Denon DCD-1500 User manual

Other Denon CD Player manuals

Denon

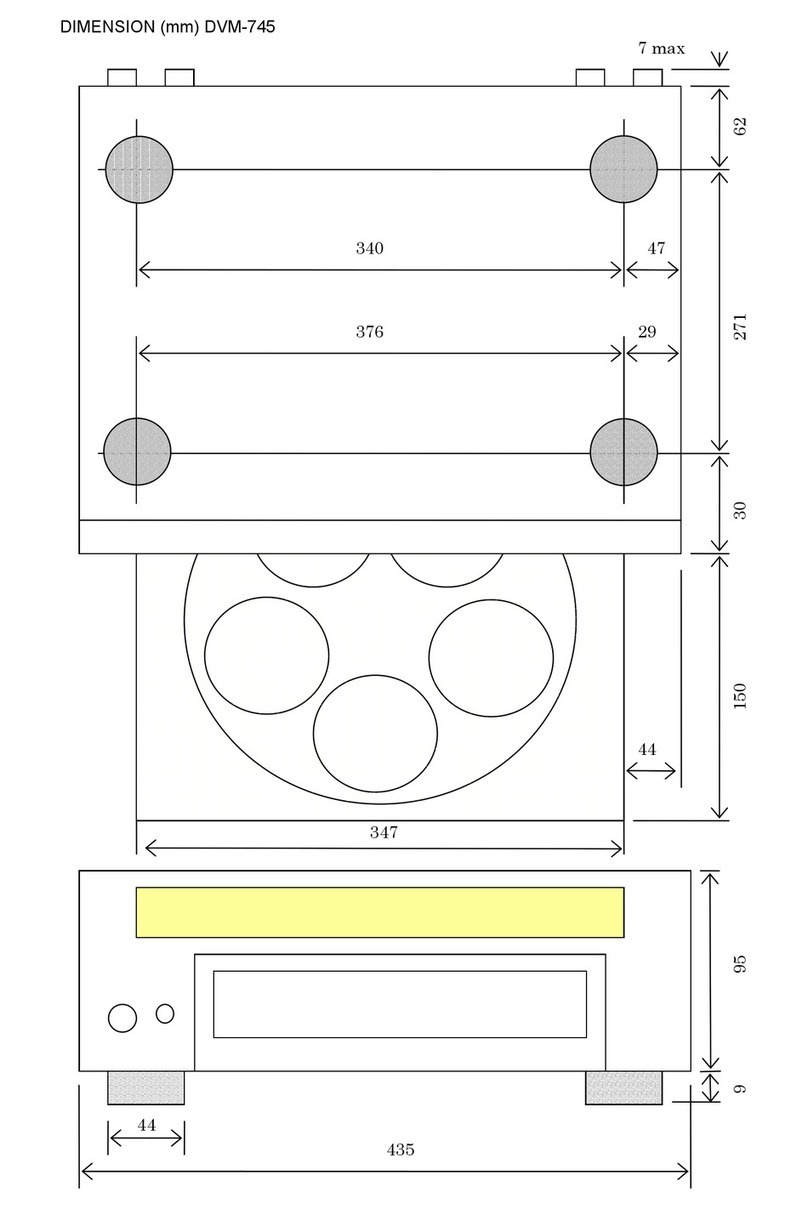

Denon DVM-1815 User manual

Denon

Denon DVM-2845CI User manual

Denon

Denon DCD-F107 User manual

Denon

Denon DCD-710AE User manual

Denon

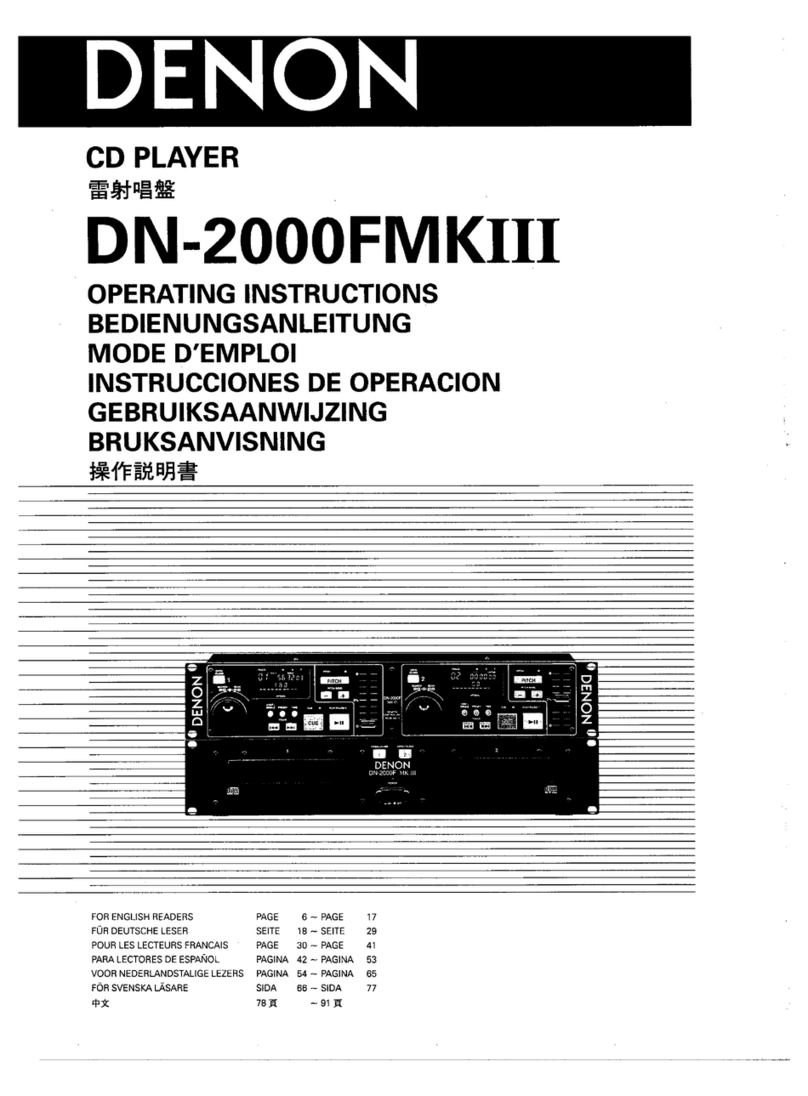

Denon DN-2500F User manual

