Demeq QH5-D User manual

P/N: QHD 501 –ENG –Rev 3 –2012

I

Chapter 1

First steps

1.1

Know the QH5

1

1.1.1

Front panel

2

1.1.2

Connectors

2

1.2

Install or replace batteries

3

1.3

Connecting the impact device

5

1.4

Using the impact device

6

1.4.1

Loading the impact body

6

1.4.2

Release and measure

6

1.5

The “Q” key

7

1.6

Display illumination and contrast

7

1.6.1

Display backlight illumination

7

1.6.2

Display contrast

8

1.7

Locking and unlocking the keypad

8

Chapter 2

Measuring with the QH5

2.1

Numerical measure screen (Normal)

10

2.1.1

Screen mode-1 (Datalogger)

10

2.1.2

Screen mode-2 (Material)

11

2.1.3

Screen mode-3 (Statistics)

11

2.2

Keys in numerical measure modes

12

2.3

Graphic measure screen (Histogram)

14

2.4

Keys in the graphic measure screen mode

15

2.5

Set impact device angle

16

2.6

Select material and hardness unit

17

Chapter 3

Menu system and editing

3.1

Instructions on using the menu system

19

3.1.1

Text editor

20

3.2

Main menu

22

3.2.1

Change hardness unit

22

II

3.2.2

Alarm settings

23

3.2.3

Set histogram range

24

3.2.4

Select language

24

3.2.5

Unit information

25

3.3

General configuration options

25

3.3.1

Set time and date

26

3.3.2

Set time and date format

26

3.3.3

Set keypad sensitivity

26

3.3.4

Set auto-off time

28

3.3.5

Adjust display contrast

28

3.3.6

Beep activation

29

3.3.7

Introduction screen

29

3.3.8

Owner information

29

3.3.9

Lock configuration options

31

3.3.10

Model upgrade licenses

32

3.3.11

Return to factory default settings

33

3.4

Measuring configuration options (Hardness)

34

3.4.1

Set impact device angle

34

3.4.2

Select material

35

3.4.3

The “Plus” key

35

3.4.4

Set group (N) number

36

3.4.5

Select measure mode

37

3.4.6

Create custom or user units

37

3.4.7

Select impact device type

41

3.4.8

Set alarm for impact device tip

42

3.4.9

Return to factory default settings

42

III

Chapter 4

Using the Datalogger

4.1

How data is organized

43

4.2

Memory menu

44

4.3

Creating a file

44

4.4

Actions over single files

45

4.4.1

View data in a single file

46

4.4.2

The “Q”key in a grid

47

4.4.3

The “Q”key in a histogram

48

4.4.2

Send data from a single file

48

4.4.3

Rename a file

49

4.4.4

View file size

49

4.5

Actions over all files

49

4.5.1

Send all files

49

4.5.2

Erase all files

49

4.6

Quick memory menu (Mem key)

50

4.7

Connecting to PC with DataCenter

51

4.8

Datalogger configuration

52

4.8.1

Configure communications

52

4.8.2

Capture modes

54

4.8.3

Advanced configuration

54

Tips on how to measure correctly

Technical specifications

Additional information

Unit maintenance

QH5 accessories

Error messages

Our website: www.demeq.com

Technical Support

IV

And thank you for purchasing a QH5 rebound hardness tester.

At dmq we develop, manufacture and distribute software and quality

control instruments offering innovation and solutions that come as a

direct result of listening to your needs as a user. We apply some of the

latest technology available in the industry to build instruments that are

robust, precise, and easy to operate.

We are convinced that our products would not be complete without

permanent technical and after sales support. So in addition to a great

product we offer:

Quick answers to your inquiries.

Unlimited access to technical information as well as

application notes.

Special offers for registered customers.

Firmware and software upgrades at no charge.

Attention to your inquiries and suggestions.

We hope that the QH5 will meet and exceed your application needs.

V

The information included in this manual applies to all QH5 series

portable hardness testers including models D, G and M.

dmq is a registered trademark of demeq S.R.L and its affiliate

companies.

The information contained in this manual is intended to educate users

on the operation of the QH5 impact hardness testers. Failure to read

and understand this manual can lead to measurement errors. Decisions

based on measurements and or results that are erroneous can lead to

property damage, personal injury or even death. Demeq S.R.L assumes

no responsibility as a result of the improper use of our instruments.

ASTM A956

Correct use of an impact hardness tester requires that you take all of

the following into consideration:

Select the instrument as well as the impact device that is best

suited for your application.

Know the specific requirements for the test you will be

conducting.

Make sure that the person operating the unit has been

trained on its use.

VI

This manual provides all of the information needed to configure and

operate the QH5 hardness tester. However there are additional factors

that can affect tests done with this instrument. Specific information on

those factors is outside the scope of this manual. When in doubt you

should always seek expert advice or refer to specific textbooks on

portable hardness testing. Additional information can also be found on

the internet and through local government agencies as well as in

technical institutes.

