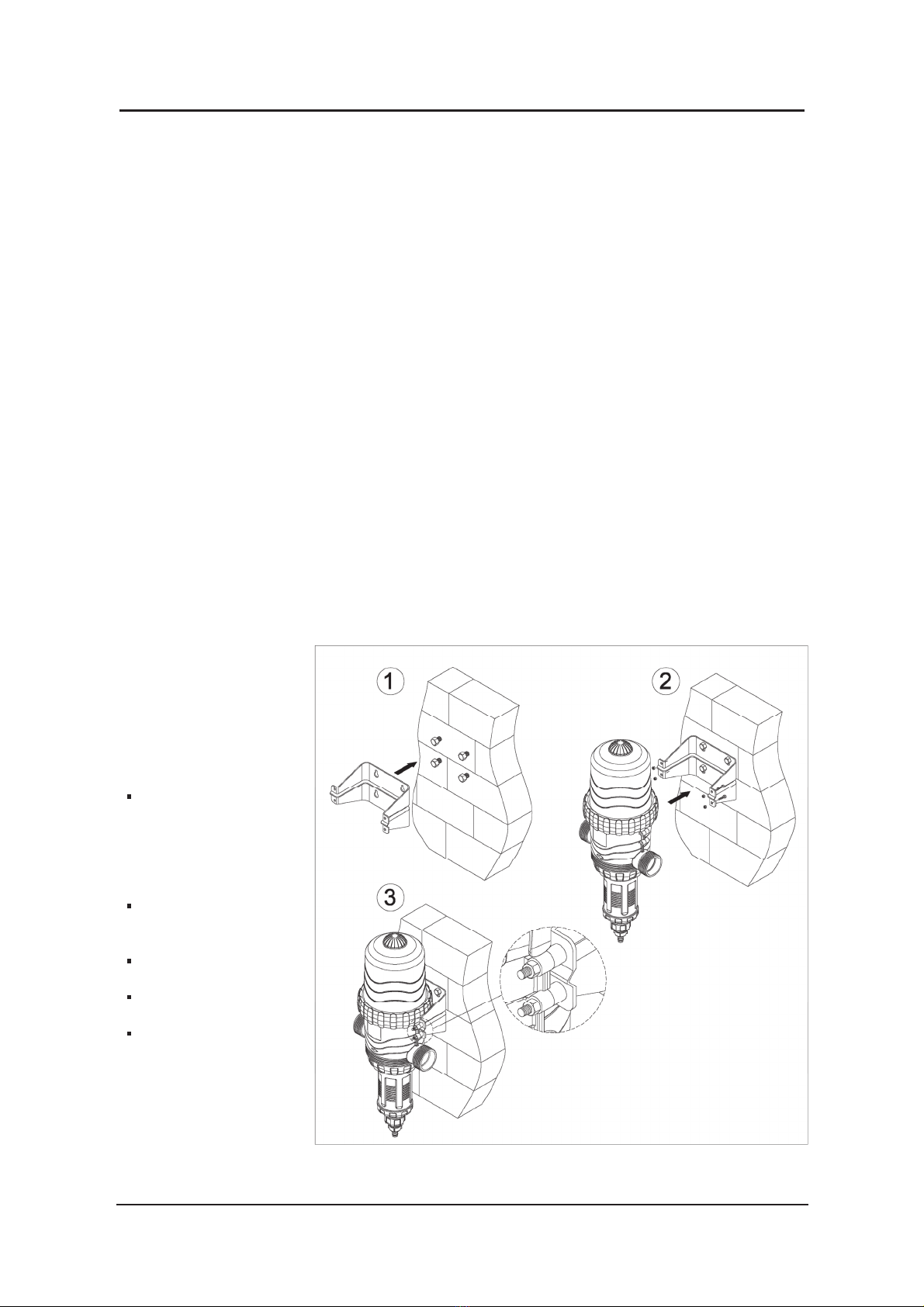

Installation of the

injector

Option A: Wall

mounting bracket

(Supplied as standard)

The package should

contain:

A proportioning dosing

injector to which are

attached two couplings

for a 63mm plastic pipe

Or two 2" threaded

couplings.

A flexible suction tube

to which is attached a

flat 1" seal and a filter.

