Denon DCD-1500II User manual

Other Denon CD Player manuals

Denon

Denon DCM-500AE User manual

Denon

Denon DVM 1845 Instruction Manual

Denon

Denon DCD-1520AE User manual

Denon

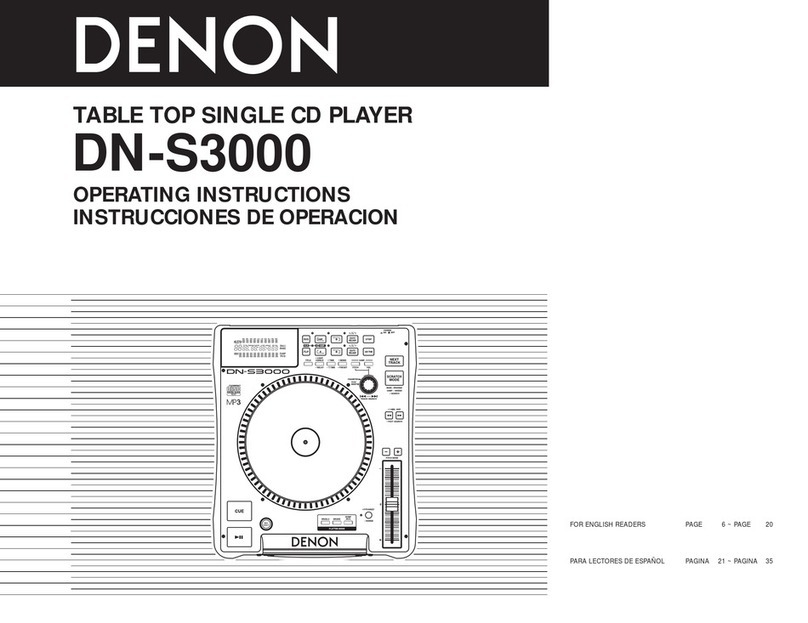

Denon DN-S3000 User manual

Denon