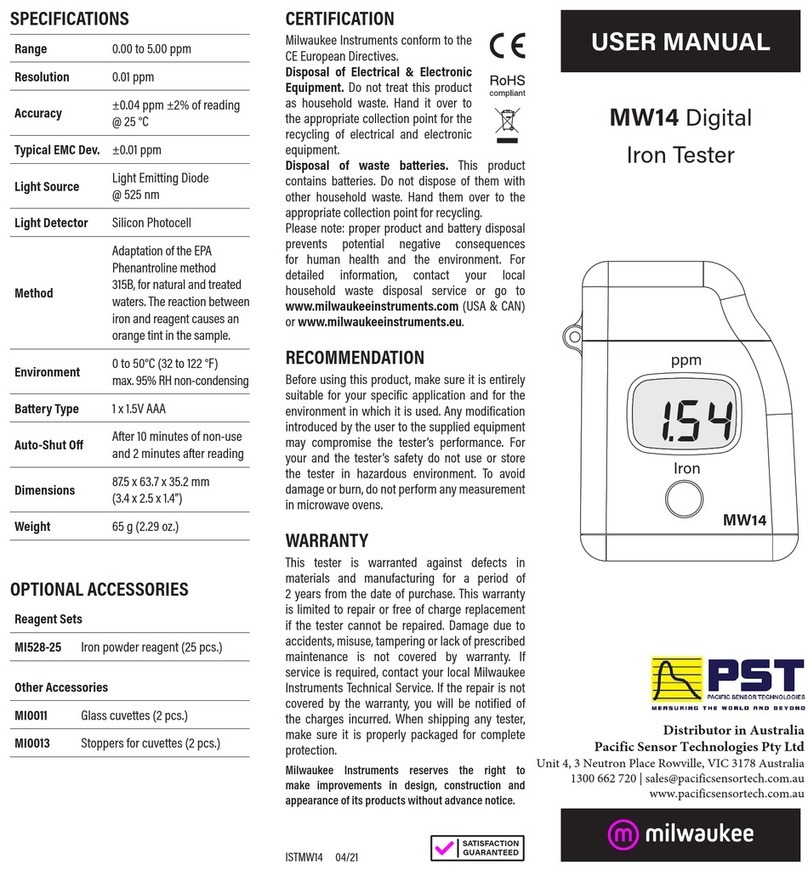

All QH5 units operate on the Leeb impact rebound method where the

ratio between the impact and rebound velocities of the impact body

that is released on the test piece, are measured to establish a Leeb

hardness value. The step by step process is represented in figure 1 as

follows: 1, the impact body is released and travels inside the impact

device; 2, the impact body tip hits the test piece; 3, the impact

produces a rebound.

Figure 1: Representation of the Leeb rebound method

VII

The measured Leeb value (HL) represents a direct hardness value that is

converted to other hardness units such as Brinell, Vickers, Rockwell and

Shore. Both the HL value and another selected hardness unit are

displayed on the unit screen simultaneously.

