preVent BR13 User manual

BR13 Instruction Manual

2

Manual BR13 Version 1.2 07.11.2019

Contents:

Page

Introduction 2

1.

Functional principle

3

2.

Installation

3

3.

Operating conditions

3

4.

Operability, maintenance and repair

3

-

standard construction

4.1.

gland packing

3

4.2. valve seat and plug 4

5.

Model with pneumatic P/R drive

5

5.1.

Changing the operating mode of the drive

6

5.2.

Replacing a membrane

6

6..

Other drives

6

7.

Diagrams / Spare parts lists

7

8.

Contacting us

12

To ensure trouble-free and safe operation of the valve, it is essential to be familiar with the contents of this BR13 Instruction

Manual, and also with the general instructions for installation and operation, before installing and operating the valve.

Failure to observe or comply with these operating instructions will invalidate the manufacturer’s guarantee and liability. The

manufacturer’s general conditions of sales and terms of delivery shall apply unless otherwise stated.

3

Manual BR13 Version 1.2 07.11.2019

1. FUNCTIONAL PRINCIPLE

The valve regulates mass-flow by a linear movement of the valve spindle, which may be operated pneumatically, electrically

or manually. As the stroke of the valve alters, the circular gap between the valve seat and the valve block is increased or

reduced. This directly influences the amount of fluid flowing through the valve.

2. INSTALLATION

The valve may be mounted in any position; however, for valves of DN 80 size and above, vertical installation with the drive

mounted above is preferred. For valves with extended construction, bellows, or drives weighing more than 50 kg, a suitable

support or suspension mounting should be provided for the drive, otherwise its own weight might cause wear and leakage at

the seals.

3. OPERATING CONDITIONS

Regulator valves should be operated under conditions that take into account the size and nature of the construction and the

type of material. To ensure trouble-free operation over the whole operational lifetime, the regulator valve and its accessories

should be regularly inspected and maintained.

Normal operating conditions:

a) With pneumatic positioning drive

Ambient temperature from - 25 to + 80°C, with silicone diaphragm of -40 °C to +80 °C

Relative humidity up to 98 %,

The control and feed air supplies must contain no mechanical impurities, oil or corrosive substances, copper or

aluminium alloys, and must be dehumidified such that the dew-point corresponds to a temperature that is at least

10 °C lower than the operating temperature of the position controller and the positioning drive.

b) With electrical positioning drive

In accordance with the manufacturer’s instructions.

c) With hand-operated drives of type NN

Ambient temperature from - 25 to + 80°C

Relative humidity up to 98 %.

4. OPERABILITY, MAINTENANCE AND REPAIR - STANDARD CONSTRUCTION

The operability of the regulator valve during use is based on maintaining an appropriate flow characteristic and not

exceeding the permitted leakage level for the valve.

To ensure long-term correct and safe operation of the valve, it is essential to carry out regular recorded inspections. Valves

that operate continuously should be checked at least every 6 months. Valves that operate discontinuously should be

checked at least every 12 months.

If it is necessary to carry out maintenance or repair work on the regulator valve, it should be carried out as follows:

4.1. Gland packing

A key criterion for operability is external seal-tightness, which is provided by the gland packing.

The gland packing to be used is normally pre-specified based on the operating conditions.

With normal gland packing, the tightness of the seal is achieved by tightening the sealing nut.

WARNING:

When the valve is supplied, the sealing nut is only hand-tightened. Before putting the valve into service, it is

essential to tighten the sealing sufficiently to achieve an adequate contact pressure, thus ensuring a secure

external seal, but without blocking the valve spindle.

If self-adjusting sealing glands are used, the constant contact pressure is provided by a stainless steel spring. For this

reason, the sealing nut should be screwed in up to the stop.

4

Manual BR13 Version 1.2 07.11.2019

To change the gland packing, proceed as follows:

Before changing the gland packing, ensure that the valve is not under pressure and is not contaminated.

1. Disconnect the connection between valve and drive. in valves with air-operated or hand-operated actuators, by undoing

connecting nut (32) after loosening low (counter) nut (34)

2. undo nut (13) fastening actuator or hand-operation and disconnect it from the valve

3. undo and remove from valve stem the interlocking nut (33) and the connecting nut (32)

4. Loosen sealing packings in the packing-chamber by loosen the nut (11) on the threaded bolts (10), the packing gland

(12) or the gland plate (18) by the TA Luft version.

