Contents

1. Safety Precautions.............................................................................................................. 1

1.1 Electrical Safety...................................................................................................................... 1

1.2 Driving Components..............................................................................................................1

1.3 High Temperature and High Pressure.............................................................................. 1

1.4 Unit Drainage........................................................................................................................... 2

2. Inspection and Handling...................................................................................................2

2.1 Product Warranty of Compressors....................................................................................2

2.2 Check of Specifications and Model................................................................................... 2

2.3 Inspection of Accessories and Appearance................................................................... 3

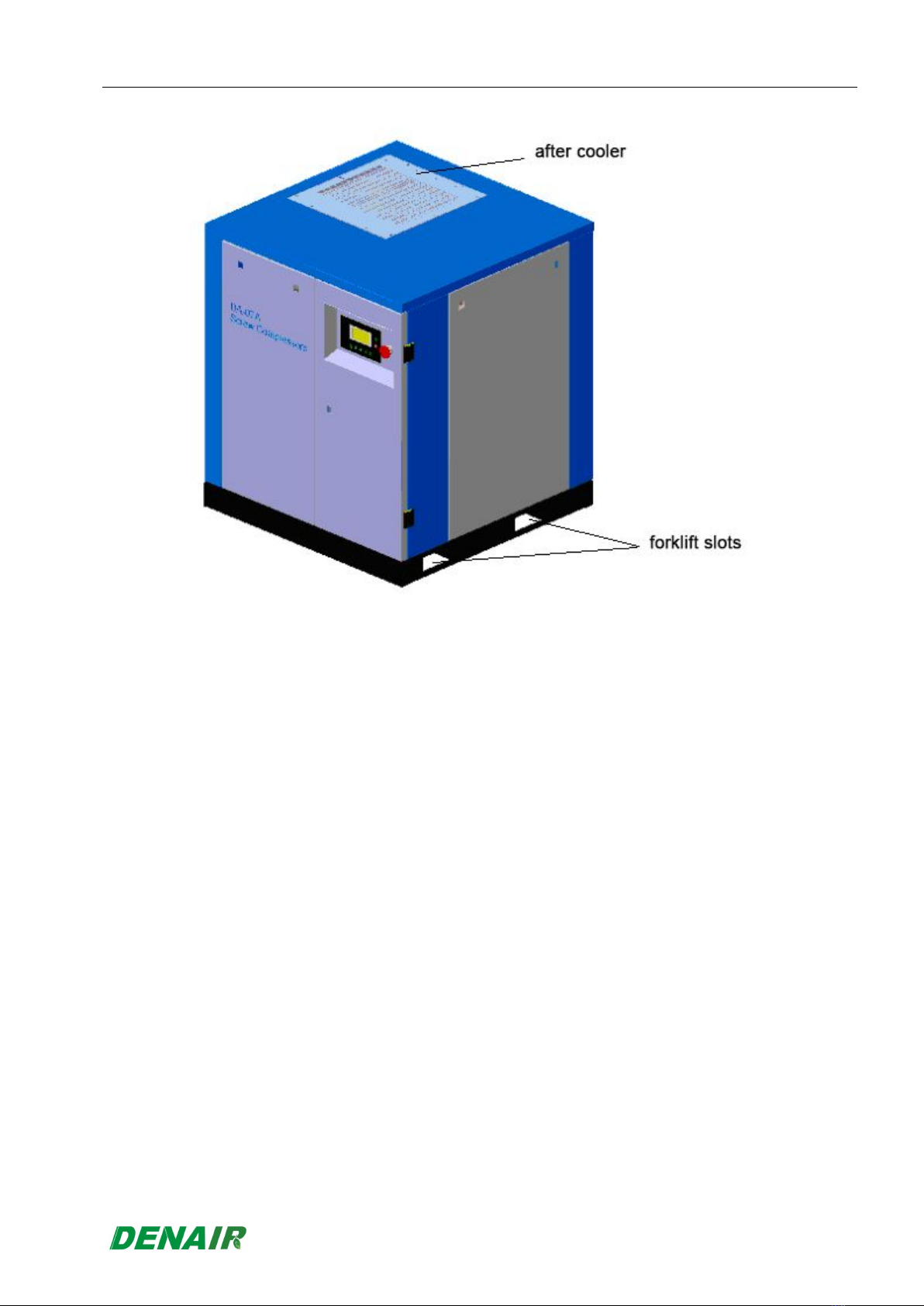

2.4 Handling Precautions............................................................................................................3