A Bracket, 4 SS screws

M8*45, 4SS nuts M8.

Spanner for TF cover

nut.

User's manual

3

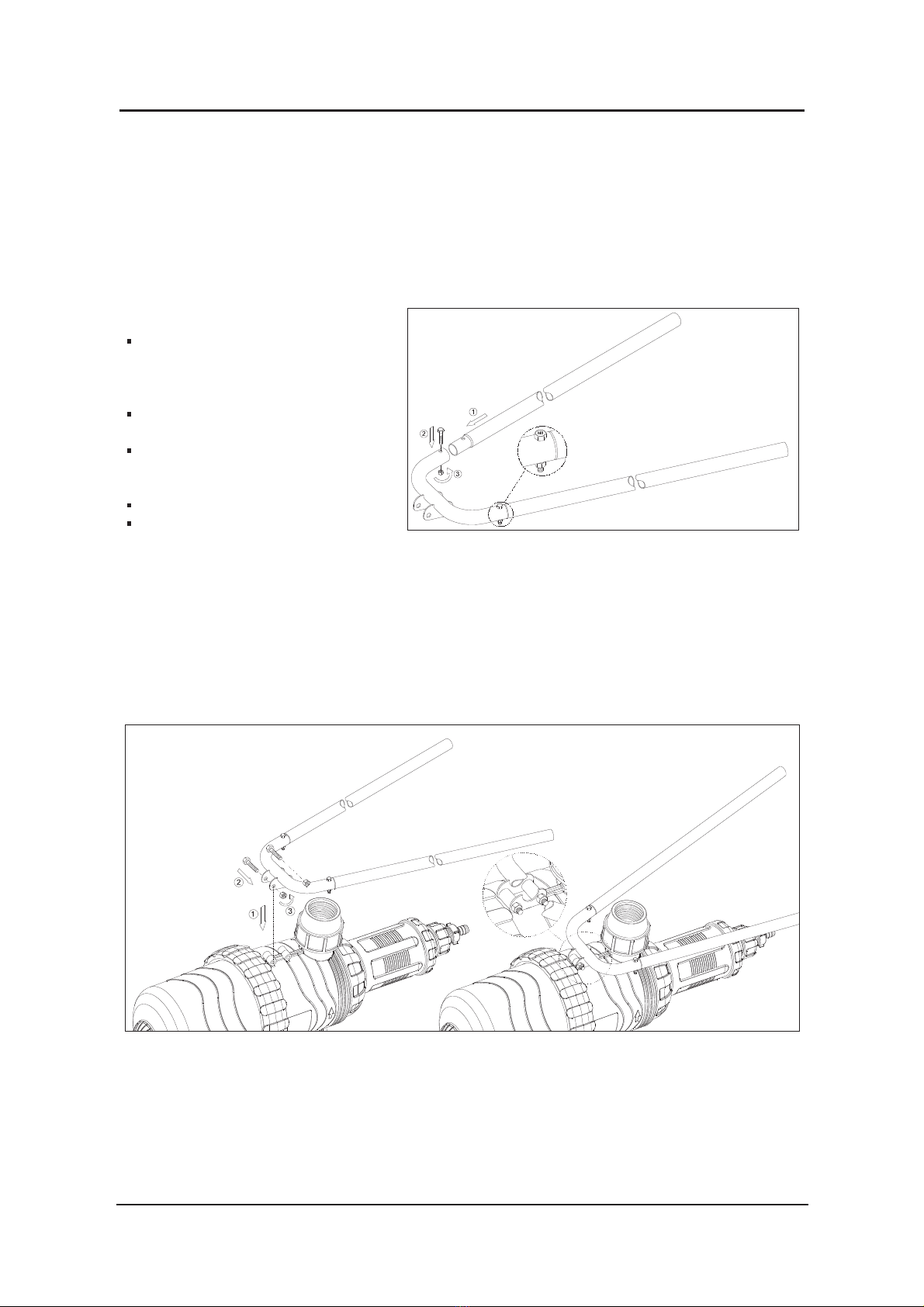

Option B: With stand

Installation of the injector (correct installation is with the stand supplied

By Tefen) – OPTIONAL

The package should contain:

A proportioning dosing injector to

which are attached two couplings

for a 63mm plastic pipe

Or two 2" threaded couplings.