5. Loosen the nut (11) at the 3-way-bottom-flange (10) and remove the flange essay and the body gasket .

6. remove fitted seat (4.2)

7. pull out head and stem (5) set from packing-chamber of the valve body and remove it

8. loosen the nut (11) the packing gland (12) or packing plate (18) and packing gland or plate

9. Remove the pilot sleeve (14) and the packing (8,15) with suitable tools and clean the packing chamber.

10. Put in the stem (5) with plug into the valve

11. Install carfully the new packing. Observe the correct placement. (in reversed order as removed)

12. Install the pilot sleeve (14) and tight it.

13. Install fitted seat (4.2) new gasket (7) and the flange essay (2) and tight it about the nuts (11).

14. Interlocking nut (33) and connecting nut (32) back on to the stem.

15. Replace caferully the drive and connect him in reverse order as by disassembling

4.2. Replacement of the valve seat and the valve plug

If it is necessary to change the valve seat and valve block due to a change in the operating conditions or due to wear and

tear, proceed as follows:

Before making the change, ensure that the valve is not under pressure and is not contaminated.

In order to achieve a better seal when changing the valve seat and valve block, we recommend lapping the seat and the

block with a fine abrasive paste.

Replacing the double plug

1. Disassembling the valve as described in point 4.1 (changing packing gland) (point 1 until 7).

2. Knock out the pin (17) and unscrew the plug, screw in a new plug, redrill and put in the pin. Please check that the

stem has no grooves or other damages.

3. Install the stem (5) with plug into the valve.

4. Tight with the nuts (11) the packing gland or gland plate that the stuffing box seals.

5. Install fitted seat (4.2) new gasket (7) and the flange essay (2) and tight it about the nuts (11).

6. Interlocking nut (33) and connecting nut (32) back on to the stem

7. Replace carefully the drive and connect him in reverse order as by disassembling

Replacing fitted seat (4.2)

1. Disconnect the connection between valve and drive. in valves with air-operated or hand-operated actuators, by

undoing connecting nut (32) after loosening low (counter) nut (34)

2. Undo nut (13) fastening actuator or hand-operation and disconnect it from the valve

3. Undo and remove from valve stem the interlocking nut (33) and the connecting nut (32)

4. Loosen sealing packings in the packing-chamber by loosen the nut (11) on the threaded bolts (10), the packing

gland (12) or the gland plate (18) by the TA Luft version.

5

Manual BR13 Version 1.2 07.11.2019

5. Loose the nut (11) at the 3-way-bottom-flange (10) and remove the flange essay and the body gasket.

6. remove fitted seat (4.2)

7. Install new fitted seat (4.2) new gasket (7) and the flange essay (2) and tight it about the nuts (11).

8. Tight with the nuts (11) the packing gland or gland plate that the stuffing box seals.

9. Interlocking nut (33) and connecting nut (32) back on to the stem

10. Replace carefully the drive and connect him in reverse order as by disassembling

Replacing screwed in seat (4.1)

1. Disassembling the valve as described in „replacing fitted seat (4.2) “. Point 1 until 6

2. Remove stem with double plug from the body

3. Screw out anticlockwise the seat (4.1) with suitable seat-tool

4. Clean the new seat or repaired seat, grease them with mounting paste and screw in.

5. Install the stem (5) with plug into the valve.

6. Tight with the nuts (11) the packing gland or gland plate that the stuffing box seals

7. Install fitted seat (4.2) new gasket (7) and the flange essay (2) and tight it about the nuts (11).

8. Interlocking nut (33) and connecting nut (32) back on to the stem

9. Replace carefully the drive and connect him in reverse order as by disassembling

5. PNEUMATIC P/R DRIVE

When the pressure rises in the drive pressure chamber, a force is applied to the membrane in the drive unit. If this force

exceeds the spring force of the springs in the second chamber, the springs are compressed and the drive spindle starts to

travel out or in, according to the function. If the pressure continues to increase, once the maximum spring force is reached

the springs will be pressed against the end-stop and the drive will halt. Thus, a simple pneumatic drive can reach a defined

position in proportion to the air pressure.

The size of the drive is based on the cm

2

surface of the membrane.