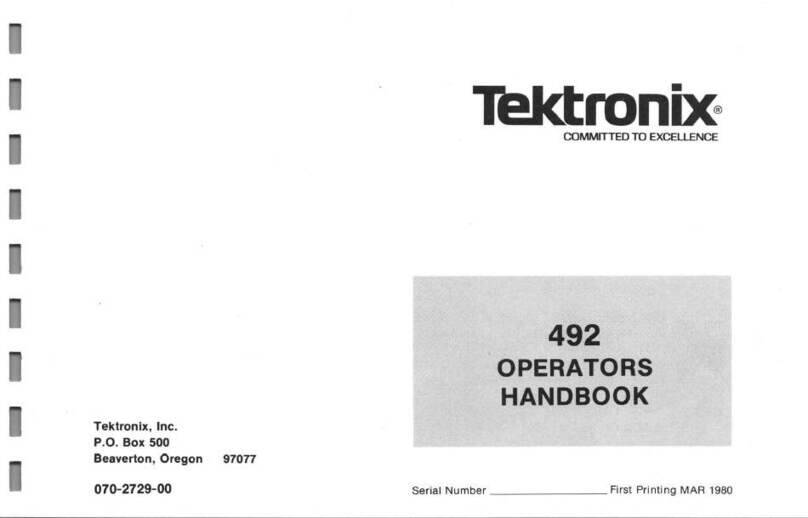

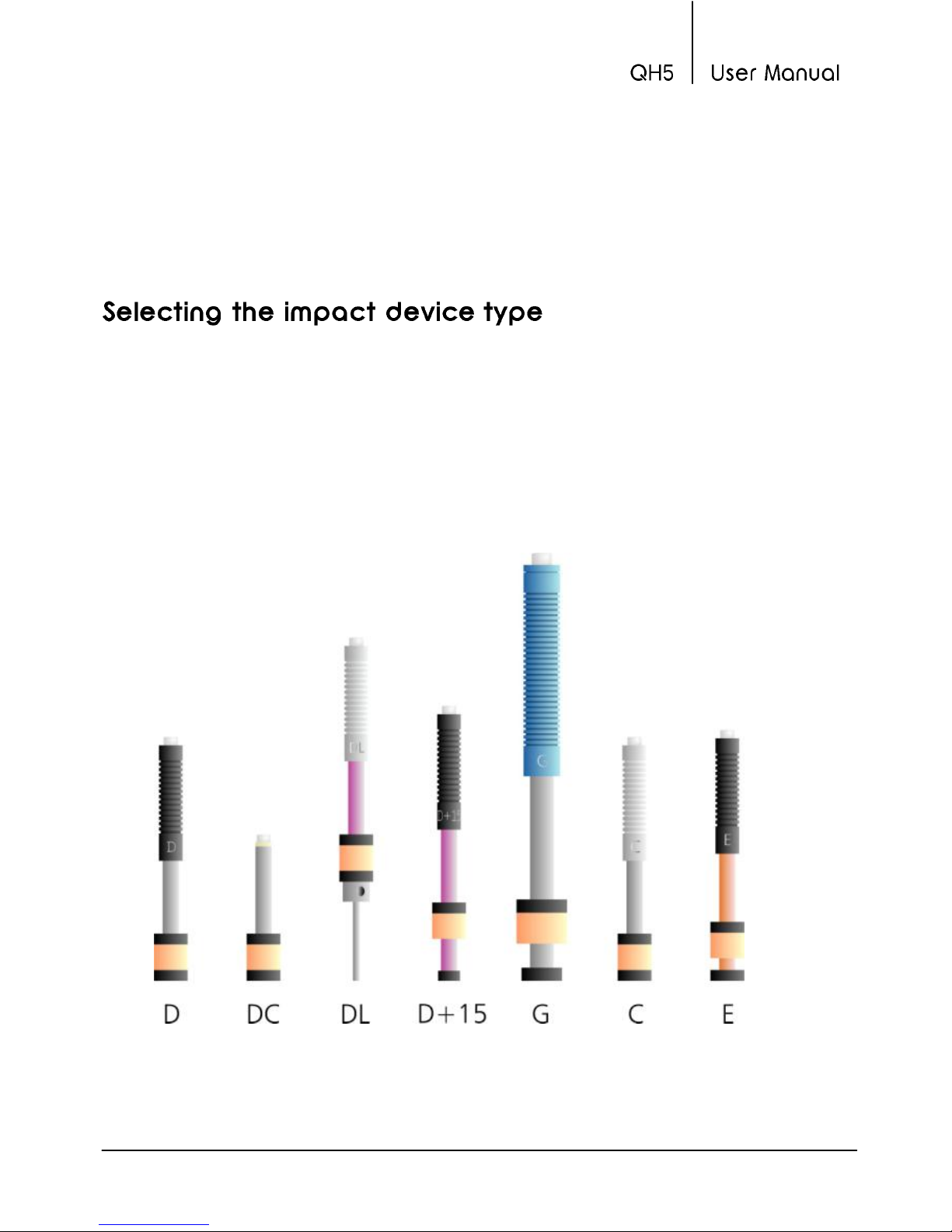

There are a number of available impact devices and each one of them

is different and ideal for specific applications. In this section general

information, measuring ranges and recommended applications are

briefly explained for each impact device type.

In figure 2 a representation of the physical aspect of each one of the

impact device types available for the QH5 is shown.

Figure 2: Representation of Impact device types for QH5 units

VIII

Impact device type D

This is the standard device in impact hardness testing because it

measures in all of the units and materials covered with the QH5. The

type D impact device covers the widest range of applications.

Impact device type DC

This device type, just like impact device type D, can also measure in all

units and materials but features a much shorter body (50mm) making

ideal for measurements in hard to reach places that cannot be

accessed with a type D device. Unlike impact device D that is spring

loaded, device DC is loaded manually

Impact device type DL

The long and thin tip on impact device type DL allows access to very

narrow areas that cannot be measured with any other impact device.

This device measures steel only.

Impact device type G

This impact device type includes a large hardness tip that is 5mm in

diameter and it also releases the highest impact energy at 90 N*mm

allowing its use over rough surfaces such as those in founded and

forged pieces and in grey cast iron.

Impact device type C

On device type C the impact tip produces the less amount of energy

when compared to other device types (up to 25% less than device type

D) therefore becoming the best choice for measuring treated surfaces

on steel parts and for measuring smaller pieces. The lower release

energy level produces the smaller test piece indentation. This device

measures steel only.

IX

Impact device type E

Impact device E uses a synthetic diamond tip (all other impact device

types use tungsten carbide tips). The diamond tip allows it to measure

harder test pieces such as those made out of template steel. This device

type measures steel only and extends the Vickers range to 1211HV

(device type D measures up to 940HV).

The table below shows detailed technical information on each impact

device type.