A flexible suction tube to which is

attached a flat 1" seal and a filter.

A stand comprising 4 legs, 2

arched braces, 4 bolts with 8 mm

nuts and 4 bolts with 6mm nuts.

Spanner for TF cover nut.

User's manual

To assemble the stand

Insert the narrow part of the leg into the opening in the tube in the arched brace. Make sure that

the holes in the leg are opposite the holes in the arched brace. Insert the 6mm bolt and tighten the

nut. Repeat with the other legs.

Attach the arched brace to the body of the injector (1) with the 8 mm bolt (2) and tighten the nut

(3). Repeat with the other arched brace.

4

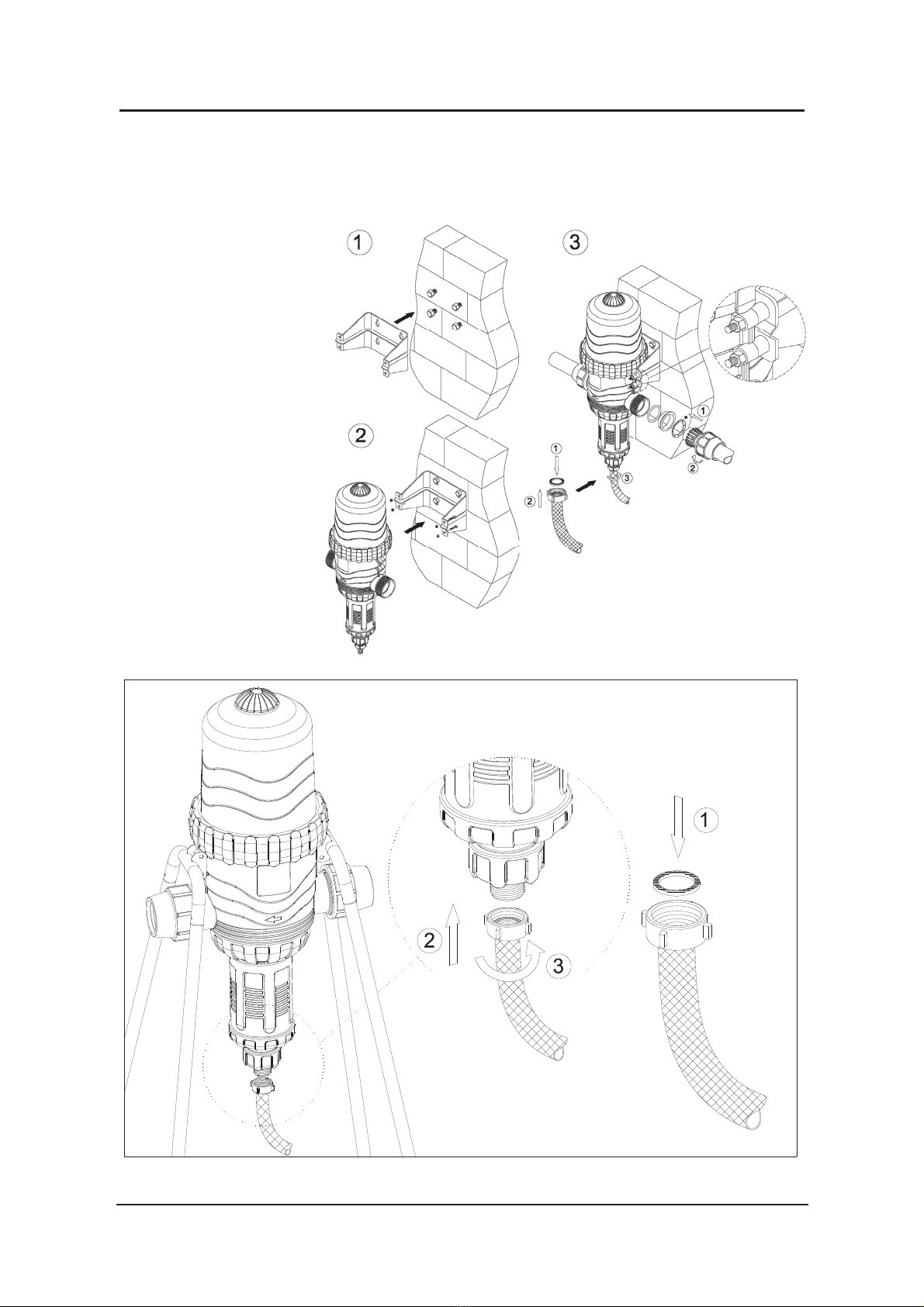

Connection of the

suction tube

Insert the flat seal into

the nut of the coupling

on the end of the tube

(1). Thread and tighten

the nut to the inlet

valve on the underside

of the injector. Make

sure that the nut is

threaded and

tightened properly

(2,3).