Drive

size

Stroke

[mm]

Spring range (kPa)

1 2 3 4 5 6 7

20 - 100 40 - 200 40 - 120 0 - 240 60 - 140 120 - 2 0 1 0 - 3 0

No. of

springs

Total

tenstion

[mm]

No. of

springs

Total

tenstion

[mm]

No. of

springs

Total

tenstion

[mm]

No. of

springs

Total

tenstion

[mm]

No. of

springs

Total tenstion

[mm]

No. of

springs

Total tenstion

[mm]

No. of

springs

Total

tenstion

[mm]

250 20 3 - 6 - 3 - 6 - 3 6 6 6 - -

400 20 3 - 6 - 3 - 6 - 3 6 6 6 - -

630 3 3 - 6 - 3 10 6 10 3 10 + 10 6 10 + 10 12 10 + 10

1000

3 3 - 6 - 3 9,5 6 9,5 3 9,5 + 9,5 6 9,5 + 9,5 12 9,5 + 9,5

50 3 - 6 - 3 12,5 6 12,5 3 12,5 + 12,5 6 12,5 + 12,5 12 12,5 +

12,5

63 3 - 6 - 3 16 6 16 3 16 + 16 6 16 + 16 12 16 + 16

Spring range and drive sizes for pneumatic drives of type P/R

P type drive: Single membrane drive.

Safe position NO (open on loss of pressure)

When pressure rises in the upper chamber, the drive spindle travels out.

R type drive: Single membrane drive.

Safe position NC (closed on loss of pressure)

When pressure rises in the lower chamber, the drive spindle travels in.

6

Manual BR13 Version 1.2 07.11.2019

5.1 Changing the operating mode of the drive

No additional components are required in order to alter the direction of operation of type P/R pneumatic drives.

Changing P to R and vice versa

1. Disconnect the valve from the drive.

2. Ensure that no air pressure is applied to the drive.

3. Remove the top cover of the position drive, taking care that the tensioning nuts (long nuts) (82) are unscrewed to

the ends – in accordance with the notes on the warning label.

The further steps in the procedure depend on the current operating mode of the drive before it is changed.

To change the drive function from P to R, proceed as follows:

4. Undo the special nuts (34) from the bolts on the positioning drive.

5. Remove the membrane with its membrane plate, spacer ring, washer and spacer cover (or spacer covers for drive

sizes 630 and 1000).

6. Remove the springs (31) from the lower casing.

7. Turn the membrane together with all the parts as listed above through 180 degrees, and fit the membrane back

over the drive bolts.

8. Screw the special nuts (34) on to the drive bolts, thus compressing the whole of the above group of components.

9. Place the springs on the membrane plate so that they fit in the guide cut-outs and their ends are aligned with the

axis of the bolts.

10. Place the top cover over the springs and initially tighten the tensioning nuts (82).

11. Compress the springs evenly until the upper part of the drive end-stop is pressed against the lower part, then insert

the rest of the bolts and screw on the nuts.

To change the drive function from R to P, proceed as follows:

4. Remove the springs (31) from the membrane plate (28).

5. Undo the special nuts (34) from the bolts on the positioning drive.

6. Remove the membrane with its membrane plate, spacer ring, washer and spacer cover (or spacer covers for drive

sizes 630 and 1000).

7. Place the springs in the designated locations in the lower cover.

8. Turn the membrane together with all the parts as listed above through 180 degrees, and fit the membrane back

over the drive bolts, so that the 6 mm diameter opening on the base and the nut on the edge of the drive membrane

plate are axially aligned with one of the openings on the edge of the membrane.

9. Screw the special nuts (34) on to the drive bolts, thus compressing the whole of the above group of components.

10. Place the springs on the membrane plate (28) so that they fit in the guide cut-outs. To check that the springs are in

the correct position, rotate the membrane (to the position of the notch on the nut at the edge of the membrane

plate) until the 6 mm opening on the base is visible. By sighting through the opening, check that there is a spring in

place on the underside.

11. Place the top cover over the springs and initially tighten the tensioning nuts (82).

12. Compress the springs evenly until the upper part of the drive end-stop is pressed against the lower part, then insert

the rest of the bolts and screw on the nuts.

5.2 Changing the membrane

Should it be necessary to change a membrane, the drive should be dismantled as described in item 6.1. Instead of putting

the drive back together in reverse order, it should simply be re-assembled in its original order after changing the membrane.

6. Other Drives

It is possible to equip model BR13 valves with electrical drives. Sizing the drive to the regulator valve is normally a part of

the bidding process.

It is also possible to supply model BR13 valves with a purely manual operation (type NN), or to fit the pneumatic drive with

an additional hand-wheel (type P/R-N).