Parameter (Unit)

Impact device type

D/DC

D+15

DL

C

G

E

General characteristics

Length (mm)

147/86

162

202

141

254

155

Diameter (mm)

20

20

20

20

20

20

Weight (g)

75/50

80

100

75

250

80

Max Hardness (HV)

940

940

950

1000

650

1200

Impact device tip

Diameter (mm)

3

3

2.78

3

5

3

Hardness (HV)

1600

5000

Material

Tungsten carbide

Diamond

X

Impact body

Energy (N*mm)

11

11

11

3

90

11

Mass (g)

5.5

7.8

7.3

3

20

5.5

Surface test piece requirements

Rugosity ISO

N7

N7

N7

N5

N9

N7

Rugos. RT (µm)

10

10

10

2.5

30

10

Rugos. RA (µm)

2

2

2

0.4

7

2

Minimum test piece weight (Kg)

Stand alone

5

5

5

1.5

15

5

With solid support

2

2

2

0.5

5

2

Coupled with

paste

0.1

0.1

0.1

0.02

0.5

0.1

Minimum test piece thickness (mm)

Coupled

3

3

3

1

10

3

Surface thickness

0.8

0.8

0.8

0.2

—

0.8

Test piece impact indentation

On parts up to 300HV

Diameter (mm)

0.54

0.38

1.03

0.54

Depth (µm)

24

12

53

24

On parts up to 600HV

Diameter (mm)

0.45

0.32

0.90

0.45

Depth (µm)

17

8

41

17

On parts up to 900HV

Diameter (mm)

0.35

0.30

—

0.35

Depth (µm)

10

7

—

10

XI

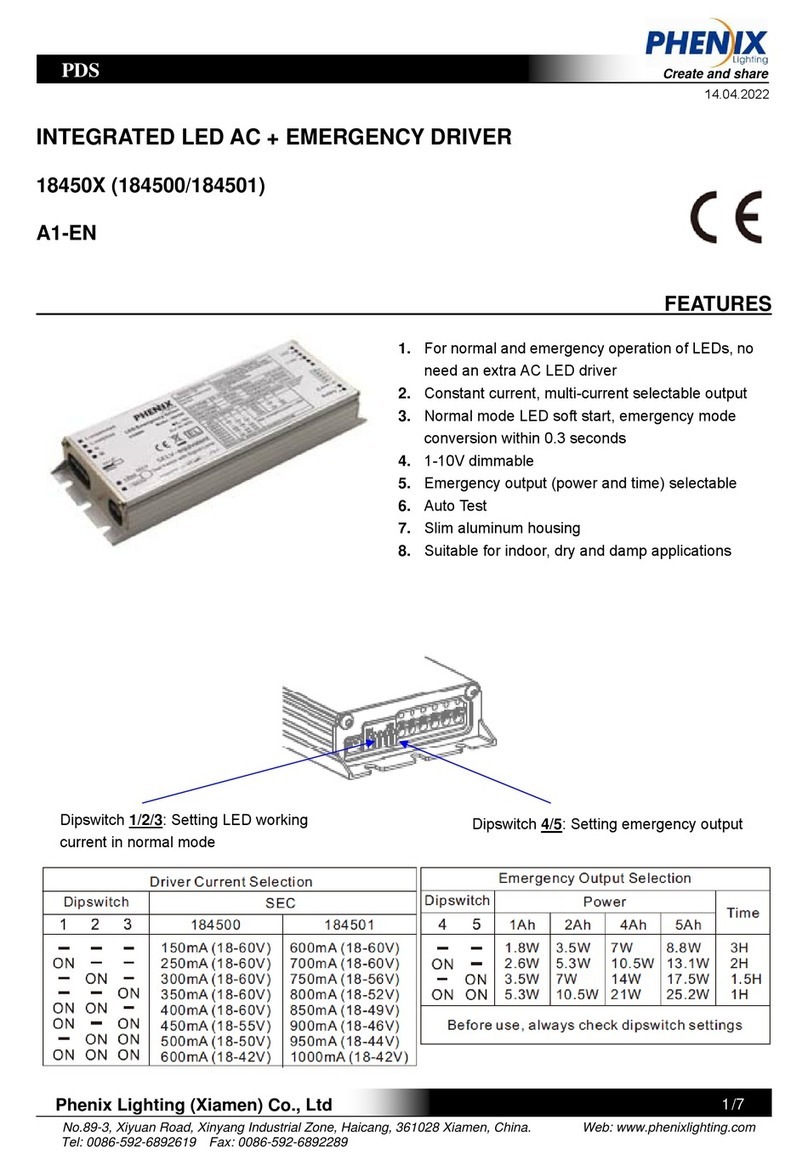

This section provides an overview of basic impact device components.

Figure 3: Impact device components

Figure 3 is a representation of the most important parts that make up

an impact device and the procedure used to remove the impact device

tip. Over time and depending on the number of measurements that

you make, the impact tip located on the impact device body must be

replaced. In order to do this turn the support ring clockwise (see figure

3-1) until the ring is released and the impact body falls off (figure 3-2).

Make sure you catch the impact body or that you work over a soft

surface where the impact body can fall on without being damaged.

Remove and replace the impact tip making sure everything is perfectly

clean and repeat this procedure to re-assemble the impact device.

