Dembla 8100F21 Series User manual

Instruction Manual

Floating Ball Valve

Series-8100F21

0062

2 G/D T 3/4/5/6

1Feb 2009

CONTENTS PAGE NO.

1.0 Foreword 2

1.1 Scope of Instruction Manual 2

1.2 Copyright and Modification Rights Reservation 2

1.3 Safety Instructions 2

2.0 Introduction 3

3.0 Installation of 'O' Ball Valve 3

3.1 Pre-Installation Checks 3

3.2 Operation 3

3.3 Lubrication 3

3.4 Replace Gland Packing & Seat Ring. 4

4.0 Recommended Spares (for 'O'-ball valve) 5

1

1.0 Foreword

1.1 Scope Of Instruction Manual

This Instruction Manual covers information regarding Installation and Maintenance of

Dembla's Floating ball Valve.

1.2 Copyrights And Modification Rights Reservation

Dembla Valves Ltd. retains the copyright on the contents of this Instruction Manual.

The Total content of this instruction manual described here corresponds to the

information during preparation of the instruction manual. It is user's responsibility to refer the latest version.

All data, specifications and illustrations here are subjected to technical modifications and improvements and

hence modification can be done by us at by time without any prior notice. No claim to modification or repair

of these valves, which have already been supplied by us, can be made.

1.3 Safety Instructions

1) Before attending to Valve Installation / Maintenance, the instruction manual must be

compulsorily read and understood properly.

2) Valve must be operated by qualified personnel.

3) Ensure that the operator handling these Valves must follow Safety Instruction.

4) Ensure that before opening the valve for maintenance or repair, wear suitable protection

when dealing with hazardous process fluids.

5) All Safety Messages such as Cautions, Warnings and Notes are highlighted in this

Instruction Manual which must be strictly followed to avoid any possibility of arising

danger / risk of damage to the equipment / person's life.

6) No Liability on Manufacturer for any wrong handling, improper commissioning and

wrong assembly.

7) No modification / conversions are allowed without written authorization from Dembla

Valves Ltd.

2.0 Introduction

Dembla's Floating Ball valves are available conforming design as per

BS – 5351

EN-17292

API6D

2

3.0 Installation Of 'O' ball Valve

3.1Pre-installation Checks: (Before installing any 'O' Ball Valve)

(1) Inspect it for any shipment damage and for foreign material that might have collected

during packing and shipment.

(2) Blow out all pipelines to remove pipe scale-chips, welding-slag, and other foreign

materials.

(3) Install the valve using accepted piping practices.

(4) Install the valve according to flow direction marked on the valve.

(5) Use self centering gasket.

(6) Install the valve preferably in a straight run of pipe away from bends or sections of

abnormal velocity.

(7) Incorrect pipe alignment will cause interference between the Ball surface and soft seat,

excessive torque and damage to ball and soft seat, resulting into seat leakage.

(8) Do not try to install valve between line flanges having inadequate gap. This may cause

damage to some valve parts.

(10)Glands are factory tightened and checked for leakage however if there is any gland

leak in valves, the gland may be further tightened just enough to stop leakage.

Excessive tightening should be avoided.

3.2 Operation

Valve closes with clockwise rotation of the valve shaft. The limit position are set in the

operators for extreme condition i.e open & close.

3.3 Lubrication

For manual operator, lubrication is required.

3

3.4 Replace Gland Packing & Seat Ring.

1) Loosen & remove locknut(15) & lock pins(10).

2) Remove lever (9)

3) Remove lock washer (14)

4) Loosen & remove second lock nut (15)

5) Remove lock plate (11) & gland bush (13)

6) Remove gland packing (8)

7) Loosen & remove body stud nut (4)

8) Remove side connection (2) along with soft seat (6)

9) Slide the ball (3) outword & remove it.

10)Remove valve shaft (5) from inside of valve body (1)

11)Remove thrust washer(12)

12) Clean all parts & keep in clean & dry space.

13) Replace soft seat (6) from both side connection (2)

14)For assembly use reverse sequence.

4.0 Recommended Spare (for “O” Ball Valve)

It is recommended to stock following spare parts for commissioning and routine service:

4

5

5.0 To Separate Actuator from Valve Body.

Before starting disassembly.

Use Bu-pass Valve pr completely shut off the process to isolate the valve from pressure. Drain fluid

from both ends of the Valve.

If the Valve Opens with Pneumatic signal pressure to Actuator, remove air from the Actuator before

attempting to remove Valve from line.

While dismantling the valve, if any port is stuck up, do not use any pressure or force Technique. Use

proven methods only.

Unscrew the Bracket Bolts from valve assembly.

Unscrew & remove the Mounting Bracket and actuator along with Accessaries.