5

Connection of the injector to a 2" line

Note the direction of the water flow. Assemble the injector with the arrow stamped on the body of

the injector pointing in the direction of the water flow. Connect the injector using the plastic

couplings.

For a drinking water line all injectors must have a backflow prevention valve installed in front of the

injector on the main water line, in accordance with local regulations.

Connection of the injector to a 63mm plastic pipeline

Note the direction of the water flow. Assemble the injector with the arrow stamped on the body of

the injector pointing in the direction of the water flow.

Cut and round the edges of the inlet and outlet pipes. The distance between the end of the inlet

pipe and the end of the outlet pipe should be 22cm.

Remove the 63mm nut and the white ring from the injector, and fit them on to the pipe a short

distance from the end.

Check that inside the injector there is the

seal for 63mm accessories and that the

bushing for the 63mm seal closes it from

the outside.

Insert the pipe into the inlet and outlet

opening and push hard so that the pipe

penetrates, and passes the seal, and is

stopped at the end of the route. To ease

Insertion apply a little silicon grease to

the end of the pipe.

Push the white ring until it contacts the

threaded part, and tighten the nut.

Repeat the process in order to connect

the pump to the pipe on the other side.

* Optional Special grip ring for P.V.C pipes

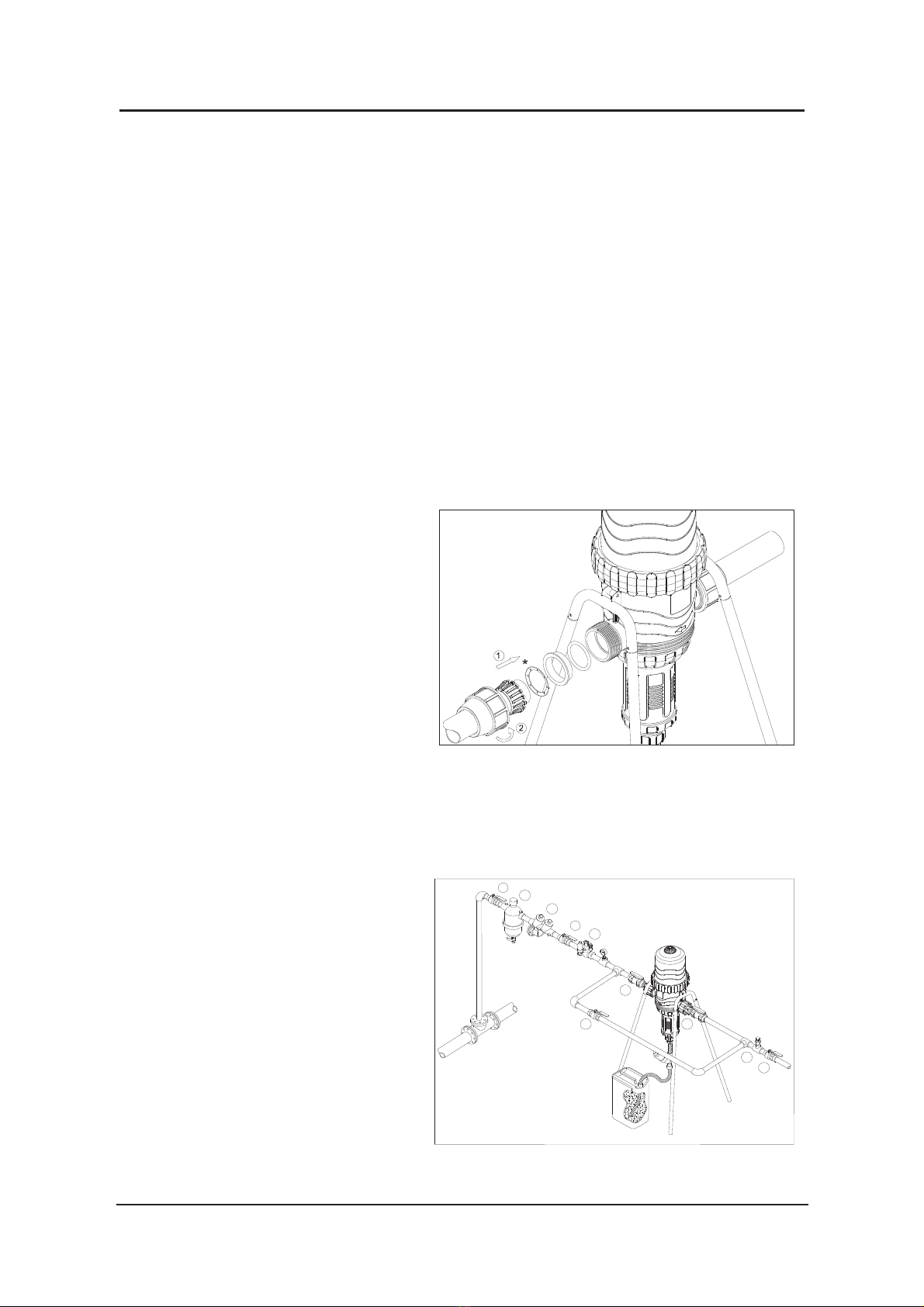

Installation of the injector on a direct line

It is recommended to fit a main valve at the beginning of the line (1), and a water filter of 200

mesh (2). A backflow prevention valve (3) must be fitted to a drinking water line, in accordance

with local regulations, in order to prevent entry of chemicals into the drinking water. Then place

the following pressure reducer (4),

to protect the injector from excess

pressure; a valve before the inlet to the

injector (5); a valve after the outlet (6);

an anti vacuum valve (7) to prevent a

siphon effect when the injector is not

working; and operating valves (8) for the

branch lines.

It is advisable to add a bypass pipe (9)

that will permit diverting the water flow

through the bypass pipe if there is a need

for irrigation without any additives, or for

dismantling the injector.

2

1

3

4

5

6

8

7

9

1

6

Installation of the injector on a bypass line

It is necessary to fit the proportional dosing injector on a bypass line when irrigating with a flow