XII

All QH5 series portable hardness testers are for industrial use only and

cannot be used in medical applications. The QH5 operates on two AA

size batteries. We strongly recommend that you use only top brand

name alkaline batteries.

Disposal of your QH5 and its components must be done in compliance

with all applicable regulations.

Because of its complexity level, software is never really completely error

free. For this reason in software controlled instruments always make

sure that the operations required for your application are in correct

working order.

Demeq S.R.L provides a limited warranty for a period of 2 (two) years

on electronic units and for 6 (six) months on transducers from the date

of purchase and may be extended for up to 5 years.

Every instrument undergoes thorough testing during manufacturing as

well as before shipping. In the event warranty service where to become

necessary, demeq S.R.L and or your local distributor or representative

will make a reasonable effort to replace your defective unit with

another new or used unit, while your instrument undergoes warranty

repair.

Chapter 1 1

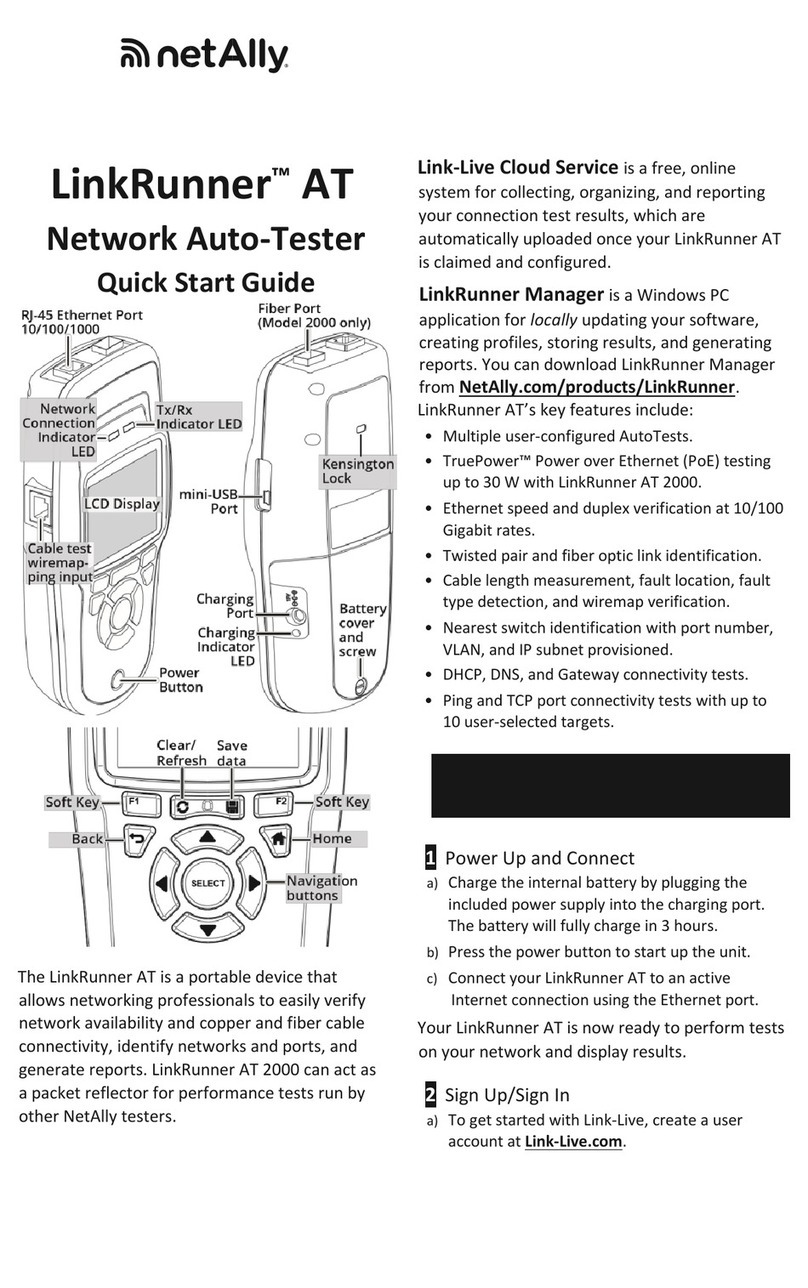

Figure 1.1: Front of the unit

1. Graphic LCD display with LED backlight illumination

2. Move Left key / View partial statistics (Stat)

3. Move Up key / Manually store a value (Store)

4. Move Right key / Switch to graphical measure mode screen

(Graph)

5. Menu key / Enter and exit measure screen / Exit and return to

menus (Home)

2 Chapter 1

6. Move Down key / Quick access to memory menu screen

options (Mem)

7. Change backlight illumination key (On, Off, Auto)

8. Enter key / Edit values on the measure screen (Edit)

9. The key: Power On and Shutdown (touch and hold for 2

seconds) / Make quick and short touches to activate special

features

10. The key: Direct measure screen access from any menu

screens / User selectable functions

11. Horizontal scrolling center point (lock and unlock keypad on

measure screen)