(See the following diagrams)

7

Manual BR13 Version 1.2 07.11.2019

7. DRAWINGS / SPARE PARTS LISTS

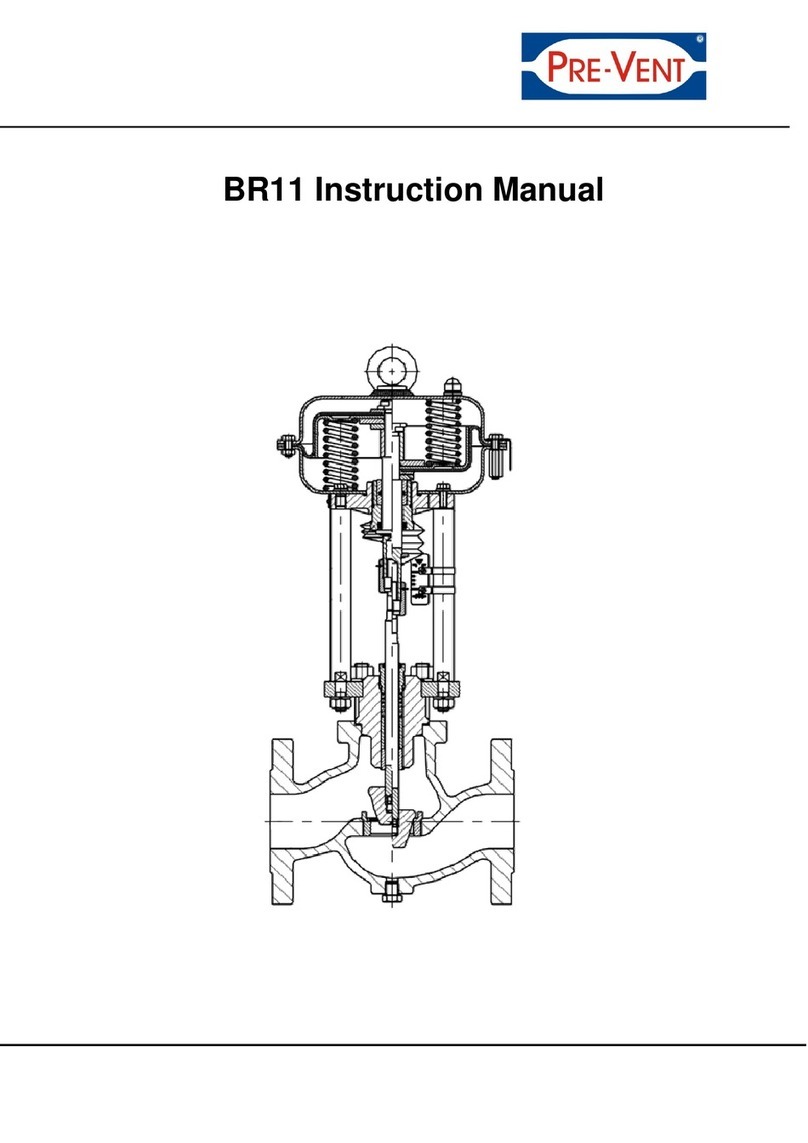

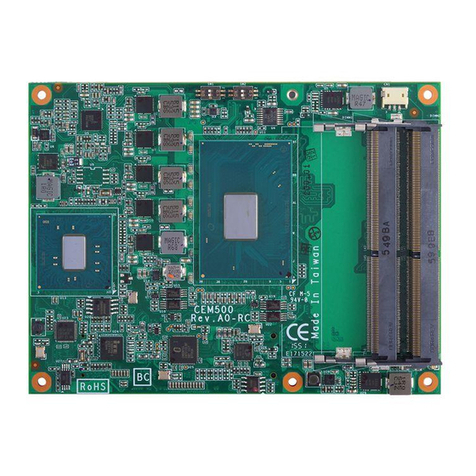

Figure 1a

valve BR13 with standard

stuffing box

Figure 1b

Valve BR13 with

TA-Luft stuffing box

8

Manual BR13 Version 1.2 07.11.2019

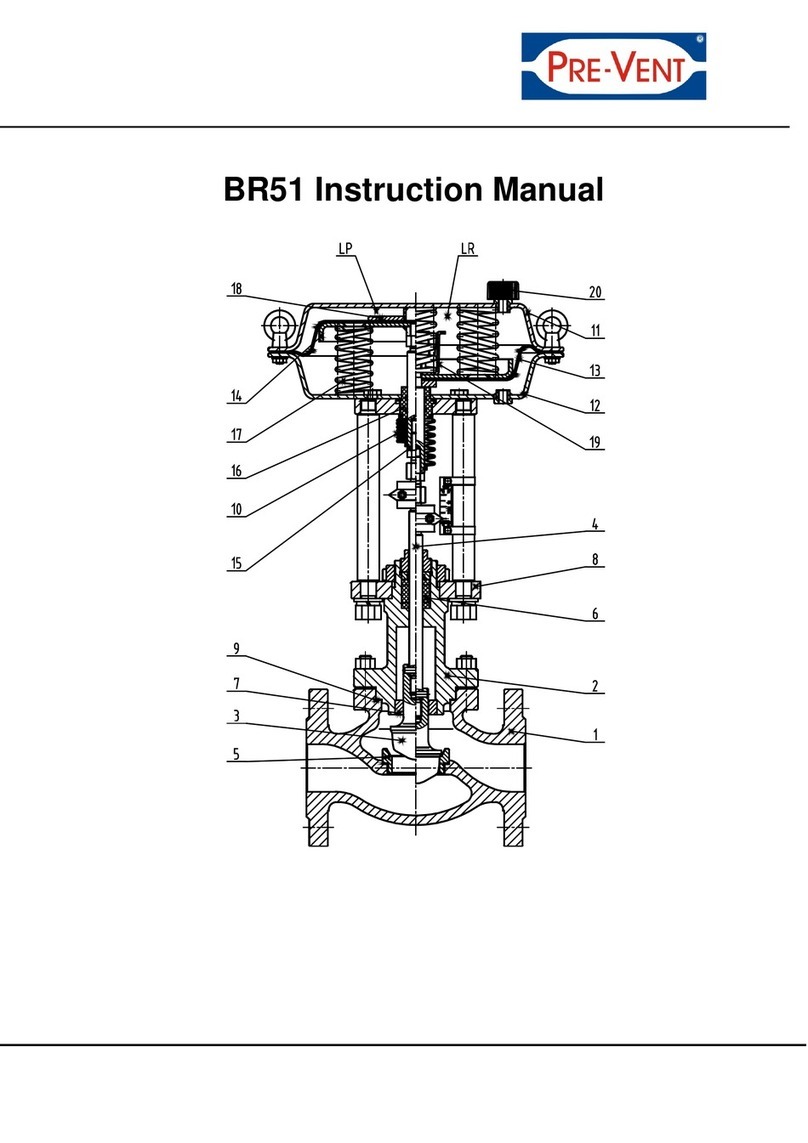

Figure 2a

Valve BR13 with pneu atic drive P/R

9

Manual BR13 Version 1.2 07.11.2019

Figure 2b

Valve BR13 with pneu atic drive

PN/RN

10

Manual BR13 Version 1.2 07.11.2019

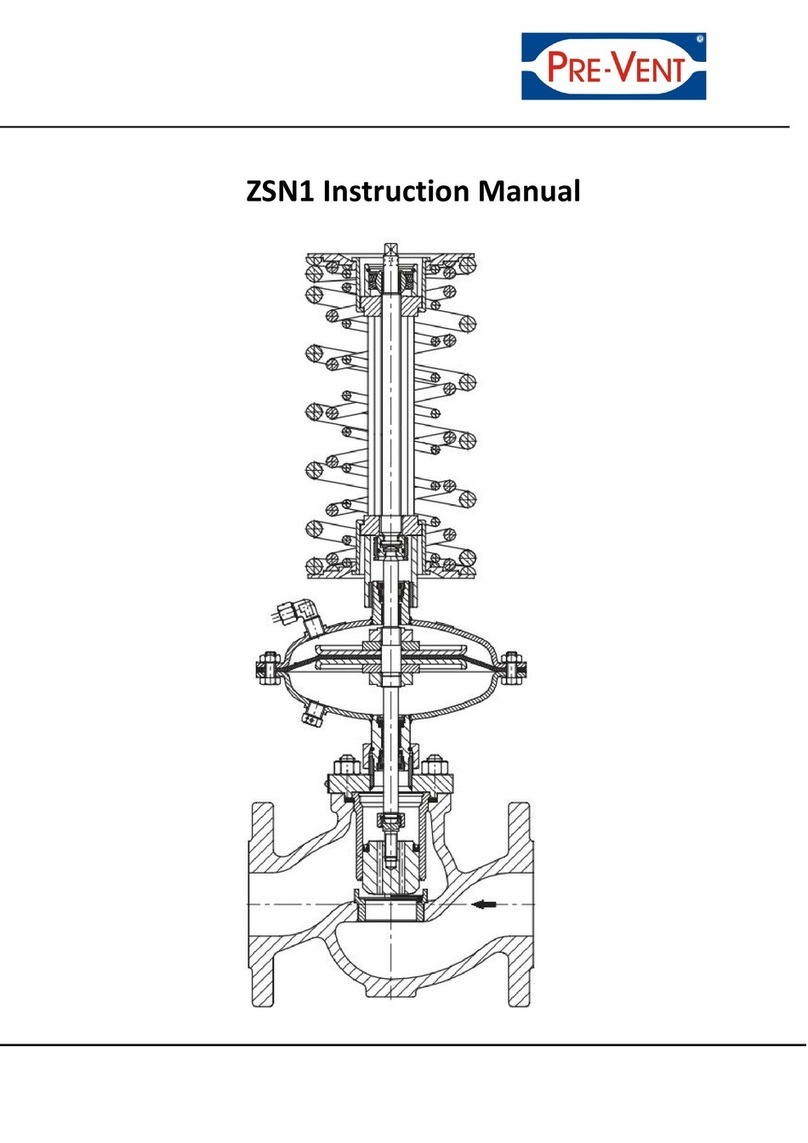

Figure 3a

Handwheel Typ 20

Figure 3b

Valve BR13 with electric drive

11

Manual BR13 Version 1.2 07.11.2019

Part name

Part name

1

Body

54

O

-

Ring

2

lange essay

(3

–

way

-

flange

)

55

O

-

Ring

3

plug

56

O

-

Ring

4.1

Screwed in seat

57

O

-

Ring

4.2

itted seat

58

snap

ring

5

stem

59

Top housing (set)

6

Guiding

sleeve

60

Drive bolt

7

Body gasket

61

Driver

8

Stuffing box