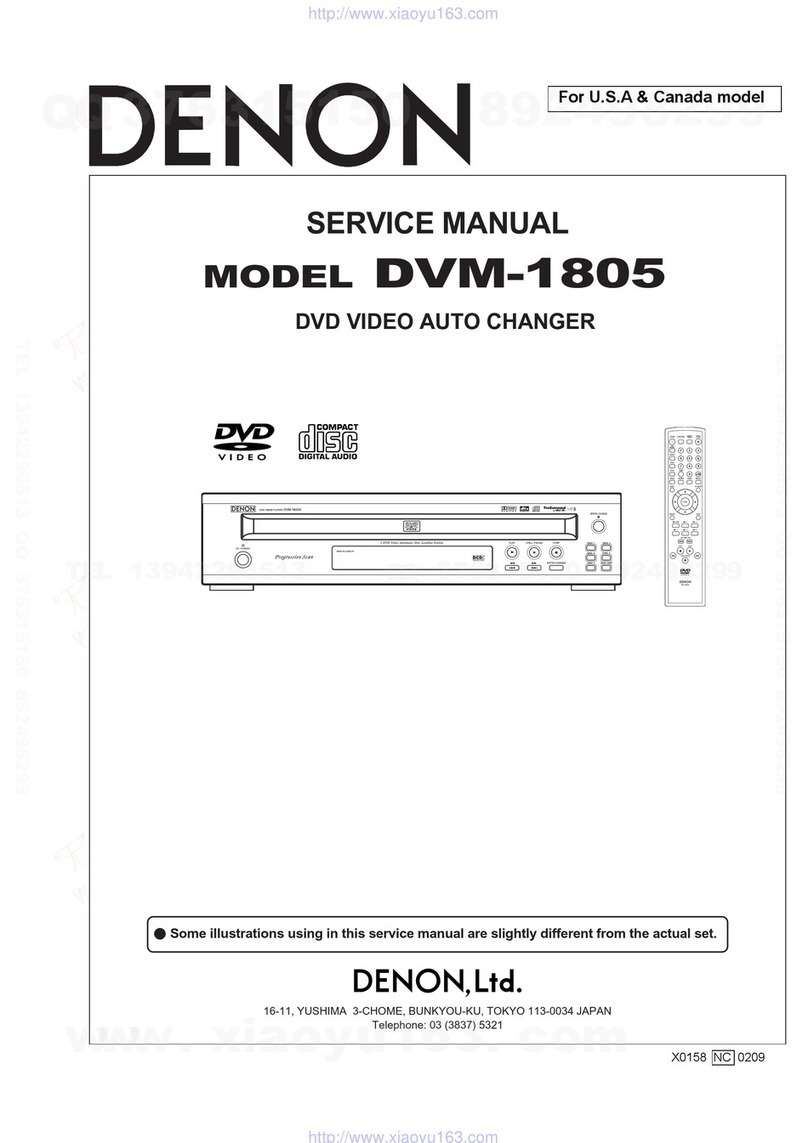

Denon DVM-1805 - DVD Changer User manual

Denon

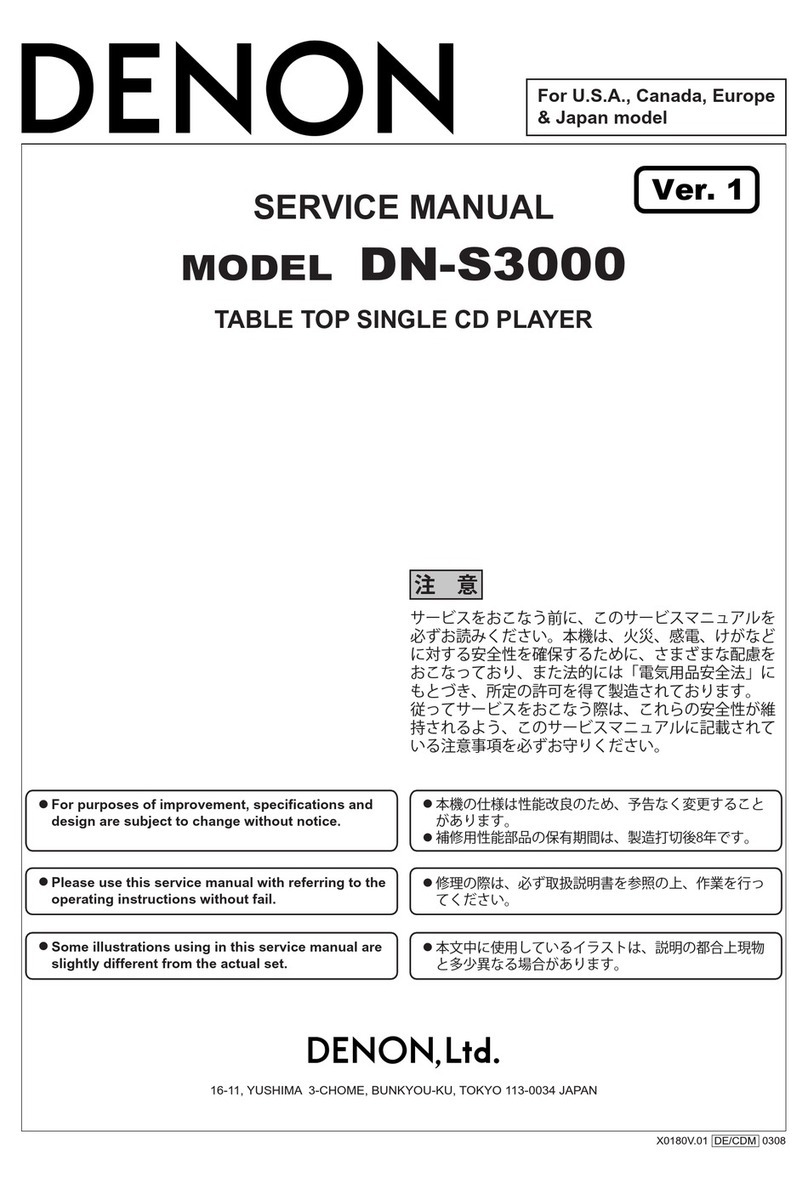

Denon DN-S3000 User manual

Denon

Denon DCD-1420 User manual

Denon

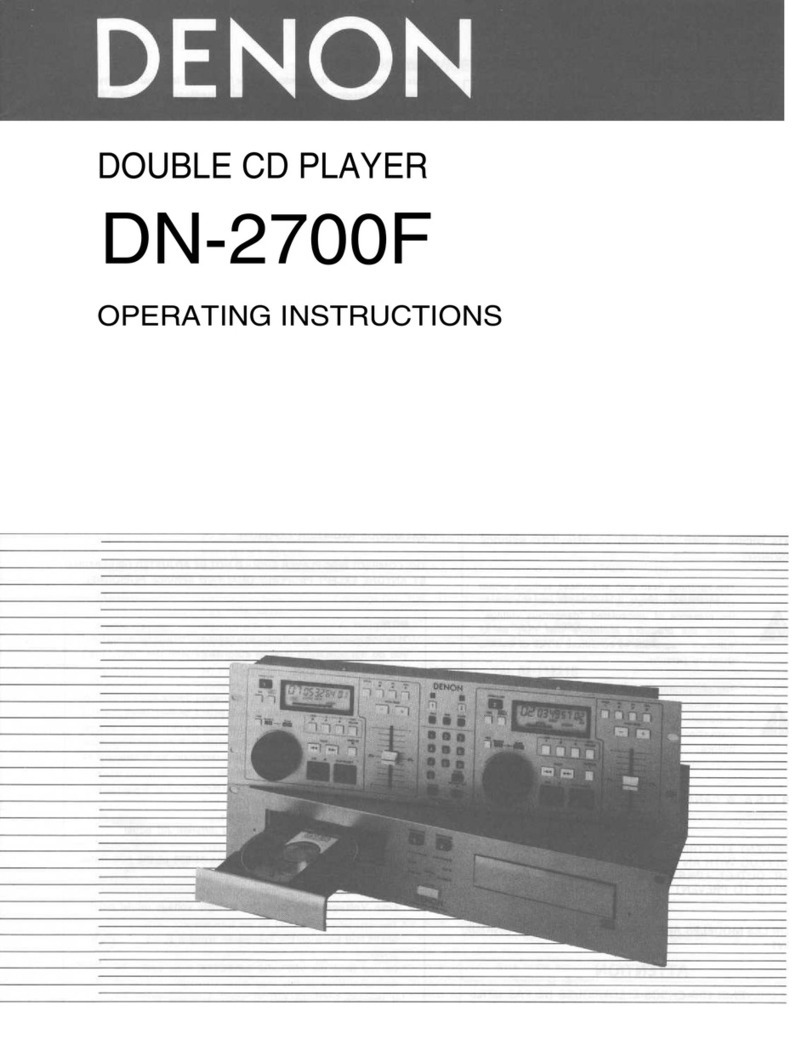

Denon DN-2700F User manual

Denon