12. Vertical scrolling center point (adjust LCD contrast)

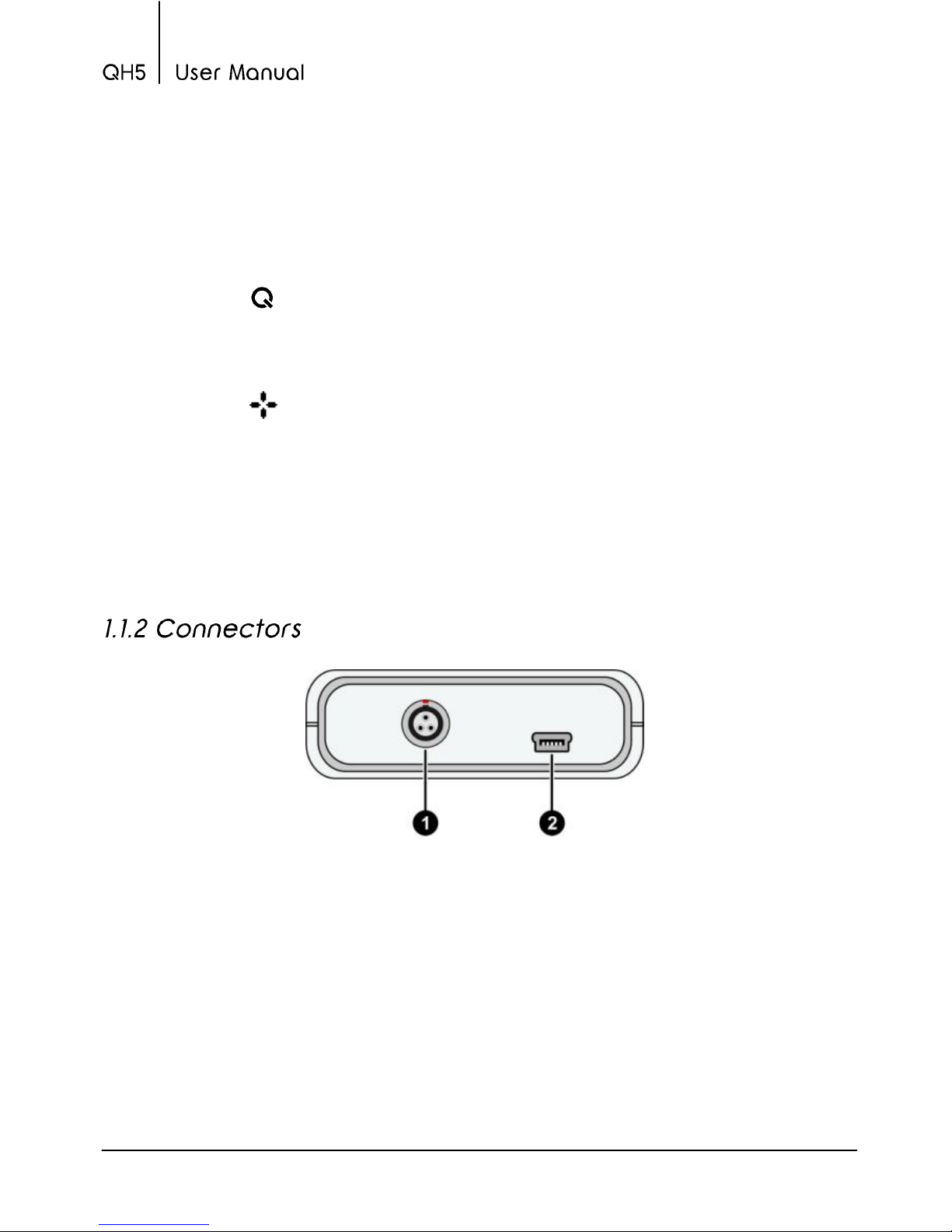

Figure 1.2: Unit connectors

1. Impact device connector type Lemo 0B

2. USB mini connector to connect to PC using a USB cable

Chapter 1 3

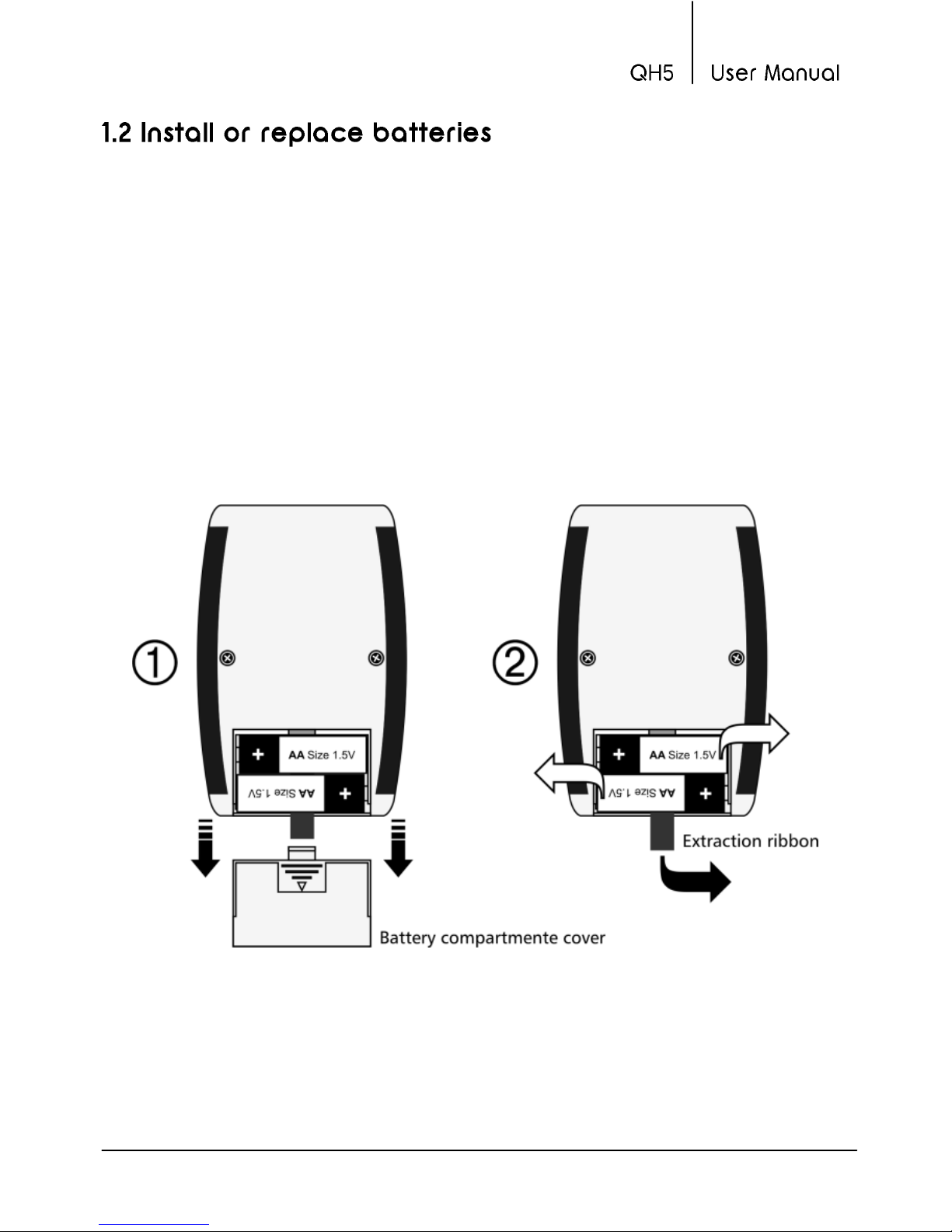

The QH5 is powered by 2 (two) AA batteries that are placed in the

battery compartment located in the back of the unit. To gain access to

the battery compartment slide the cover as shown in figure 1.3-1 and

gently push the extraction ribbon upward and slightly towards the

right to release the batteries (figure 1.3-2).

When you install new batteries, first insert the positive end of each

battery so that it coincides with the positive pole inside the battery

compartment as you see in figure 1.4-1.

Always leave the extraction ribbon underneath the batteries.

Figure 1.3: Removing batteries

4 Chapter 1

Figure 1.4: Replace / Insert batteries

Notes

Always use new alkaline top brand batteries for

extended battery life.

Do not mix new and old batteries. Always replace both

batteries.

Rechargeable batteries type NiMH can be used but will

result in less time of continuous operation.

Chapter 1 5

Important

Do not remove batteries while the unit is powered as

this may affect the Datalogger (See Appendix:

“Additional information, Error Messages”)

The QH5 uses a type Lemo 0B 3-pin connector located on top of the

unit. All dmq impact devices are provided with Cal-Tag technology

allowing you to easily switch or replace impact devices with no need to

calibrate the unit. Universal non-brand impact devices can also be used

as long as they have the same connector, but dmq does not guarantee

their performance.

To connect the impact device simply

align the red dot on the male

connector with the red dot on the

female connector located on the unit

and press gently until connected (see

figure 1.5)

To release the impact device hold the

knurled section on the male connector

and gently pull out.

Never remove the connector using the

cable.

Figure 1.5: Connecting the impact device

6 Chapter 1

The procedure explained herein is applicable to all impact device types

except for impact device type DC as it does not use a spring loading

mechanism.

Place the impact device over the surface you want to measure and load

by gently pushing the moving body of the impact device in the same

direction as the test piece surface. Keep pushing the moving body until

you reach the bottom limit and then bring the moving body back to its

initial position.

The impact device is now loaded and ready to be used.

Once the impact device has been loaded use one hand to firmly hold

the bottom of the impact device (the part that touches the surface you

want to measure) against the surface and use your other hand to press

the release button located on top of the impact device.

After pressing the button, the impact tip will hit the test piece surface

and a hardness value will immediately be displayed.

Repeat this same procedure for each measurement.