62

holder

9

spring

63

Drive wheel

10

Bolt

64

Special bolt

11

Nut

65

washer

12

Packing gland

66

washer

13

astening nut

67

Thrust bearing

14

Pilot sleeve

68

bolt

15

Spacing

sleeve

69

washer

16

Nut (low)

70

O

-

Ring

17

Pin

71

O

-

Ring

18

Gland plate

72

Snap ring Z

19

Nameplate

73

Connector

20

Rivet pin 3x6

74

21

Column

75

Warning plate

22

Bracket

76

turnbuckle

23

Bottom housing

77

Stem casing

24

Top housing

(set)

78

O

-

Ring

25

Diaphragm plate

79

Drive yoke

26

diaphragm

80

Drive wheel

27

Spacing ring

81

Drive sleeve

28

spring

82

Drive cap

29

Packing

-

box set

83

Drive stem

30

Actuator stem

84

key

31

Special nut

85

Stroke plate

32

Connecting nut

86

Ball bearing

33

Interlocking nut

87

Grease nipple

34

Low (counter) nut

88

indicator

35

Position indicator

89

Pin with notches

36

Column clamping ring

90

screw

37

Stroke plate

91

Connecting plate

38

washer

39

washer

40

Spacing sleeve

41

Stopper ring

42

Venting pin

43

Actuator nameplate

44

Bolt

45

bolt

46

bolt

47

screw

M4x8

48

nut

M4

-

A

49

Nut

50

nut

51

Spring washer

52

Washing ring

53

Scraping ring

12

Manual BR13 Version 1.2 07.11.2019

PRE-VENT GmbH

Sales - Production - Service

Piracher Straße 74

84489 Burghausen, Germany

fon +49 8677 98788-0

fax +49 8677 98788-80

Email:

Web: www.pre-vent.com

Manual version 1.2 07.11.2019

9. Contacting us

Details / specific information (Operating instructions with spare parts lists) are available for download on our website.

Table of contents

Other preVent Control Unit manuals

Popular Control Unit manuals by other brands

IFM Electronic

IFM Electronic Ecomat 300 AL1030 Device manual

STIEBEL ELTRON

STIEBEL ELTRON WPM G Operation

ITOH DENKI

ITOH DENKI F-RAT-NX75 user manual

JUMO

JUMO mTRON B 70.4015.4 installation instructions

Pentair

Pentair HYPRO PROSTOP-E Installation and operation manual

autosen

autosen AD006 operating instructions