Remove the Pinion Shaft from Valve Shaft

6

6.0 Actuator Operation

The Actuator Drive Shaft rotates through a full 90°. Rotation is accomplished be

feeding supply air into the center chamber(through Port A) forcing the two opposing

Piston outword, remaining in counter-clockwise rotation of the Drive Shaft to the

‘Open’ position.(Refer Fig. A)

For closure is accomplished by means of Springs contained in the end cap chambers,

which force the Piston inward when the supply air to the center chamber (Port A) is

allowed to exhaust. (Refer Fig. A)

For double-acting Actuators, Rotation is accomplished be feeding supply air into the

center chamber ( through Port A ) forcing the two opposing pistons outward, resulting

in counter-clockwise rotation of the Dive Shaft to the ‘Open’ position, for closure is

obtained by feeding supply air into the end cap chambers (through Port B) which

forces the Piston inward, resulting in clock-wise rotation of the Drive Shaft. (refer

Fig.B.)

To reverse the stroke direction of the Actuator, remove both Piston, rotate them by

180° and re-install. This will reverse the direction of rotation of the output shaft. (refer

Fig. C)

ACTUATOR ASSLY.

DOUBLE ACTING

(OPEN-CCW & CLOSE-CW)

ACTUATOR ASSLY.

SINGLE ACTING

(OPEN-CCW & CLOSE-CW)

Port-A Port-B Port-A Port-B

Drive shaft with pinion gear

Center chamber

Pistons

Piston spring

End cap chamber

ACTUATOR ASSLY.

SINGLE ACTING

(OPEN-CW & CLOSE-CCW)

Port-A Port-B

Center chamber

Pistons

Piston spring

End cap chamber

(FIG.A) (FIG.B) (FIG.C)

Rack Rack

Drive shaft with pinion gear

7

In the event of air failure, the Actuator can be cycled manually, This is accomplished by

applying a wrench to the exposed tap shaft of the Actuator and turning it in the desired

direction. This is not recommended on Model PD500/PE280 and larger size of Actuators.

For these, Dembla Valves Limited offers optional Manual Over-ride Gear units, with

declutch able hand wheels. ( Not Shown).

CARE MUST BE TAKEN TO ENSURE THAT THE ACTUATOR IS NOT OPERATED

AUTOMATICALLY THROUGH AIR SUPPLY WHILE MANUAL OPERATION IS BEING

PERFORMED !

Is is recommonded to stock the following spares parts for commissioning and routine

service.

Note : While ordering spares, please do not miss to indicate ‘Valve Serial No.’

Appearing on nameplate fixed on the actuator Valve Serial No. also appears on the

Valve Body dully punched. The Valve serial No. beings with prefix V, eg V-

12345.........

7.0 Manual Operation

8.0 Torque for Studs

9.0 Recommended Spares

Studs

5/16”

3/8”

1/2”

5/8”

3/4”

Torque Nm

5

7

30

50

170

PART NAME

RECOMMENDED QUANTITY

Seat Ring

Gasket Body to

Side Connection

Gland Packing

One Set for every valve

One set of 'O' Ring for every five valve

One set of 'O' Ring for every five valve

One set of gasket for every five valve

SR. NO.

1

2

3

4

!Note

8

10.0 Parts Illustrated (Floating Ball Valve With Rotary Actuator)

PART NAME

RECOMMENDED QUANTITY

Seat Ring

Gasket Body to

Side Connection

Gland Packing

One Set for every valve

One set of 'O' Ring for every five valve

One set of 'O' Ring for every five valve

One set of gasket for every five valve

SR. NO.

1

2

3

4

9

Disassembly of Floating Ball Valve:

1. Loosen and remove the Hex Bolts (Actuator-MOR) .

2. Pull and remove the Actuator from top side.

3. Loosen and remove the Hex Bolts (MOR-Bracket) .

4. Remove MOR .

5. Remove Pinion Shaft .

6. Loosen and remove the Hex Bolts (Body-Bracket) .

7. Remove the Bracket .

8. Loosen and remove Lock Nut .

9. Remove Gland Bush .

10. Remove Gland Packing ( .

11. Loosen and remove Body Nut .

12. Remove Side connection along with Soft Seat and Gasket .

13. Slide the Ball outward and remove it.

14. Remove Valve Shaft from inside of Body .

15. Remove Thrust Washer .

16. Clean all parts and keep in clean and dry space.

17. Remove Soft Seat from both Side Connection if required.

18

15

17

14

13

16

12

11

11

8

4

6

3

5

9

6

7

1

2

11.00 Disassembly & assembly Procedure of Floating Ball Valve

2

10

Assembly of Floating Ball Valve:

1. Insert Soft seat in both Body and Side connection if removed.

2. Put the Thrust washer on the collar of Valve Shaft .

3. Insert Valve Shaft in Body along with Thrust Washer .

4. Insert Ball in Body and match across flat of ball slot with

Valve Shaft's across flat.

5. Insert Gasket in Body .

6. Install Side connection on Body .

7. Insert and tighten Body Nut .

8. Insert Gland Packing on the top of Body .

9. Insert and tighten Lock Nut on Valve Shaft

10. Keep the Bracket on Body

11. Insert and tighten Hex Bolts (Body-Bracket) .

12. Keep Pinion Shaft on Valve Shaft .

13. Keep MOR on Bracket by inserting Pinion Shaft

in MOR .