Important

The Leeb method for hardness testing has requirements

and limitations that must be considered in order to

obtain reliable and accurate measurements (See

Appendix: “Tips on how to measure correctly”)

This manual suits for next models

2

Table of contents

Popular Test Equipment manuals by other brands

Bms Bulut Makina

Bms Bulut Makina DIGIROCK-RB Operational manual

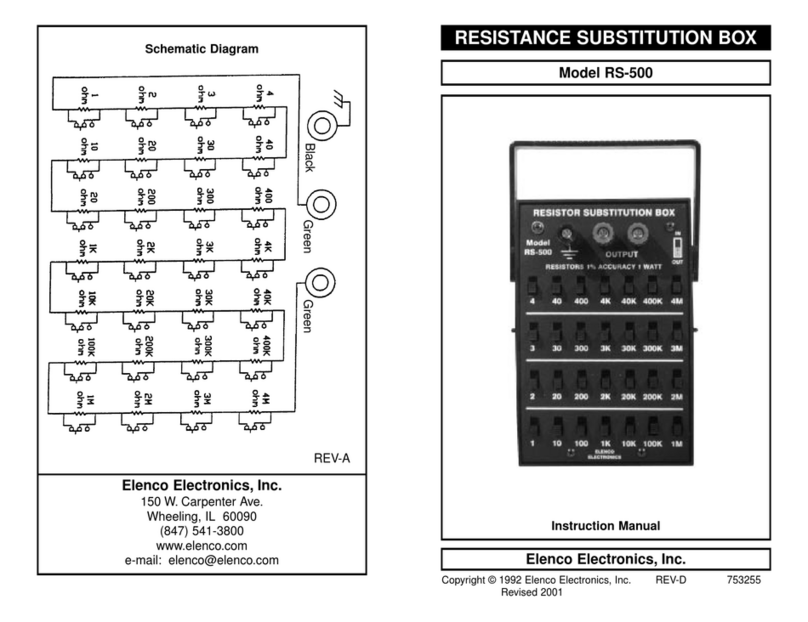

Elenco Electronics

Elenco Electronics RS-500 instruction manual

PCE Health and Fitness

PCE Health and Fitness PCE-RT 2300 user manual

Hantek

Hantek DSO-3004 USB Series user manual

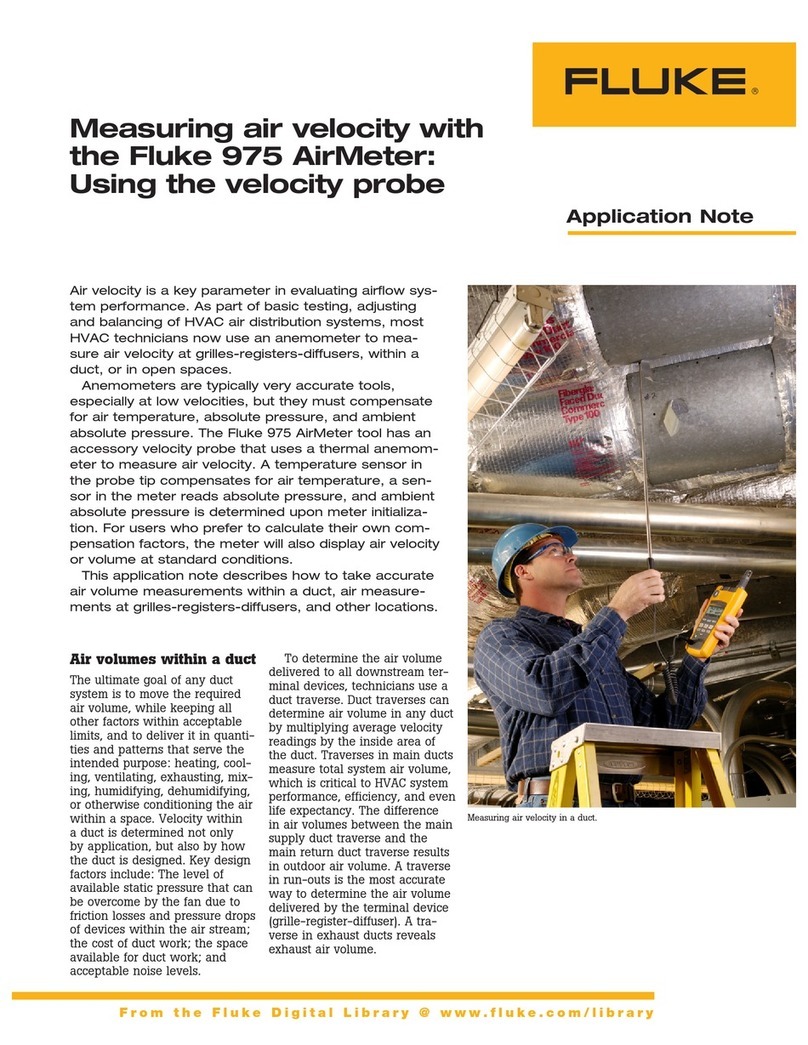

Fluke

Fluke 975 AirMeter Application note

BEAMEX

BEAMEX MC5-IS user guide