Denon

Denon DVD-3910 User manual

Denon

Denon DCD-720AE User manual

Denon

Denon DN-D4000 User manual

Denon

Denon DVD-2910 User manual

Denon

Denon DN-951FA User manual

Denon

Denon DCD-1520AE User manual

Denon

Denon DCD-A100 User manual

Denon

Denon DND4500 - Dual CD Player User manual

Denon

Denon DVD-1930CI User manual

Denon

Denon DCD-50 User manual

Denon

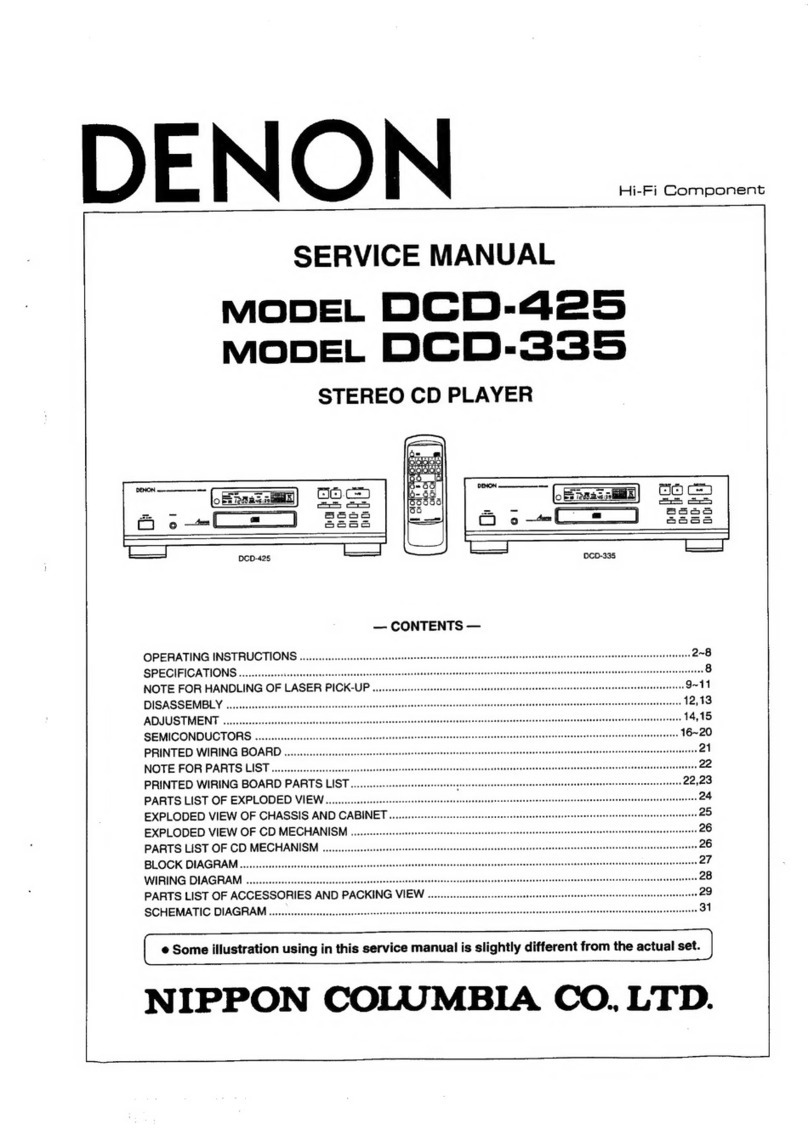

Denon DCD-425 User manual

Denon

Denon DCD-900NE User manual

Denon

Denon DCM-500AE User manual

Denon

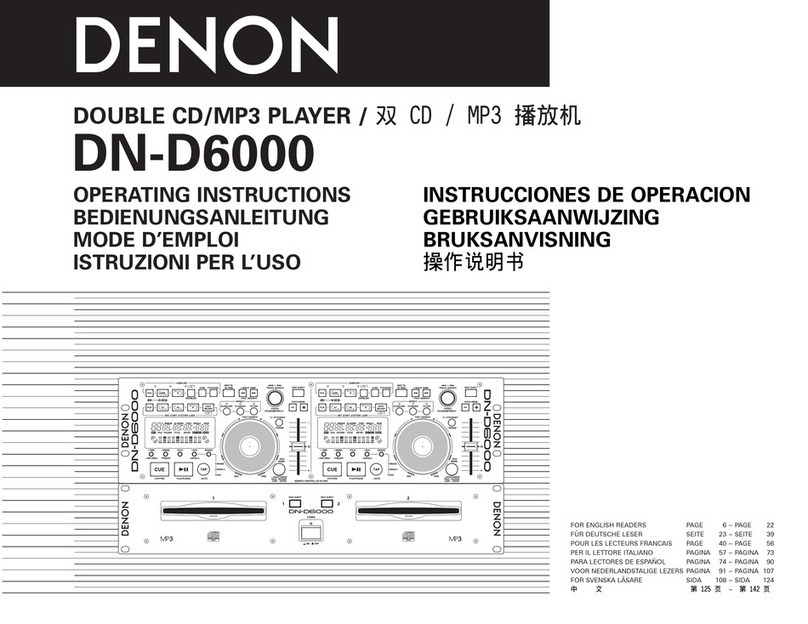

Denon DND6000 - Dual DJ CD Player User manual

Denon

Denon DCD-510AE User manual