rate higher than 25 m3/hour. The bypass enables only part of the water flow to pass to the

Injector and activate it, while the rest passes through the main line. Using the choke valve on

the main line, the flow of water passing through the main line is regulated so that only

A proportion of the flow passes through the bypass and activates the injector. The metering must

be calculated in accordance with the flow rate passing through both lines.

It is necessary to fit a main valve at the beginning of the line (1), water filter of 200 mesh (2),

backflow prevention valve (3) must be fitted to a drinking water line, according to local

regulations, in order to prevent entry of chemicals to the drinking water. A pressure reducer (4),

a T connection for diversion from the main line to the bypass, a valve(5)on the bypass before the

inlet to the proportioning dosing injector, a valve (6) after the outlet from the injector on the

bypass, and a T connector for the return to the main line. On the main line between the bypass

junction and the return connection a choke valve should be fitted (7), preferably an angled valve,

to regulate the flow rates between the main line and the bypass.

After the return connection from the bypass there should be fitted anti vacuum valve (8) and

valves for the branch lines (9).

A- High pressure

B- Low pressure

12

3

4

5

6

8

9

7

A

B

7

Installation of two injectors in parallel

When the water flow rate in the irrigation line is higher than the maximum nominal flow rate of

the injectors, the water may be divided between two units. If the 2 injectors are used for

pumping the same type of additive the scales should be adjusted in an identical manner to the

same level of metering. Two different additives may be metered at different levels. The metering

in each unit must be calculated for each flow rate passing through the two injectors.

It is necessary to fit a main valve at

the beginning of the line (1), water

filter of 200 mesh (2), backflow

prevention valve (3) must be fitted to

a drinking water line, according to

local regulations, in order to prevent

entry of chemicals to the drinking

water. A pressure reducer (4), a T

junction from the main line into 2

lines (5). On each branch there

should be fitted a regulation valve

(6), the injector, a non-return valve

(7) after the outlet from the injector

and a return connection to the main

line (8) anti vacuum valve (9).