3. Installation..............................................................................................................................4

3.1 Environment Requirements.................................................................................................4

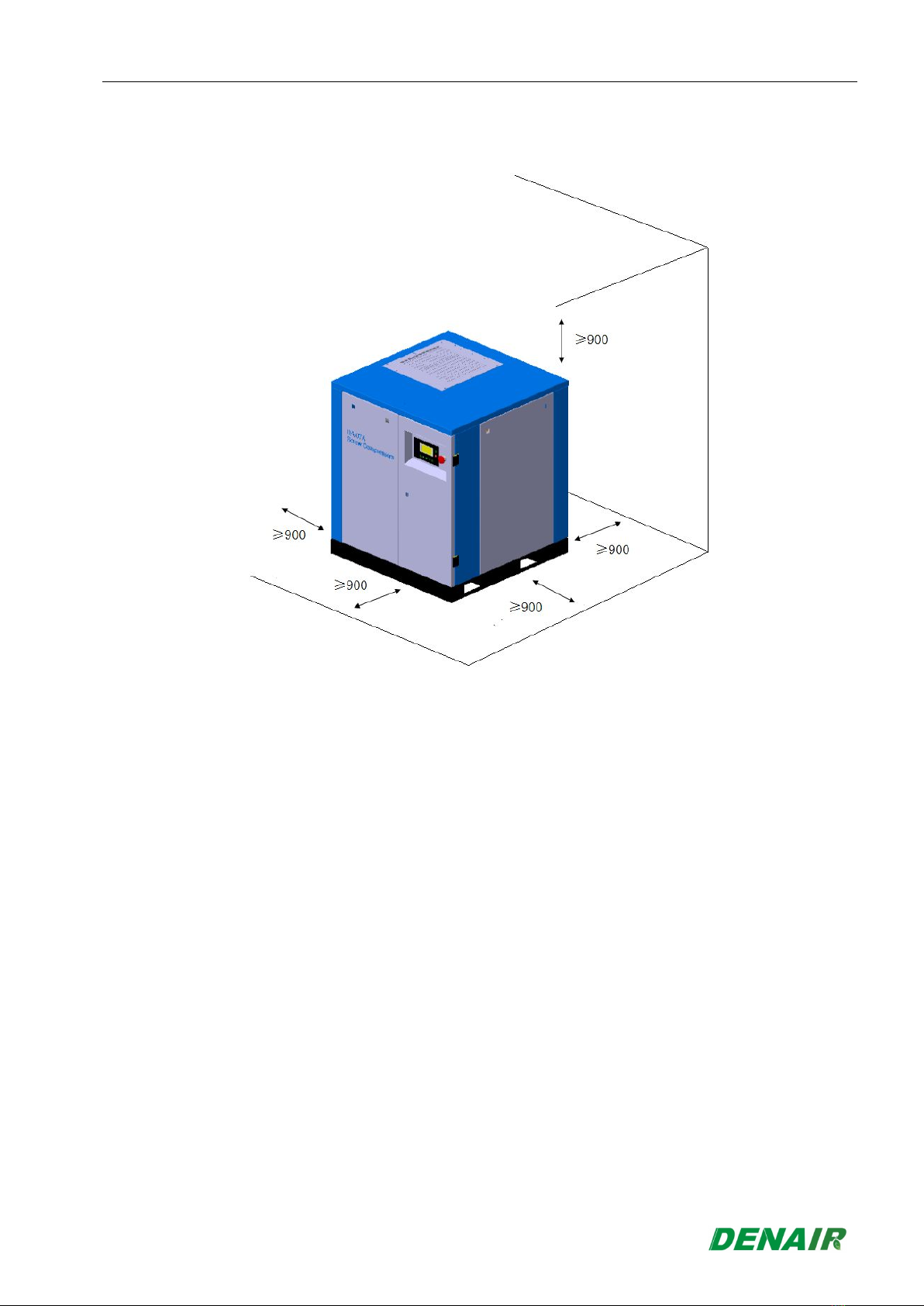

3.2 Installation Location Requirements.................................................................................. 5