Denon DCD-485 User manual

Denon

Denon DCD-A110 User manual

Denon

Denon DCD-1700NE User manual

Denon

Denon DN-2100F User manual

Denon

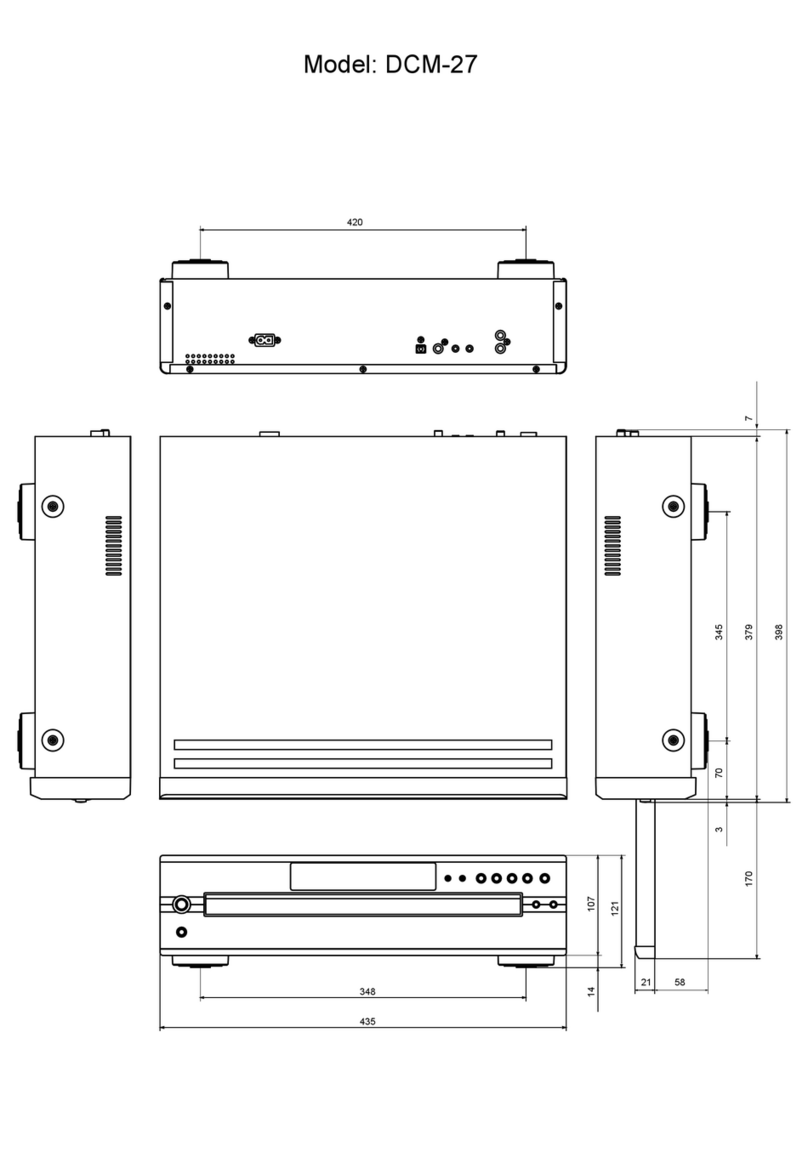

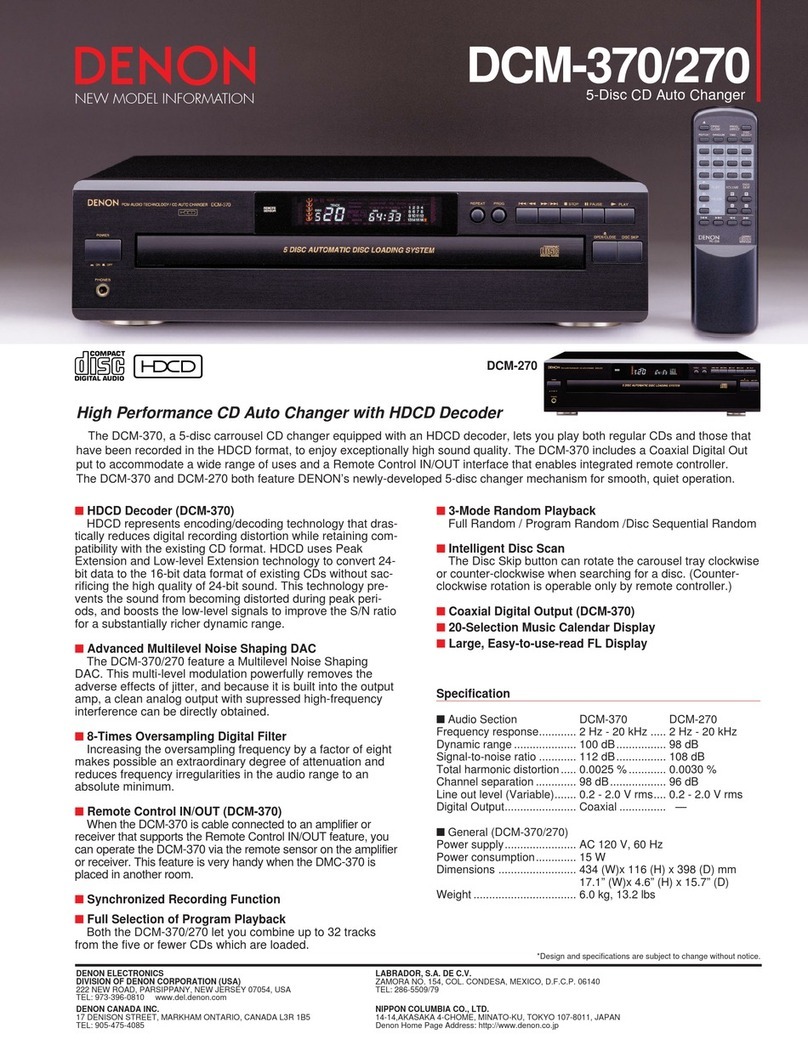

Denon DCM-270 User manual

Denon

Denon Dn-c620 - Dnc620 Professional Broadcast Cd... User manual

Denon

Denon DCD-315 User manual

Denon

Denon DCD-F107 User manual

Denon

Denon DN-501C User manual

Denon

Denon DCD-800NE Operating and maintenance instructions

Denon

Denon DCD-800NE User manual

Denon

Denon DCD-1400 User manual