Both sides of the instillation must be

identical.

Connection to the additive tank

The suction tube should be connected to the additive tank (preferably about 5cm above the

bottom) – diagram A. The liquid additive must pass through a chemical resistant filter of 200

mesh, which must be cleanedregularly.

When making the connection to a large additive tank, use a chemical resistant valve and a

normally closed hydraulic valve to prevent a siphon effect.

The normally closed hydraulic valve should be connected to a hydraulic command tube.

If the additive is pumped from inside

an open tank (diagram B) a heavy

weight should be attached to the end

of the suction tube that will keep the

opening of the suction tube inside

the additive and prevent the tube

from floating and falling outsidethe

tank.

Make sure that the level of the

additive is always below the injector.

Otherwise uncontrolled flow of the

additive may occur.

8

Adjustment of metering

On the metering cylinder there is a scale indicating the

percentage of additives. When the injector is not

operating and there is no pressure in the unit, turn the

adjustment sleeve clockwise to increase the amount of

additive or turn counterclockwise to decrease the amount

of additive. The actual rate should be checked. If

necessary, adjust by increasing or decreasing the

adjustment sleeve.

Servicing

The water filter at the inlet to the injector and the additive

inlet filter should be cleaned frequently.

* NOTE: If it is planned not to use the injector for a long time, it should be operated for a few

minutes with the suction tube inside a tank of clean water, in order to flush away traces of additive

from inside the injector and prevent them from adhering to it.

If there is a drop in temperature below 4°C (40°F) risk or a risk of freezing, the injector should be

drained. In order to drain the unit, close the inlet and outlet valves properly. Unscrew and

dismantle the 1" coupling nut that connects the suction tube, press on the non-return valve

(insert your finger or a small rod) in order to drain all the water trapped in the unit, while

pressing the air bleed valve at the top of the injector (with your other hand).

Suggested maintenance

Replace injection seals every 12 months:

Kit # 1- seals 0.1-1%(Catalog No. 35000000008)

Kit # 2-TF seals 0.2-2.5% (Catalog No. 35000000002)

Kit # 3-TF seals 1-5% (Catalog No. 35000000003)

Troubleshooting guide

Problem Check Solution

The injector is fitted with the arrows in the opposite direction to the

water flow direction.

Fit the injector with the arrows in the direction

of flow.

.sevlavehtnepO.desolcerasevlavteltuodnatelniehT

.retlifehtnaelC.dekcolbsiretliftelniehT

The injector

does not

work

.evlavniamehtnepO.erusserpetairporppaehttawolfretawonsierehT

Open the nut locking the motor cover, remove the motor cover, and

remove the mechanism. Check if the motor seals are defective. Replace the motor seals.

.sgnirpselggotehtecalpeR.nekorberasgnirpselggotehtfikcehC

Check if the seals above the valves are defective or have been

displaced. Replace the seals.

The injector

has stopped

working

Check if one of the parts of the mechanism is broken. Replace the broken part.

The leak is from the connection between the body and the cover.

Open and remove the motor cover, replace the

seal, fit the cover, and thoroughly tighten the

cover locking nut.

The leak is from the connection of the suction tube. Remove the suction tube, replace the defective

seal and reconnect.

There is a

leak from

the injector

The leak is from the non-return valve. Dismantle the non-return valve and replace the

defective seal.

.retlifehtnaelC.dekcolbsiretlifnoitcusehT

Dismantle the injector unit and check if the suction seal is defective. Replace the suction seal.

There is no

suction in

the additive

inlet .evlavnruter-nonehtecalpeR.evitcefedsievlavnruter-nonehT

For advice, technical support and purchase of spare parts, contact the authorized sales

representative in yourarea.

Table of contents

Other DEMA Water Pump manuals

Popular Water Pump manuals by other brands

SHIMGE

SHIMGE SG(m) Series Service manual

Samoa

Samoa UP03B Series Parts and technical service guide

Pacific hydrostar

Pacific hydrostar 69297 Owner's manual & safety instructions

Acquaer

Acquaer CJE050-1 owner's manual

T.I.P.

T.I.P. FlatOne 6000 INOX Translation of original operating instructions

SPX

SPX L1600 instruction manual