6

1. If adequate suction head is available, air can be

relieved from the casing and packing box by one of

two means:

a. For packed pumps, remove pipe plug (264) or

recirculation line fitting from discharge flange.

Replace when casing has been completely filled.

b. For pumps with mechanical seals, remove pipe

plug (208) from stuffing box or seal gland if

flexible-mounted. Do not replace the plug until all

air has escaped.

2. In cases where there is suction lift and system liquid is

not available, install a foot valve in the suction line.

Prime by filling suction piping and casing completely

through the tap in the discharge flange. Provide an air

vent at the high point.

When the pump is fully primed, start the motor and slowly

open the valve in the discharge line.

Inital Adjustments - Packed Pumps

After the pump has been started, packing box glands

should be tightened to prevent excessive loss of liquid.

In cases where packed pumps are operating with a

suction lift over 20 feet, the packing should be lubricated

through the stuffing box tap from an external source. See

“Packing Box” .

Packing should not be too tight, as this will result in

burning the packing and scoring of the shaft sleeve. The

best gland adjustment will allow liquid to drip slowly from

the packing box gland. This will permit proper lubrication

of the shaft and dissipate generated heat. The gland must

NEVER be tightened to the point where leakage through

the stuffing box is completely stopped.

Initial Adjustments - Pumps with Mechanical Seals

Mechanical seals are factory-adjusted at the time the

pump is assembled and, normally, need no further

adjustment in the field. The only prerequisite to operating

an In-Line pump equipped with a mechanical seal is to

make certain the seal chamber is filled with a compatible

liquid before starting the pump.

NOTE: Numerals shown within parentheses after part

names on this and pages following provide ready

identification of such parts in the cross sectional

drawings.

MAINTENANCE

D - Lubrication

Motor Bearings - See motor manufacturer’s recommendations

on motor name plate.

Packing Box - Packing must be continuously lubricated.

Packed pump are normally furnished less an external

recirculation line. When operating with suction lift and

clean liquid, recirculation from the pump discharge to

the packing box (or suitable grease) may be used, see

“Initial Adjustments” . When lubrication is supplied from an

outside source, it should be cool, clear water, light lithium

base grease, or a compatible lubricating fluid.

Single Seal - Pumps with single seals are normally

furnished with an external recirculation line. A portion

of the liquid being pumped is recirculated from the

casing through the seal chamber to serve as a lubricant

and coolant. An alternate method is to supply a cool,

compatible lubricating liquid from an outside source to

the seal chamber at a pressure 15 to 25 psi higher than

suction pressure.

Double Seal - On double seal applications, the seal

chamber must be filled with lubricant or clear, compatible

lubricating liquid under pressure. The liquid may be from

an outside source or may be from the pump discharge

passing through a filter and/or heat exchanger when

necessary. Pressure on the box must be 15 to 25 psi

higher than suction pressure. The liquid must circulate

through the outlet and a restriction must be placed in the

outlet to assure pressure on the seal chamber.

Packing Box Care - Before installing new rings of

packing, clean the packing box and inspect parts for wear.

If the shaft sleeve is worn, replace it, new packing will not

do an adequate job on a worn sleeve. Die molded packing

rings are preferable. Insert two rings. Twist the rings

sideways when installing, DO NOT pull the rings straight

out over the shaft. Stagger the joints to minimize leakage.

Tamp each ring in place and then slip the lantern ring into

the packing box behind them. Add three more rings behind

the lantern ring. Replace the gland and bolts, rotate the

shaft, and tighten gland securely. Be sure the lantern ring

is positioned to receive lubrication through the orifice in

the housing. Tighten nuts securely to seat the packing,

rotate the shaft several turns, and then loosen the nuts to

“finger-tightness” for starting.

IMPORTANT! - Liquid being pumped should

drip slowly but constantly through the packing

and gland. This will prevent overheating, high

power consumption, and shaft sleeve damage.

If packing replacement becomes frequent:

a. Check motor bearing for excessive wear causing

shaft run-out.

b. Check packing for proper grade. Also, check

whether special packing is used, see pump data

card.

c. Check shaft sleeve for excessive wear or scoring

d. Check for crystallization of solution and for

embedded abrasives in the packing. Method of

packing lubrication may not be satisfactory.

e. Check recirculating line, if used, as well as

relevant fittings for partial or full blockage.

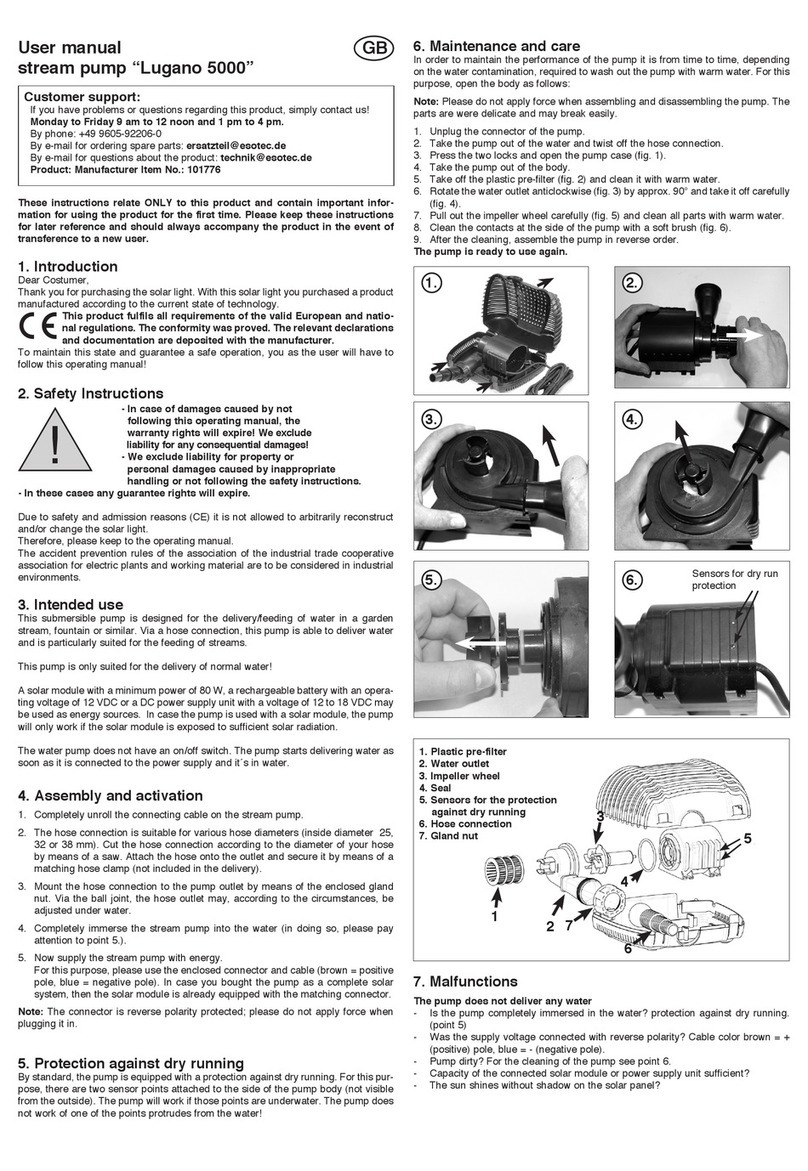

E - DISASSEMBLY

The In-Line Pumps feature “pull-out maintenance”

whereby the rotating assembly can be removed while the

casing remains in the line. To facilitate disassembly, refer

to Figure 6 thru 9 and to assembly drawings on page 10.