14. Insert and tighten Hex Bolts (MOR-Bracket) .

15. Keep Actuator on MOR .

16. Insert and tighten Hex Bolts (Actuator-MOR) .

612

9 5

519

31

5

71

21

4

81

5

11

12 1

16

5

13

14 12 13

14

17

14

15

18

11.00 Disassembly & assembly Procedure of Floating Ball Valve

Dembla

Sales Office: Works:

M/S. Dembla Valves Ltd.

C-30, Jai Matadi Compound, Kalher

Village,Thane-Bhiwandi-Agra Raod -

421302,

Maharashtra,India.

Tel - +91-9292234790 - 97

E-mail - [email protected]

More info - www.dembla.com

M/S. Dembla Valves Ltd.

A/8, Arahm Logistic, Valshind Village,

Mumbai -Nashik Highway

(NH3),Bhiwandi

Thane - 421302. Maharashtra (India)

Dembla Valves |

Table of contents

Other Dembla Control Unit manuals

Popular Control Unit manuals by other brands

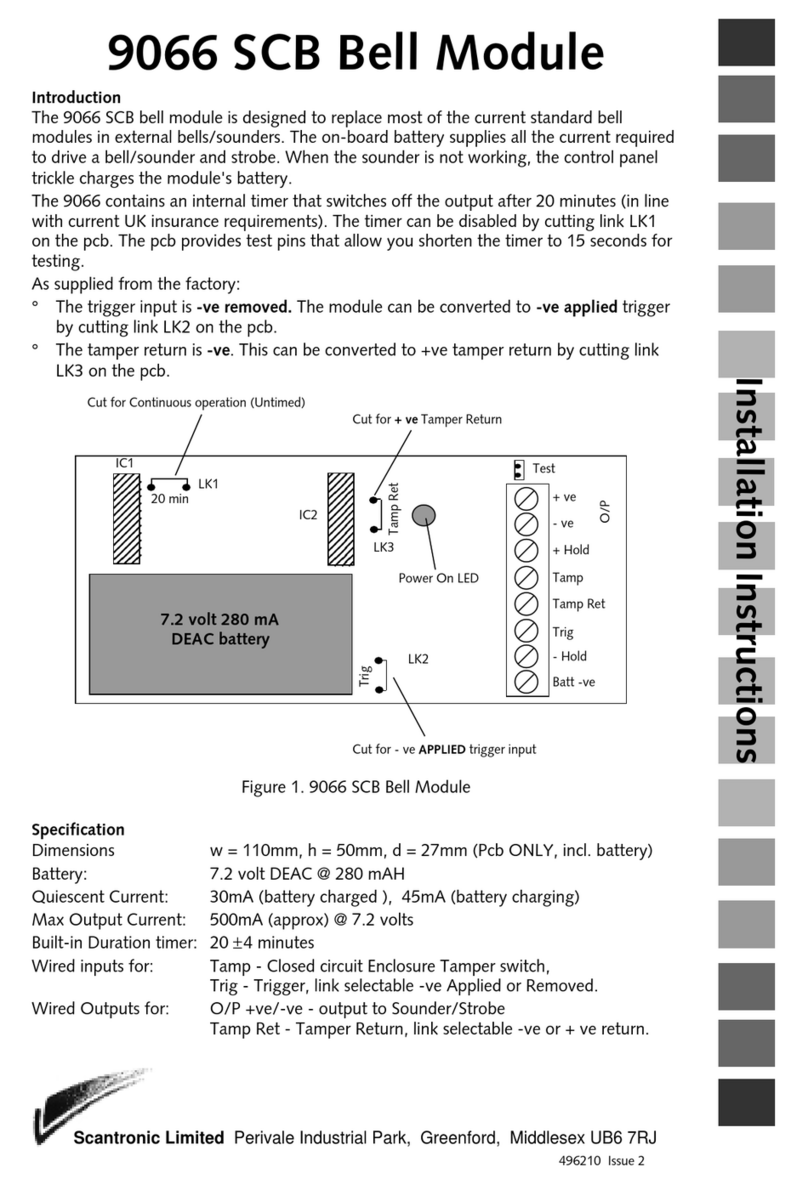

Scantronic

Scantronic 9066 SCB installation instructions

AL Tech

AL Tech B 2070-2 installation manual

Self Climat

Self Climat FILSTOP 2 quick start guide

Kieback&Peter

Kieback&Peter RPW414-FTL-902-ALC operating instructions

preVent

preVent BR13 instruction manual

AIR GAP

AIR GAP Fluidmaster 6000 Series installation guide

GiBiDi

GiBiDi SR100 Instructions for installations

Paradox

Paradox Digiplex EVO PRT3 Programming instructions

Delta

Delta MultiChoice Ara T27T867 Series owner's manual

Plast-O-Matic

Plast-O-Matic EASYMT Series instructions

seeed studio

seeed studio Grove user manual

Data Video

Data Video ZEK-2 instruction manual