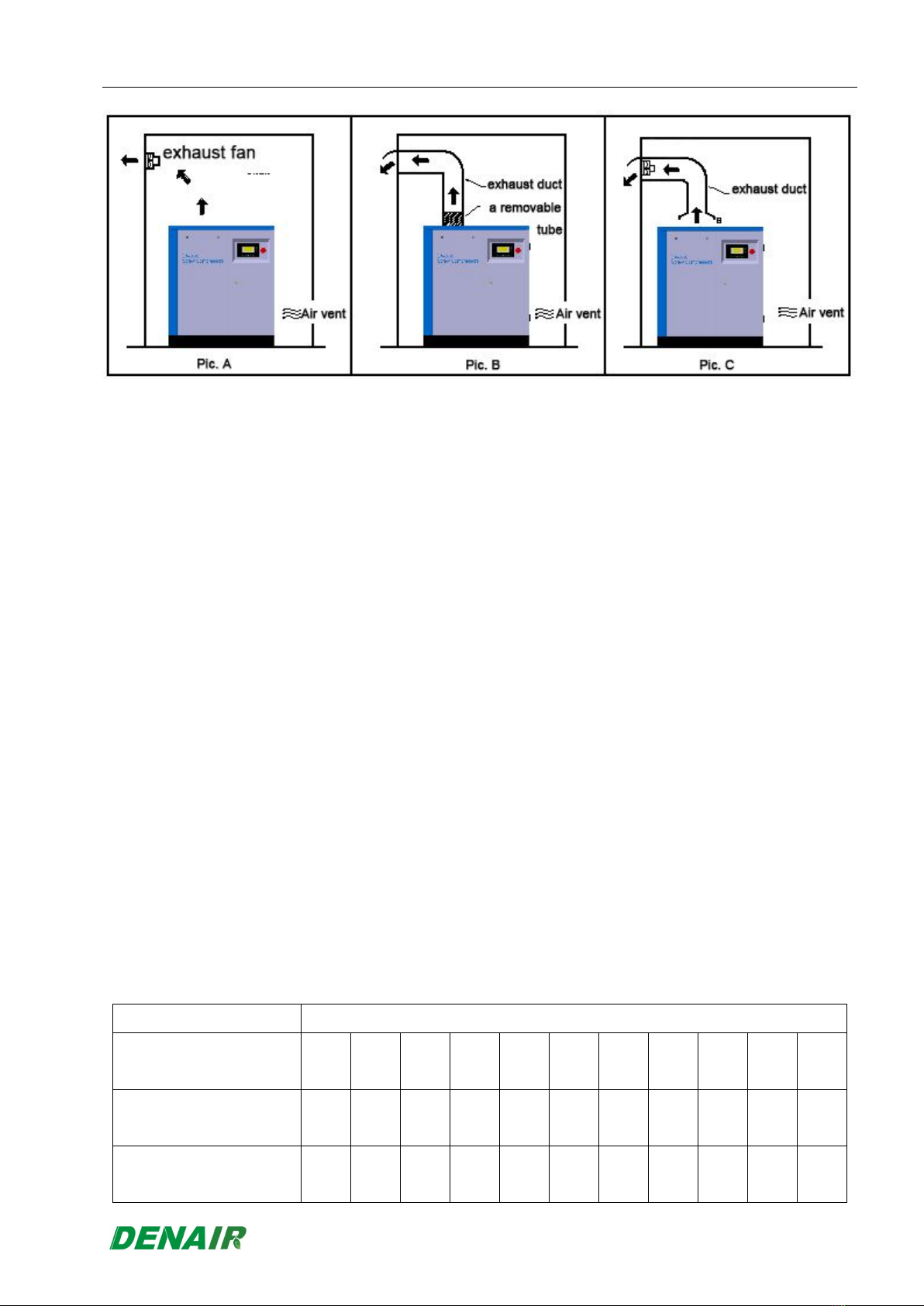

3.3 Ventilation and Cooling Requirements.............................................................................5

3.4 Selection Requirements for Air Rate of Ventilating fans............................................. 6

3.5 Warning..................................................................................................................................... 7

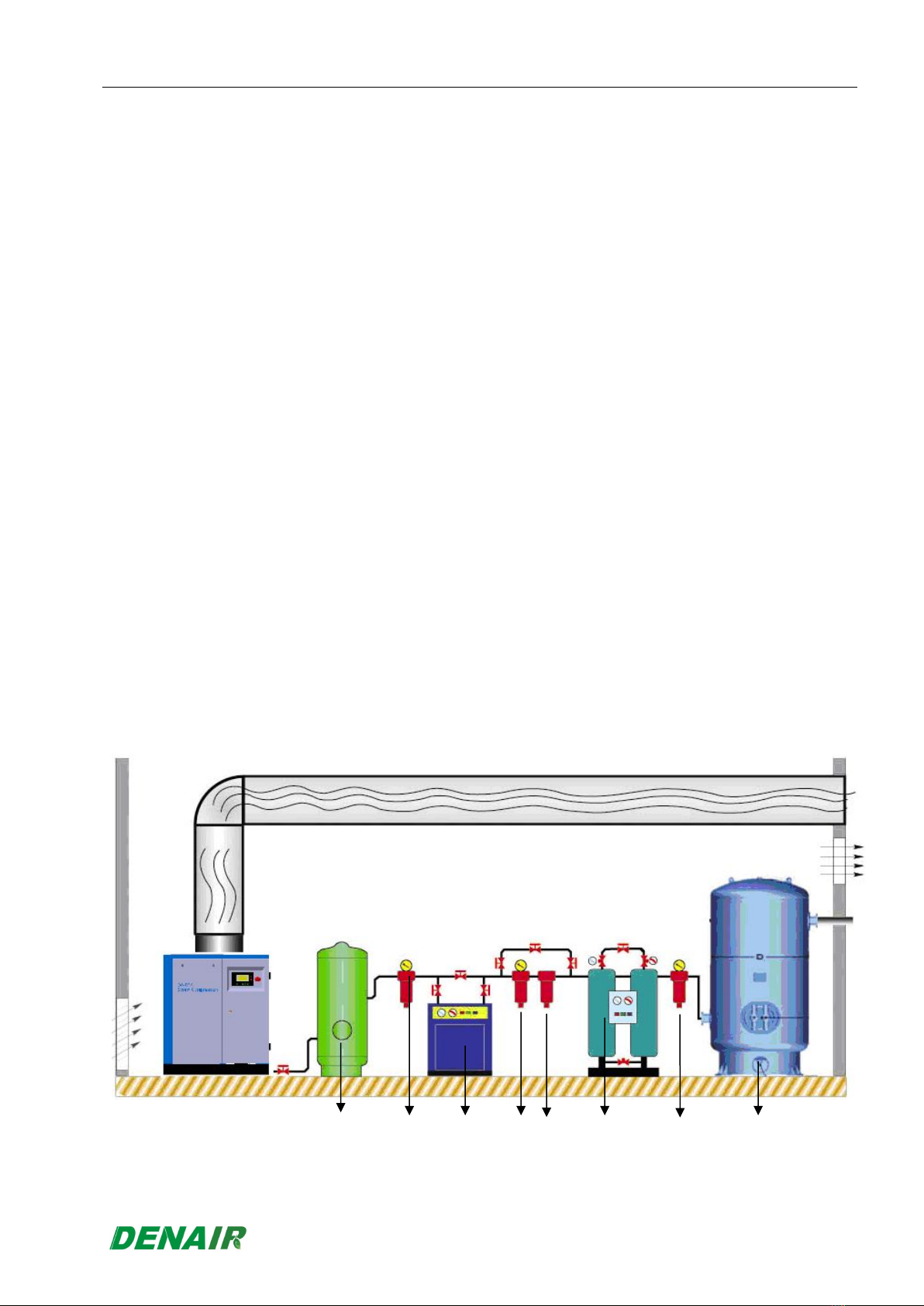

3.6 Suggestions for Pipeline...................................................................................................... 8

3.7 Electric Appliances Installation Precautions and Control System......................... 11

4. Introduction to the System............................................................................................14

4.1 Overall System......................................................................................................................14

4.2 Composition of the Compressor Unit.............................................................................14

4.3 Lubricating Oil System....................................................................................................... 15

4.4 Oil-gas Separation System................................................................................................ 15

5 Operation of Controller.................................................................................................. 16

5.1 Key Description.................................................................................................................... 16

5.2 Contents of Controller........................................................................................................ 16

5.3 Contents of User Parameter..............................................................................................19

5.4 Schematic Wiring Diagram................................................................................................ 20

5.5 Control Operation................................................................................................................ 21

5.6 Warnings and Prompts....................................................................................................... 22

5.7 Safety Protection..................................................................................................................23

6. Function Description of System Components...................................................... 24

6.1 Air Filter.................................................................................................................................. 24

6.2 Inlet Valve............................................................................................................................... 24

6.3 Oil-gas Barrel........................................................................................................................ 24

6.4 Oil Separator..........................................................................................................................25

6.5 Safety Valve........................................................................................................................... 25

6.6 Pressure Maintenance Valve.............................................................................................25